9

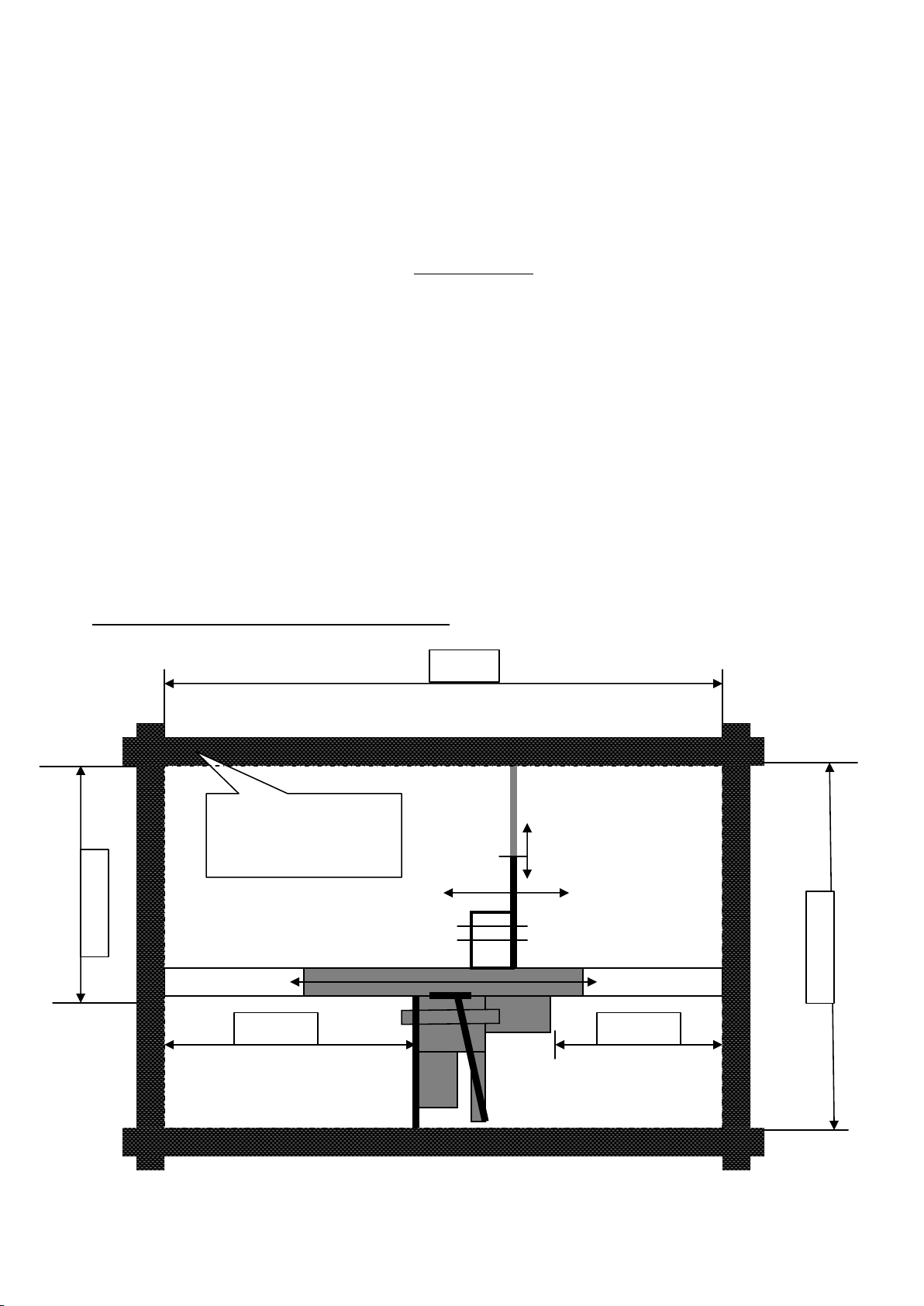

Fit sliding rear fence

Swivel blade guard out of the way.

Remove the first nut of each of the 3 studs coming off the rear fence sliding rod

Leaving 2 thin locknuts locked together on 2 of the studs and 1

x thicker nut on the other with one

washer. Wind this nut all the way towards rod.

Insert the 3 studs into the 3 holes.

Carefully with assistance and concentrating on

the front 2 studs

going into the cast mounting

brackets.

Fit a washer and nut on to eac

h and screw nut on

until stud can be seen just coming out of each nut

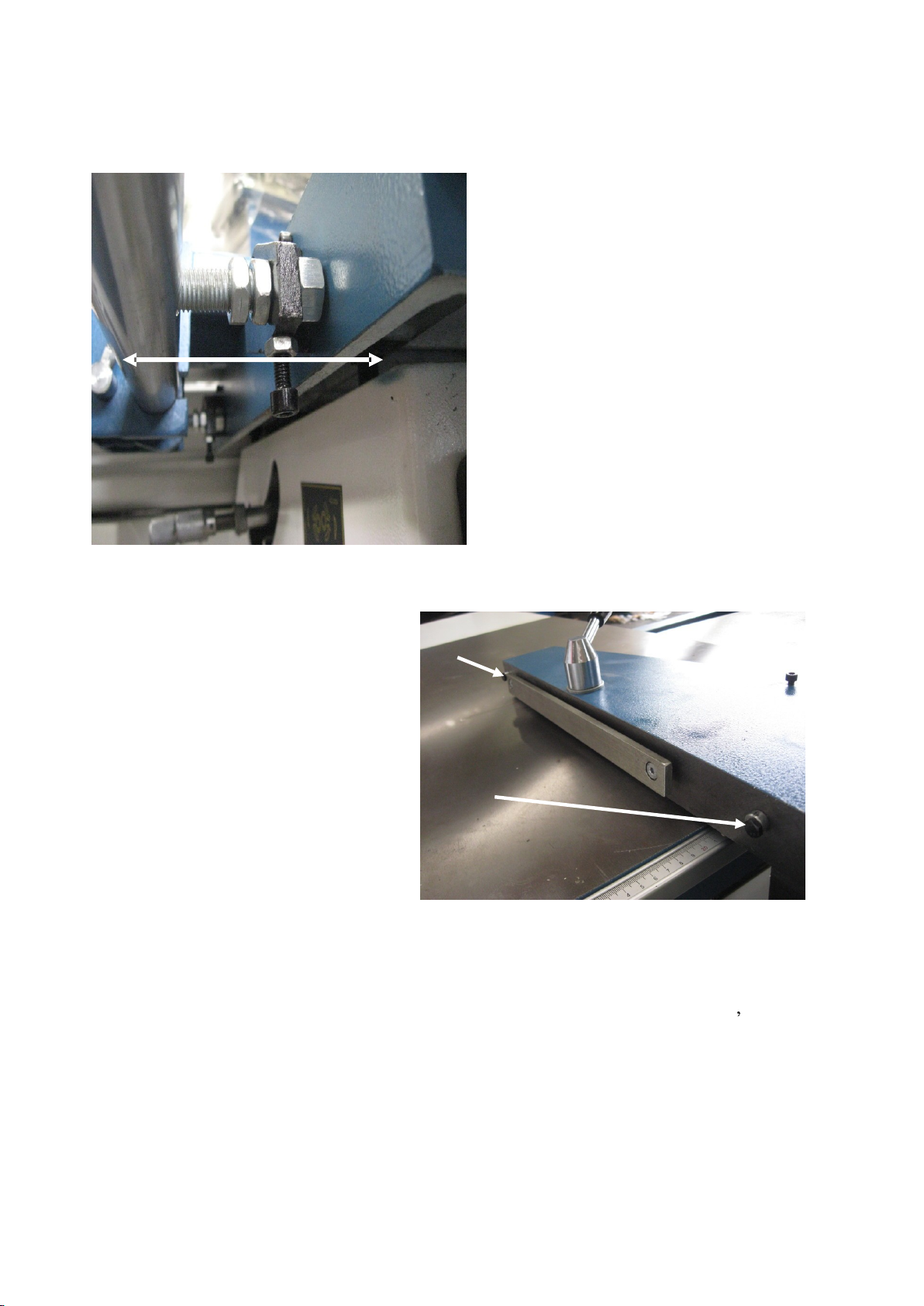

Pushing the studs down onto the adjustment bolts

in the slots, tighten up these 2 nuts

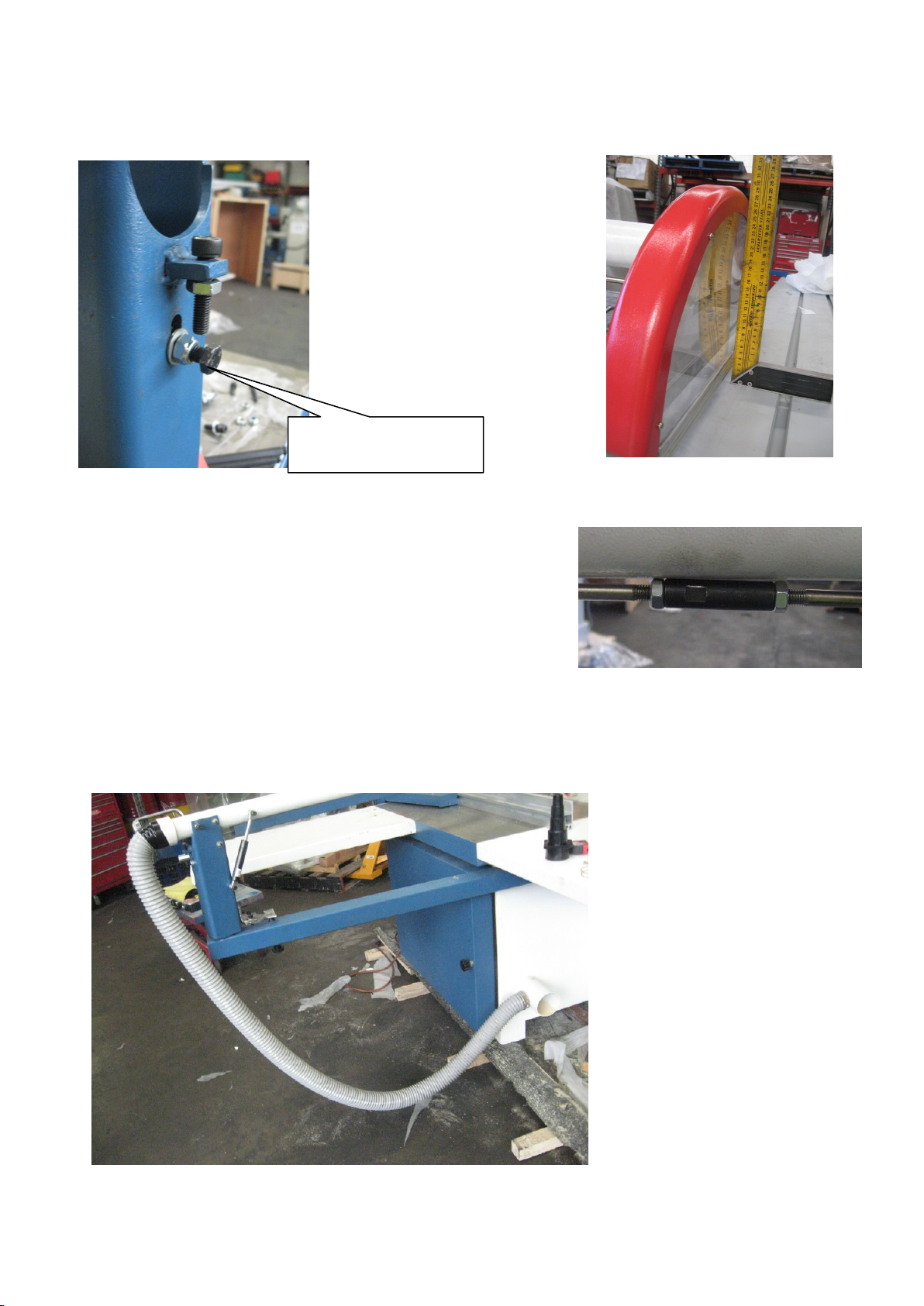

Carefully slide on the fence sliding casting

Note the position of lock lever. The pin may

have

to be pushed in to slide lock clamp over

shaft

Slide the casting up to the main table

Fit the fence extrusion onto the sliding casting,

lock in place and then slide the fence assembly

up approximately 100mm off the

aluminum

insert in the blade gap.

Me

asuring as shown by the 2 arrows

When fitting

sliding fence

casting to rod

Ensure lever is

in this position

This pin may

have to be

pushed down!

Rea

r fence sliding rod

Rear Fence

measurement tape