Inhaltsverzeichnis

U-PW powerway System Manual 01

01 About this manual

01.01 Subject of the manual ........................................................................................................06

01.02 Related documents ............................................................................................................07

01.03 Imprint................................................................................................................................08

01.04 Symbols and warning signs used.......................................................................................09

01.05 Abbreviations .....................................................................................................................10

02 Safety

02.01 Intended use ......................................................................................................................16

02.02 Misuse................................................................................................................................16

02.03 General safety instructions.................................................................................................17

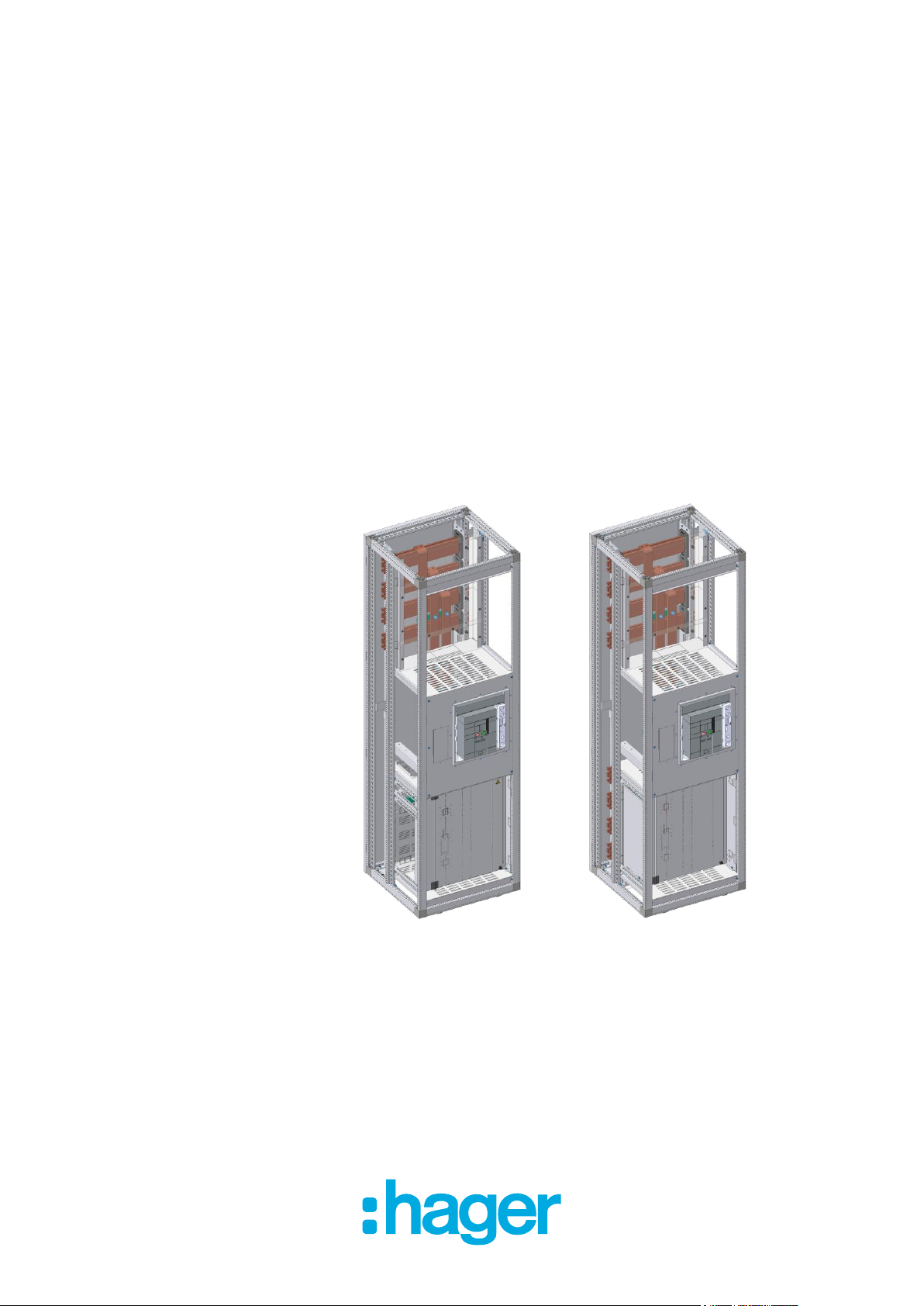

03 powerway enclosures and

components

03.01 System overview ................................................................................................................20

03.02 Technical data....................................................................................................................21

03.02.01 unimes H............................................................................................................................21

03.02.02 powerway enclosures.........................................................................................................22

03.03 Type key.............................................................................................................................23

03.04 Order overviews .................................................................................................................24

03.05 Component overview .........................................................................................................25

03.06 Spatial distribution .............................................................................................................26

03.07 Partition concept................................................................................................................26

03.08 Configuration of enclosure front.........................................................................................36

03.09 U-PWE/U-PWK ..................................................................................................................38

03.09.01 Versions and applications ..................................................................................................41

03.09.02 Main busbar system H-SaS................................................................................................45

03.09.03 Field connection on main busbars .....................................................................................48

03.09.04 Connection to H-SaS and ACB ..........................................................................................49

03.09.05 Examples of field connection/coppering ............................................................................50

03.09.06 ACB and functional units....................................................................................................51

03.09.07 Current transformer installation options .............................................................................53

03.09.08 Functional units..................................................................................................................56

03.09.09 Cross-connection space/auxiliary circuit wiring .................................................................57

04 Project planning and mounting

04.01 Operating safety and system availability ............................................................................62

04.02 Electrical connection ..........................................................................................................63

04.03 Forms of internal separation...............................................................................................66

04.04 Securing escape and emergency routes ............................................................................67