Distribution Unit

138--118

DISTRIBUTION

UNIT

I3647.DOC010302Edition: November 21, 2003

CONTENTS Page

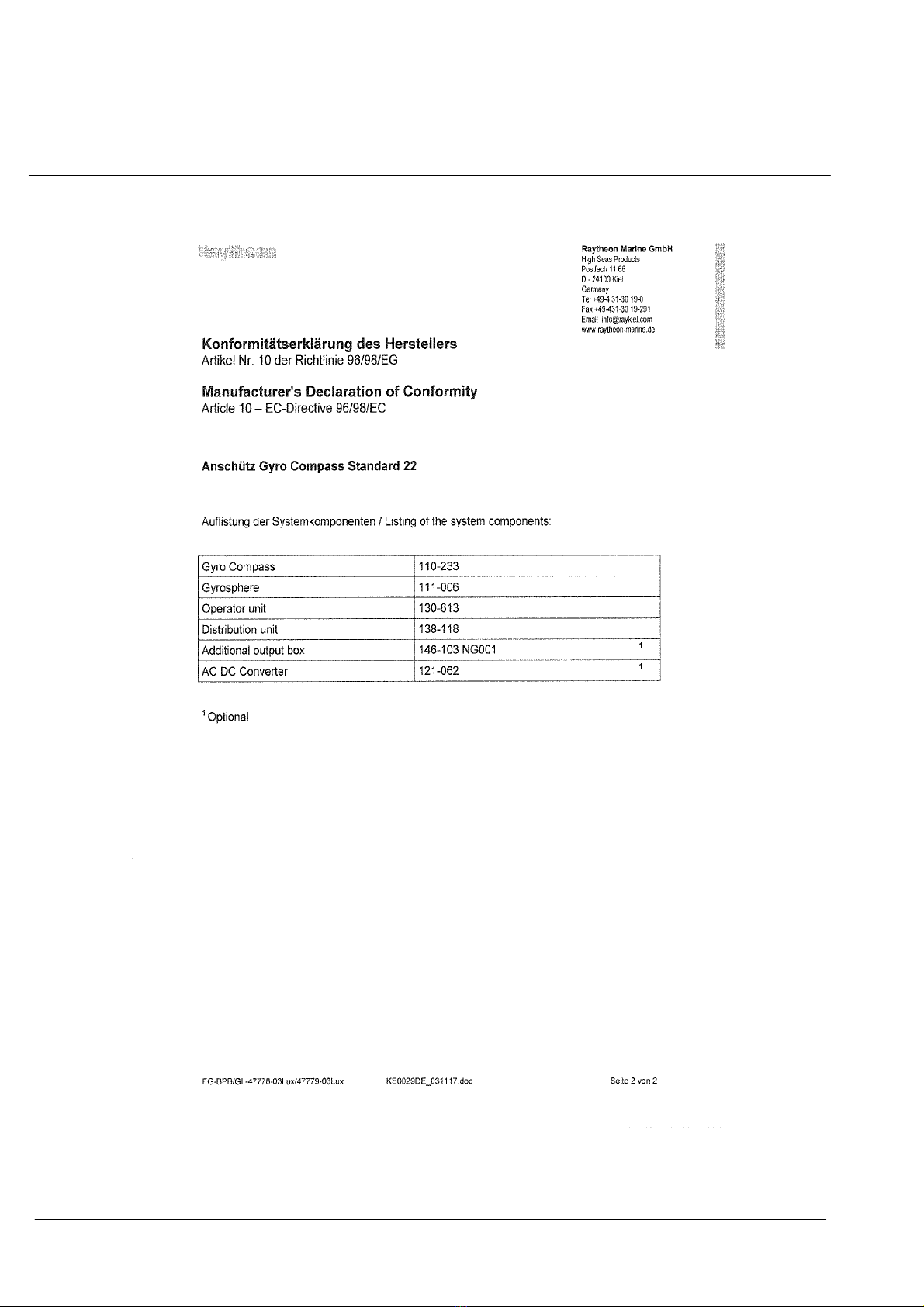

DeclarationofConformity ................................................

1 General 1..............................................................

1.1 CAN--Bus 2.............................................................

1.2 Technical Data 3.........................................................

1.2.1 Mechanical Data 3.......................................................

1.2.2 Electrical Data 3.........................................................

1.2 Information about LED‘s, push buttons and connectors of the integrated PCB‘s 4

2 Installation of the Distribution Unit 10........................................

2.1 General remarks 10.......................................................

2.1.1 General information about establishing an earth connection 12.................

2.2 Installation 13............................................................

2.2.1 Installation of the options 13...............................................

2.3 Connections 15...........................................................

2.3.1 Connection of the options 15...............................................

3 Switching On the Distribution Unit 15........................................

4 Setting of Jumpers and DIP--Switches 16....................................

4.1 Setting of Jumpers 16.....................................................

4.2 Setting of DIP--Switches 17................................................

4.2.1 General information in use of the DIP--Switch and push buttons 17..............

4.2.1.1 Setting of CAN Bus address 18.............................................

4.2.1.2 Adjustment of the 8 output channels 19......................................

4.2.1.3 Adjustment of NMEA Formats 21...........................................

4.2.1.4 Scaling of RoT Output 23..................................................

4.2.1.5 Selection of magnetic compass 24..........................................

4.2.1.6 Displaying heading or speed information 25..................................

5 Switching OFF the Distribution Unit 26.......................................

6 Adjustments 27...........................................................

6.1 Adjustment of magnetic sonde 27...........................................

7 Maintenance and Repair 29................................................

8 Functional description of DIP switch settings (SEC) in the service mode 30.......

Drawings:

Gyro Compass STD 22 Cable and Connection Diagram 110--233 HP009 Sheets 1--3

Distribution Unit Dimensional Drawing 138--118 HP005

Distribution Unit Wiring Diagram 138--118 HP008