1

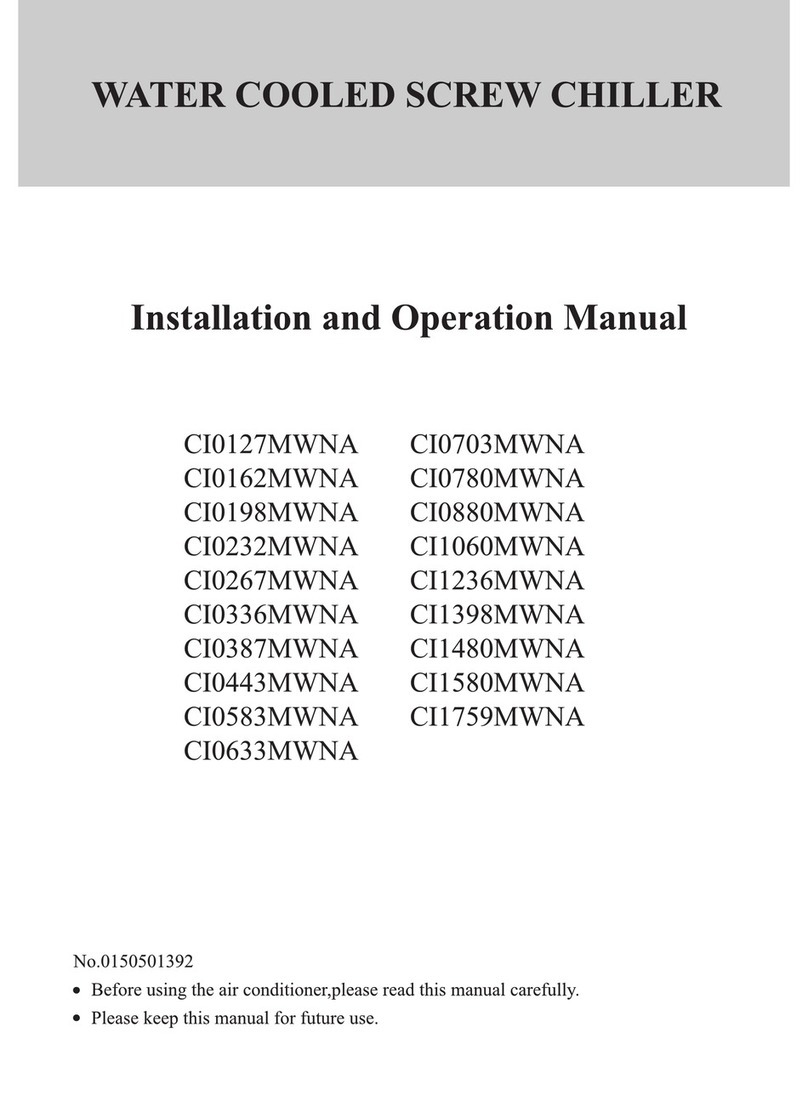

CONTENTS

1. Nomenclature ........................................................................................................................................................ 1

2. Feature .................................................................................................................................................................. 1

2.1 Product feature.................................................................................................................................................... 1

2.2 High Efciency..................................................................................................................................................... 2

2.3 Easy Installation .................................................................................................................................................. 2

2.4 Comfort................................................................................................................................................................ 4

2.5 High Reliability..................................................................................................................................................... 5

3. Specication .......................................................................................................................................................... 7

4. Dimension.............................................................................................................................................................. 9

5. Refrigerant system diagram ................................................................................................................................ 10

6. Installation ........................................................................................................................................................... 11

6.1 Symbol precautions........................................................................................................................................... 11

6.2 Installation ......................................................................................................................................................... 13

6.3 Water pipe connection....................................................................................................................................... 16

6.4 Electrical Connection Precautions..................................................................................................................... 21

6.5 Debugging and running ..................................................................................................................................... 26

6.6 Regular inspection of the project....................................................................................................................... 27

6.7 Maintenance...................................................................................................................................................... 28

7. Controller Operation Instruction........................................................................................................................... 29

8. Wiring diagram .................................................................................................................................................... 40

9. PCB photo and address code setting.................................................................................................................. 41

10. Fault code.......................................................................................................................................................... 42

11. Trouble shooting ................................................................................................................................................ 44

12. Unit operating range and service condition ....................................................................................................... 46

12.1 Unit operating range........................................................................................................................................ 46

12.2 Unit operating conditions................................................................................................................................. 46

13. Technical parameters ........................................................................................................................................ 47

14. Sensor charistic................................................................................................................................................. 48

15. Appendixi table for manual updated information ............................................................................................... 49