SAFETY RECAUTIONS

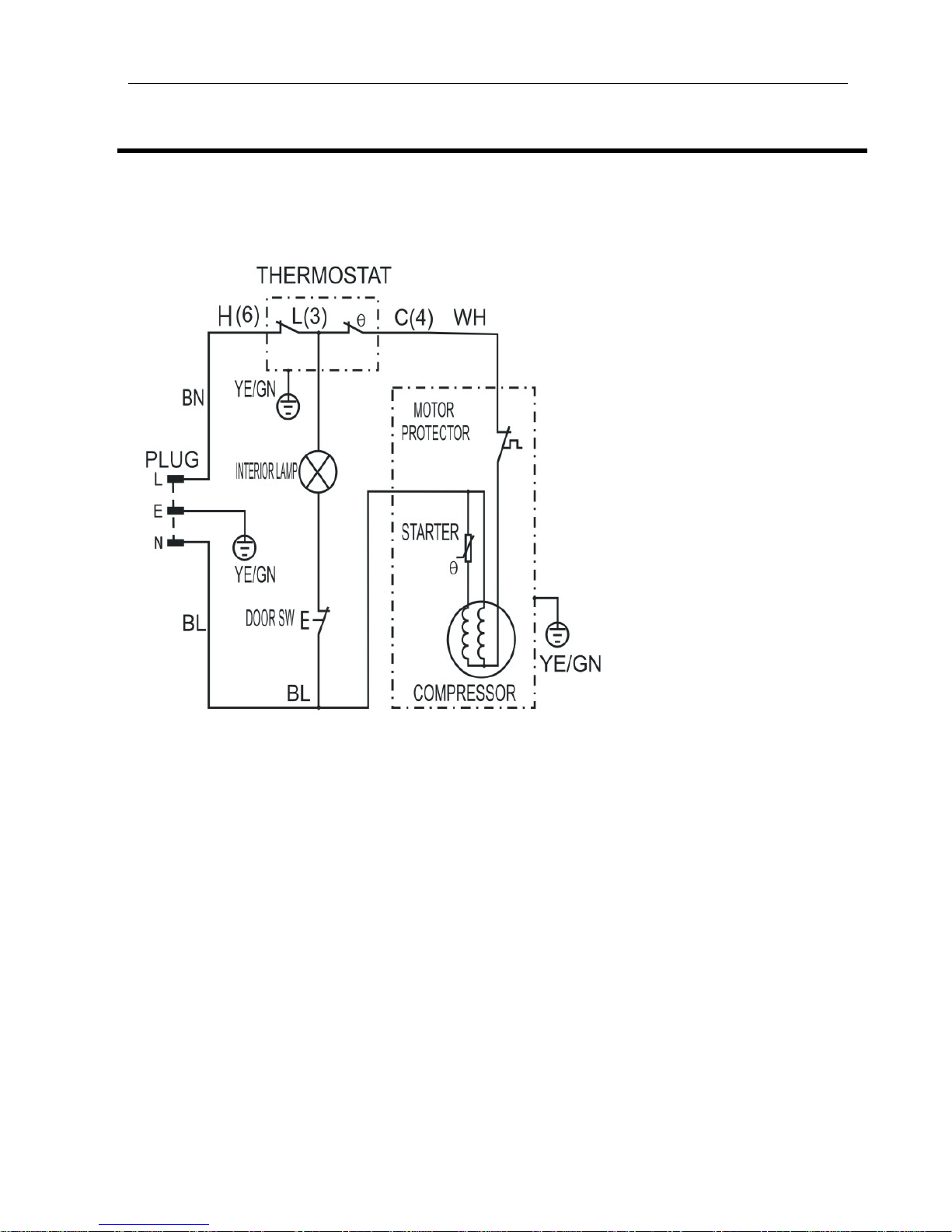

1. Check if there is any leak of current.

2. Cut out the power supply before the repair to avoid an electrical shock hazard.

3. In the case of a live-line test, insulating gloves should be worn to avoid potential electrical shock.

4. Confirm the rated current, voltage and capacity before testing with any kinds of instruments.

5. Watch if the upper door is open when you check something at a lower position.

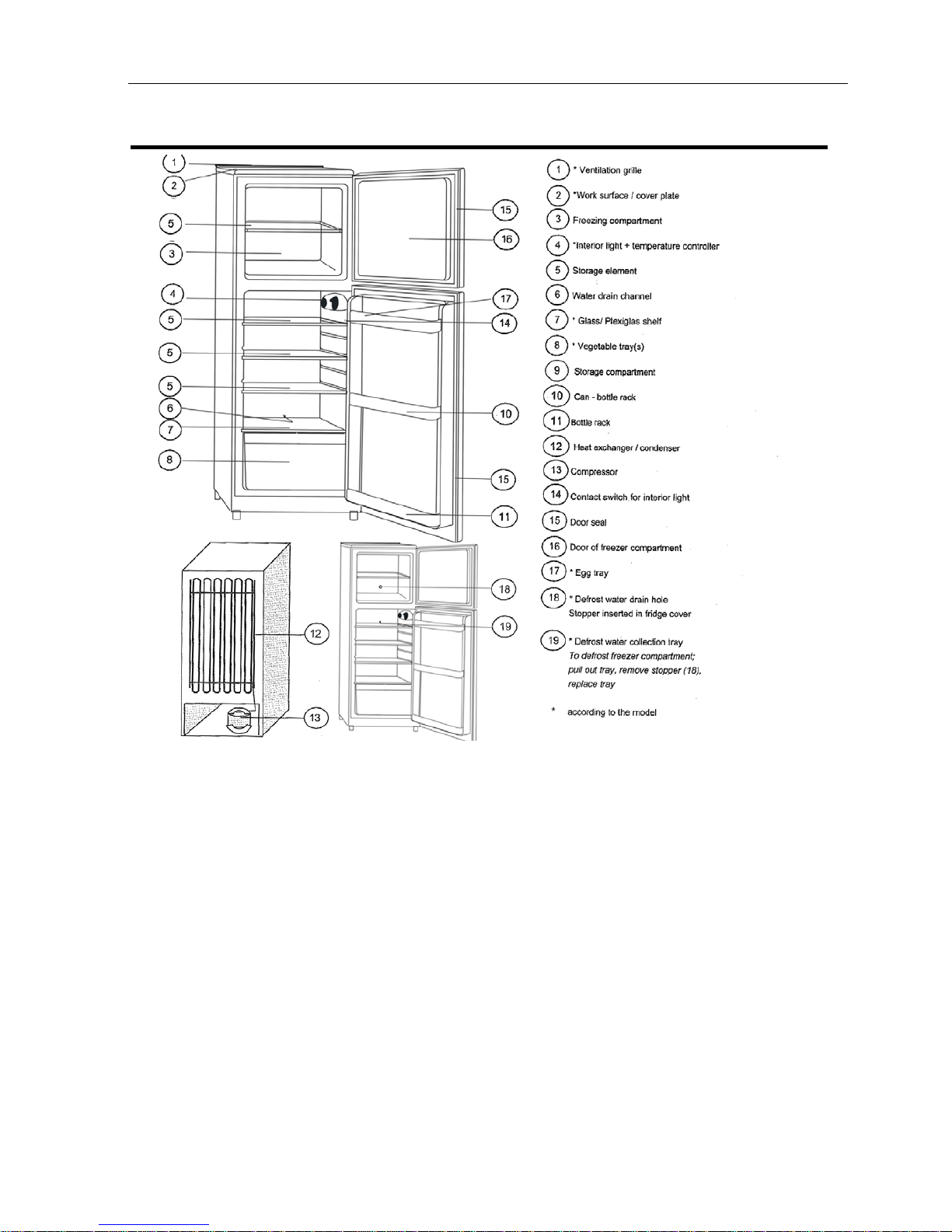

6. Take out every part in the cabinet before moving the machine, especially things like panels (e.g. glass

shelf).

7. Please wear intact cotton gloves wh en repair any parts of the evapor ator, so that scr atches by th e

sharp fins can be avoided.

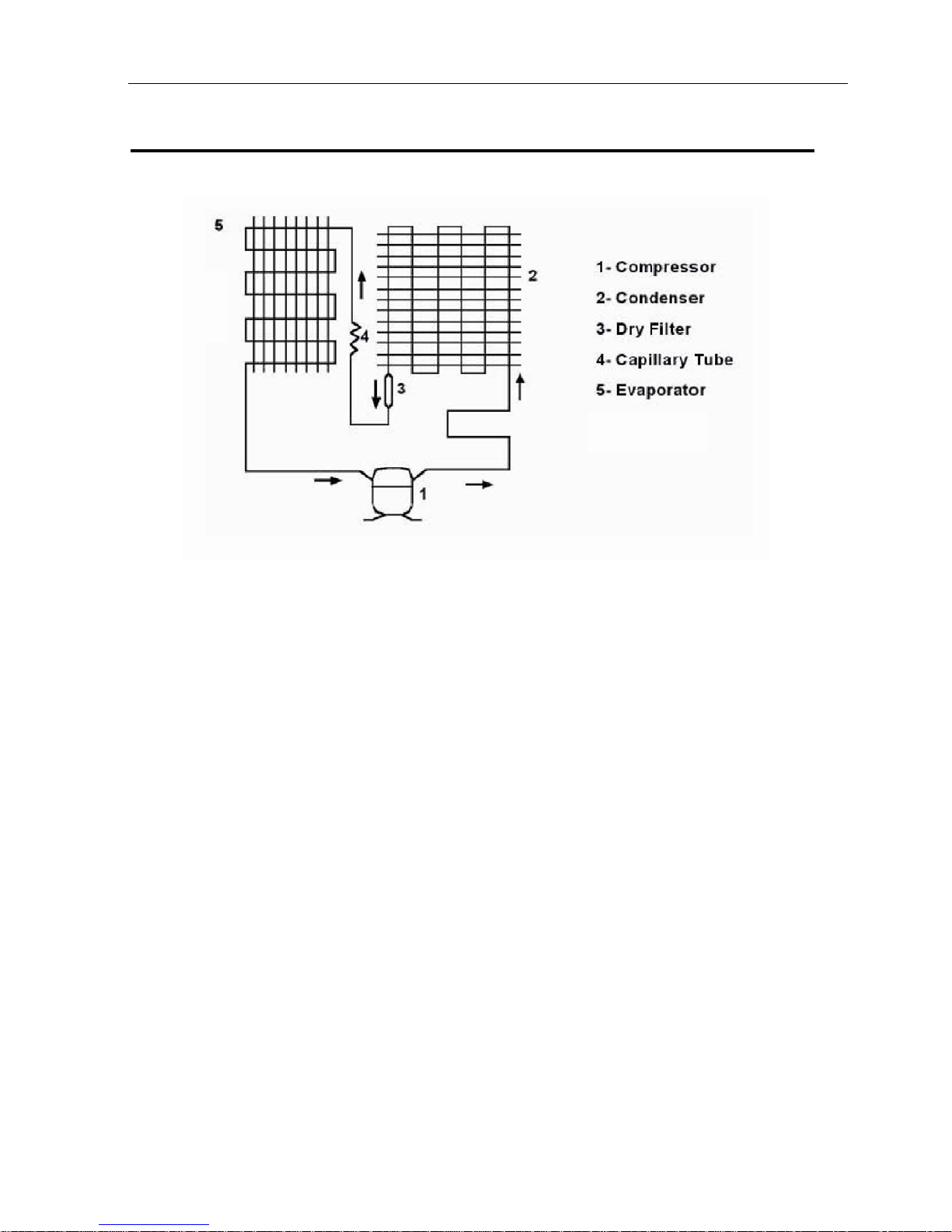

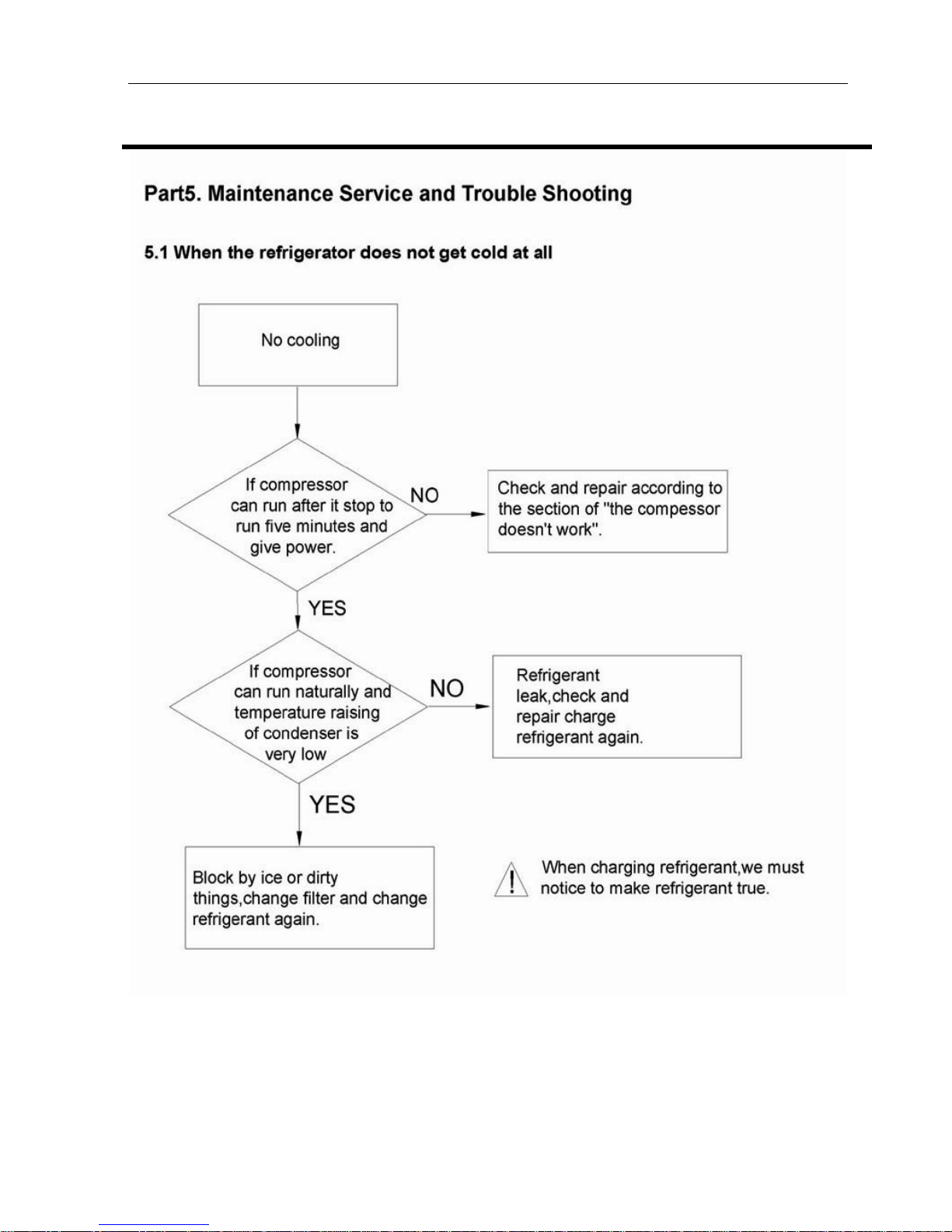

8. If there is a breakdown with the refrigeration system, please surrender the machine to the service

center, else the leaked refrigerant may pollute the atmosphere.

9. The refrigerator use AC of 220V with a frequency of 50Hz.

10. A big fluctuation of voltage (exceed the range 220~240V) may cause a start failure of the refrigerator,

a burn -out o f the control p anel and compressor, or an abn ormal sound from the co mpressor in

operation. In this condition an automatic voltage regulator over 750W should be added.

11. Take care not to damage the supply line. Don’t yank at the line; pull the plug out gently from the

receptacle. Don’t press the line under the cabinet or step on it. Take care not to roll on or damage the

supply line when moves the machine from the wall.

12. Don’t use the supply line any more when there is damage to the line or an abrasion to the plug. Go to

the authorized service center for a replacement.

13. In the case of leakage of inflammable gases like carbon monoxide, open the door and windows. Don’t

pull out or insert the plugs of the appliance.

14. This product is designed only for h ousehold use. Any put of medicine, dang erous flammable,

explosive articles and highly corrosive acid or base is forbidden.

15. It is recommended not to put any receptacles, stabilized power suppl y or appliances like microwave

oven on the board of the refrigerator. Don’t use appliance within the refrigerator (except recommended

type), else there may be electromagnetic interference or other accidents.

16. Don’t store or use gasoline and other flammable articles near the refrigerator which may lead to a fire