7

B. The preset mode (Select the set temperature)

When changing the soldering iron temperature, there is a preset function that selects the temperatures set

(up to 5 can be stored).

Initial preset temperatures

P1: 250℃ (482℉), P2: 300℃ (572℉), P3: 350℃ (662℉), P4: 400℃ (752℉), P5: 450℃ (842℉)

The initial number of active presets is set to 5 at the factory.

The default selected preset is set to P3 at the factory.

Example : Changing preset temperature from preset No.1 (250℃) to No.3 (350℃).

The procedure for making changes to the preset temperatures is the same with “A. The temperature

setting mode” in 6. OPERATION (Soldering iron).

Change the mode on the parameter setting screen. (Refer to “7. Parameter Setting (Soldering Iron)”)

*Preset selection screen

Be displayed

alternately.

Press the button

twice.

Be displayed

alternately.

Press the button

once.

Press the button

once. Heater control will begin with new

preset temperature.

CAUTION

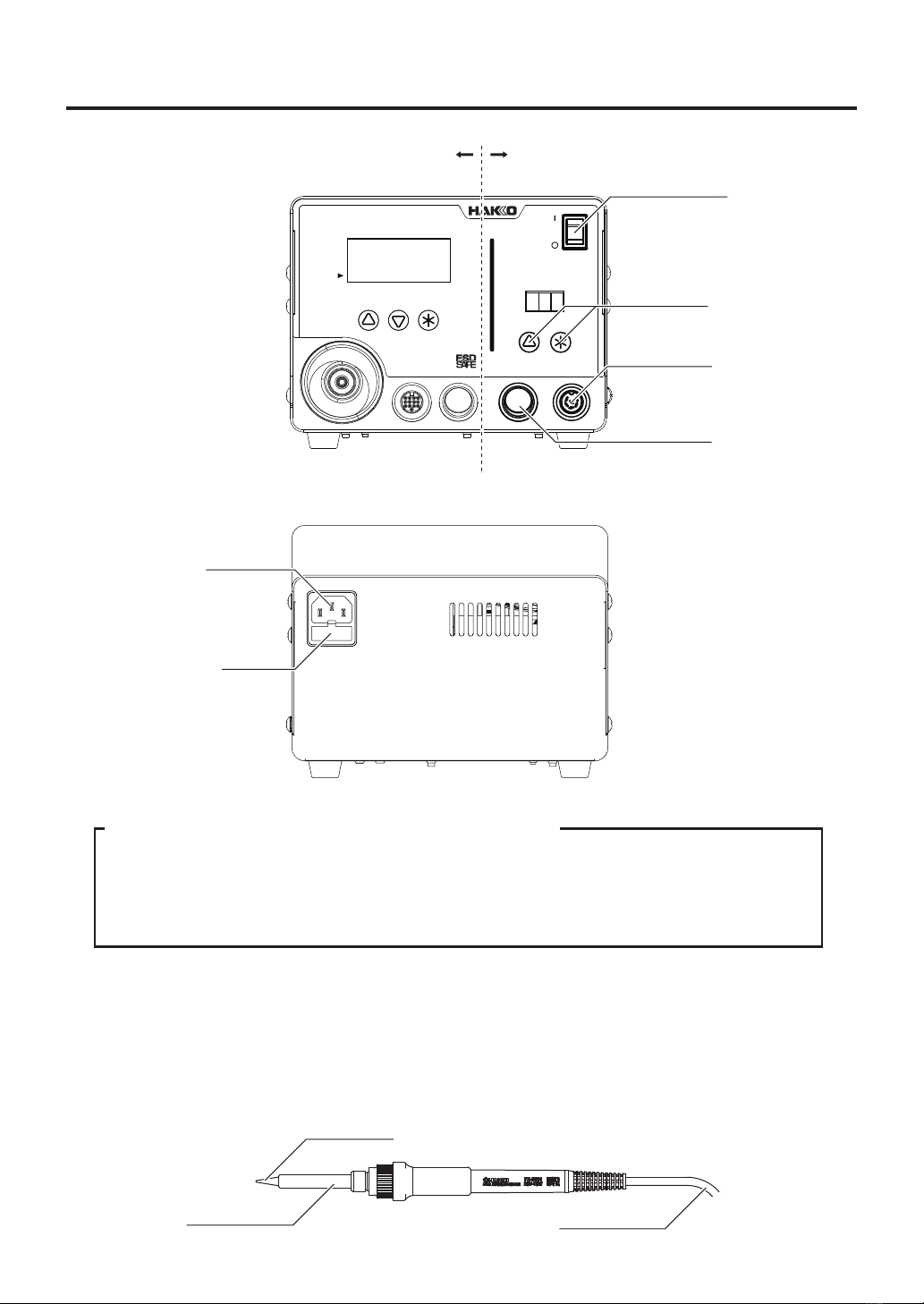

C. The adjust mode (Performing the temperature adjustment)

When replacing the iron, heater or tip, a temperature adjustment may be required.

Use the adjust mode to perform the temperature adjustment.

• Enter the observed value in the adjust mode after the tip temperature stabilizes.

• The maximum single adjustment that can be made is ±150℃ (270℉) relative to the set temperature.

If a larger adjustment is needed, make the first adjustment at the maximum value of 150℃ (270℉),

then repeat the adjustment process.

Example : If the measured temperature is 380℃ and the set temperature is 400℃.

1. Press and hold the button for at least two seconds.

●is displayed.

When you press the button, the display will move

to the adjust mode.

2. Changing from to .

●

The procedure for changing the value in adjust mode

is the same

with “A. The temperature setting mode”

in 6. OPERATION (Soldering iron).

3. Press the button to exit the setting after changing

the values.

● The tip temperature will be adjusted accordingly.

CAUTION

* How to distinguish between

Temperature Setting Mode and Adjust Mode.

The display differs in the temperature setting

and the adjust mode.

In the Temperature

Setting Mode In the Adjust Mode

Identification lamps are on

in the adjust mode.

Please be sure to confirm the status of the

identification lamps so that you do not enter

a value in the wrong mode.

NOTE :

During adjust mode, the hundreds digit will

accept values from 0 through 6 if the temperature

is set to display in ℃, or the values 0 through 9

if the temperature is set to display in ℉.

6. OPERATION (Soldering iron) (continued)

8

D. Password function (Restriction on setting changes)

It is possible to restrict certain setting changes to the unit.

There are three choices for the password setting. (The factory default is "0 : Open")

○: You can make changes without entering a password.

△: You can choose whether or not a password is needed to make changes.

×: A password is required to make changes.

0 : Open

○

○

○

○

1 : Partial

×

△

△

△

2 : Restricted

×

×

×

×

Move to the parameter setting mode

Move to the temperature setting mode

Move to the preset mode

Move to the adjust mode

The letters

for password

Example: The procedure for changing the set temperature when the unit is restricted by a password.

(Password is “AbC”)

Select and input three letters for password

from six letters on the right.

The unit will move to the change setting screen for each mode after entering the password.

Please change the setting for each mode according to the procedure.

Enter the parameter setting to change the mode.

Please refer to “7. PARAMETER SETTING (Soldering iron)”.

Press the button

once.

Press the button

once.

Press and hold the

button for at

least one second.

Press the button

twice.

Press the button

three times.

Press the button

once.

Press the button

once.

CAUTION

• If the password you entered is incorrect, the display will

show three dashes for you to re-enter the password.

• If you enter the password incorrectly twice in a row, the

display will return to the previous screen.