Hakko Electronics FG-102 User manual

Table of Contents

..................... 1

................................................. 2

................ 2

...................................................... 3

....................................................... 11

................................ 29

.......................................... 34

............................ 34

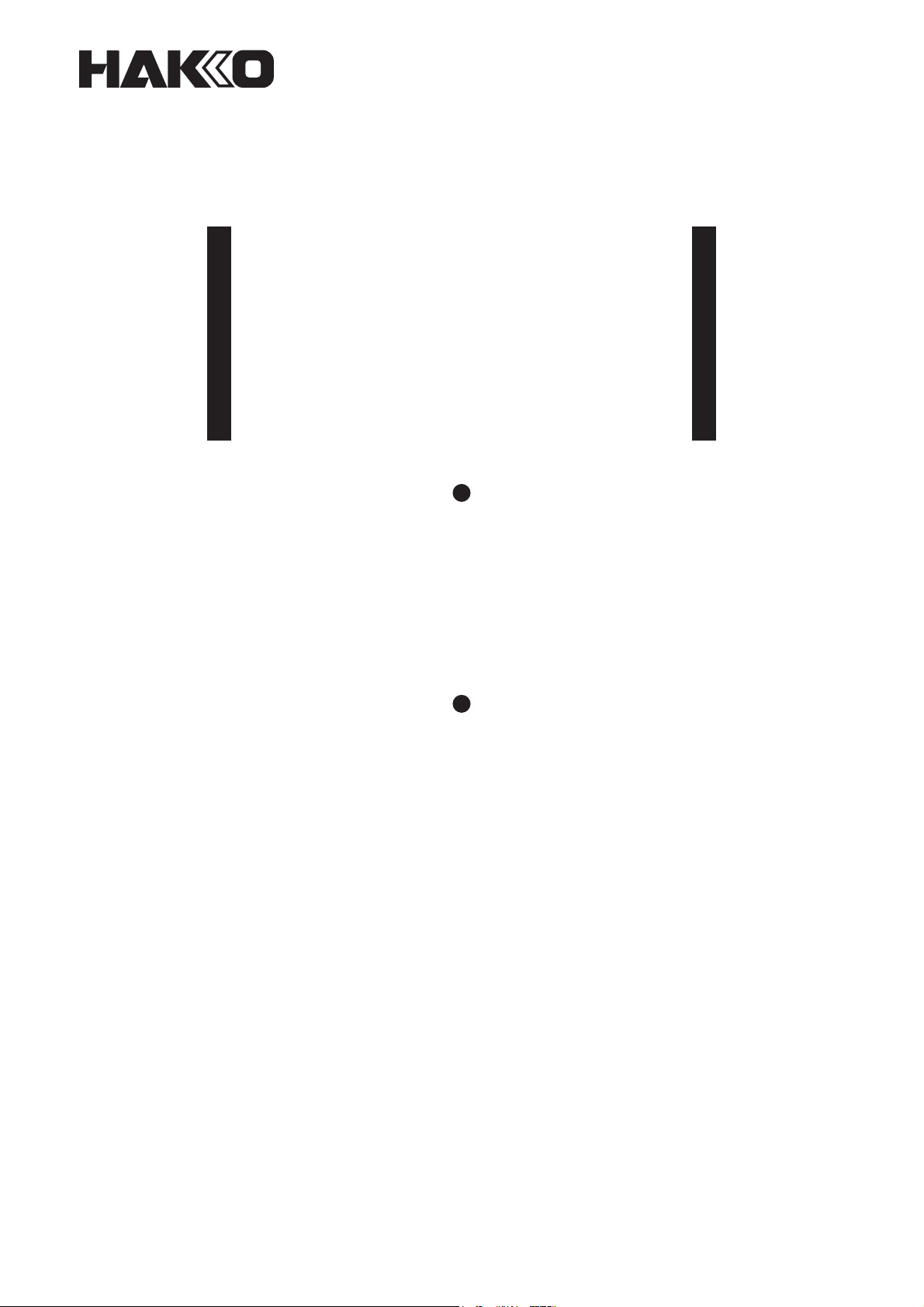

1. PACKING LIST AND PART NAMES

2. SPECIFICATIONS

3. WARNINGS, CAUTIONS AND NOTES

4. INITIAL SETUP

5. OPERATION

6. SAVING DATA ON THE PC

7. ERROR MESSAGES

8. TROUBLESHOOTING GUIDE

Thank you for purchasing the HAKKO FG-102 Thermometer.

This thermometer can transfer the following data to PC making them into one file.

And it can set up some particular temperature setting groups

to determine temperature ranges.

Please read this manual before operating the HAKKO FG-102.

Keep this manual readily accessible for reference.

THERMOMETER

FG-102

Instruction manual

HAKKO FG-102

Barcode reader

USB cable

Software (CD-ROM)

Sensor (10 pcs./set)

.................................................... 1

..................................................... 1

............................................................. 1

.............................................. 1

.............................................. 1

AA sized (LR6) battery (6 pcs for trial)

Barcode seal (For Unit ID 30 sheets)

Barcode seal (For Measurer ID 30 sheets)

Instruction manual

.................. 6

................... 1

........... 1

................................................. 1

1. PACKING LIST AND PART NAMES

1

Sensor

terminals Slide pin

Slide button

Barcode

reader connector

Handle

PC interface

Holder

Battery box

HAKKO FG-102

Barcode reader

USB cable

Sensor

(10 pcs)

AA sized

(LR6) battery

(6 pcs - for trial)

Barcode seal

(For Unit ID)

Barcode seal

(For Measurer

ID)

for FG102

*******

for FG102

*******

*

010001

*

*

M10001

*

Software (CD-ROM)

Please check to make sure that all items listed

below are included in the package.

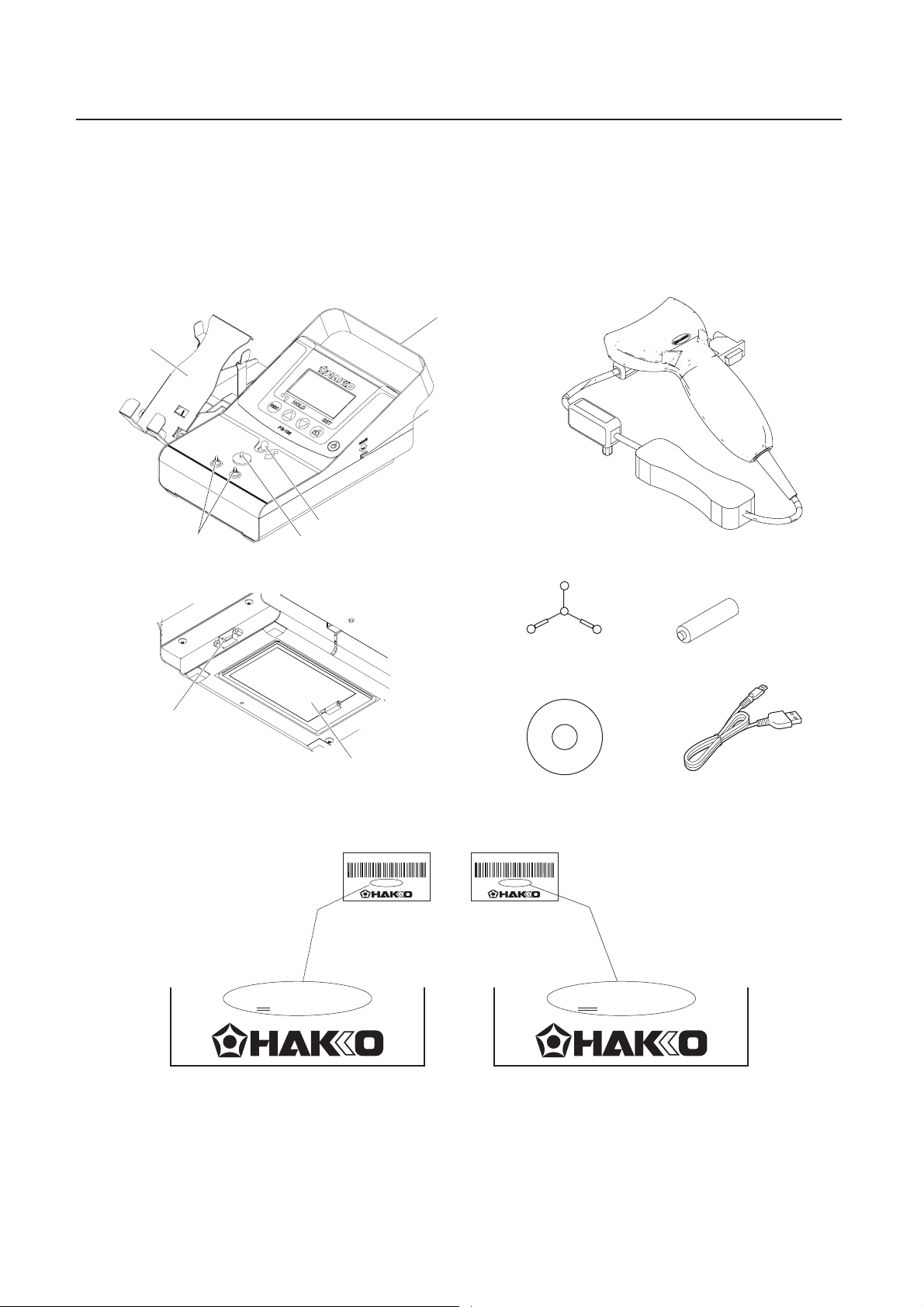

2. SPECIFICATIONS

3. WARNINGS, CAUTIONS AND NOTES

2

*1

Temperature sensor (191-212) can only be used to measure temperatures below 500

°

C (932

°

F).

To measure higher temperatures, use an applicable temperature probe.

*4 If the sensor burns out, the burn-out will be indicated. Once the indication occurs, replace

the sensor with new one.

The specifications may be subject to change without notice.

*2 is blinking: The batteries are low. Prepare new batteries.

*3

will be always shown: The battery is depleted and must be replaced.

1℃

0 - 700℃*1

K (CA) type thermocouple

±3°C (between 300 and 600°C)

±5°C (Other than above)

Besides measured temperatures, display indications include the following:

AA sized (LR6) battery × 6 (alkaline cell recommended)

193 (W) × 90 (H) × 219 (D) mm (w/o barcode reader)

0.93 kg (w/o batteries, bar code reader)

2 m

1.1 m

A-miniB

0 to 40℃, max.80% RH, without condensation

Applicable rated pollution degree 2 (According to IEC/UL61010-1)

1℉

32 - 1,300℉*1

±6°F (between 572 and 1,112°F)

±10°F (Other than above)

Celsius type Fahrenheit type

Burnout alarm*4

Battery

status*2, 3 MAX HOLD

Measurement

Mode

HAKKO FG-102

M

H

305

Temp ****

℃

2014/08/31/14:01

Model name

Resolution

Temperature measurement range

Applicable sensor

Measurement tolerance

Display

Power supply

Outline dimensions

Weight

Length of cord

(Barcode reader)

Length of the USB cable

USB type

Ambient temperature/humidity range

Environmental condition

CAUTION

When using the thermometer to measure the temperature of the soldering iron tip or de-soldering

nozzle, pay great attention to the temperature of the tip or nozzle that will be as high as 200 to 450°C

(392 to 842°F). Careless handling of such a hot object may result in a burn or fire.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

Warnings, cautions and notes are placed at critical points in this manual to direct the operator’s

attention to significant items. They are defined as follows:

CAUTION : Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved. Two examples are given below.

WARNING: Failure to comply with a WARNING may result in serious injury or death.

NOTE : A NOTE indicates a procedure or point that is important to the process being described.

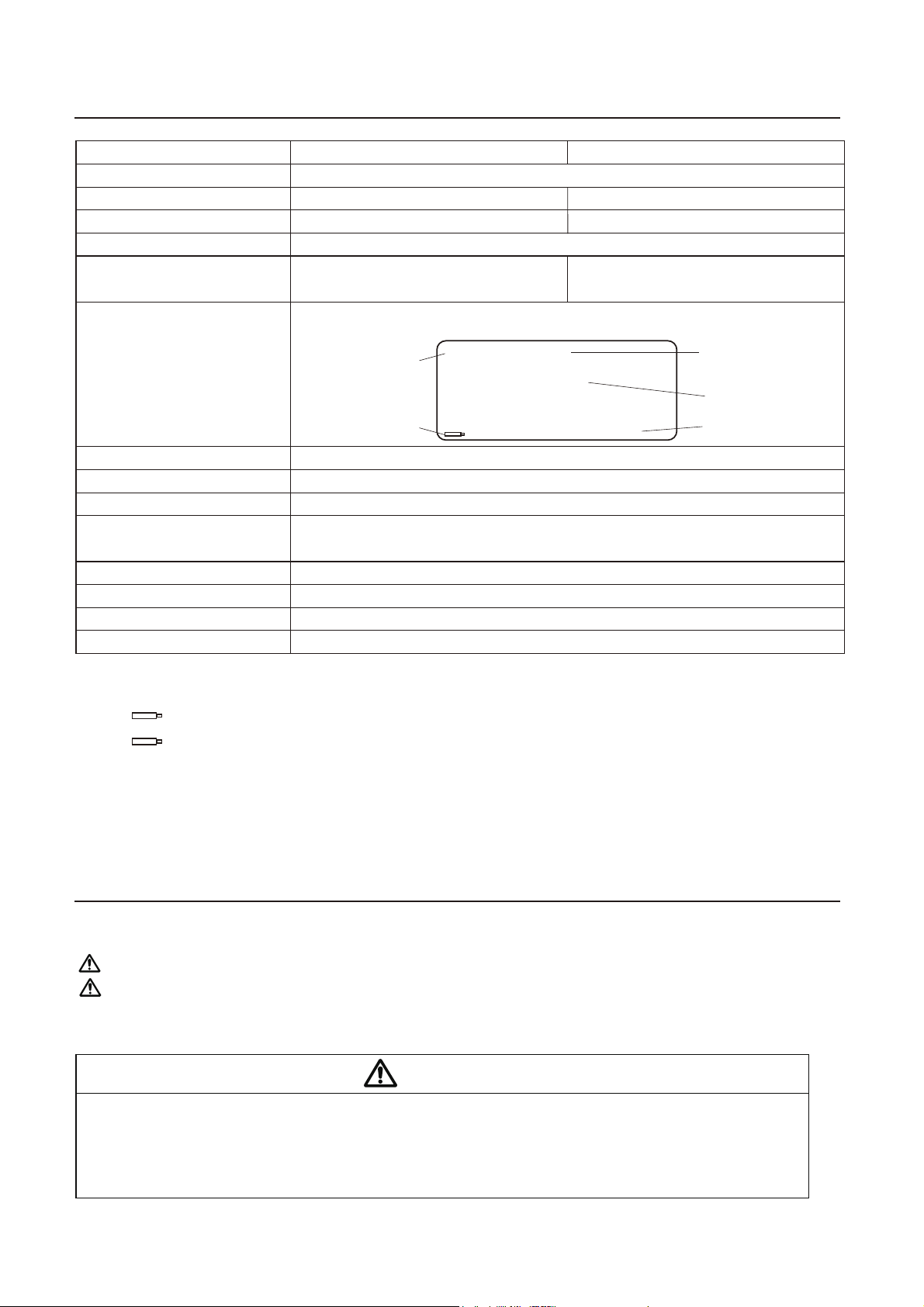

4. INITIAL SETUP

3

●

Attach the sensor that comes with the equipment.

1.

Press the slide button. The slide pin will move toward the terminal.

2.

With the slide pin moved toward the terminal, attach the sensor.

3.

When attaching the sensor, fit the red-marked side to the red-indicated terminal and the

blue-marked side to the blue-indicated terminal.

A. Preparation of the HAKKO FG-102 side

Slide pin

Slide button

Sensor

terminals

CAUTION

Since the sensor is made of a very thin (φ0.2) copper-clad aluminum wire,

any hard press on it may break the wire. Be careful when handling it.

Attachthesensor

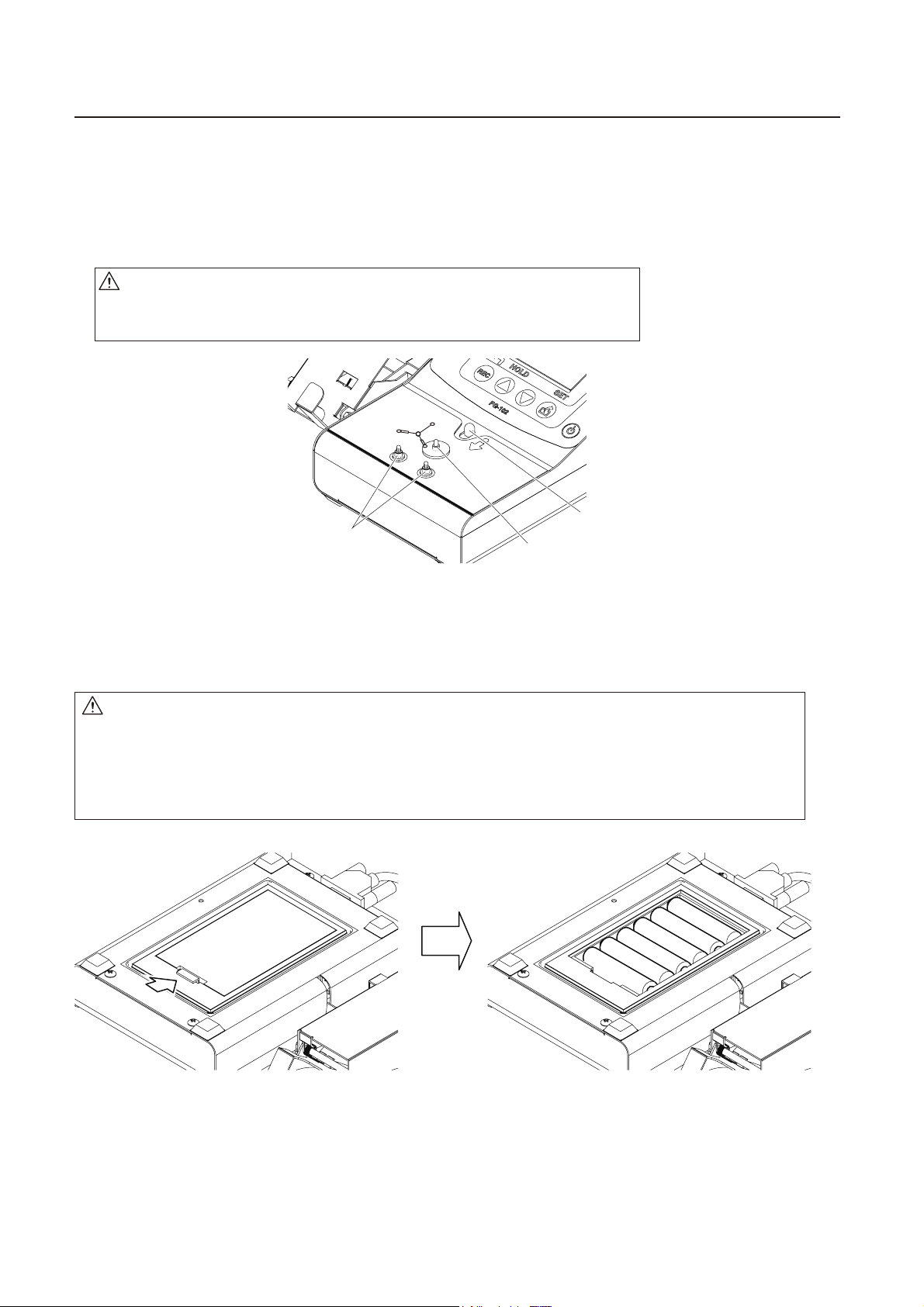

●

Set the batteries.

Put six pieces of size AA batteries in the battery box.

CAUTION

・

Make sure the polarity.

・Avoid any mixed use of new and old batteries.

・While NiCad and nickel metal hydride rechargeable batteries may be used, they last shorter heat

generation and(or) liquid spill. Use of alkaline batteries is recommended than NiCad batteries.

・When replacing the batteries, the data saved on the main body will not be lost.

Cover Battery

4

B.

Preparation on the soldering iron side

Stick the barcode that comes with the equipment or a printed one to the soldering iron station or

the iron. When sticking the barcode to a unit, be careful of the following points.

CAUTION

・

Select a flat surface and avoid any curved surface wherever possible when sticking

the barcode seal.

・

The barcode itself should be 2.5 mm wide or over.

・

There should be a margin of 2 mm or over on both ends of the barcode, as shown on the figure.

・

Do not use metallic luster for the background when making a barcode seal.

・

Do not cover the barcode with lustrous or reflective tape or anything like that.

Barcode

readerconnector

●

Connect barcode reader

Connect barcode reader to the D-subminiature and fix the screws.

Connecting barcode reader

The bar code pasted Example

for FG102

*******

for FG102

*******

2mm

5

C. Preparation on PC

●Confirmed operating environment

The operation of the accompanying software has been confirmed in the following environment:

1) OS:Windows 7 Professional Service Pack1

CPU:Intel Core i3-3110M 2.40Hz 4.0GB RAM

2) OS:Windows 8

CPU:Intel Core i3-2370M 2.40Hz 4.0GB RAM

●Connection with PC

・Installing driver software

To connect FG-102 with a PC, installation of the driver software is required.

Please carry out installation from the accompanying CD.

* Installation requires Administrator’s privileges.

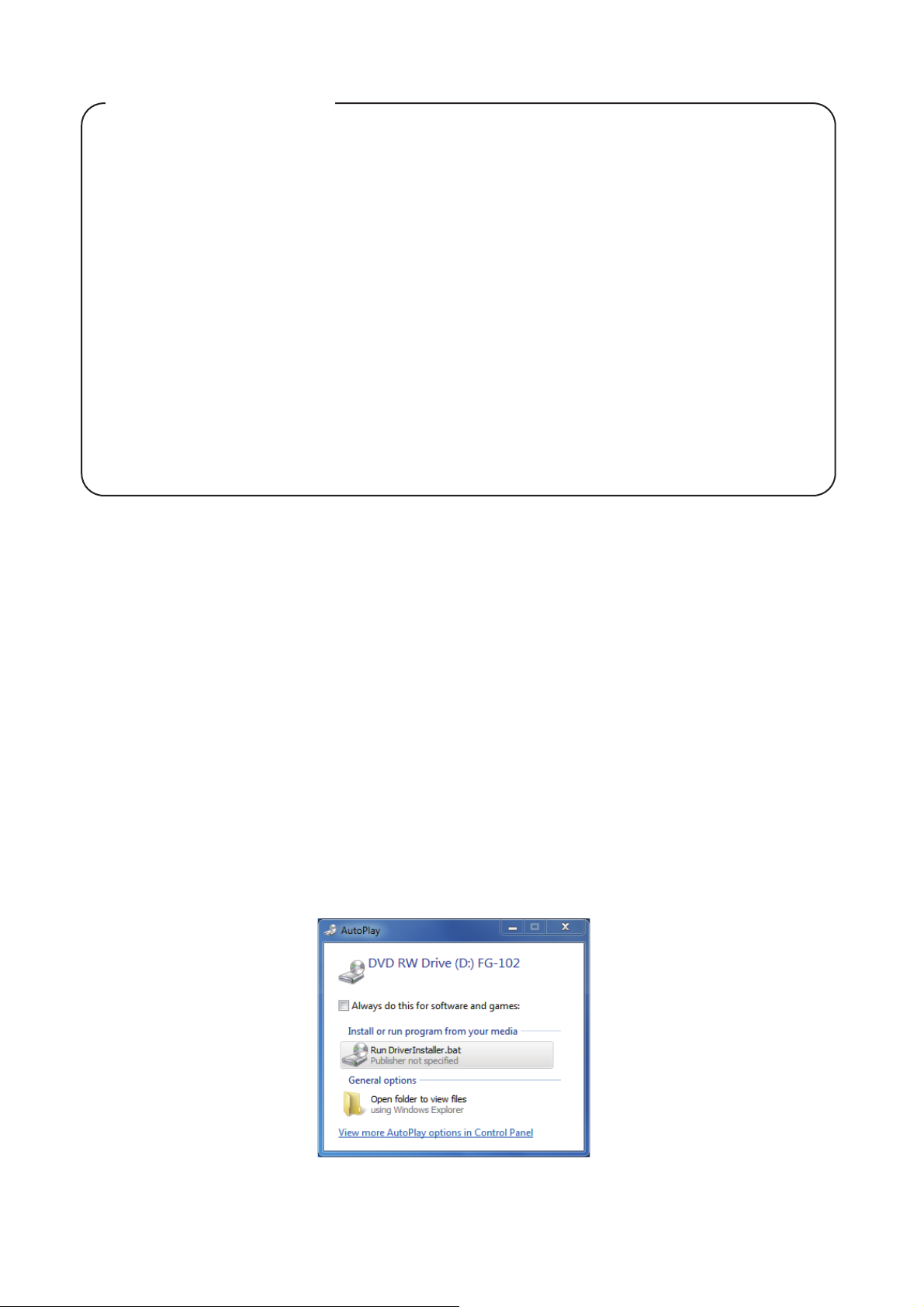

1. Please insert the accompanying CD-ROM into the CD-ROM drive of the PC.

2. Select Run DriverInstaller .bat.

The following window appears.

AutoPlay confirmation window

■ ID barcode specifications

ID barcode specifications

Barcode types:CODE 39、Check digit ○

Barcode format

Equipment ID :Number of initials “0 (Zero)” + 5 digits

Measurer ID :Number of initials “M” + 5 digits

* The following shows the readable barcode resolution and distance.

(One mil equals to 1/1000 in. and a width of 4 mil is approximately 0.1 mm wide)

Distance

30 - 90 mm

30 - 105 mm

10 - 180 mm

10 - 220 mm

10 - 280 mm

10 - 360 mm

Resolution :

4 mil :

5 mil :

7.5mil :

10 mil :

13 mil :

20 mil :

6

3. Select the language and press the Enter key.

4. Enter Y and press the Enter key.

5. Wait until the driver is installed.

* If no window appears or the window was closed, double-click DriverInstaller located in the

CD-ROM to start it.

・Connect the HAKKO FG-102 and the PC

1. Turning on the power of HAKKO FG-102

2. Connect it with the PC.

Wait until FG-102 is recognized by the PC. This step may take several minutes.

StartingDriverInstaller

7

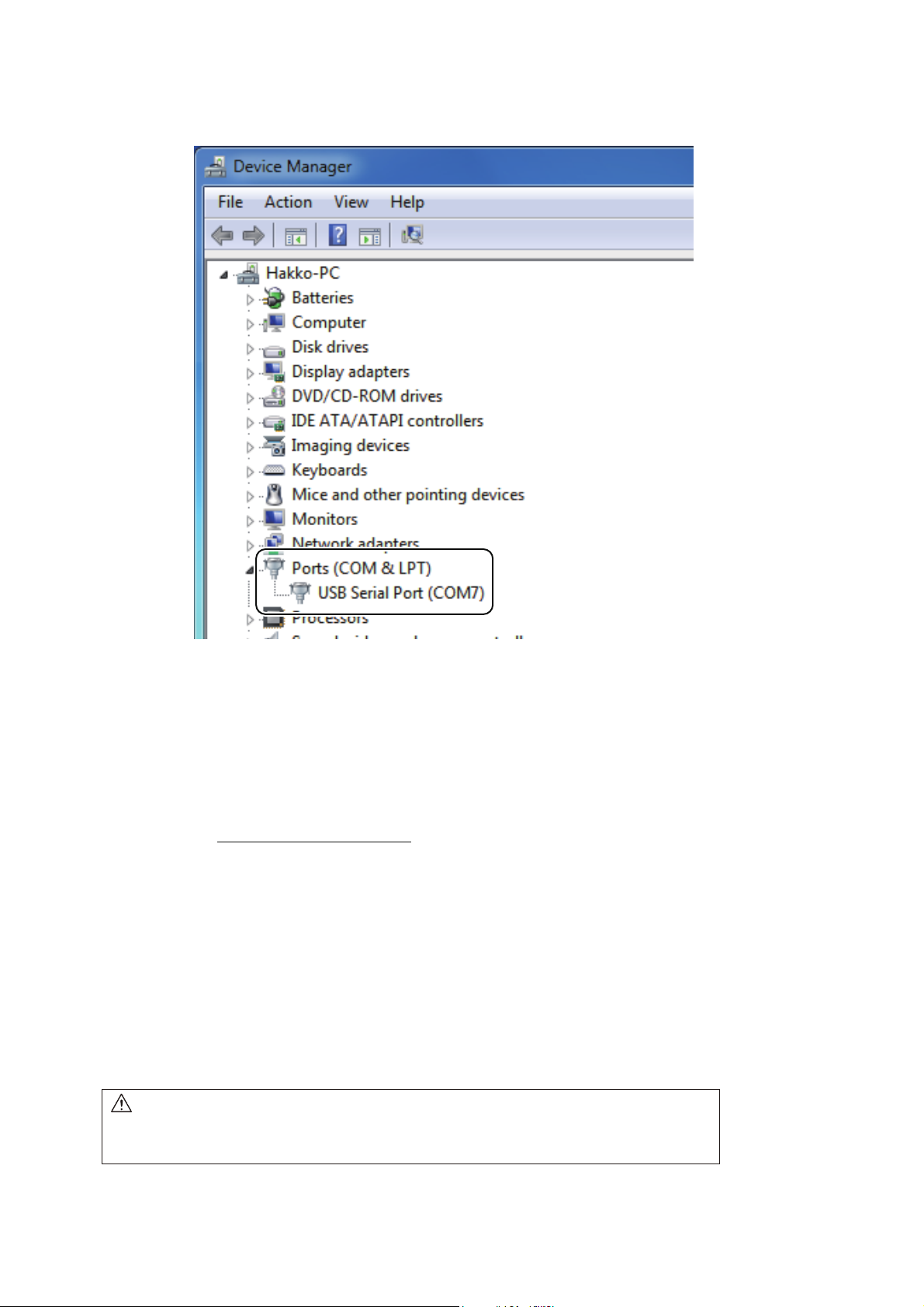

3. Open the Device Manager and make sure that the driver has been installed.

* The COM number may differ from the one shown in the picture below.

The latest version of the driver software can be downloaded from Cypress’s web site.

Cypress’s web site http://www.cypress.com/

User registration to Cypress.com is required for downloading.

CheckingDeviceManager

● Installing PC software

Communicate with the equipment and install a piece of software to save the data.

1. Open the CD-ROM that comes with the equipment and copy a folder named

“PC communication software” to the PC.

2. Open the folder and double-click “FG102_DataSave.exe” to confirm that the software starts up.

CAUTION

Intheprocess,afileFG102.iniwillbecreated.Sincethefileisnecessaryfor

thatsoftware,donotdeleteit.

DeviceManager

8

* If the software on the PC will not run

"The configuration of this application incorrect, it was not able to start the application.

There are cases where the issue is resolved by installing the application again. ", "***.

Dll can not be found."

If the display such as leaves, the following software to the Microsoft home page Download

from, please install.

• Microsoft Visual C++ 2010 Redistributable Package

• Microsoft .NET Framework 4 Redistributable Package

Microsoft web site:http://www.microsoft.com/

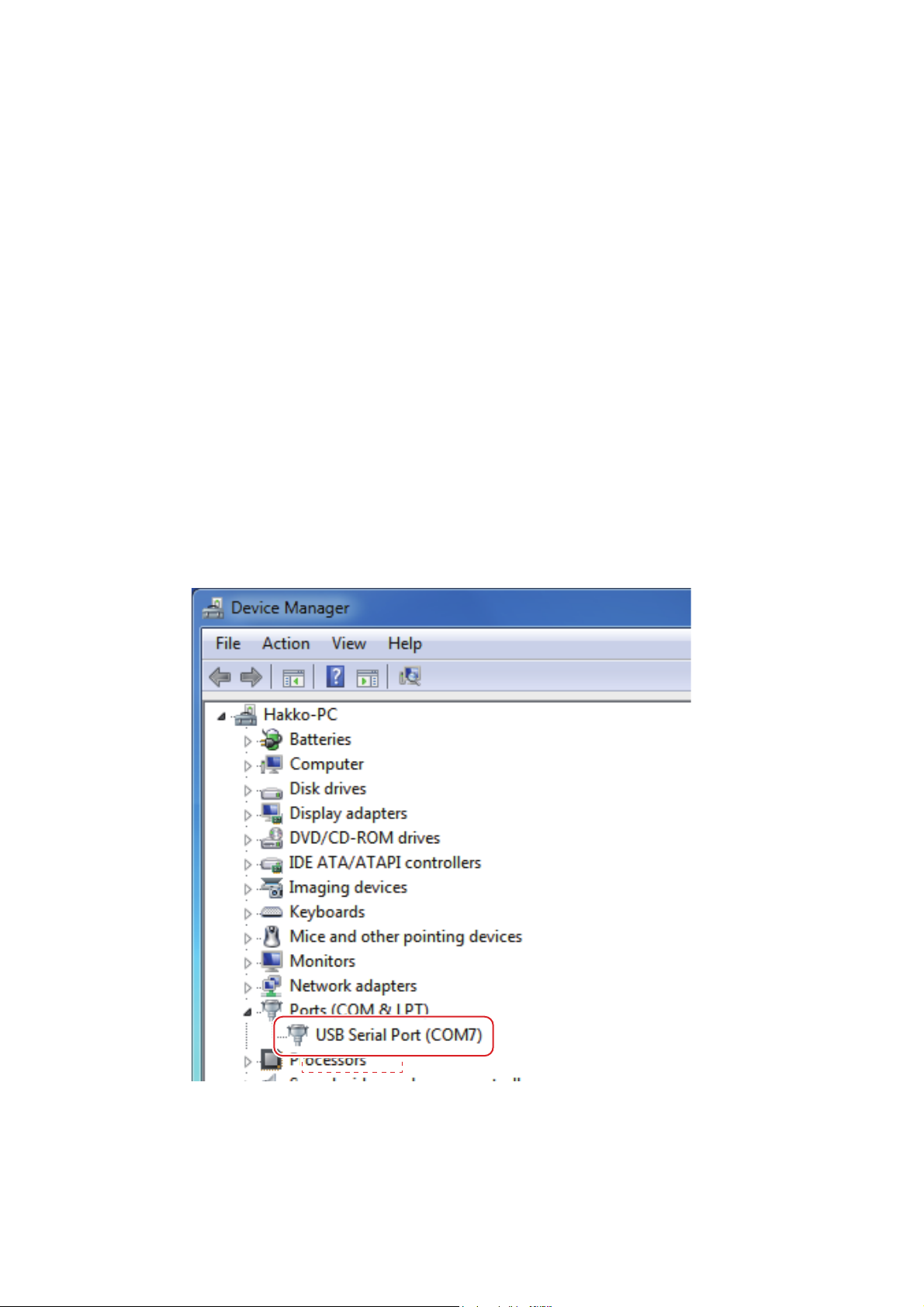

● Take note of the COM number.

* Once the COM number is set, the set number is recorded. You can safely close the software.

* Please note that, in the case where more than one units of the equipment, the number may differ

from unit to unit.

* Do not connect more than one unit at the same time.

* If you change the PC, the number will change. So please be careful.

1. Connect the FG102 and the PC with a cable.

2. Open the COM port tab from device manager of the PC.

3. Make a memo of the number shown on the red-marked Cypress serial (COM**).

(7 for thecase shown above)

9

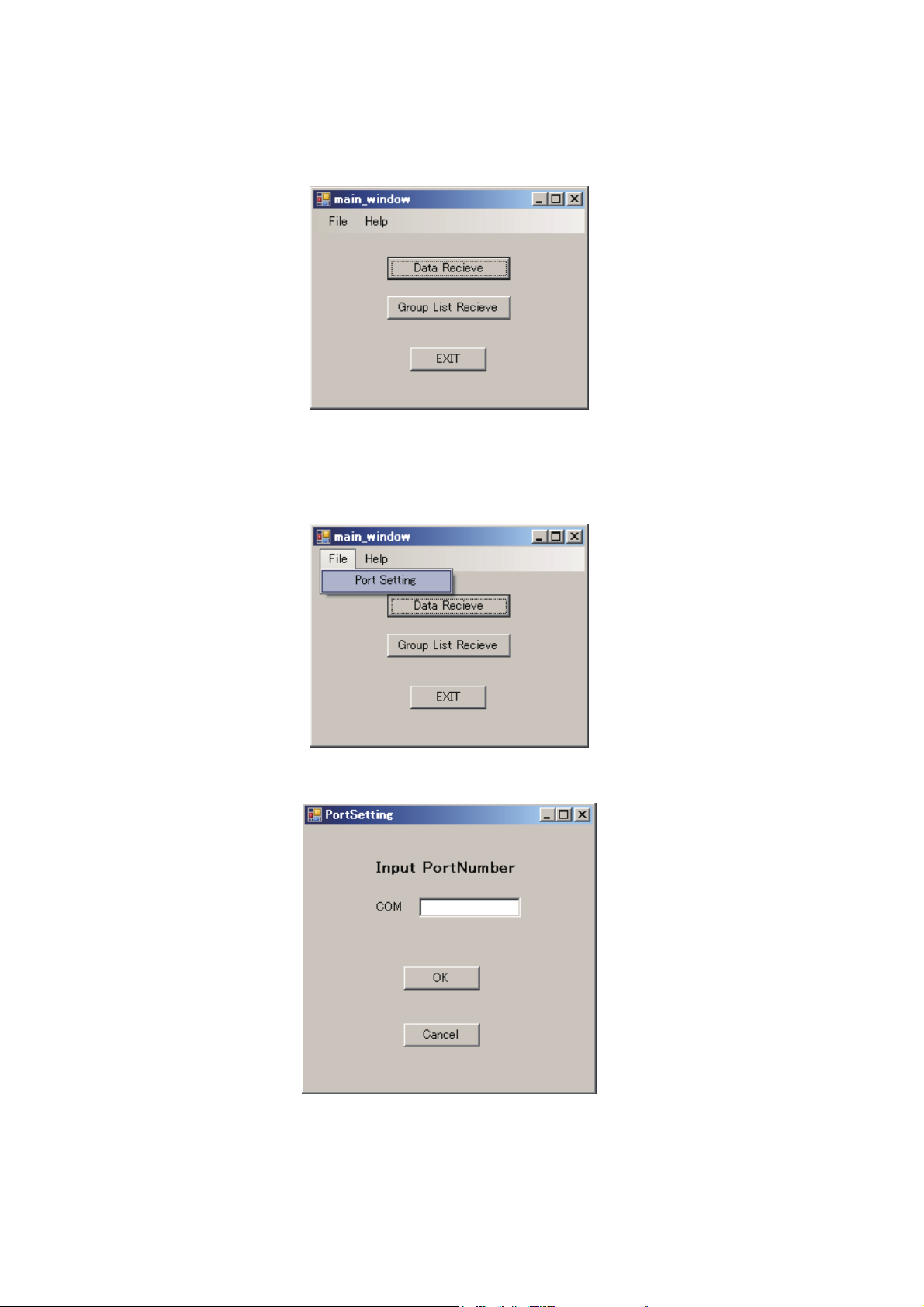

4. Double click the software “FG102_DataSave.exe” and start it.

5. Select File-Port Setting and open it.

Startscreenofthesoftware

SelectPortSetting

ScreenofPortSetting

Table of contents