Haklift Oy

Asessorinkatu 3-7

20780 Kaarina, Finland

Tel. +358 2 511 5511

sales@haklift.com

www.haklift.com

Lifting Solutions Group

Axel Johnson International

5. Warnings

•Before use make sure all the wire rope hoist’s screws are tightened. Also check the product common

condition and that the handles move freely. Check that the wire rope is clean. If the wire is damaged, the

wire rope hoist won’t work properly and must be switched immediately.

•Only use one lever at the same time. Never touch the discharge handle when the wire rope hoist is loaded.

•Don’t pull on the handle too hard since the overload safety pin will break. Don’t use homemade overloading

safety pins on the wire rope hoist!

•Don’t extend the lever length. Abort the lifting process straight away if the load needs more power for lifting

or lowering it.

•Never be on top of the load and make sure no one is working close or under the load that is being lifted.

•Don’t let the load spin during the lift. Avoid to impact, shock or swinging the load.

•Only direct loading. The wire rope hoist must not be exposed to a bending load, where the wire is loaded

in an improper way. Use the wire rope hoist by keeping the wire rope hoist hook and anchor peg in line

with each other. Don’t load on the tip of the hook. Loading with the hook is only allowed in the longitudinal

direction and the load must be directed to the middle of the hook’s radius.

•The working load limit which is marked on the product must not be exceeded.

•Don’t use other wire ropes that aren’t from the distributer and accepted by the manufacturer. When the

radius of the wire has changed dimension more than 10% it must be changed immediately. Don’t ever

push the wire rope from the front of the wire rope hoist since the hook will be on the wrong side.

•Keep the wire rope hoist clean, don’t let any dirt into it, mud or any other harmful substance that could

break the wire rope hoist. Oil the wire rope hoist frequently.

•Never lift or pull people with the wire rope hoist.

•Never leave the load without supervision.

•Don’t ever use a hammer etc. for releasing the release lever.

6. Usage environment

•Admissible operating temperature -10 ⁰C ... +50 ⁰C. Using the wire rope hoist in icy conditions, make sure

that the wire or machinery isn’t frozen.

•The product should not be used in explosive dangerous areas.

•Don’t use with food, cosmetics or pharmaceutical products, and must not be subjected to severe corrosive

influences (e.g. acids).

•Don’t use any surface finishing that could have an impact on the material. Don’t expose the product to

heat, welding or drilling. Keep the product clean, dry and protected from corrosion.

7. Maintenance, inspections and repairs

•Maintenance: The wire rope hoist and wire must be washed, dried after use in wet conditions and

protected from corrosion.

•Inspections: The product must be clean when checked. The product must be checked before every use

in case of visible damage. Once a year a competent person must check the product and make the

approval. This time period must be shortened if the working conditions require it. When checking the

product it has to be checked visually and also tested. Parts and components should be checked for

damage, wearing, corrosion etc. and also analyze the wire rope hoists workability as a safe lifting tool. The

wire rope hoists clamps should be checked by testing them with the nominal load capacity. If you notice

any deviation on the wire rope hoist it should be disassembled and inspected thoroughly.

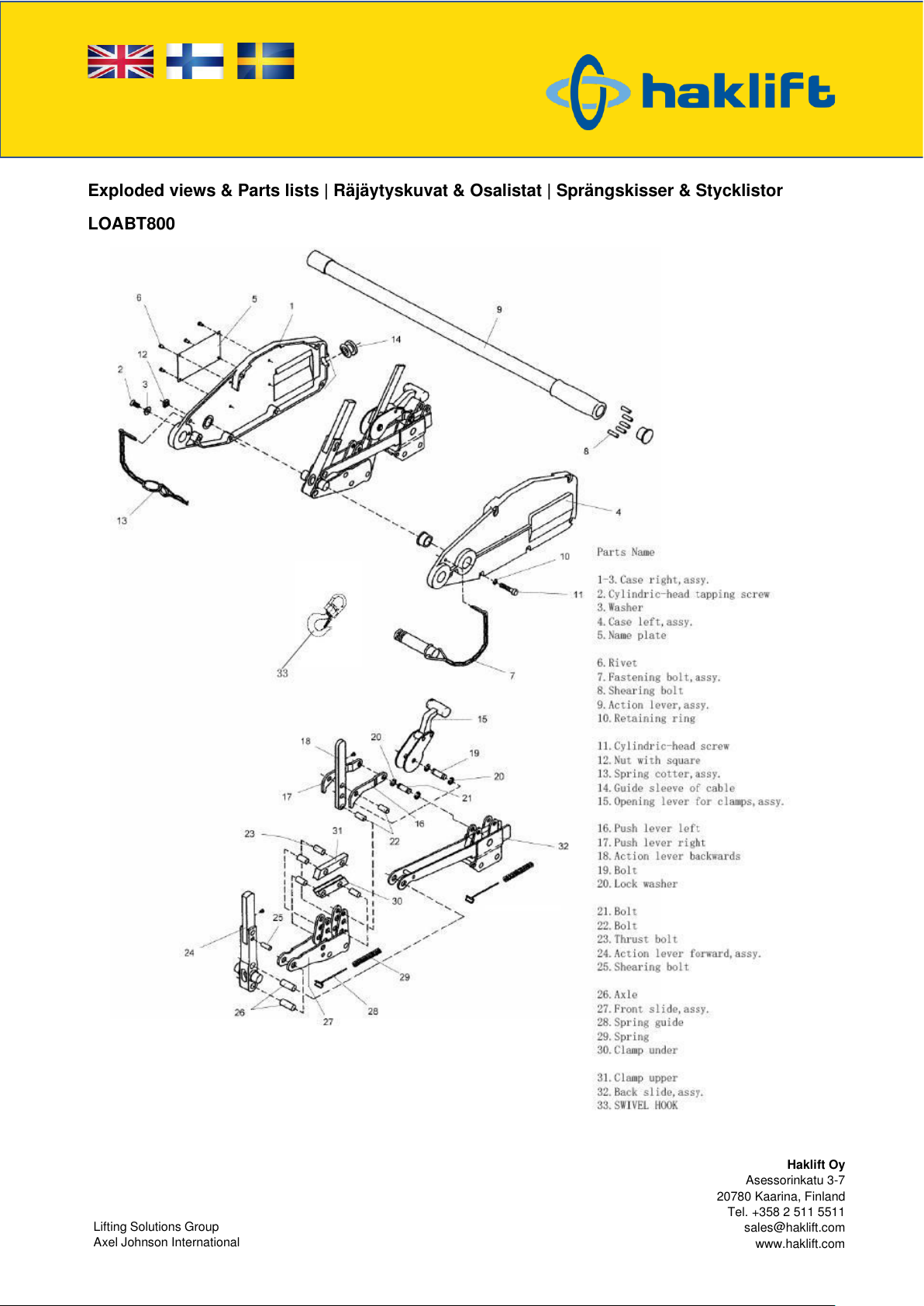

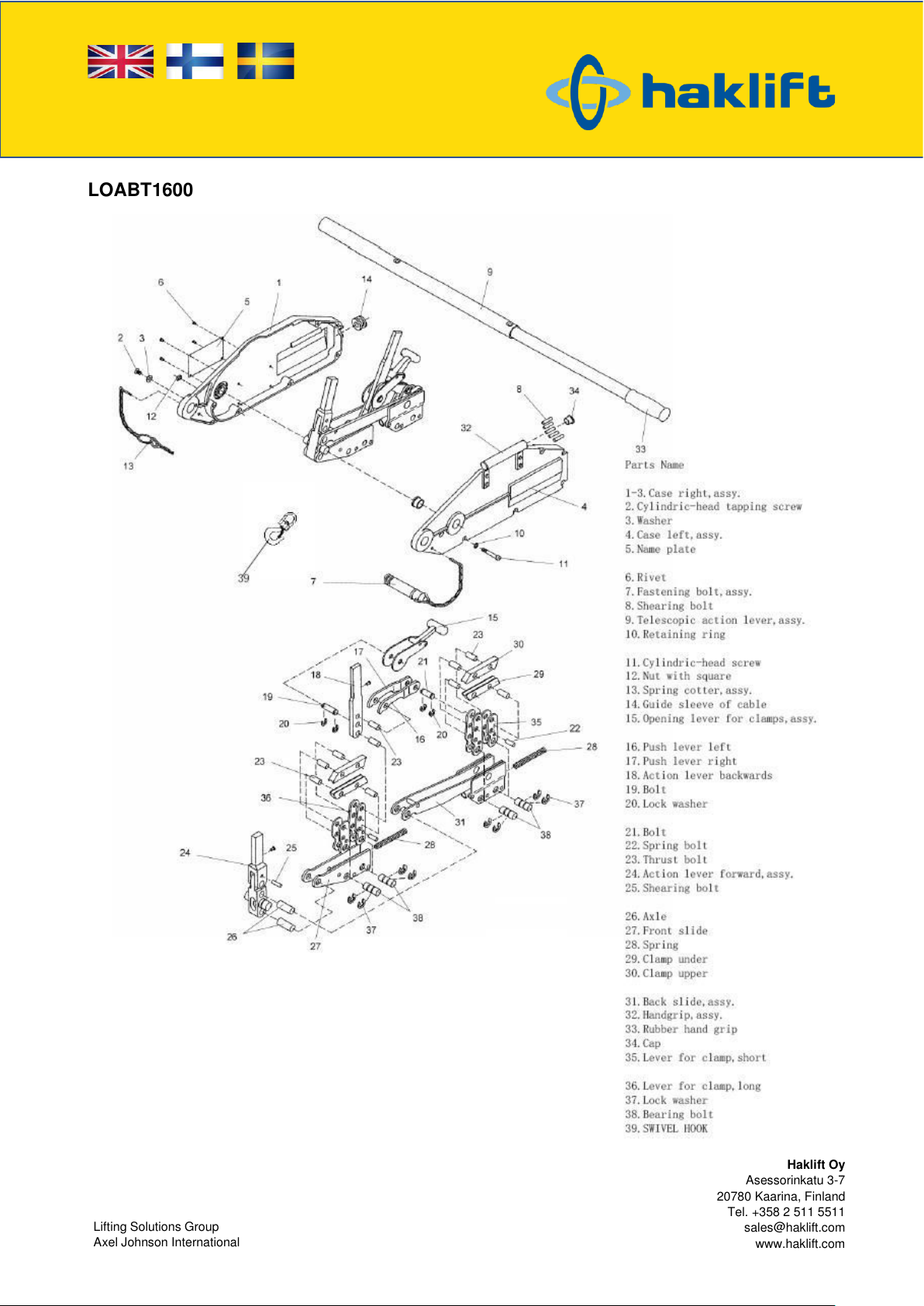

•Repairs: All possible repairs concerning the wire rope hoist and wire rope are to be made by the seller’s

authorized technician.