Safety Instructions

THIS MACHINE PRODUCES A HIGH

PRESSURE WATER JET, WHICH CAN

BE DANGEROUS. FOLLOW ALL THE

MAINTENANCE AND SAFETY

INSTRUCTIONS DETAILED IN THIS

MANUAL. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR DEATH.

THE PRESSURE WASHER HAS BEEN

CHECKED PRIOR TO DESPATCH. IF

YOU HAVE ANY QUESTIONS PLEASE

CONTACT THE CUSTOMER CARELINE.

In addition to the safety information

given in this manual all other

applicable general safety

regulations need to be observed.

Make sure that the connection to

the electric system corresponds to

the latest edition of regulations and

safety standards.

It is strongly recommended that the

electrical power supply for this

machine includeseither a residual

current device to interrupt power

supply if dispersion current to

ground exceeds 30mA for 30mS,

or a grounding circuit.

Do not use the unit if the electric

cable or plug is damaged. Consult

a qualified electrician for repair.

Never direct the water jet at the

unit itself.

Never touch the mains plug with

wet hands; never work bare-foot.

Do not operate the unit in

potentially explosive locations.

Before any cleaning or

maintenance, the electro-pump

must be disconnected from the

power supply.

Do not use in the rain.

This unit is for domestic use only.

The water jet can be dangerous if

used incorrectly; never direct the

water jet towards yourself or others,

do not clean clothing or foot wear,

never direct the water jet towards

animals or electrical appliances.

Never put hand or fingers over the

spray tip while operating the unit.

Never try to stop or deflect leaks with

any body part.

Do not let children or persons not

familiar with these safety instructions

use the unit.

Before start-up make sure that the

lance is not open as this could

release a sudden jet of high pressure

water which could turn the lance into

a dangerous whip.

We recommend the use of safety

goggles and suitable ear protection.

Vehicle tyres/tyre valves may only be

cleaned from a minimum distance of

30cm otherwise they could be

damaged. The first indication of this is

a discolouration of the tyre. Damaged

vehicle tyres/tyre valves can be

dangerous.

Never draw in solvent-containing

liquids, undiluted acids or solvents!

This includes petrol, paint thinners

and heating oil. The sprayed vapour

is highly flammable, explosive and

toxic, also acetone, undiluted acids

and solvents as these corrode

materials used on the unit.

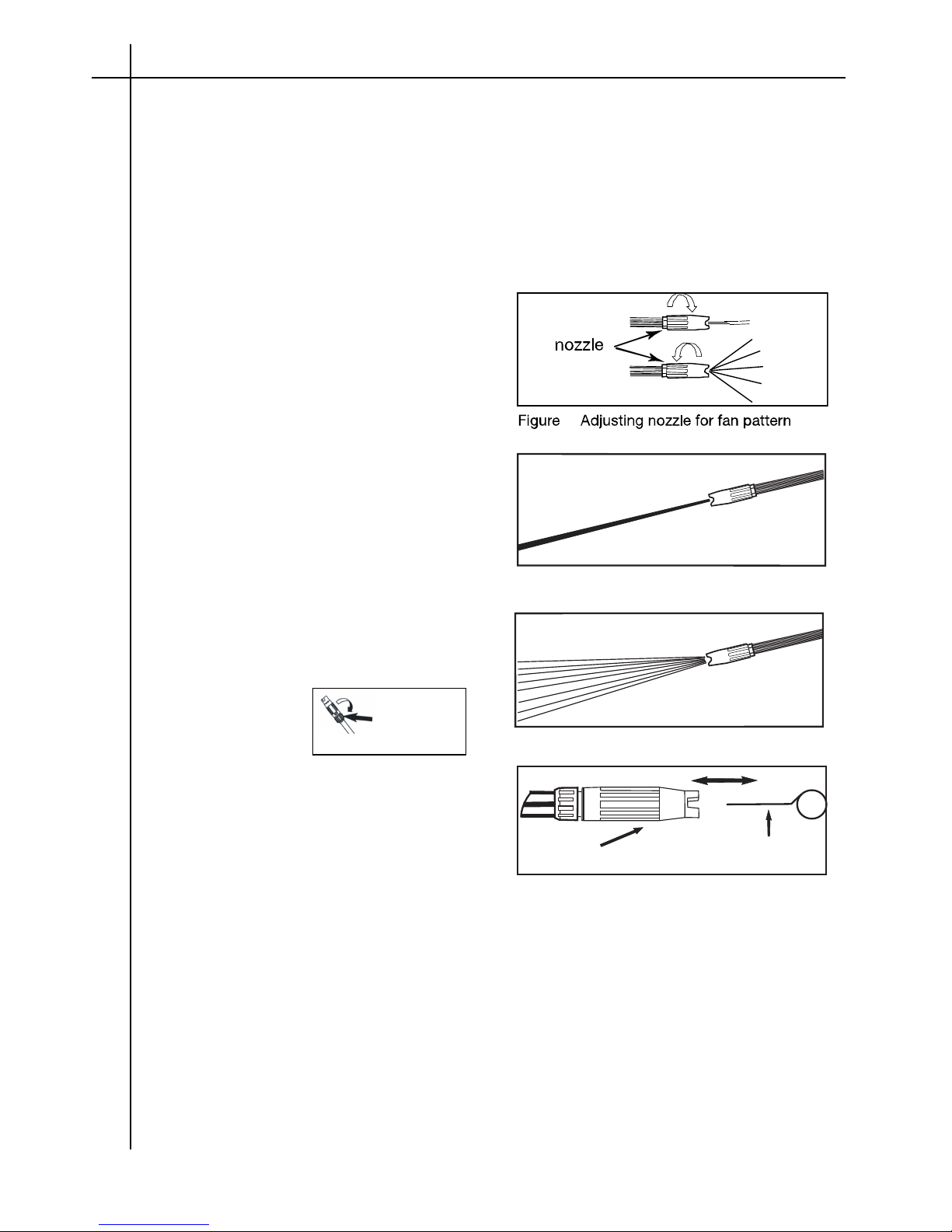

Use only the nozzle supplied with this

machine.

Do not drive vehicles over the high

pressure hose or the electrical cables.

Do not kink or allow contact with

sharp objects. The hose is easily

damaged.

Customer Careline: 0845 601 7834 3