Mar 20

CHAPTER 1 - BATTERIES AND BATTERY SWITCHES

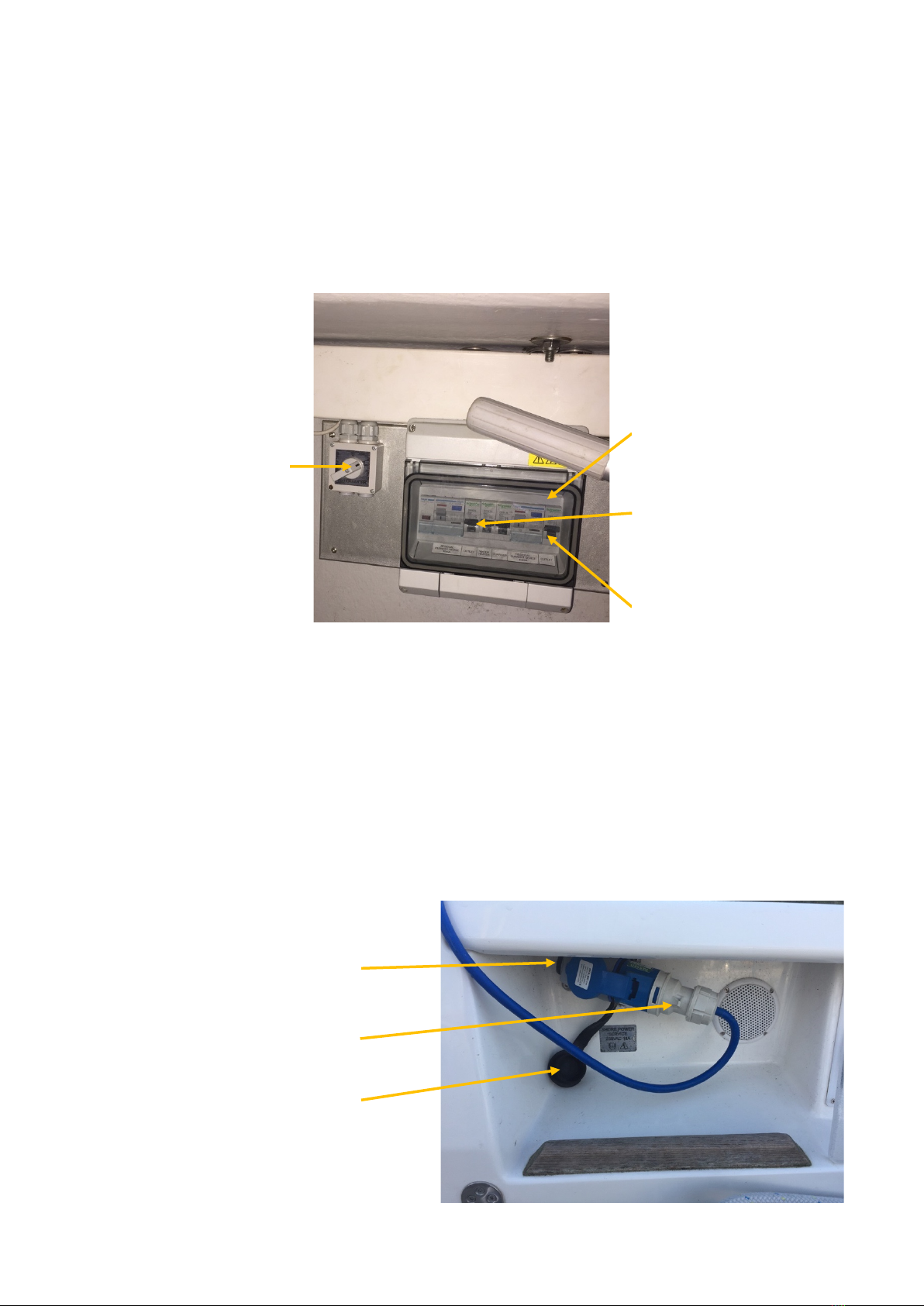

1. The HR yachts are equipped with separate domestic and start batteries located under

the lateral saloon seat amidships, forward of the saloon table. Both can be isolated by the

Battery Isolation Switches accessed from wooden door, under the inboard end of the lateral

saloon seat at the base of the mast post.

Battery switch compartment Battery master switches

2. Charging. Don't underestimate the time required to charge the batteries. Full

charge may take up to 15 hrs using the engine, dependant on electrical load, or overnight if

the yacht is plugged into shore power (charging is automatic. DO NOT adjust the charger

settings – irreparable damage can occur). The alternator on the main engine will give full

charge at 1300 rpm. The only volt metre is on the Furuno cockpit display; you will need to

find the correct page. As a minimum, this should be checked daily before sailing, once

shore power has been disconnected, ideally it should be checked and hourly when

completing the ship’s log. The voltage should not be allowed to exceed 14.2V and should

not be allowed to fall below 11.5V. If this occurs; charge the batteries as soon as possible.