Page 2 of 2 75.5293.03 20090317

Do not leave problems unresolved. If a satisfactory solution cannot be achieved after troubleshooting a problem, please

contact BEA Inc. If you must wait for the following workday to contact BEA, leave the door inoperable until satisfactory

repairs can be made. Never sacrice the safe operation of the automatic door or gate for an incomplete solution.

The following numbers can be called 24/7. For more information, visit www.beasensors.com.

7 Company Contact

US and Canada:

Canada:

Northeast:

1-866-249-7937

1-866-836-1863

1-866-836-1863

Southeast:

Midwest:

West:

1-800-407-4545

1-888-308-8843

1-888-419-2564

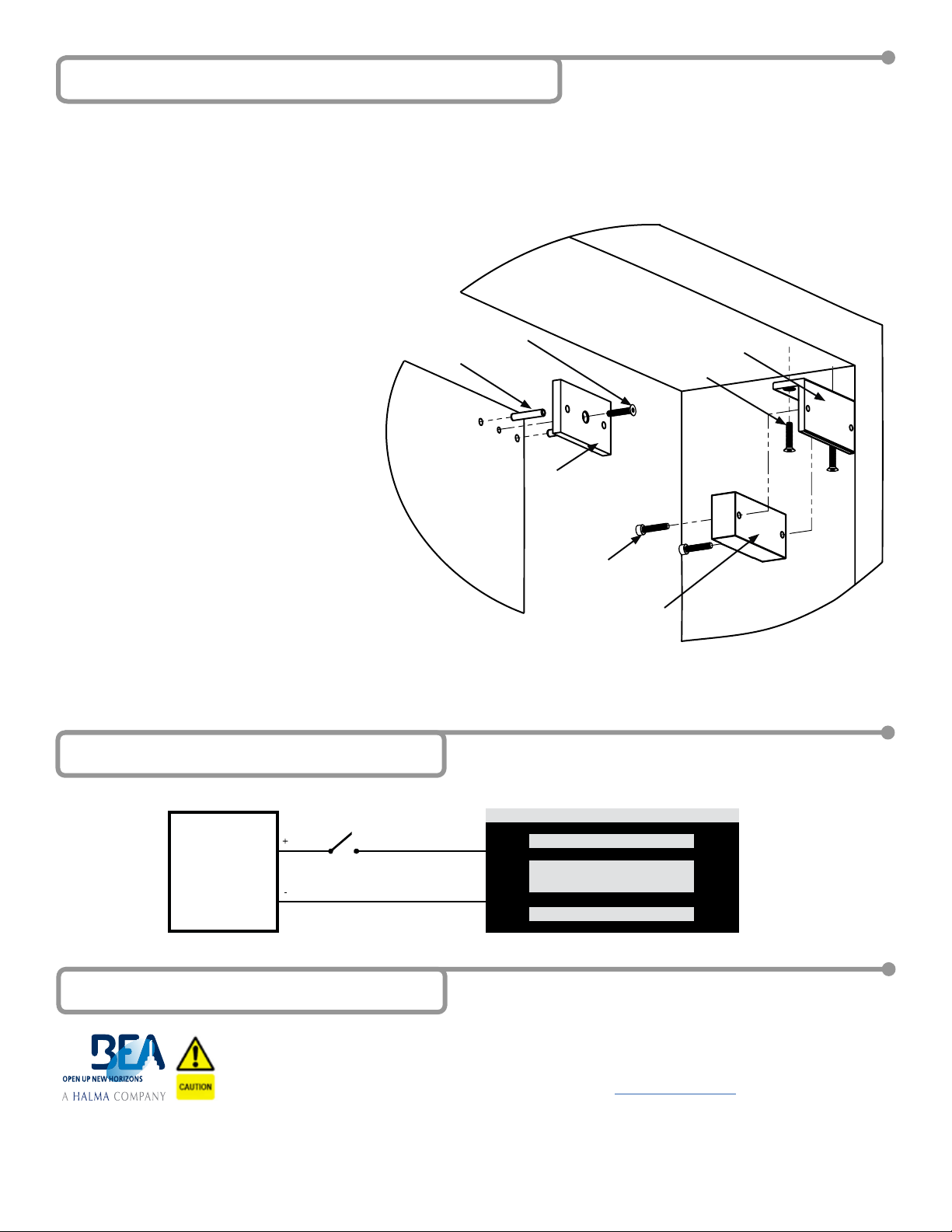

1. Inspect the frame header to determine if an angle bracket or ller plate is required.

2. Fold the enclosed mounting template on the dotted line and then mark and drill

holes as indicated. Drill two 1/8” (3.1 mm) holes at the locations marked ‘B’. For

single doors, locate the template against the door and header on the lock jamb

side of the frame.

3. Disassemble the mounting plate from the maglock assembly using the enclosed

hex key. Insert 2 screws into the slotted holes and secure the mounting

plate to the doorframe using two of the #8 mounting screws. Do not

tighten these screws fully until the maglock is properly aligned.

4. Gently tap (2) 3/16” (5mm) spring pins into the rear side of

the armature(s). Drill matching holes on the door to

receive these pins.

5. Align armature/strike plate to magnet, and then

drill a 5/8” (16mm) hole in door for sexnut and

aluminum reinforcement tube for hollow doors.

Using the M8 x 1.25 x 40mm hex head screw

and enclosed hex key, mount armature to door

using two metal and one rubber washers.

6. Continue to fasten mounting plate to heading

using remaining screws. Then, reassemble

maglock assembly to mounting plate.

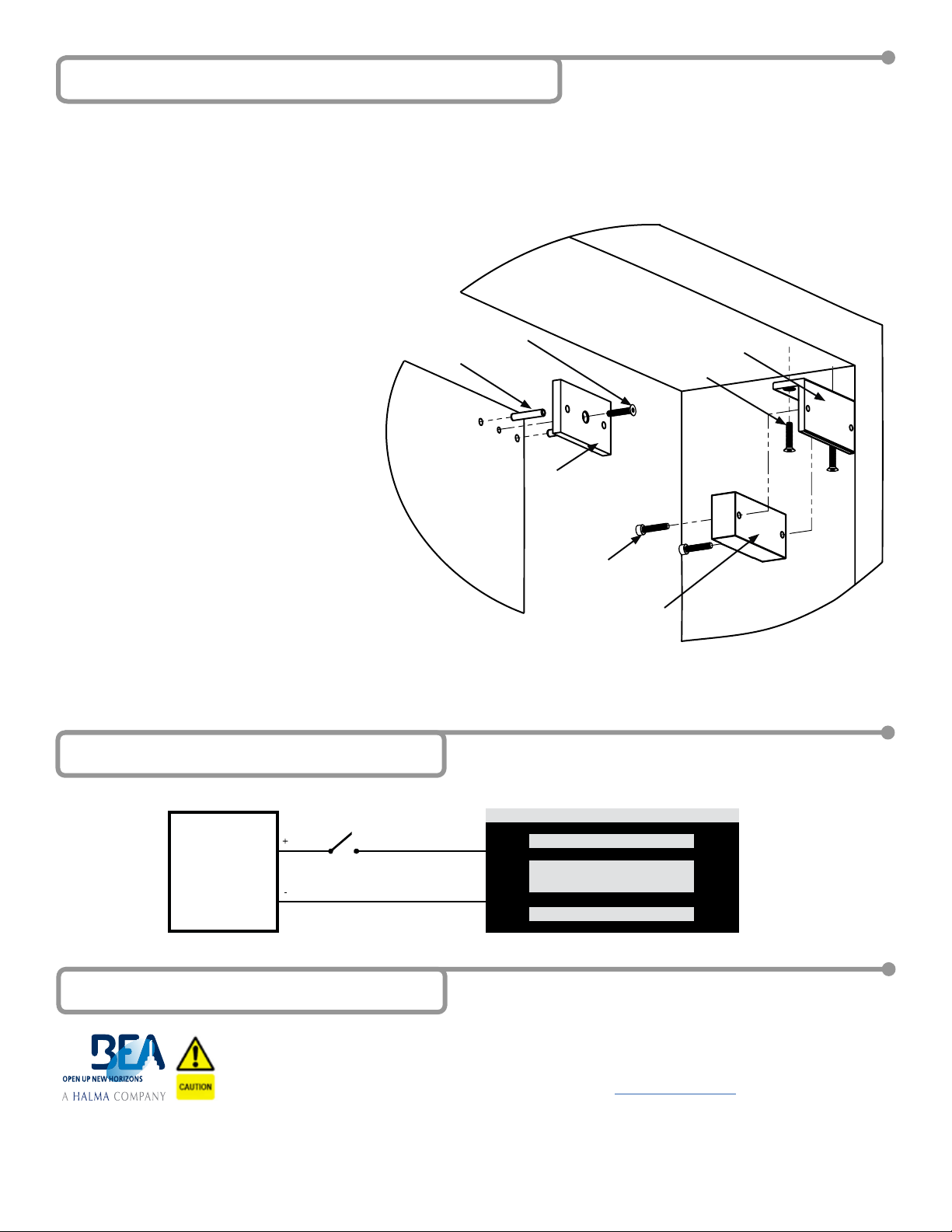

7. Route the enclosed wiring harness through

the rectangular hole in the mounting plate.

Make the electrical connection as shown

below.

8. Make sure that armature/strike plate can be

shaken slightly. This will permit full armature

contact and maximize holding force.

5 Installation - Mechanical

6 Installation - Electrical

ARMATURE /

STRIKE PLATE

MOUNTING PLATE

MOUNTING

SCREWS

MAGLOCK

ASSEMBLY

MOUNTING PLATE

ASSEMBLY SCREWS

TUBES

ARMATURE / STRIKE

PLATE SCREW

RED

BLACK

DC

POWER

SUPPLY

- ONLY -

SWITCH