Description

For secure head retention in all applications the top M8 head xings must be used.

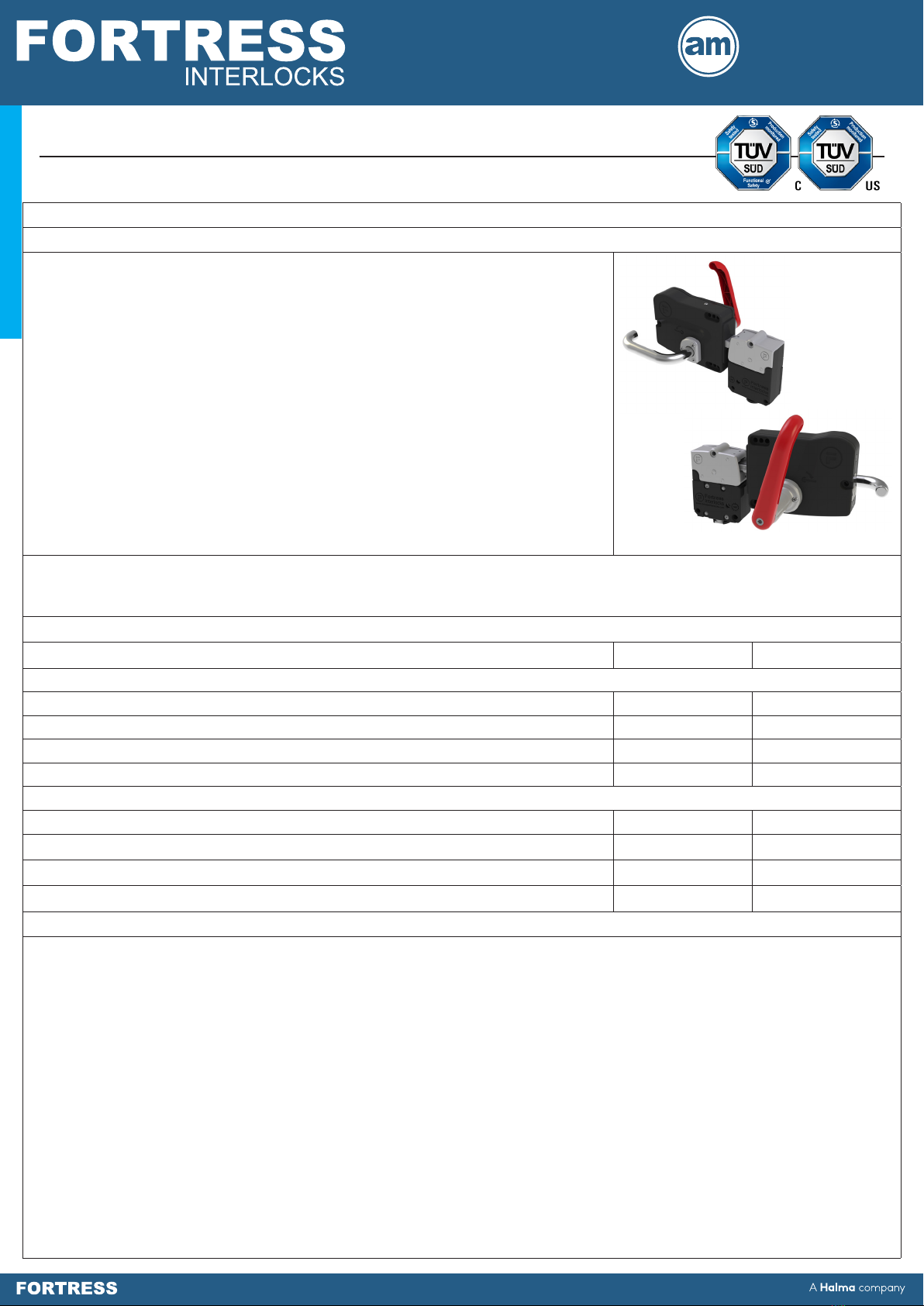

Fortress provides a single action escape release function from inside a guarded

area through the use of a head and handle application. This unit may be installed

in left or right orientation to hinged doors. The tongue incorporates a self-aligning

feature to cater for misalignment on guards. Simply turning the red handle will open

a locked guard from the inside and open the safety contacts. Releasing versions of

other modules are the type that MUST be used in conjunction with this module.

• Intuitive single action escape release handle.

• Escape release activation releases tongue and opens safety contacts.

• Handle includes Lock-Out for 4 padlocks of 8mm diameter.

• 10kN retention force.

• Stainless steel tongue is ideal for fast and frequent access.

• 2 mounting position at 180° increments allowing on site handing change

possible.

• Misalignment tolerance of +/- 10mm with +/- 4° angular misalignment.

• Security tool reset after escape release actuation or auto reset function available.

• Head can be tted with lock-out device for additional lockout capability.

NOTICE!

If, as a result of risk assessment, it cannot be discounted that persons can be enclosed within a danger zone, the guard locks

with additional removable keys (safety keys) must be used or comparable measures must be taken - GS ET 19.

Options & Ordering Information

Description Part No. Handling

proHead

Security Tool Reset Escape Release Head I6 Left / Right

Security Tool Reset Escape Release Head c/w Drop Down Lock-Out I7 Left / Right

Automatic Reset Escape Release Head A6 Left / Right

Automatic Reset Escape Release Head c/w Drop Down Lock-Out A7 Left / Right

proHandle

Escape Release Handle EI2 Left

Escape Release Handle EI4 Right

Escape Release Handle - Allowing Closing of Door From Inside EJ2 Left

Escape Release Handle - Allowing Closing of Door From Inside EJ4 Right

Important:

This product is designed for use according to the installation and operating instructions enclosed. It must be installed by

a competent and qualied personnel who have read and understood the whole of this document prior to commencing

installation. If the equipment is used in a manner not specied by the manufacturer the protection provided by the equipment

may be impaired. Any modication to or deviation from these instructions invalidates all warranties.

Fortress Interlocks Ltd accepts no liability whatsoever for any situation arising from misuse or mis-application of this product.

Note: The availability of spare Actuators and Keys makes it possible to easily bypass the safety devices and, for this reason,

the security of any spare Actuators and Keys must be eectively monitored.

DO NOT LEAVE OVERRIDE/RESET KEY IN PLACE!

Always keep in a secure place, under management control, as it allows access to areas that may have a residual

hazard, and may result in incorrect operation of some devices.

Safety switches (such as a STOP or LOK) must be tted in conjunction with this unit to monitor when the Internal

Escape Release has been activated. When lock adaptors are also used it is not possible to change outside from a

STOP to a LOK (and vice versa) without other changes to the locks - seek advice from Fortress.

BEWARE OF INTENTIONAL MISUSE CAUSED BY OPERATORS WANTING TO BYPASS SAFETY SYSTEMS. THE

INSTALLER SHOULD ASSESS THE RISKS AND MITIGATE AGAINST THEM.

IF YOU HAVE ANY QUESTIONS OR QUERIES OF ANY NATURE WHATSOEVER PLEASE CONTACT THE SUPPLIER

WHO WILL BE PLEASED TO ADVISE AND ASSIST.

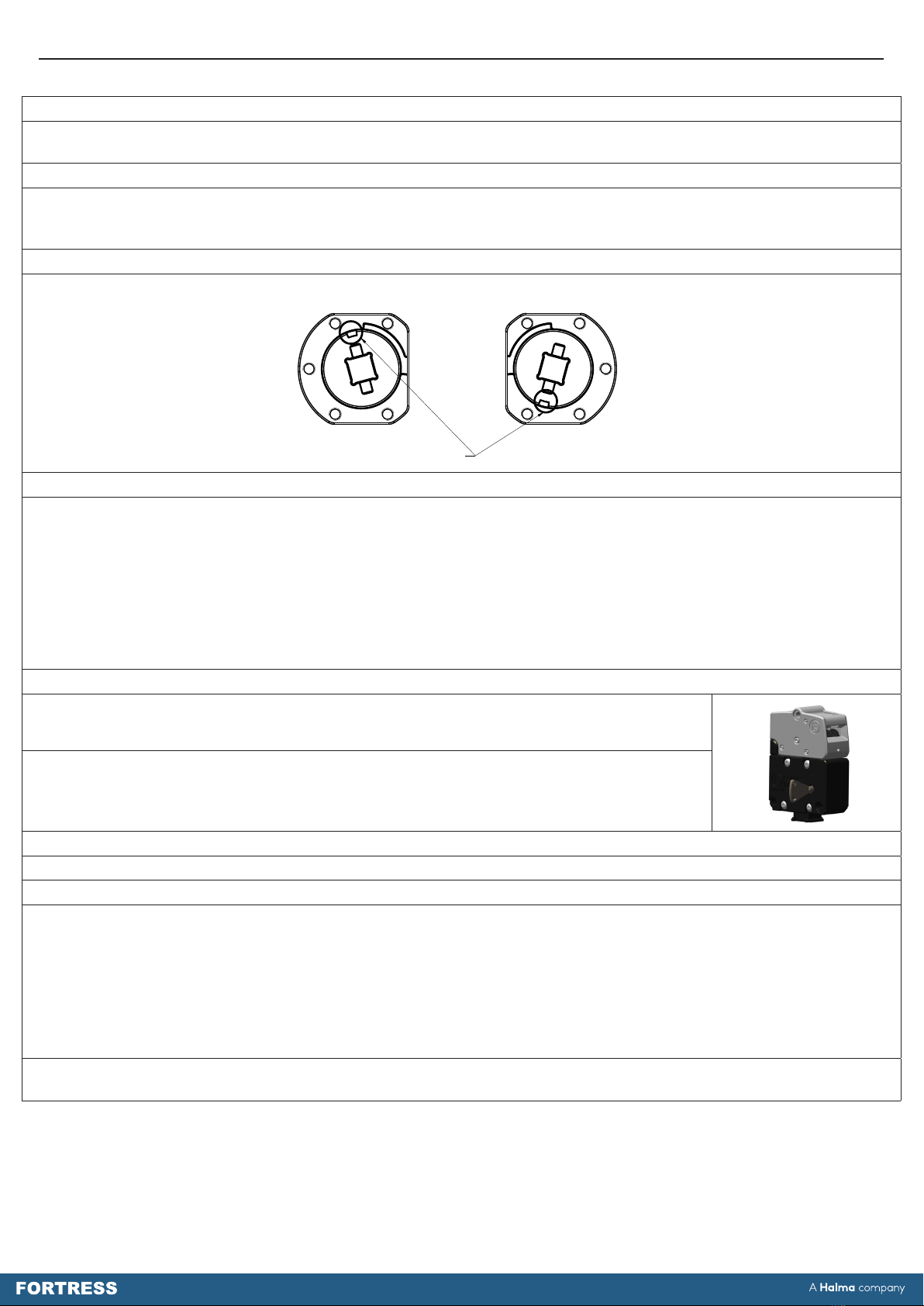

Operating Instructions: Single Action Escape Release

Head & Handle

1

Actuators