6

2Introduction

2.0 Introduction

The Wagtech PotatestTM is a portable water quality test kit. It has been designed primarily to

test the microbiological quality of drinking water; assessing whether or not there has

been faecal contamination of a water source. It allows the end user to test directly for Total

or aecal Coliforms as well as the critical indicators of microbiological quality: Turbidity,

pH and ree and Total Chlorine.

The Wagtech PotatestTM conforms to advice given by the World Health Organisation

(WHO) for the field based testing of microbiological water quality. The parameters measured

for, and techniques/procedures used are based on accepted laboratory methods and are

adapted for use in demanding field conditions.

More information on the “WHO uidelines for Drinking Water Quality” can be

found at www.palintest.com

As with all the kits in the Wagtech range, ease of use is integral to the design. The Wagtech

PotatestTMis suitable for use by technicians of all skill levels and this manual provides the

essential information required to conduct rapid water quality testing in the field.

This instruction manual is also available in rench, Spanish and Mandarin.

Additional advice and training is available upon request. Contact us directly at

2.1 Before You Use Your Kit

2.1.1 Microbiological

Analysis of Drinking Water

Drinking water contaminated by faecal

matter may contain pathogenic (disease

causing) organisms and represent a risk

to public health.

It is impractical to attempt to isolate specific

pathogens because they are present in

relatively small numbers compared with

other types of microorganisms. Moreover,

there are many types of pathogen and each

requires a unique microbiological isolation

technique. The accepted approach is to

analyse for indicator organisms that inhabit

the gut in large numbers and are excreted in

human/animal faeces. The presence of these

indicator organisms in water is evidence of

faecal contamination and therefore a risk

that pathogens are present. If indicator

organisms are present in large numbers,

the contamination is considered to be

recent and/or severe.

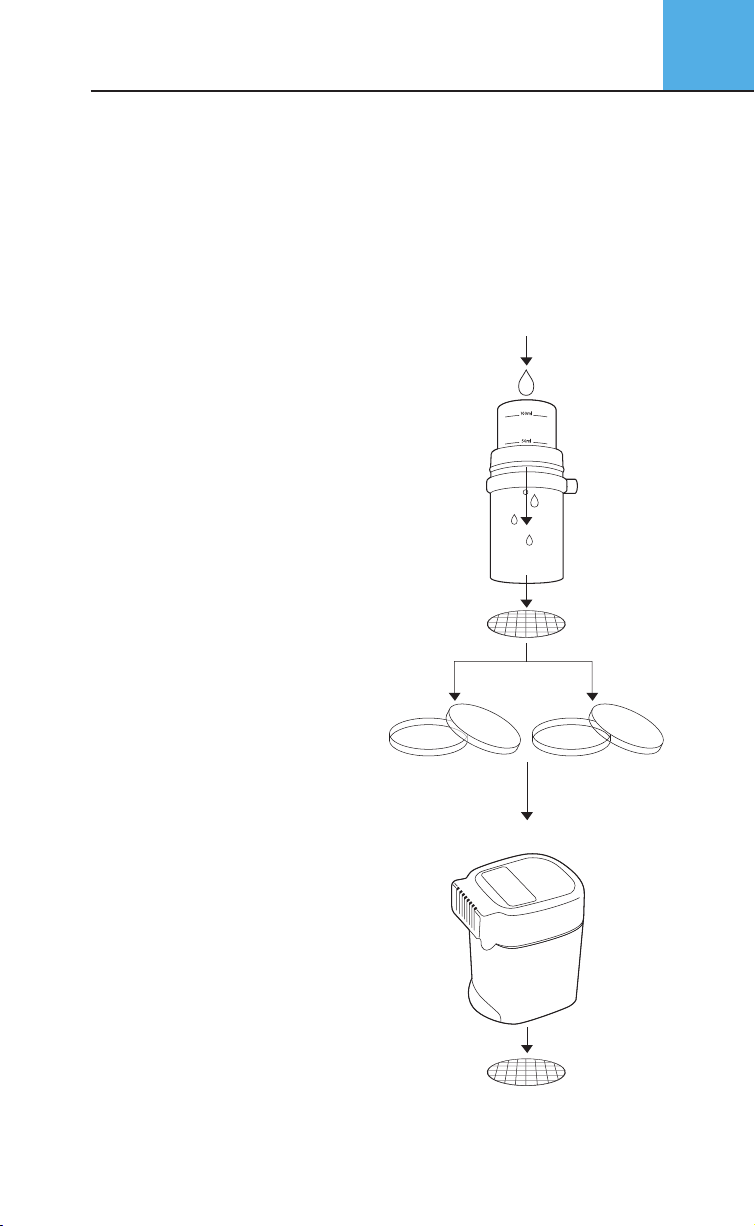

The group of indicator bacteria tested for with

the PotatestTM are called Coliforms; more

specifically the focus is on the enumeration of

Thermotolerant Coliforms (sometimes called

aecal Coliforms). These are bacteria that

originate from faecal sources. However the

PotatestTM is also capable of testing for

Total Coliforms by simply selecting a different

incubation temperature.

Thermotolerant Coliforms or aecal Coliforms

are used in water microbiological testing

to denote coliform organisms which grow

at 44 or 44.5°C and ferment lactose to

produce acid and gas.

In practice, some organisms with these

characteristics may not be of faecal origin

and the term Thermotolerant Coliforms is

therefore more correct and is becoming

more commonly used. Nevertheless the

presence of Thermotolerant Coliforms nearly

always indicates faecal contamination.

Usually, more than 95% of Thermotolerant

Coliforms isolated from water are the gut

organism Escherichia coli (E. coli), the

presence of which is definitive proof

of faecal contamination.

As a result, it is often unnecessary to

undertake further testing to confirm the

specific presence of E. coli.