18 19

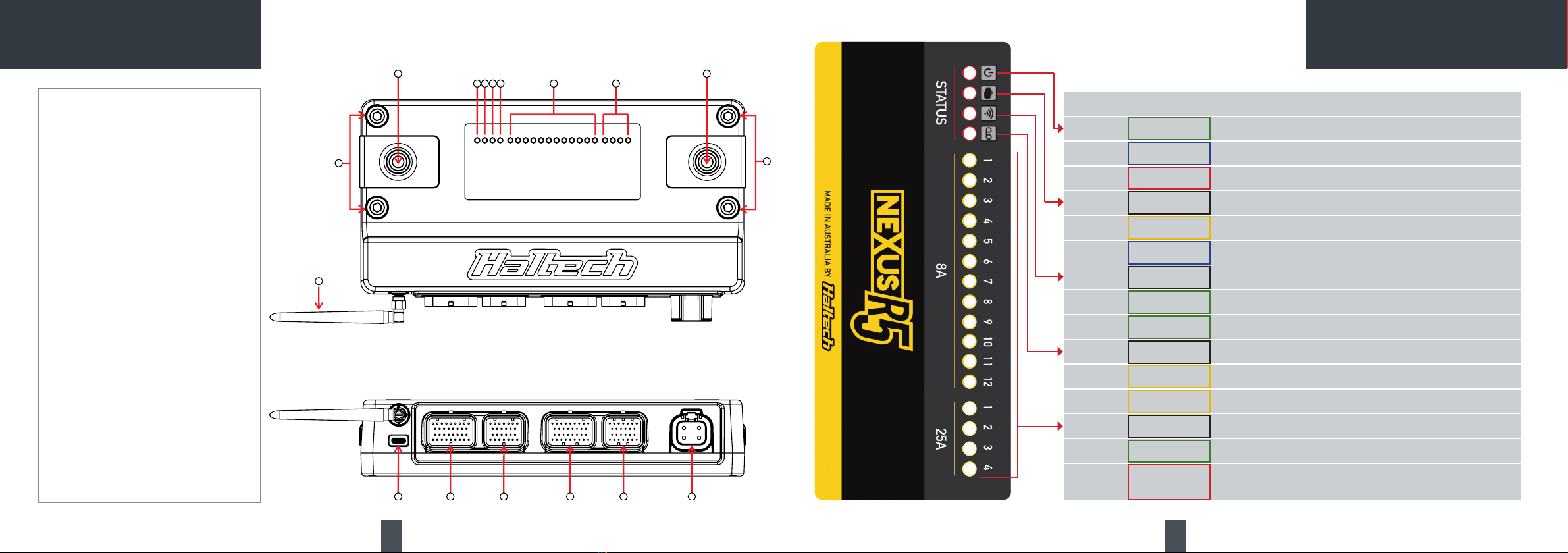

8A High Current Outputs (8A HCO)

The NEXUS R5 features 12 high side outputs which

are capable of driving 8A to 12V.

Each output has a software programmable fuse

current.

Once the electronic fuse blows the output turns

off for a software programmable delay duration,

before reactivating the output.

Use the software to define the maximum number

of retries before the output is deactivated untilthe

next ECU reboot. The ECU LEDs display the output

state.

8A HCOs are PWM capable and can be used to

power CAN devices or solenoids.

They can also control automatic transmission

shift solenoids, water pumps, some nitrous and

transbrake solenoids etc.

Specs:

• Automatic overcurrent protection

• Flyback protected

• 0 to 30V voltage feedback

• High side current feedback

• 100Hz max switching speed

• Capable of 0-100% duty cycle

25A High Current Outputs

The NEXUS R5 features four high/low outputs

capable of sinking 25A to ground and driving

25A to 12V. Each output has a programmable

fuse current, slow-start current and duration.

Once the electronic fuse blows the output turns

off for a pre-programmed delay duration before

reactivating the output. Use the NSP software to

define the maximum number of retries before the

output is deactivated until the next ECU reboot.

The ECU LEDs display the output state.

25A HCOs are PWM capable and can be used

for ignition power and injector power as well

as to PWM thermofans and fuel pumps, control

transbrake solenoids, nitrous solenoids etc.

Specs:

• Automatic overcurrent protection

• Flyback protected

• -30 to 30V voltage feedback

• High side current feedback

• 1kHz max switching speed

• Capable of 0-100% duty cycle

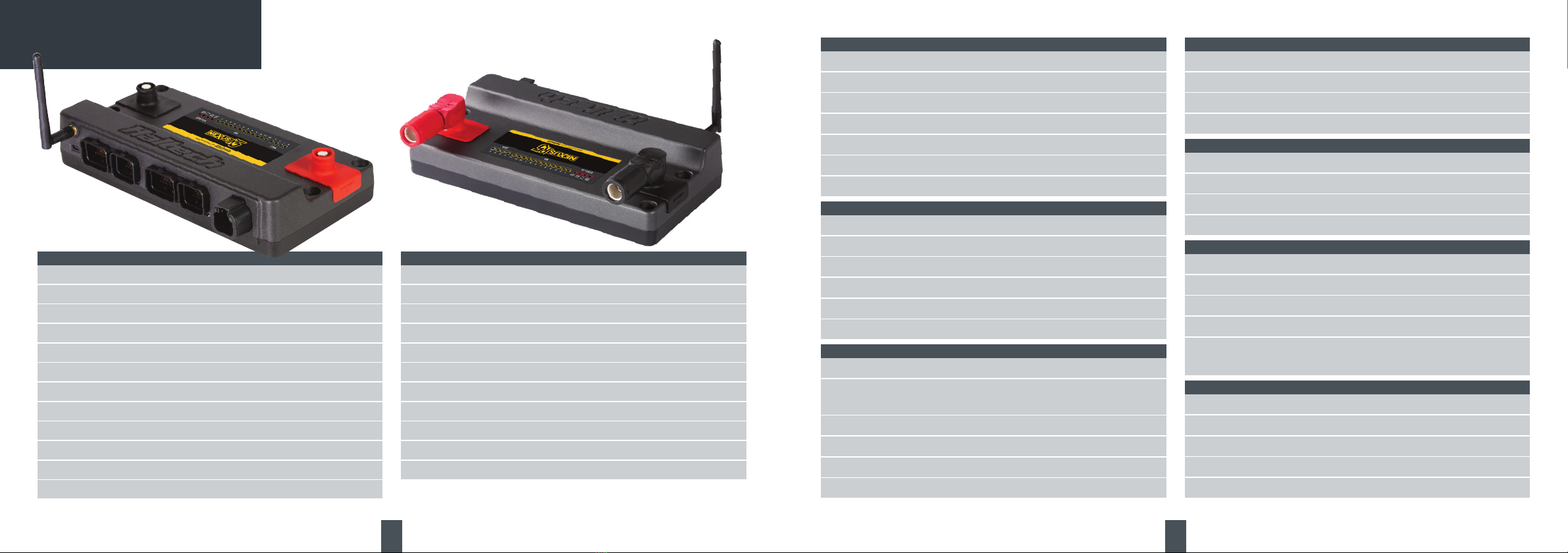

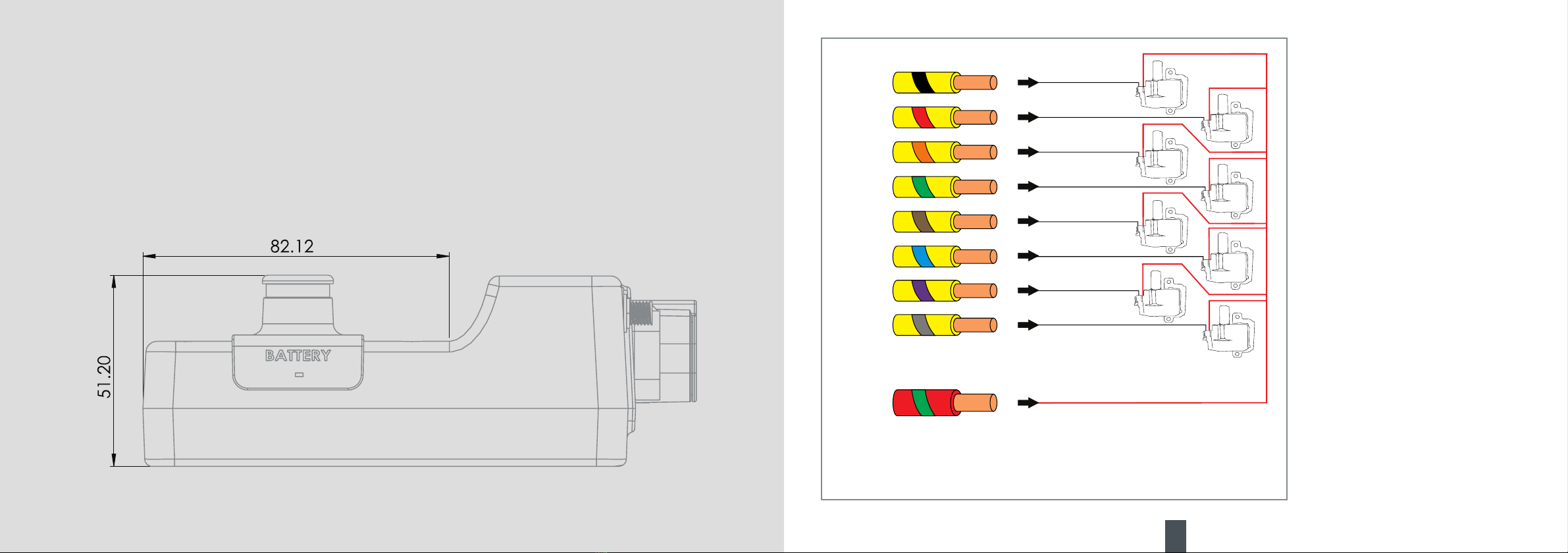

NEXUS R5 WIRING

8A HCO

TO GROUND

25A HCO

TO GROUND

THERMOFA N

Example Wiring Connections

Example Wiring Connections

Crank (Trigger) and Cam (Home) Inputs

The crank and cam position sensors are required

so that the ECU has the necessary information

available to determine engine speed and position

at any point in time.

Generally two sensors are required - a cam

position and crank position, however many

engines will have just a cam position sensor that

is capable of giving the ECU enough information to

run the engine correctly.

Vehicles that have a crank position sensor only

are not capable of determining the difference

between compression stroke and exhaust stroke

and therefore are not suitable for sequential fire

applications.

In this case a cam position sensor may need to be

added.

It is recommended that four-core or twin-core

shielded cable is used for crank and cam position

sensors. Shields must be terminated to battery

ground at one end only.

Specs:

• -5V to 5V input

• 1 million samples per second

• Selectable 1k2 or 440R pull-up to 5V

• Selectable ground reference (full differential

standard mode)

• -75 to 75V indefinite withstand

• 48kHz max signal frequency

There are two common types of crank/cam sensor

signals:

• Hall effect/optical signal

(0-5V digital square wave signal)

Hall effect sensors usually have 3 wires; a power

supply (5V, 8V or 12V), a ground and a signal

out wire. The power supply can be taken from

the Sensor +5V pin, sensor +8V pin or a HCO as

required.

• Reluctor signal (analog style signal)

This type of sensor will generally only have two

wires, signal positive (+) and signal negative ( - )

Sensors with a +5V supply do not require the pull-

up resistor be enabled, for example, rotary trim

modules.

Any sensor +5V pin can be used with any signal

ground pin for sensors.

Xindicates not connected

Please isolate and insulate

to avoid damage to ECU

Xindicates not connected

Please isolate and insulate

to avoid damage to ECU

Hall Eect Sensor

X

o

-

+

+12V

Signal Ground

Crank (Trigger) (+)

Crank (Trigger) (-)

Reluctor Sensor

X

-

+

X

+12V

Signal Ground

Crank (Trigger) (+)

Crank (Trigger) (-)

Example Wiring Connections