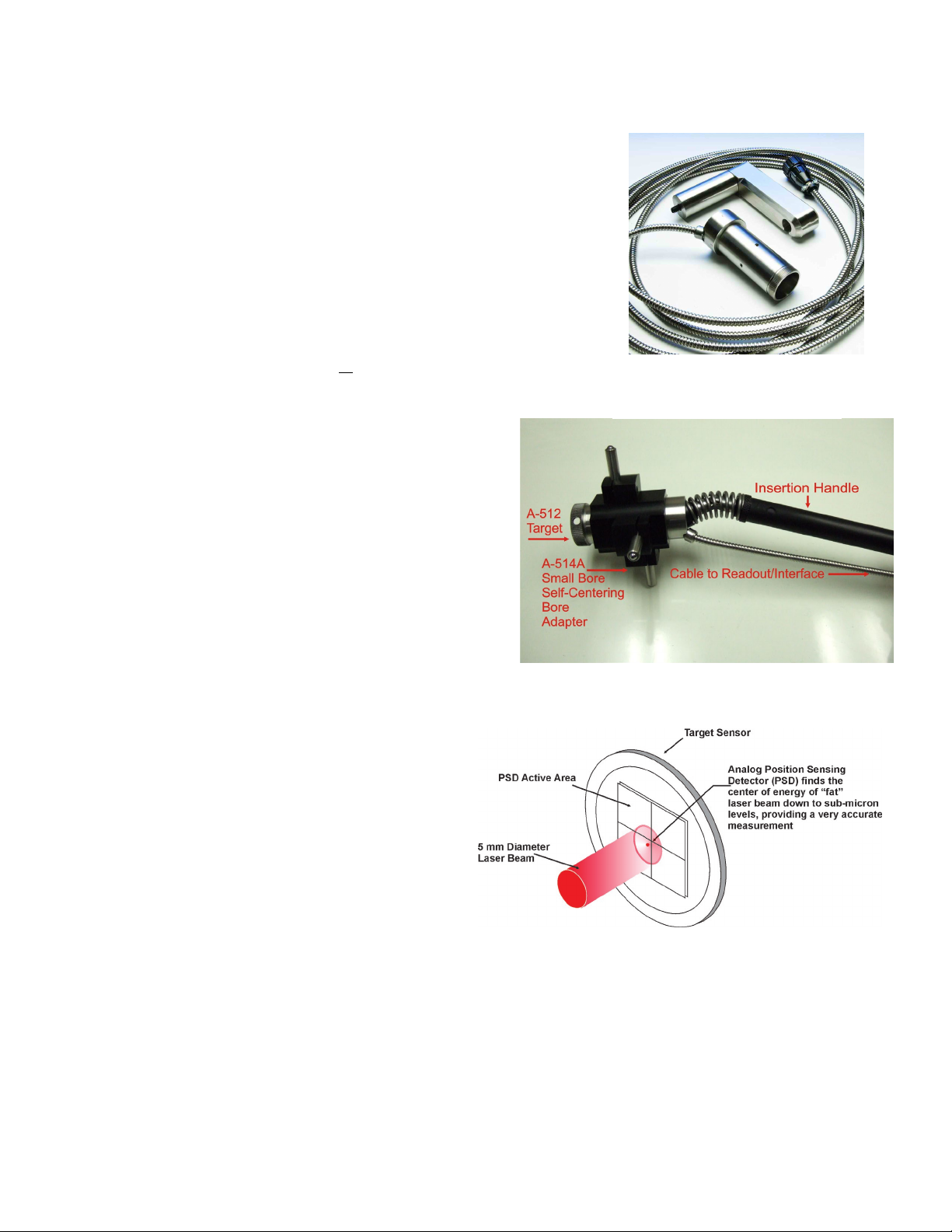

Model A-512 2-Axis Self-Centering Target

The A-512 Target unit is comprised of a target cell, a bore adapter, and

an insertion handle (see Figure 5). The target is inserted into the bore to

sense the position of the laser beam. Laser beam position data is

displayed on a readout. As the bore is adjusted, the readouts display data

in real time.

The target cell is a position-sensitive photo cell surrounded by a

stainless steel housing. When light contacts the photo cell, the

continuous flow of current across the cell is altered. The location of the

contact is recorded as a change in voltage, which the digital readout or

computer interface displays as an offset from the target center. The

effective cell sensitivity range is ± .100 in. (2.5 mm), and changes in

the x and y axis positions of the target can be displayed on a digital

readout to within .0005 in. (0.0127 mm) over 50 ft. (15 m).

The target cell has a milled keyway designed to slipfit

onto a location pin in the bore adapter for self- centering

mode. Four matched and offset (90°) stainless steel legs

serve to center the adapter in the bore. Adapters are

available in many different sizes for use in specialized

bores.

The A-512 2-Axis Bore Target has a 10x10 mm PSD and

is designed specifically for our A-514 line of self-

centering bore adapters. This unique feature allows our

target to be inserted into a bore without any mechanical

setup, such as bore sweeping or the need to rotate the

target to determine mounting errors (a common problem

with most other systems). Insert the target into the bore,

ensure it is oriented at 12:00, and in seconds you have a

measurement. The target is concentric to its

housing to within .0003 in. (0.0075 mm). When

used with the A-514 adapters, the sensor is

centered to the bore within .0006 in. (0.015mm).

Another unique feature of our A-514 adapters is

they can handle a fairly large range of bore

diameter changes of up to .020 in. or 0.5 mm. This

means you don’t need to worry about bore

diameter changes to get accurate measurements.

When using an A-510 Target with the A-510

adapters or the A-512 Target with the A-514A and

A-514B adapters, two types of insertion handles may be

used. One is a solid stainless steel handle intended for

individual bores. The other is a pole for long, continuous

bores such as extruder barrels or gun barrels. The solid

stainless steel handle is designed for the weight of the

handle to firmly lock the target into place. The pole type

is designed with a spring and a universal joint at the rear

of the target, which locks the target into place.

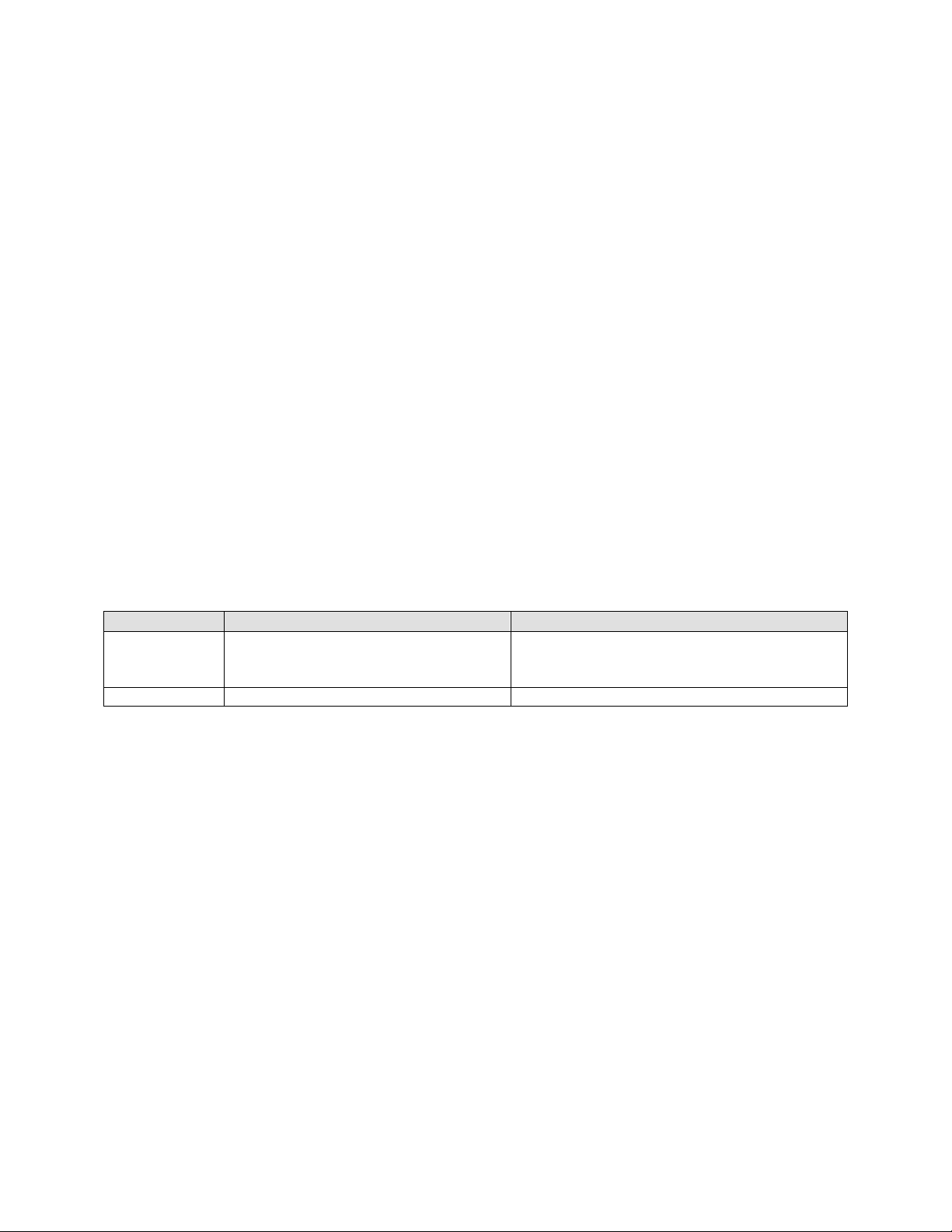

Figure 4 – A-512 2-Axis Self-Centering

Target

The laser is detected, or intercepted, by position-sensing

detectors (PSDs). The center of energy of the laser spot

is detected and converted to an electrical signal

proportional to its location on the surface of the target.

This signal is converted into a calibrated reading, using

a variety of hand-held readouts or computer interfaces

for use with our software.

Figure 5 – A-512 Target with A-514A Small Bore Self-Centering Bore

Adapter