REV321-12

WARNING: Failure to read and follow these installation instructions and safety precautions could result in personal injury, equipment damage,

shortened service life or unsatisfactory equipment performance. All information in this document is vital to the proper installation and operation of

the equipment. It is important that all personnel who will be coming in contact with this product thoroughly read and understand this manual.

Turbine

Vibrators

VIBCO

INSTRUCTION MANUAL

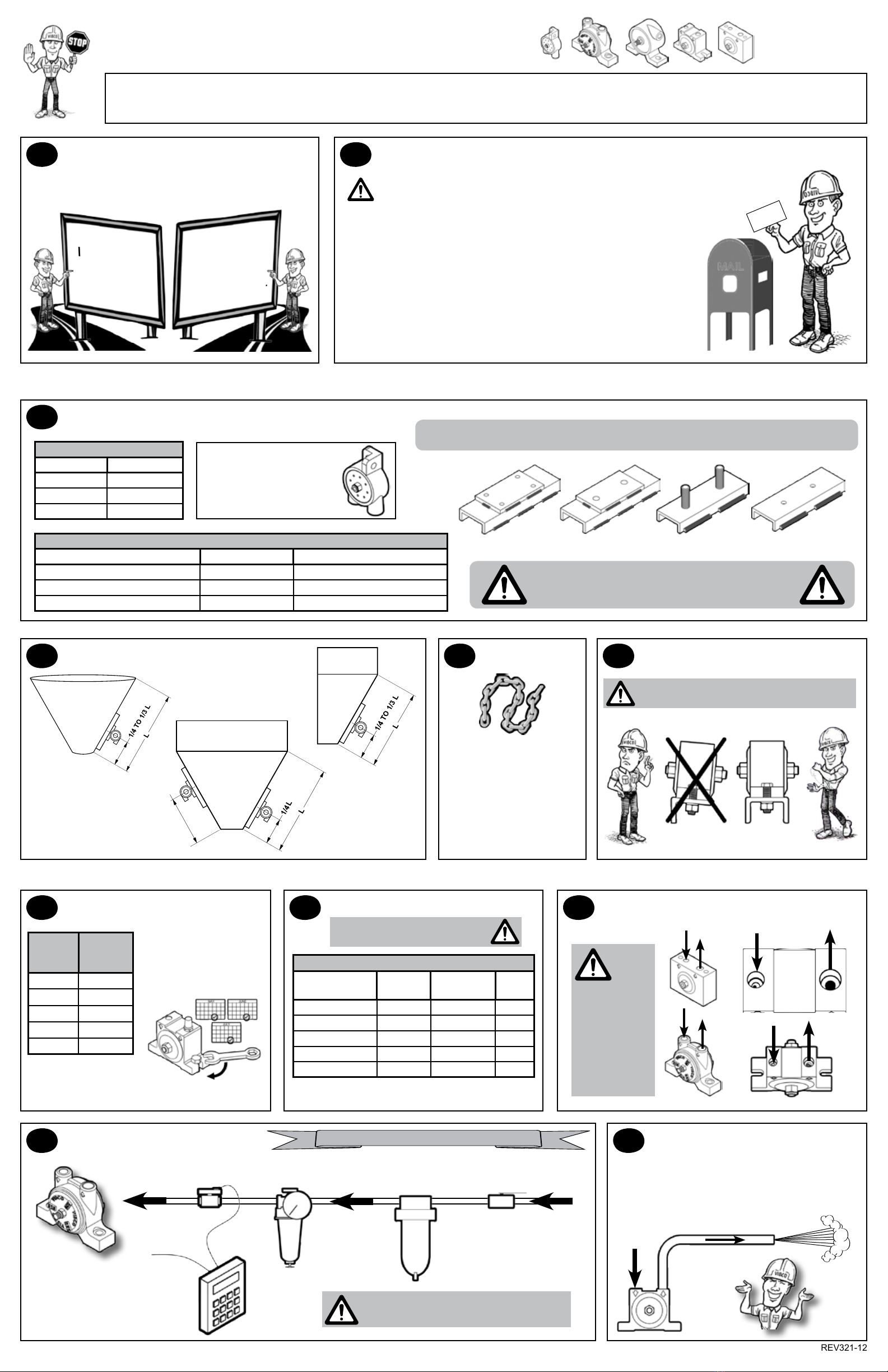

7bolting procedure

MOUNTING PLATES, CHANNEL IRON & ACCESSORIES AVAILABLE FROM VIBCO OR LOCAL DEALER

2mounting instructions checklist

1start

NEW

INSTALLATION

START

HERE!

REPLACEMENT OR

CROSS OVER UNITS

CHECK MOUNTING

AREA BEFORE

REPLACING UNIT.

thank You For choosing

a Vibco Vibrator!

3mounting plates & channel irons

4Vibrator placement 5restraint 6mounting oF Vibrator

8air hose 9input/output

oDetermine length of channel iron.

oSelect thickness of mounting plate & method of mounting.

oSTITCH weld mounting plate to channel iron.

oDetermine vibrator placement on bin.

oSTITCH weld channel iron to bin.

oPlace vibrator on mounting plate.

Check the mounting plate for warping. Secure rmly.

oInstall safety chain or wire.

oConnect pneumatics.

oFILL OUT WARRANTY CARD!!!!

The warranty is void if vibrator is not properly installed. During installation

follow and check off the following steps and your vibrator should provide

you with years of trouble-free service.

WARRANTY

DON’T

FORGET

TO MAIL

IN YOUR

WARRANTY

CARD!

NEVER PLACE VIBRATOR DIRECTLY

ON SKIN OF BIN OR HOPPER!

Drill/tap holes or use studded plate

You must stitch Weld MOUNTING PLATE & CHANNEL IRON!

NEVER CONTINUOUSLY WELD. STOP WELDS 1” FROM ENDS TO PREVENT CRACKING.

CORRECT MOUNTING PLATES

Lbs. of force Plate thickness

Up to 100 lbs. 1/4” plate

100 to 500 lbs. 3/8” to 1/2” plate

over 500 lbs. 1/2” plate

SUGGESTED CHANNEL LENGTH

Lbs. of force/bin wall thickness Channel iron width Channel iron length

up to 100 lbs / bin wall < 3/16” (thin) 3” channel iron 18” to 36” on both sides of vibrator

up to 500 lbs. / bin wall = 3/16” to 1/4” 4” channel iron 3” to 4” on both sides of the vibrator

over 500 lbs / bin wall = 3/8” to 1/2” 4” channel iron 6” to 8” on both sides of the vibrator

Flange style mounting

requires only one bolt to

mount. Mounting locations

will vary depending on

application.

Conical

Bin 1/2

Rectangular

Bin

2 Vibrators On

A Single Bin

THESE ARE JUST

EXAMPLES.

GO ONLINE

www.vibco.com

TO SEE MORE

ALWAYS

INSTALL

SAFETY CHAIN

Mount one end to the vibrator

and the other to the hopper

or bin above the vibrator

NEVER ATTACH CHAIN TO

THE MOUNTING PLATE

DAMAGE TO THE BIN AND THE VIBRATOR

CAN OCCUR IF NOT MOUNTED SECURELY.

Angle Iron Channel Iron

Make sure the vibrator is

secured tightly. Retighten

after the rst 10 -15

minutes of operation &

check them periodically to

maintain proper tightness.

Be sure surfaces are

smooth, at & free of

any debris.

GRADE

5 BOLT

SIZE

MAX

TORQUE

ft-lbs

1/4” 13

5/16” 25

3/8” 48

1/2” 115

5/8” 145

Remember to check

those bolts!

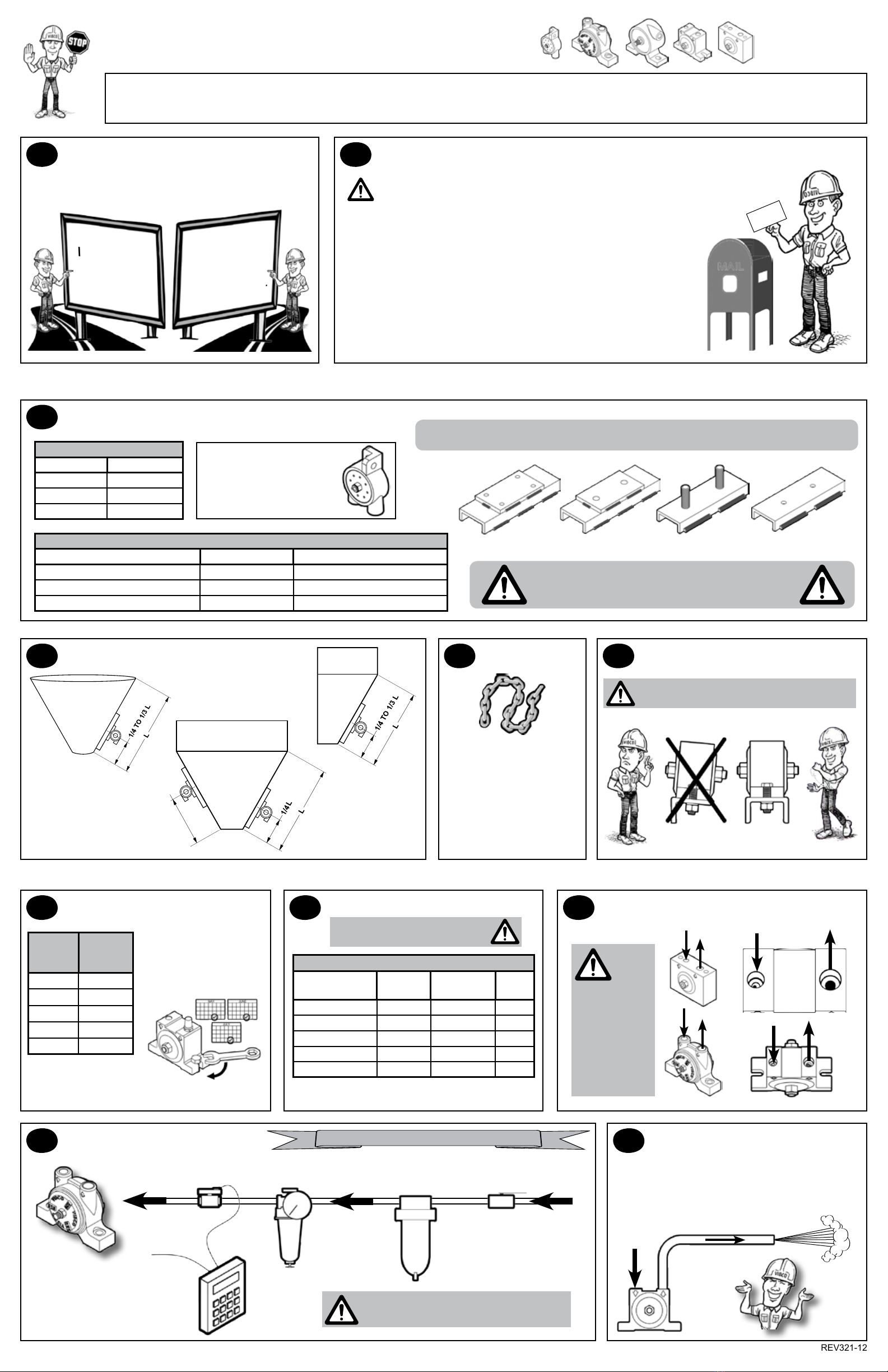

TO DETERMINE CORRECT AIR HOSE SIZE**

TURBINE MODEL

NUMBER

MIN AIR

HOSE DIA

MIN FR*

THREAD DIA CFM

100 - 130 1/8” 1/4” 4 - 6

160 - 250 1/4” 1/4” 7 - 10

320 - 380 3/8” 3/8” 10 - 18

440 - 510 1/2” 1/2” 18 - 21

570 3/4” 3/4” 21 - 30

* F=lter R=regulator

** these specs for installation of single unit;

for multiple units, adjust to maintain CFM

TAPERED THREADS!! DO NOT

OVER TIGHTEN FITTINGS.

On

BVS,

BBS,

MLT & MHI

models, the

smaller INNER

port is the air

inlet and the

larger INNER

port is the

exhaust.

IN OUT

10 pneumatic hook-up 11 air discharge

Timer

Ball

Valve

Air

Filter

Air

Regulator

Solenoid

Valve

To Control

Switch

To

Vibrator

ALL ACCESSORY ITEMS AVAILABLE FROM VIBCO

DO NOT LUBRICATE AIR...NO

LUBRICATION NECESSARY

Clean or Sanitary Environments:

Models BVS, MLT & MHI are equipped with a

threaded exhaust port to allow for exhaust air to

be piped off remotely.