Before you start use the following steps to verify

that the venting system is adequately sized:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA B149.1 or .2 Installation Code-latest

edition and these instructions. Determine that there is no

blockage or restriction, leakage, corrosion and other

deficiencies, which could cause an unsafe condition.

3. In so far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building. Turn on clothes dryers and any

exhaust fans such as range hoods and bathroom exhausts,

so they shall operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so that the

appliance will operate continuously.

5. After it has been determined that each appliance connected

to the venting system properly vents when tested as

outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-burning appliance to

their previous conditions of use.

6. If improper venting is observed during any of the above

tests, the venting system must be corrected.

Note: A vent is the vertical passageway used to convey flue

gases from the unit or the vent connector to the outside

atmosphere. A vent connector is the pipe which connects the

unit to a vent or chimney. Vent connectors serving Category I

appliances shall not be connected into any portion of mechanical

draft systems operating under positive pressure.

Venting Instructions

1. All vertically vented heaters are category I venting.

All horizontally vented heaters are category I or III

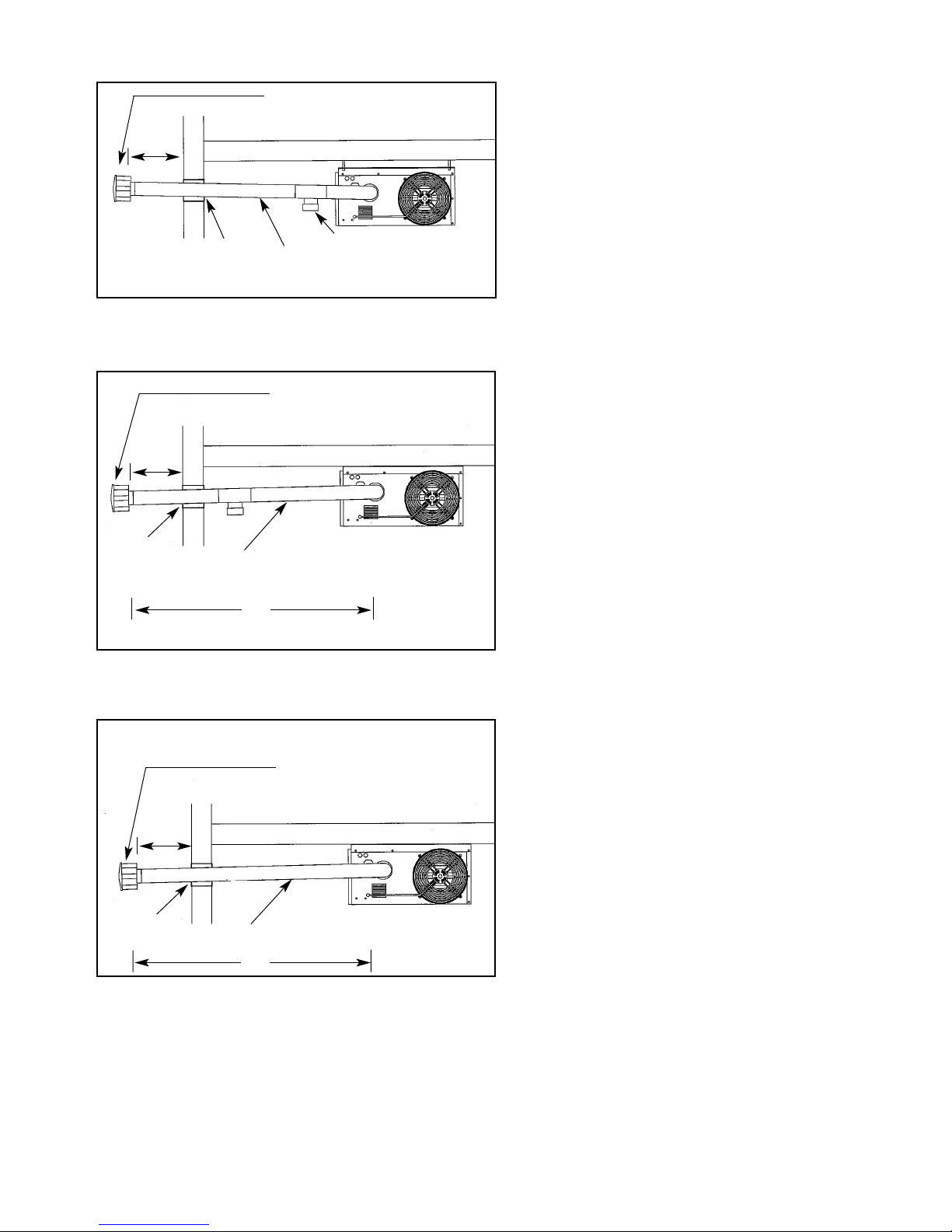

depending on venting. For a unit to be classified vertical,

the horizontal run may not exceed 75% of the vertical rise.

2. Using Table 5.1, determine the venting requirements for the

category determined above. A category III heater must

conform to the venting requirements called out in Table 5.1,

which are detailed in the following sections, as well as

additional requirements also detailed in following sections.

3. Vertically vented heaters may be vented with either single

wall or double wall vent pipe. Follow the double wall

manufacturers clearances to combustibles.

4. All heaters come with a factory installed 3" vent adapter for

attaching the vent pipe to the heater. Attach the vent pipe to

the adapter with 3 non-corrosive screws. (Drill pilot holes

through the vent pipe and adapter prior to screwing in place)

5. Do not use any vent pipe smaller than 3". Refer to the

National Fuel Gas Code for the minimum material thickness.

6. A minimum of 12" straight pipe is recommended from the

power exhauster outlet before turns in the vent system.

Suspend horizontal runs at a minimum of 3' intervals.

7. Avoid venting through unheated spaces when possible.

When single wall pipe does pass through an unheated

space, insulate runs greater than 5' to minimize

condensation. Inspect for leakage prior to insulating and

use insulation that is noncombustible with a rating of not

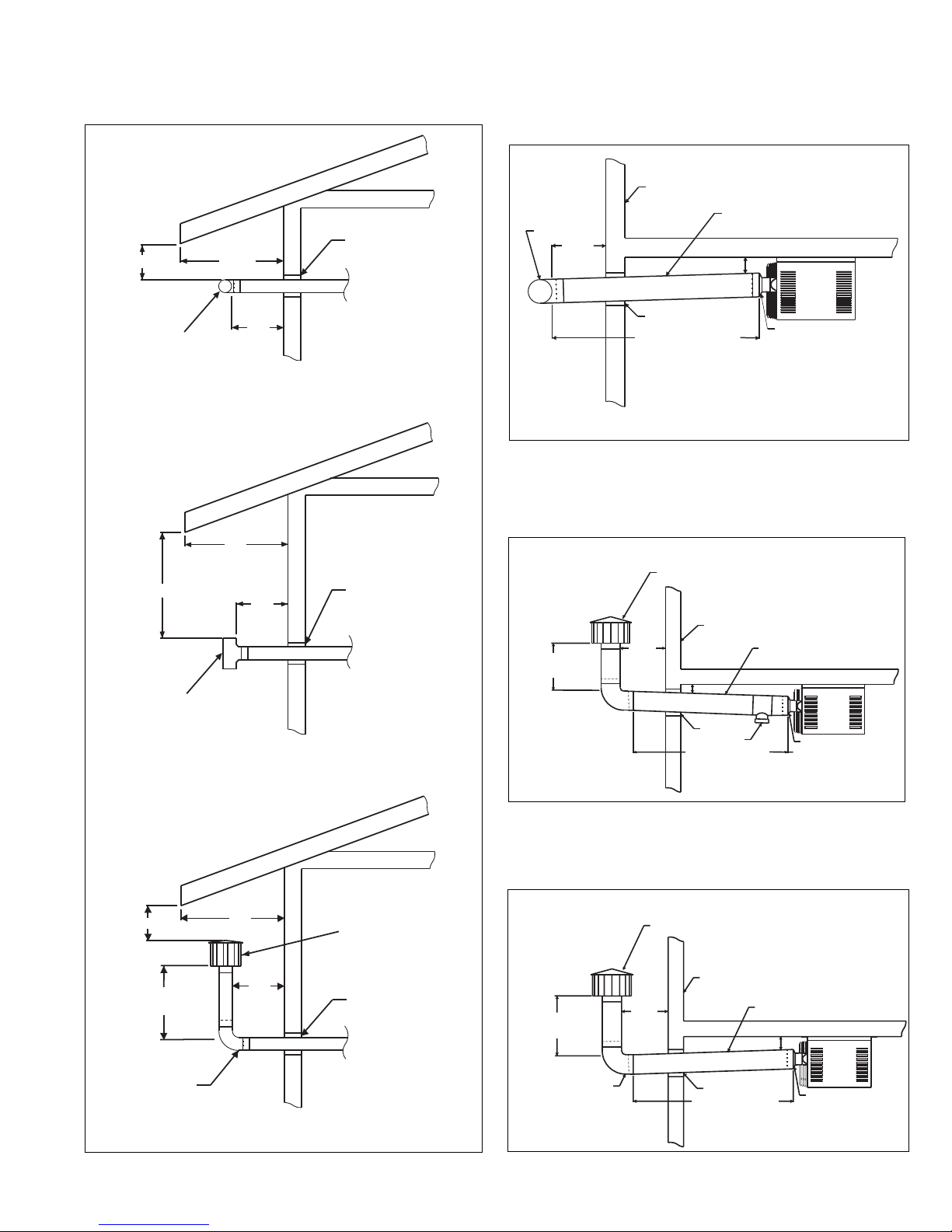

less 350°F. Install a tee fitting at the low point of the vent

system and provide a drip leg with a cleanout cap as

shown in Figures 6.2 and 6.3. The drip leg should be

cleaned annually.

8. Keep single wall vent pipe at least 6" from combustible

material. The minimum distance from combustible material

is based on the combustible material surface not exceeding

160°F. Clearances from the vent pipe (or top of the unit)

may be required to be greater than the minimum clearance

if heat damage (such as material distortion or discoloration)

may occur.

9. When a single wall vent passes through a combustible wall

or floor, a listed thimble must be used. When a type B

double wall vent passes through a combustible wall or floor,

follow the vent pipe manufacturers clearances to

combustibles. Refer to Figure 6.1.

10. This heater is equipped with a power exhaust system.

DO NOT use any additional power exhaust systems or vent

dampers. FAILURE TO FOLLOW THESE INSTRUCTIONS

could result in serious injury or death.

11. All vertically vented heaters are category I and must be

connected to a factory built chimney or vent complying with

a recognized standard, or a masonry (or concrete) lined

chimney with a material acceptable to the authority having

jurisdiction. Venting into an unlined masonry chimney is

not permitted. Refer to the National Fuel Gas Code for

common venting.

12. Secure all vent joints with at least 3 corrosion-resistant

screws. Use an approved vent terminal to reduce down

drafts and moisture in the vent.

13. The vent must terminate no less than 5' above the vent

connector. The top of the vertical stack should extend

above any portion of a building within a horizontal distance

of 2' (see Figure 6.2).

14. The outlet of the vent should extend as shown in Figure

6.3 and Table 6.1 if the following conditions are met:

Vent diameter is less than 12 inches, vent is of double wall

construction and is a listed product, and the vent does not

terminate within 10' of a vertical wall or similar obstruction.

For vents that have a diameter of 12 inches or larger,

constructed of single wall, or terminate within 2' of a vertical

wall or similar obstruction, the vent pipe shall extend at

least 2' higher than any portion of a building within a

horizontal distance of 2' (refer to Figure 6.2).

55

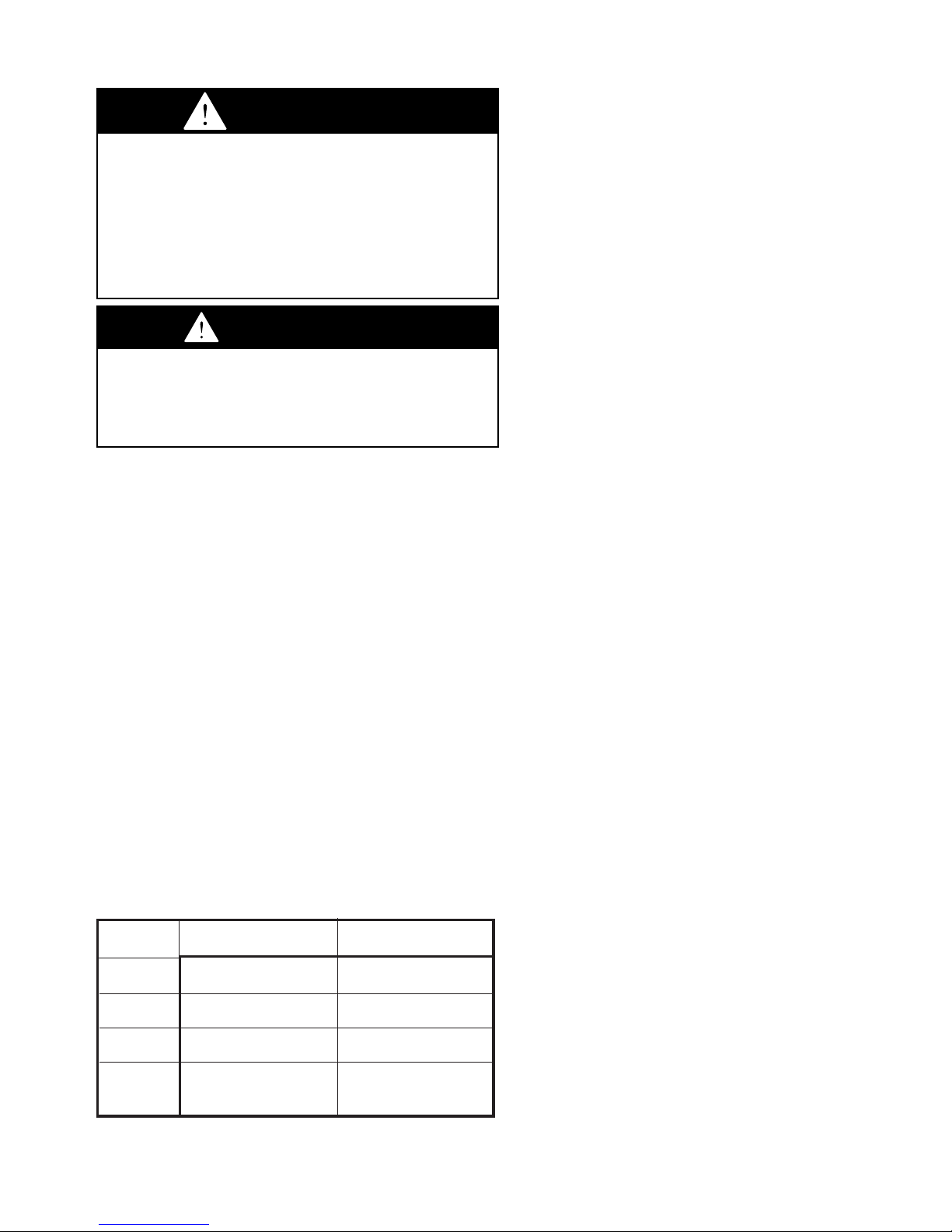

Table 5.1

ANSI Unit Heater Venting Requirements

Venting

Category Description Requirements

I Negative vent pressure Follow standard

Non-condensing venting requirements.

II Negative vent pressure Condensate must

Condensing be drained.

III Positive vent pressure Vent must be gas tight.

Non-condensing

IV Positive vent pressure Vent must be liquid and

Condensing gastight. Condensate

must be drained.

INSTALLATION

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If you are replacing an existing heater, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA B149.1 or .2 latest edition. Failure to

follow these instructions can result in serious injury or death.

CAUTION

Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) - latest

edition. In Canada installation must be in accordance with

CAN/CGA-B149.1 for natural gas units, and CAN/CGA-B149.2

for propane units.

Venting