8

MAINTENANCE & CLEANING

1. After use each time, carefully clean the bowl, agitators etc, and make sure to keep the

machine clean.

2. Lubricate the bowl side ways regularly.

3. The transmission gearbox is packed with special grease that will be sufficient for six months.

To add or replace grease, it is necessary only to remove the upper cover and the bearing cover

DO NOT CLEAN BY WATER DIRECTLY

DO NOT HOSE OR PRESSURE CLEAN THIS MIXER.

DO NOT USE ANY ABRASIVE CLEANERS

Ensure that the machine is disconnected from the main electrical power supply prior to

cleaning.

It is important that correct and detailed cleaning procedures are made for all surfaces that

come into contact with food. The cleaning frequency should be clearly defined for the mixer (i.e.,

daily, after production runs, or more often if necessary) and also the type of cleaning required

must also be identified. The objective of cleaning and disinfecting food contact surfaces is to

remove food debris (that bacteria require to grow), and to kill bacteria that are present. It is

important the cleaned surfaces are stored dry to prevent bacteria growth. Cleaning equipment

(brushes, etc.) used must also be stored in a clean and sanitary manner. The correct procedure

for cleaning of the splash zone and the food-contact surfaces are as follows:

1. Pre-clean - remove excess food waste by sweeping, wiping or pre-rinsing.

2. Main clean - loosen surface waste and grease using a detergent.

3. Rinse - remove loose food waste, grease and detergent.

4. Disinfection - kill the bacteria.

5. Final rinse - remove the disinfectant.

6. Drying - remove all moisture.

• Note with light contamination the pre-clean and main clean can be combined.

• Some surfaces do not need to be disinfected after every wash.

• Disinfect any items which come either into direct contact with food or with the hands of

operators.

• The best method of drying surfaces is to let them air-dry, but if this is not possible, use paper

towels or a clean dry cloth.

• It is important the disinfecting chemicals are approved for food contact surface application.

CLEANING BEFORE INITIAL USE:

Before using the mixer for the first time, ensure to wash the mixer bowls, agitators and

attachments in hot water and a mild detergent solution. This procedure should be followed for

bowls and agitators before use for egg whites or whole eggs.

CLEANING AFTER USE:

After use, clean the mixing bowl, agitators and attachments with hot water and a suitable non-

abrasive detergent and soft bristle brush. Rinsing the bowl with hot water immediately after use

will also speed up the cleaning of the bowl afterwards.

Note: Do not clean the Aluminium agitators in a dishwasher. Wash immediately after use in a

bowl of warm soapy water.

Ensure to wipe down the mixer with a hot damp cloth, thoroughly wiping the bowl support,

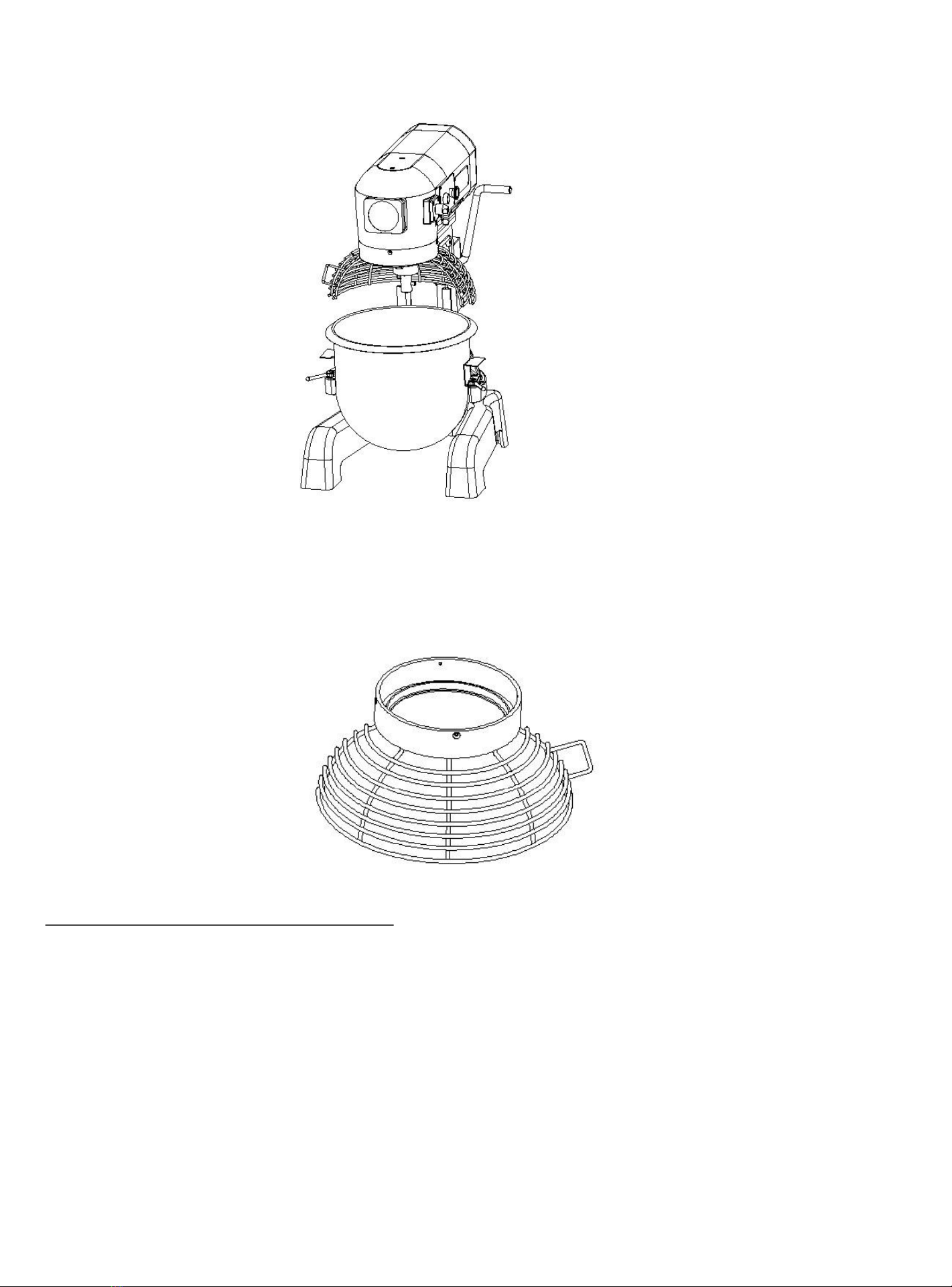

pedestal, base and all exterior surfaces. All food debris must be removed. The guard should be

cleaned in hot soapy water. The guard assembly has been designed to be easily removed for

cleaning.