Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered trademark. evised:

GENERAL INFORMATION.

The LPA 3-15R Power Amplifier is a class C

device designed to be installed as an integral

part of a transmitter enclosure in a repeater

installation with a .5 Watt 0MHz exciter

module. Output power is approx 1 -15W at

13.6Vdc.

The Power Amplifier operates on +13.6 Vdc

at about to .5 Amp, depending on output

power level. It has a 50-ohm input and out-

put impedance and is designed for continu-

ous duty. A low-pass filter reduces harmonic

output to very low levels.

CONSTRUCTION.

General.

Most of the pertinent construction details

are given in the component location and

schematic diagrams and parts list.

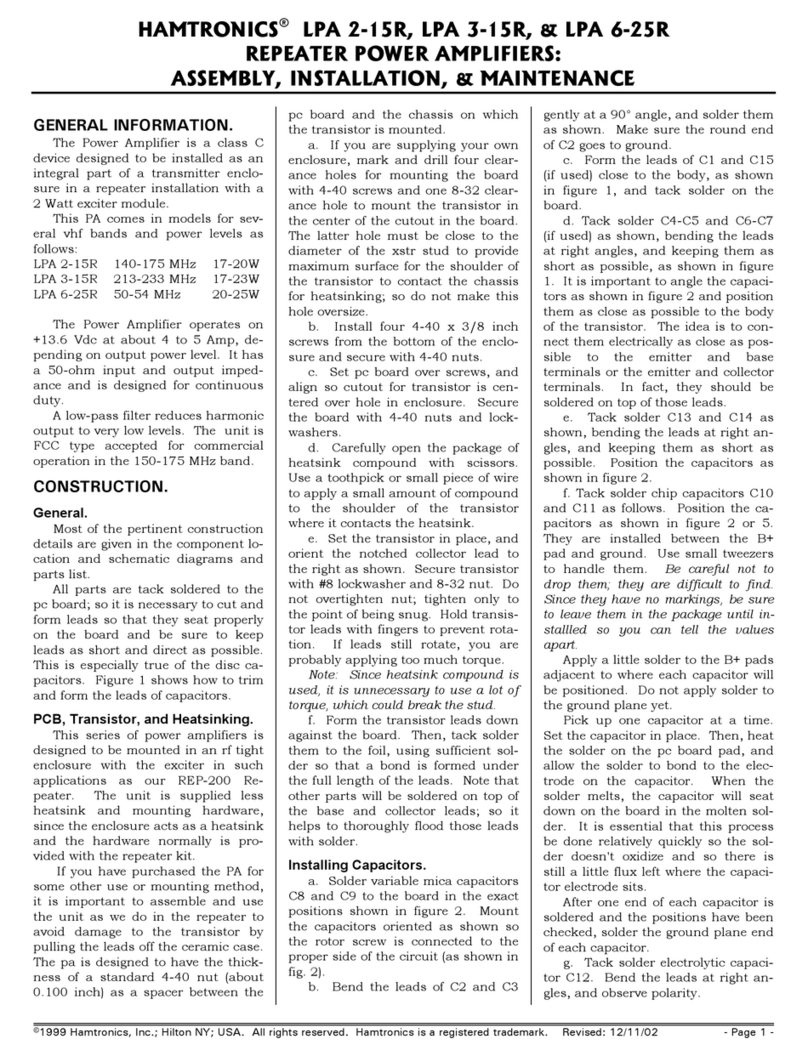

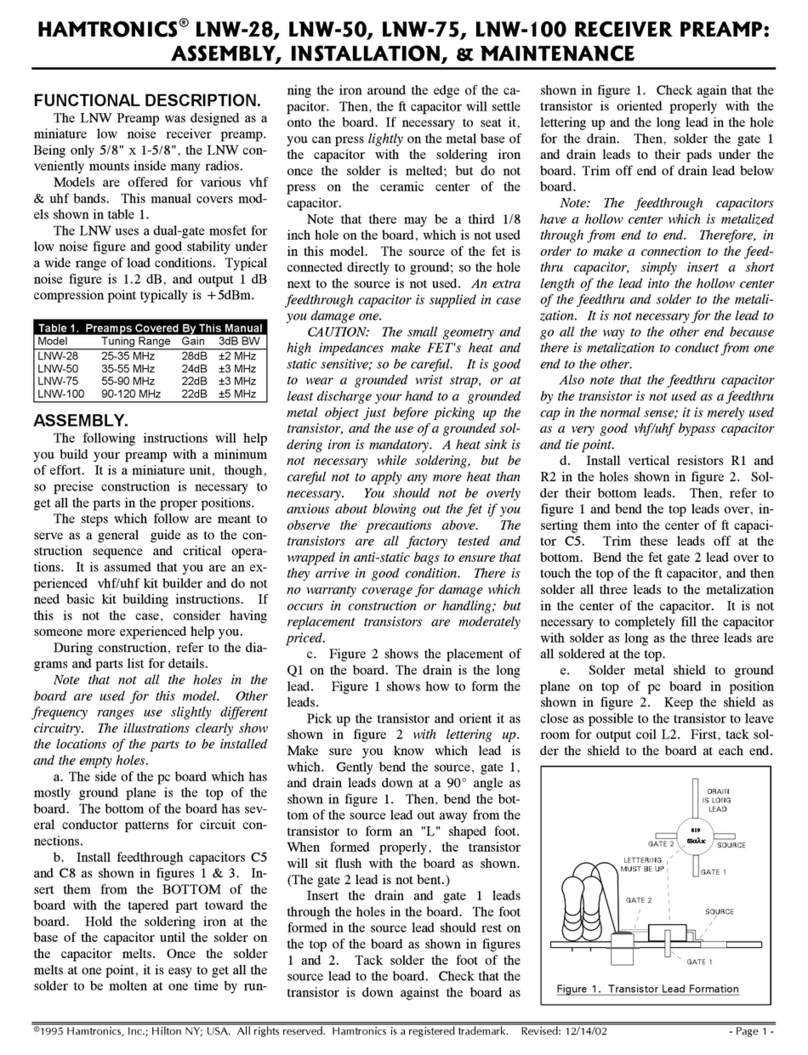

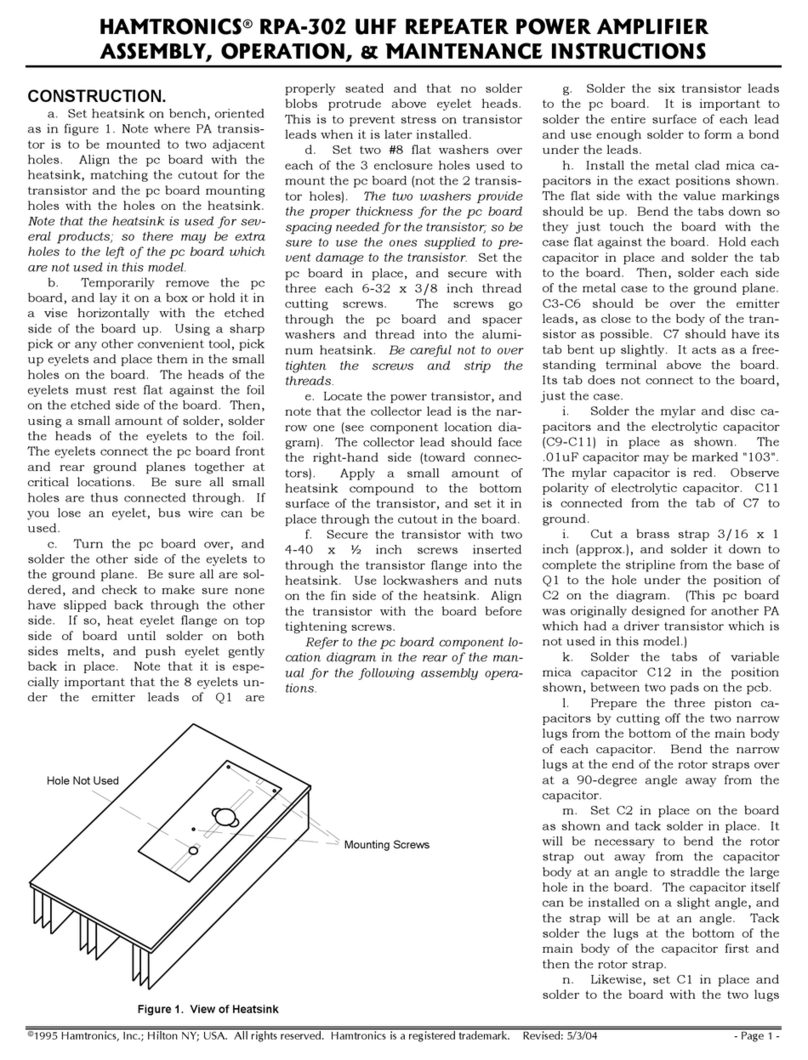

All parts are tack soldered to the pc board;

so it is necessary to cut and form leads so

that they seat properly on the board and be

sure to keep leads as short and direct as pos-

sible. This is especially true of the disc capaci-

tors. Figure 1 shows how to trim and form

the leads of capacitors.

Mounting the board.

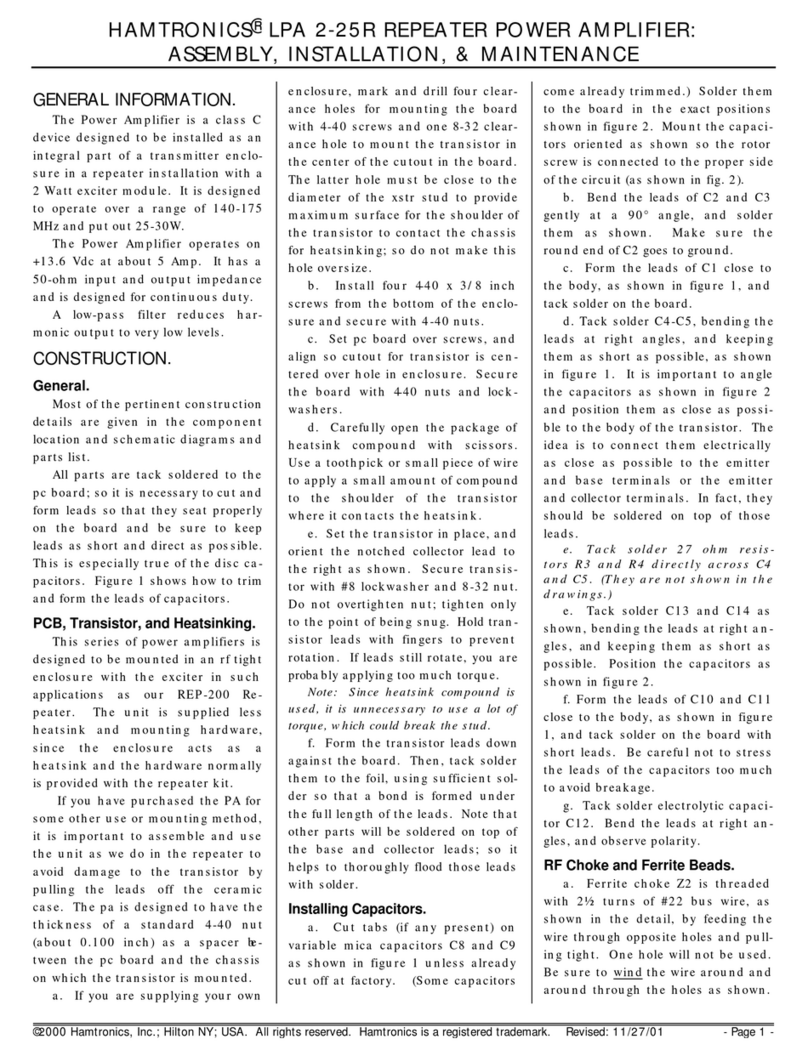

Note: This series of power amplifiers is de-

signed to be mounted in an rf tight enclosure

with the exciter in a separate rf tight box to

avoid feedback into the exciter. The unit is

supplied less heatsink since the enclosure acts

as a heatsink. It is important to mount the

unit carefully to avoid damage to the transis-

tor by pulling the leads off the ceramic case.

The PA is designed to have the thickness of

two thin #4 flat washers (about 0.050 inch to-

tal) as a spacer between the pc board and the

chassis which the transistor is mounted on.

a. Mark and drill four clearance holes for

mounting the board with 4-40 screws and

one 8-3 clearance hole to mount the transis-

tor in the center of the cutout in the board.

The latter hole must be close to the diameter

of the xstr stud to provide maximum surface

for the shoulder of the transistor to contact

the chassis for heatsinking; so do not make

this hole oversize.

b. Carefully open the package of heatsink

compound with scissors. Use the toothpick

to apply a small amount of compound to the

shoulder of the transistor where it contacts

the heatsink. Only a light coating is needed.

c. Install four 4-40 x 3/8 inch screws from

the bottom of the enclosure. Place two flat

washers as spacers over each of the screws,

as previously described.

d. Set pc board over screws, and align so

transistor is centered over hole in enclosure.

Secure the board with 4-40 nuts and lock-

washers.

e. Secure transistor with #8 lockwasher and

8-3 nut. Do not overtighten nut; tighten

with a nut driver only to the point of being

snug. Caution: Since heatsink compound is

used, it is unnecessary to use a lot of torque,

which could break the stud.

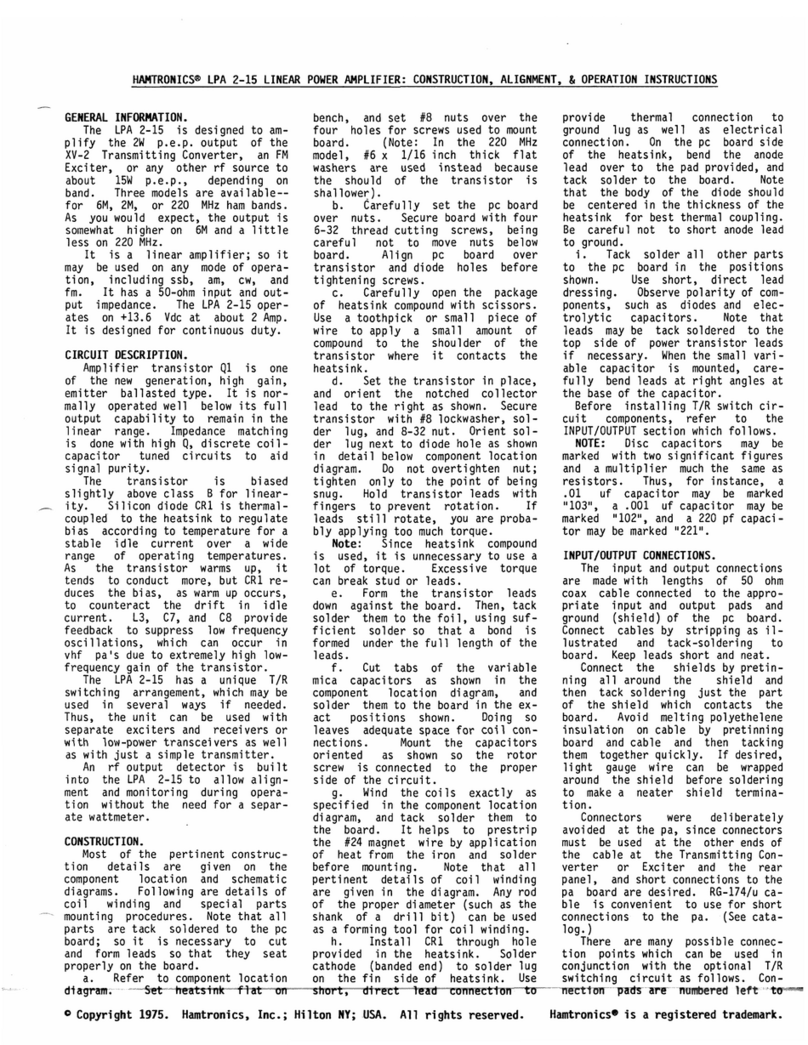

Coil Forming and Placement.

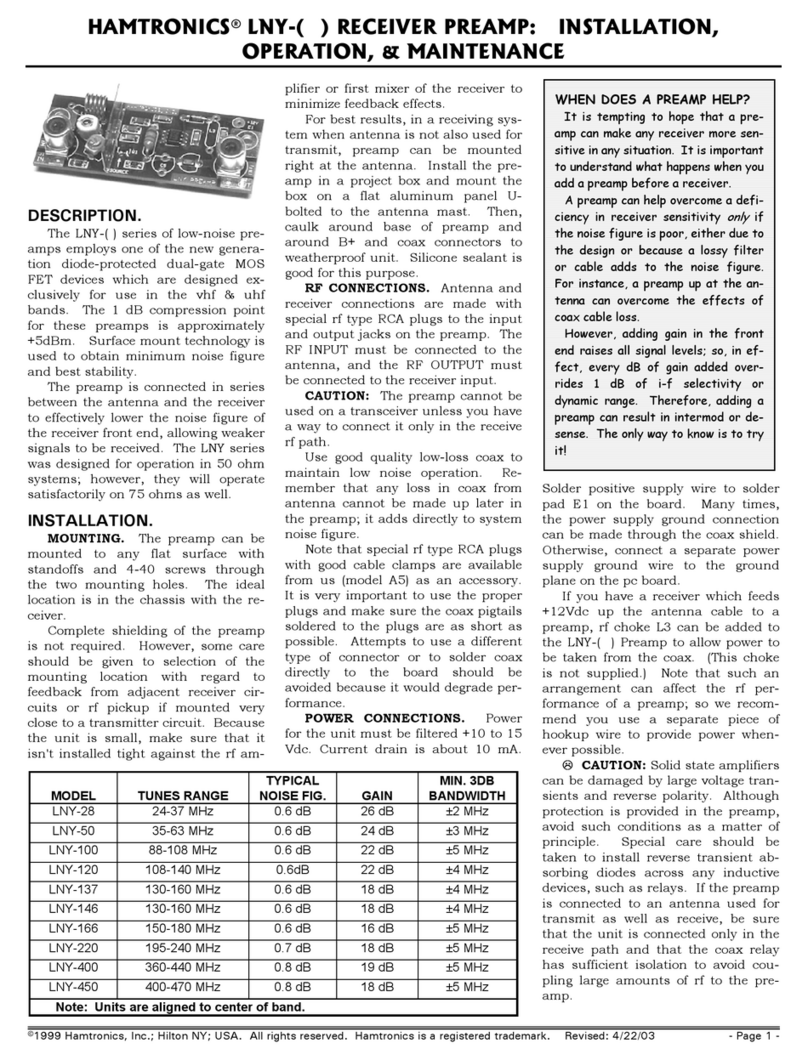

Figures 5 & 6 show exactly how coils are

formed. You need to form the coils exactly as

specified, using #18 bus wire supplied. Tack

solder them to the board in the positions

shown.

L1 and L3 actually are jumpers formed with

legs so that the top of the jumpers are 1/8

inch above the board, as shown in figure 6.

L4 is 1-3/4 turns on 1/4 inch i.d. L5 is 1-1/4

turns on 1/8 inch i.d. Spacing between turns

of the coils should be minimal, with turns

separated just enough to prevent shorting to-

gether. The feet are formed on L5 just so the

bottom wire of the coil doesn't short to the

ground plane. (Note that L1 and L3 are

shown in figure 5 at a smaller scale than the

rest of the coils.)

RF INPUT/OUTPUT

CONNECTIONS.

The input and output connections are made

with RG-174/u or similar 50-ohm coax cable

connected to the appropriate input and out-

put pads and ground plane of the pc board.

See diagram. Connect cables by stripping as

illustrated and tack-soldering to board. Note

that stripped length of coax is inductive; so

keep leads short and neat.

Avoid melting polyethelene insulation on

cable by pretinning board and cable and then

tacking them together quickly.

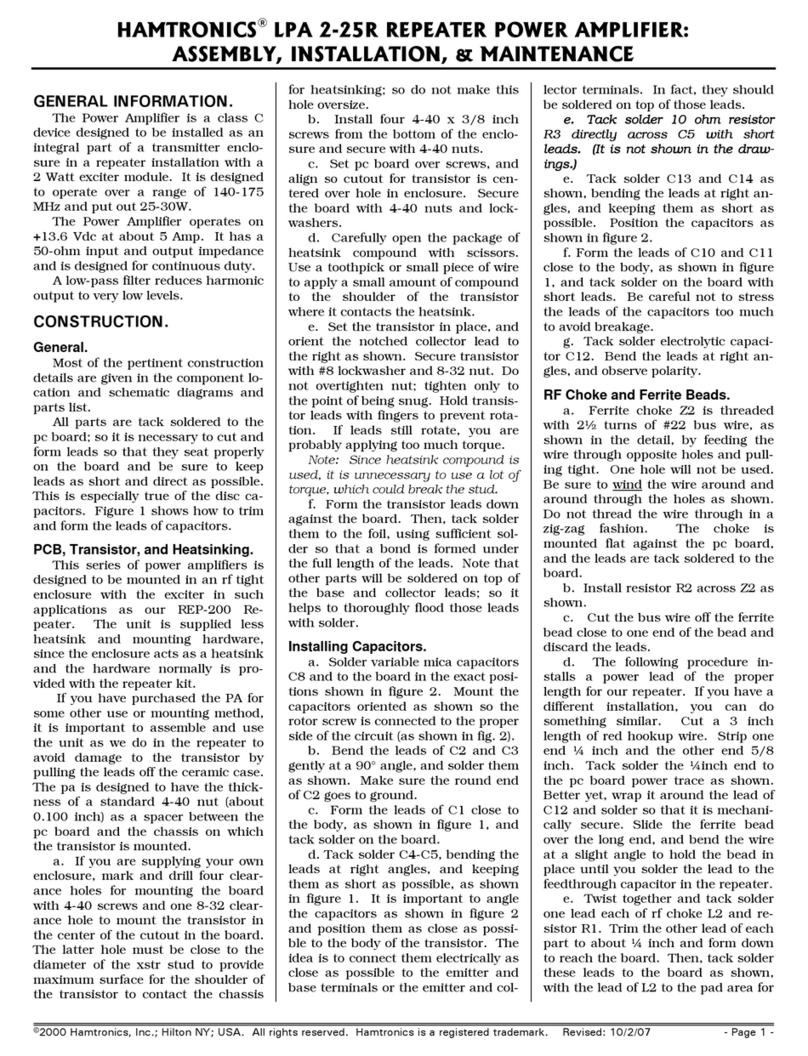

POWER CONNECTIONS.

+13.6Vdc should be connected to the B+

pad at the top of the pc board through the

ferrite bead provided. A hookup wire should

be attached to the ferrite bead’s lead or the

bead can be removed and installed directly

on hookup wire tack soldered in place of the

lead the bead is on (as shown in Fig. 5). The

ground return normally is connected to the

pc board through the mounting hardware.

Note that the output capability of the PA

drops rapidly as the voltage is reduced below

13.6Vdc; therefore, you should try to use a

power source of sufficient voltage and mini-

mize cable losses so that you have full B+

available at the PA.

CAUTIONS TO PROTECT

TRANSISTORS.

Because it is so easy to damage rf power

transistors in the field due to accidents and

abuse, transistor manufacturers do not pro-

vide any warranty to cover replacements

once a transistor is installed in the unit. They

test them thoroughly at the factory because

they are expensive parts. Therefore, they do

not honor claims that "the transistor must

have been bad from the factory". For your

protection, please be sure to observe the fol-

lowing precautions:

1. Sometimes, transistors may be de-

stroyed by parasitic oscillations occurring dur-

ing tuning because of the extremes of

capacitor settings, or due to accidental short-

ing of components. To protect against such

damage as much as possible, turn power sup-

ply voltage down to about 10 Volts when you

first apply power until the unit is tuned.

Then, turn up to full 13.6Vdc. Of course, final

tuning should be done at full 13.6V.

. Never exceed 14Vdc, as even a small

over-voltage causes strain on transistors be-

cause of additional heat.

3. Be sure you have a low impedance con-

nection to the power supply, i.e., short, heavy

cable.

4. Do not attempt to operate PA until ex-

citer has been properly aligned by itself, op-

erating into a 50-ohm load.

ALIGNMENT.

Alignment is very simple. Connect the input

to an exciter which has already been tuned

into a 50-ohm dummy load. Connect the

output to a 50-ohm load of sufficient power

rating. Use an in-line power meter.

Apply B+ and rf drive. Alternately tune the

four variable capacitors for maximum out-

put. Continue repeaking capacitors until

maximum output is achieved and all interac-

tions between capacitors are worked out.

Note that C8 normally tunes near or at min-

inimum capacitance (piston up near top).

Caution: Do not retune exciter with PA con-

nected. Once the exciter is tuned into a 50Ω

load, it should not be retuned. Tuning the in-

put of the PA takes care of matching the PA

to the exciter.

With 13.6Vdc power applied and .5W

drive, the 0 MHz unit should put out about

1 -15W, and the current drain should be

about - .5A.

HAMTRONICS

LPA 3-15R REPEATER POWER AMPLIFIER:

INSTALLATION, & MAINTENANCE