©2000 Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered trademark. Revised

GENERAL INFORMATION.

The Power Amplifier is a class C

device designed to be installed as an

integral part of a transmitter enclo-

sure in a repeater installation with a

2 Watt exciter module. It is designed

to operate over a range of 40- 75

MHz and put out 25-30W.

The Power Amplifier operates on

+ 3.6 Vdc at about 5 Amp. It has a

50-ohm input and output impedance

and is designed for continuous duty.

A low-pass filter reduces harmonic

output to very low levels.

CONSTRUCTION.

General.

Most of the pertinent construction

details are given in the component lo-

cation and schematic diagrams and

parts list.

All parts are tack soldered to the

pc board; so it is necessary to cut and

form leads so that they seat properly

on the board and be sure to keep

leads as short and direct as possible.

This is especially true of the disc ca-

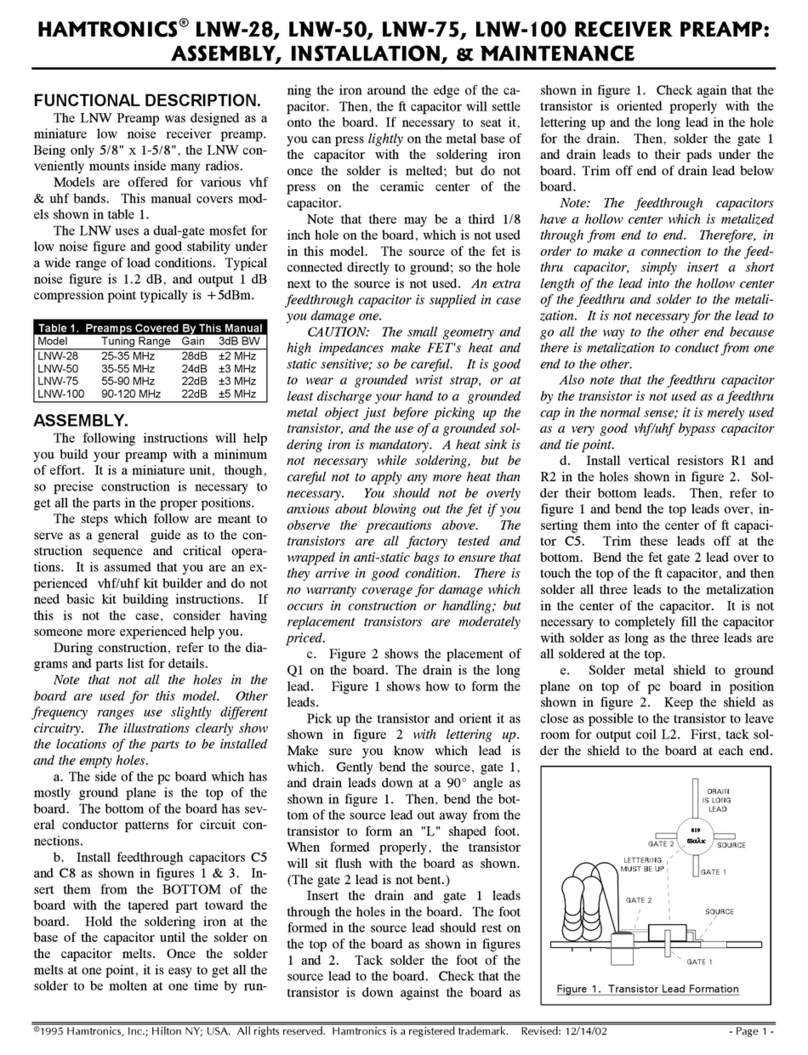

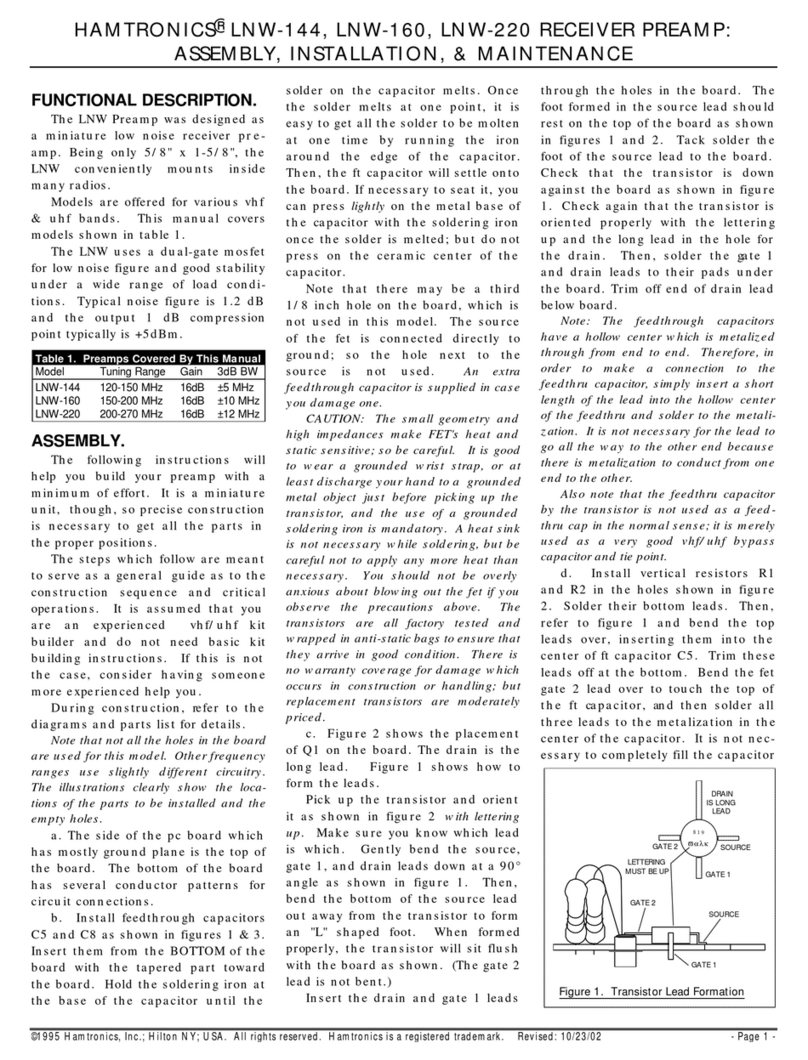

pacitors. Figure shows how to trim

and form the leads of capacitors.

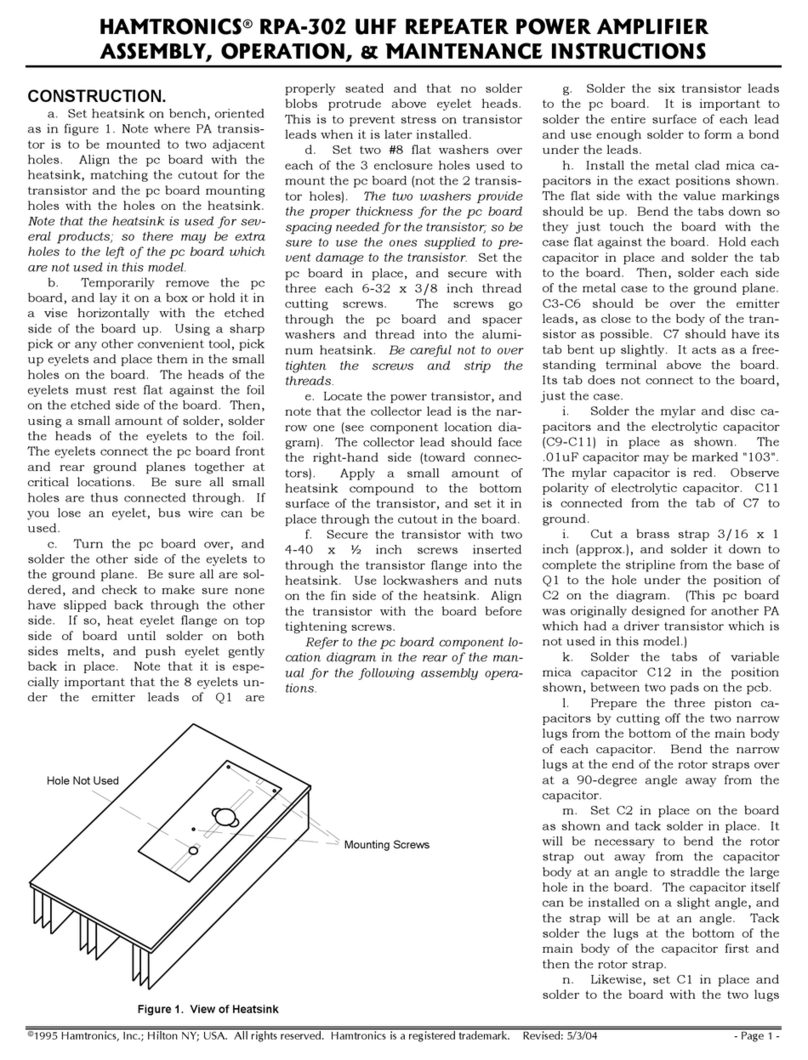

PCB, Transistor, and Heatsinking.

This series of power amplifiers is

designed to be mounted in an rf tight

enclosure with the exciter in such

applications as our REP-200 Re-

peater. The unit is supplied less

heatsink and mounting hardware,

since the enclosure acts as a heatsink

and the hardware normally is pro-

vided with the repeater kit.

If you have purchased the PA for

some other use or mounting method,

it is important to assemble and use

the unit as we do in the repeater to

avoid damage to the transistor by

pulling the leads off the ceramic case.

The pa is designed to have the thick-

ness of a standard 4-40 nut (about

0. 00 inch) as a spacer between the

pc board and the chassis on which

the transistor is mounted.

a. If you are supplying your own

enclosure, mark and drill four clear-

ance holes for mounting the board

with 4-40 screws and one 8-32 clear-

ance hole to mount the transistor in

the center of the cutout in the board.

The latter hole must be close to the

diameter of the xstr stud to provide

maximum surface for the shoulder of

the transistor to contact the chassis

for heatsinking; so do not make this

hole oversize.

b. Install four 4-40 x 3/8 inch

screws from the bottom of the enclo-

sure and secure with 4-40 nuts.

c. Set pc board over screws, and

align so cutout for transistor is cen-

tered over hole in enclosure. Secure

the board with 4-40 nuts and lock-

washers.

d. Carefully open the package of

heatsink compound with scissors.

Use a toothpick or small piece of wire

to apply a small amount of compound

to the shoulder of the transistor

where it contacts the heatsink.

e. Set the transistor in place, and

orient the notched collector lead to

the right as shown. Secure transistor

with #8 lockwasher and 8-32 nut. Do

not overtighten nut; tighten only to

the point of being snug. Hold transis-

tor leads with fingers to prevent rota-

tion. If leads still rotate, you are

probably applying too much torque.

Note: Since heatsink compound is

used, it is unnecessary to use a lot of

torque, which could break the stud.

f. Form the transistor leads down

against the board. Then, tack solder

them to the foil, using sufficient sol-

der so that a bond is formed under

the full length of the leads. Note that

other parts will be soldered on top of

the base and collector leads; so it

helps to thoroughly flood those leads

with solder.

Installing Capacitors.

a. Solder variable mica capacitors

C8 and to the board in the exact posi-

tions shown in figure 2. Mount the

capacitors oriented as shown so the

rotor screw is connected to the proper

side of the circuit (as shown in fig. 2).

b. Bend the leads of C2 and C3

gently at a 90° angle, and solder them

as shown. Make sure the round end

of C2 goes to ground.

c. Form the leads of C close to

the body, as shown in figure , and

tack solder on the board.

d. Tack solder C4-C5, bending the

leads at right angles, and keeping

them as short as possible, as shown

in figure . It is important to angle

the capacitors as shown in figure 2

and position them as close as possi-

ble to the body of the transistor. The

idea is to connect them electrically as

close as possible to the emitter and

base terminals or the emitter and col-

lector terminals. In fact, they should

be soldered on top of those leads.

e.

e.e.

e.

Tack solder 10 ohm resi

Tack solder 10 ohm resiTack solder 10 ohm resi

Tack solder 10 ohm resis

ss

stor

tor tor

tor

R directly across C5 with shor

R directly across C5 with shorR directly across C5 with shor

R directly across C5 with short

t t

t

leads. (It is not shown in the dra

leads. (It is not shown in the draleads. (It is not shown in the dra

leads. (It is not shown in the draw-

w-w-

w-

ings.)

ings.)ings.)

ings.)

e. Tack solder C 3 and C 4 as

shown, bending the leads at right an-

gles, and keeping them as short as

possible. Position the capacitors as

shown in figure 2.

f. Form the leads of C 0 and C

close to the body, as shown in figure

, and tack solder on the board with

short leads. Be careful not to stress

the leads of the capacitors too much

to avoid breakage.

g. Tack solder electrolytic capaci-

tor C 2. Bend the leads at right an-

gles, and observe polarity.

RF Choke and Ferrite Beads.

a. Ferrite choke Z2 is threaded

with 2½ turns of #22 bus wire, as

shown in the detail, by feeding the

wire through opposite holes and pull-

ing tight. One hole will not be used.

Be sure to wind the wire around and

around through the holes as shown.

Do not thread the wire through in a

zig-zag fashion. The choke is

mounted flat against the pc board,

and the leads are tack soldered to the

board.

b. Install resistor R2 across Z2 as

shown.

c. Cut the bus wire off the ferrite

bead close to one end of the bead and

discard the leads.

d. The following procedure in-

stalls a power lead of the proper

length for our repeater. If you have a

different installation, you can do

something similar. Cut a 3 inch

length of red hookup wire. Strip one

end ¼ inch and the other end 5/8

inch. Tack solder the ¼inch end to

the pc board power trace as shown.

Better yet, wrap it around the lead of

C 2 and solder so that it is mechani-

cally secure. Slide the ferrite bead

over the long end, and bend the wire

at a slight angle to hold the bead in

place until you solder the lead to the

feedthrough capacitor in the repeater.

e. Twist together and tack solder

one lead each of rf choke L2 and re-

sistor R . Trim the other lead of each

part to about ¼ inch and form down

to reach the board. Then, tack solder

these leads to the board as shown,

with the lead of L2 to the pad area for

HAMTRONICS

LPA 2-25R REPEATER POWER AMPLIFIER:

ASSEMBLY, INSTALLATION, & MAINTENANCE