©1995 Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered trademark.

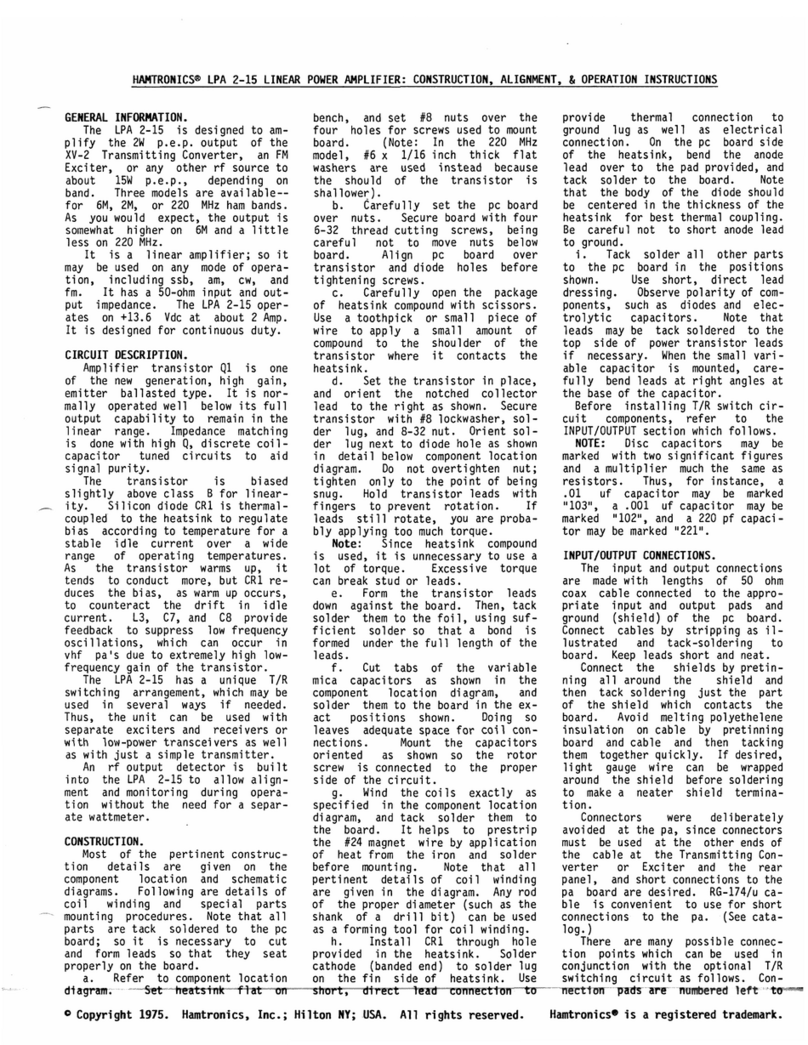

GENERAL INFORMATION.

The LPA 4-10R is designed to be

installed as an integral part of a

transmitter enclosure in a repeater

installation with a two Watt exciter

module. The transistor is biased for

class-C operation to give 8-10 Watts

output. The LPA 4-10R operates on

+13.6 Vdc at about 2 Amp. It has a

50-ohm input and output impedance

and is designed for continuous duty.

CONSTRUCTION.

Most of the pertinent construction

details are given in the component lo-

cation and schematic diagrams and

parts list. All parts are tack soldered

to the pc board; so it is necessary to

cut and form leads so that they seat

properly on the board and be sure to

keep leads as short and direct as pos-

sible.

Note: This series of power amplifiers

is designed to be mounted in an rf tight

enclosure with the exciter in such appli-

cations as our REP-200 Repeater or an

RF Tight box. The unit is supplied less

heatsink and mounting hardware, since

the enclosure acts as a heatsink and the

hardware normally is provided with the

repeater kit. If you have purchased the

PA for some other use or mounting

method, it is important to assemble and

use the unit as we do in the repeater to

avoid damage to the transistor by pull-

ing the leads off the ceramic case. The

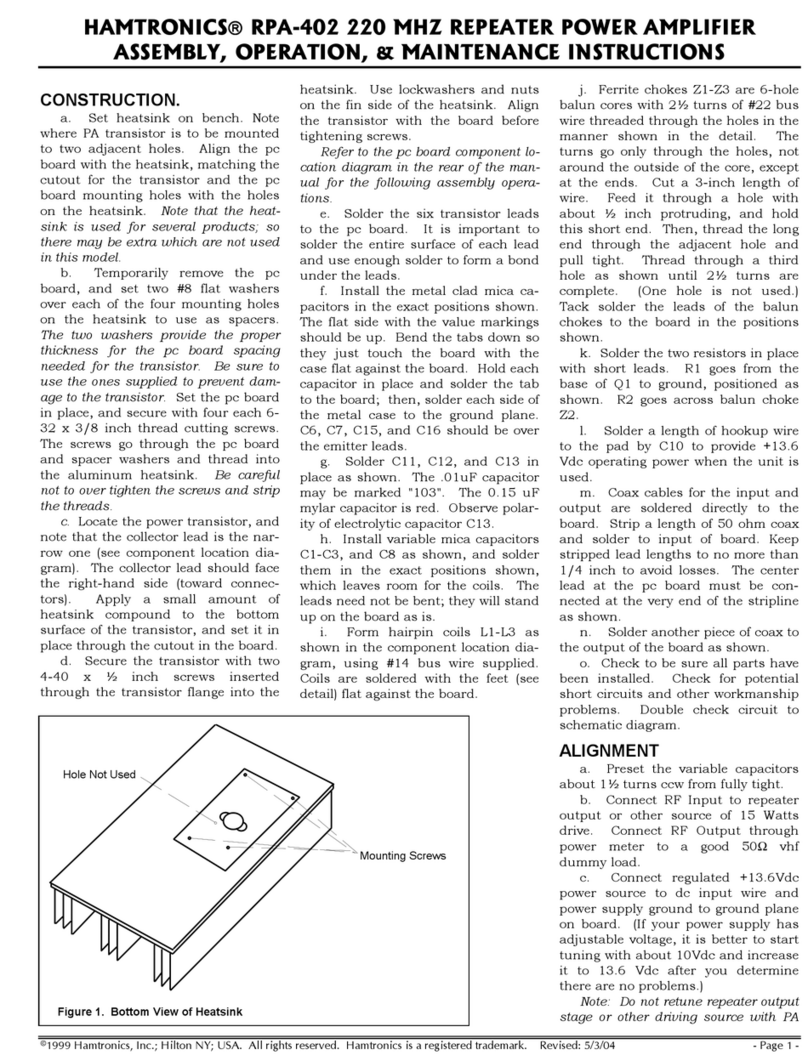

LPA 4-10R is designed to have the

thickness of a standard #8 SAE flat

washer or two thin #4 flat washers

(about 0.050 inch total) as a spacer be-

tween the pc board and the chassis

which the transistor is mounted on.

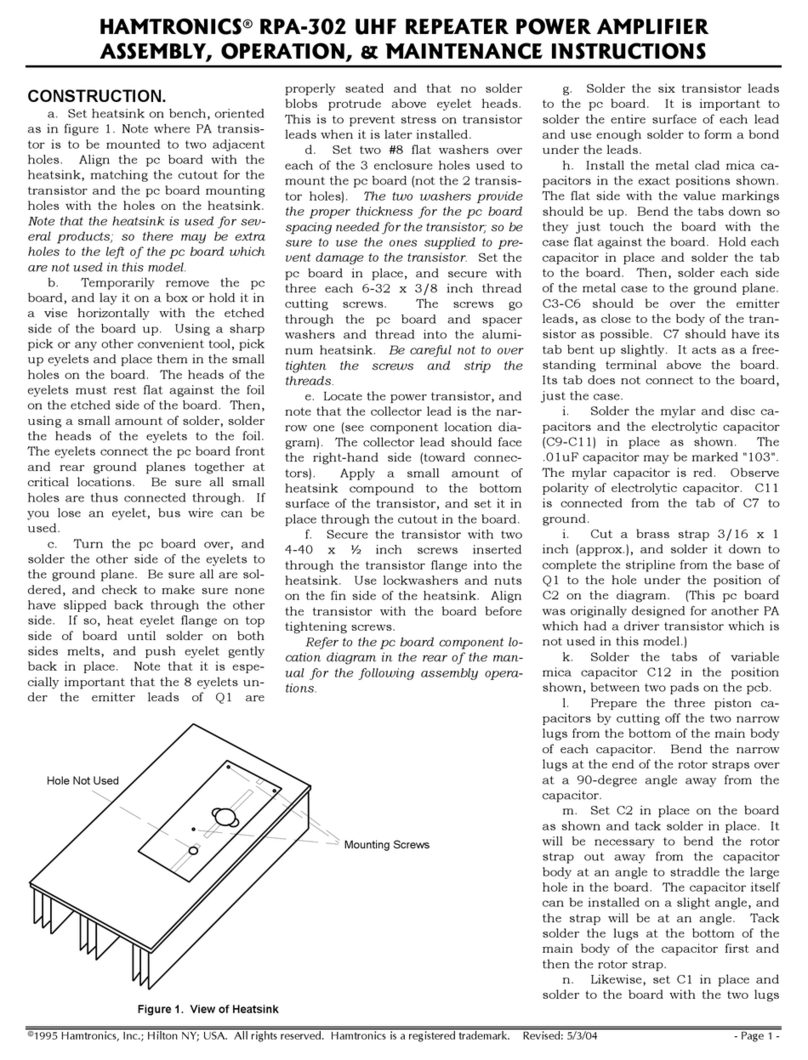

a. If you are supplying your own

enclosure, mark and drill four clear-

ance holes for mounting the board

with 4-40 screws and one 8-32 clear-

ance hole to mount the transistor in

the center of the cutout in the board.

The latter hole must be close to the

diameter of the xstr stud to provide

maximum surface for the shoulder of

the transistor to contact the chassis

for heatsinking; so do not make this

hole oversize.

b. Install four 4-40 x 3/8 inch

screws from the bottom of the enclo-

sure. Place flatwashers as spacers

over the screws, as previously de-

scribed.

c. Set pc board over screws, and

align so cutout for transistor is cen-

tered over hole in enclosure. Secure

the board with 4-40 nuts and lock-

washers.

d. Carefully open the package of

heatsink compound with scissors.

Use a toothpick or small piece of wire

to apply a small amount of compound

to the shoulder of the transistor

where it contacts the heatsink.

e. Set the transistor in place, and

orient the notched collector lead to

the right as shown. Secure transistor

with #8 lockwasher and 8-32 nut. Do

not overtighten nut; tighten only to

the point of being snug. Hold transis-

tor leads with fingers to prevent rota-

tion. If leads still rotate, you are

probably applying too much torque.

Note: Since heatsink compound is

used, it is unnecessary to use a lot of

torque, which could break the stud.

f. Form the transistor leads down

against the board. Then, tack solder

them to the foil, using sufficient sol-

der so that a bond is formed under the

full length of the leads. Note that

other parts will be soldered on top of

the base and collector leads; so it

helps to thoroughly flood those leads

with solder.

g. Cut tabs of variable mica ca-

pacitor C6 and piston variable capaci-

tors C2, C3, C7, and C8 as shown in

the detail on the component location

diagram, and solder them to the board

in the exact positions shown. Doing

so leaves adequate space for coil con-

nections. Mount the capacitors ori-

ented as shown so the rotor screw is

connected to the proper side of the

circuit.

Note: There are two sizes of bus

wire in the kit: #22 is the finest and

#14 is the heaviest.

h. Ferrite choke Z2 is threaded

with 2-1/2 turns of #22 bus wire, as

shown in the detail, by feeding the

wire through opposite holes and pull-

ing tight. One hole will not be used.

Be sure to wind the wire as shown,

not in a zig-zag fashion. The choke is

mounted flat against the pc board, and

the leads are tack soldered to the

board.

i. Tack solder R2 across Z2 as

shown, being careful not to short to

turns on the choke.

j. Install chip capacitors as fol-

lows. Use small tweezers to handle

them. Be careful not to drop them; they

are difficult to find. Since they have no

markings, be sure to leave them in the

package until installed so you can tell

the values apart. Note where capaci-

tors are to be positioned. The chip

capacitors must straddle the area be-

tween the pad and the ground plane,

with one electrode soldered to each.

Apply a little solder to the pads ad-

jacent to the transistor leads where

one end of each capacitor will be posi-

tioned. Do not apply solder to the

ground plane yet.

Pick up one capacitor at a time.

Set the capacitor in place. Then,

heat the solder on the pc board pad,

and allow the solder to bond to the

electrode on the capacitor. When the

solder melts, the capacitor will seat

down on the board in the molten sol-

der. It is essential that this process

be done relatively quickly so the sol-

der doesn't oxidize and so there is still

a little flux left where the capacitor

electrode sits.

After one end of each of the ca-

pacitors is soldered and the positions

have been confirmed to be correct,

solder the ground plane end of each

capacitor.

k. Wind the coils exactly as speci-

fied in the component location dia-

gram, and tack solder them to the

board. Note that all pertinent details

of coil winding are given in the dia-

gram. Any rod of the proper diameter

(such as the shank of a drill bit) can

be used as a forming tool for coil wind-

ing.

HAMTRONICS® LPA 4-10R UHF REPEATER POWER AMPLIFIER