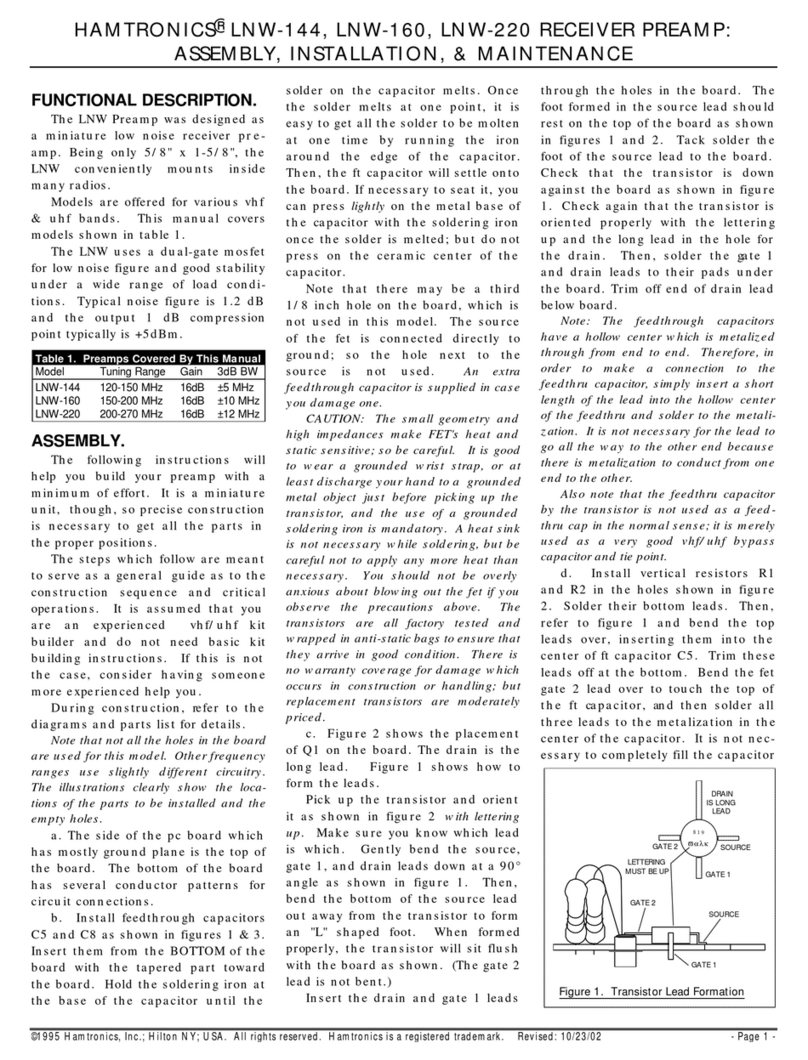

©1995 Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered trademark. Revised: 1/31/00 - Page 2-

leaving the side with the longer di-

mension for the cover screws to en-

gage. Before tightening the screws,

carefully align the angle nuts flush

with the edge of the chassis. After

the angle brackets are installed, you

can set the cover over the heat-

sink/end plate assembly and see if

any minor adjustments are neces-

sary to make the cover screw holes

line up with the angle brackets. It

may be necessary to temporarily

loosen the screws holding the end

plates to the heatsink to realign the

end plates farther apart or closer to-

gether.

i. Install feedthru capacitor C14

from the outside of the end plate as

shown in figure 2. Insert the capaci-

tor through a #8 ground lug, through

the outside of the end plate, and se-

cure with a #8 lockwasher and nut

on the inside. Tighten the nut on

the inside of the assembly with a ¼-

inch nut driver. Be careful not to break

the ceramic by putting force on capacitor

leads, and be careful not to over tighten

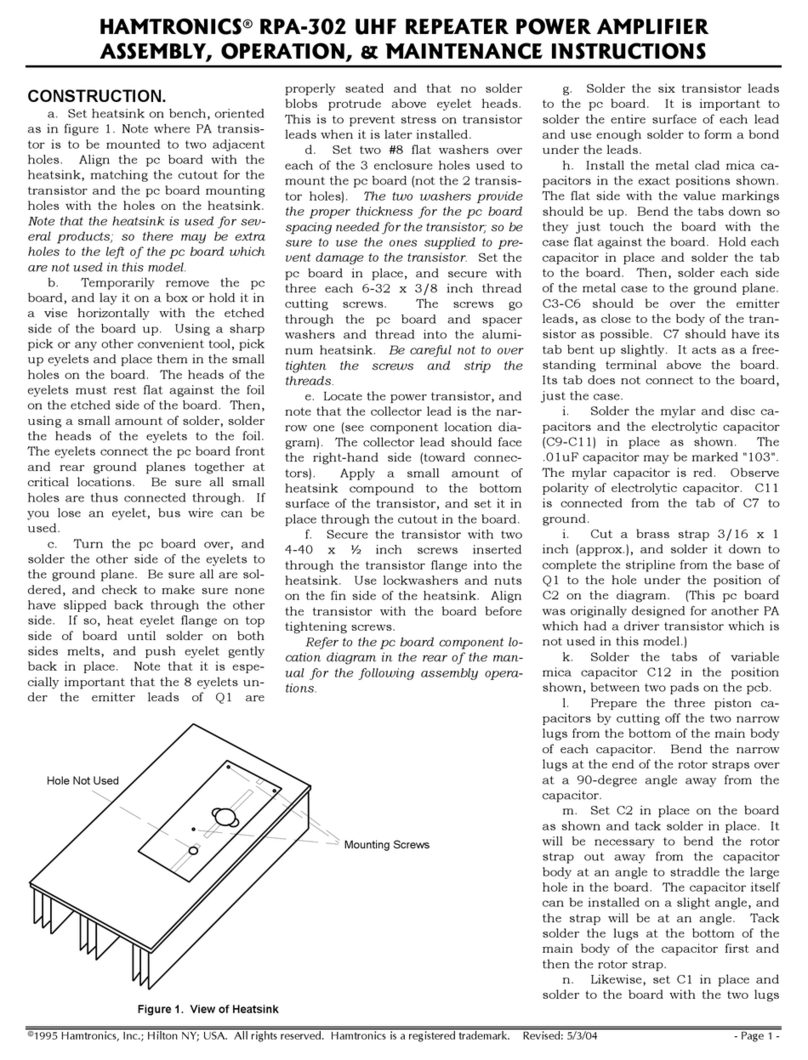

nut.j. Attach two SO-239 or 'N' con-

nectors to the outside of the end

plate, using three 4-40 x 1/4 inch

screws with nuts and one 4-40 x 3/8

inch screw with a ground lug and nut

for each connector. The ground lugs

should be positioned as shown in the

inset in figure 1 so that they are as

close as practical to the center lug of

the connectors.

Refer to the pc board component lo-

cation diagram in the rear of the manual

for the following assembly operations.

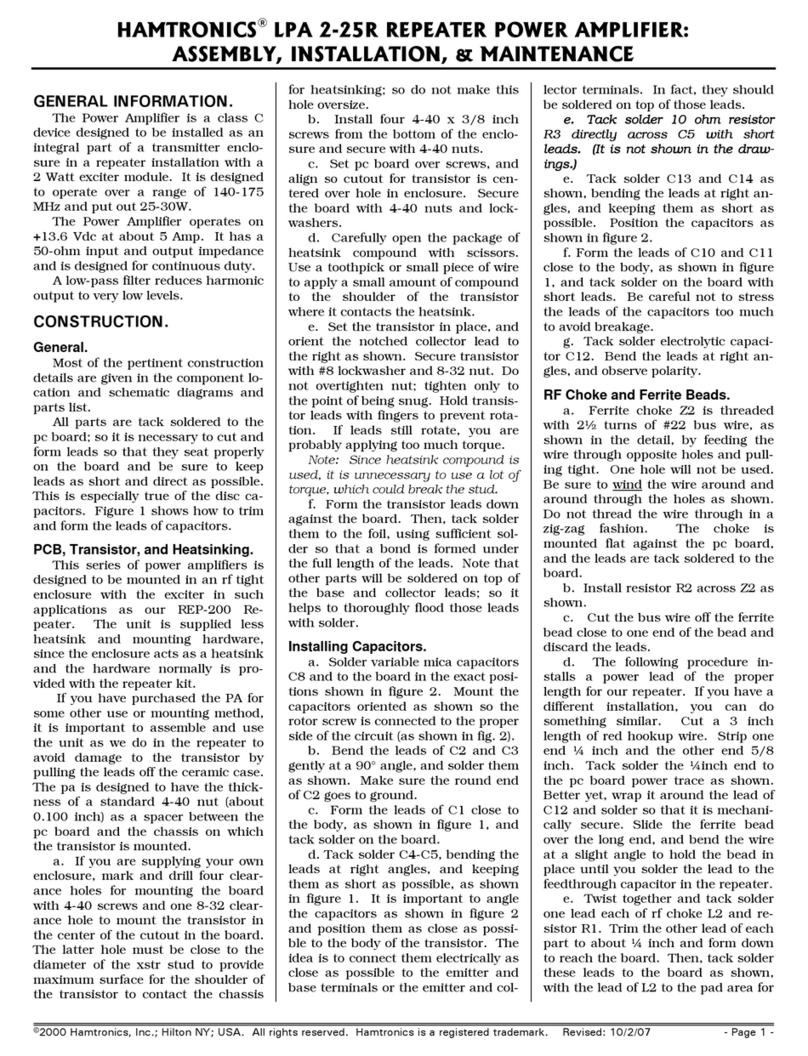

k. Solder the six transistor leads

to the pc board. It is important to

solder the entire surface of each lead

and use enough solder to form a bond

under the leads.

l. Install the metal clad mica ca-

pacitors in the exact positions shown.

The flat side with the value markings

should be up. Bend the tabs down so

they just touch the board with the

case flat against the board. Hold

each capacitor in place and solder

the tab to the board. Then, solder

each side of the metal case to the

ground plane. C3-C6 should be over

the emitter leads, as close to the

body of the transistor as possible. C7

should have its tab bent up slightly.

It acts as a free-standing terminal

above the board. Its tab does not

connect to the board, just the case.

m. Solder the mylar and disc ca-

pacitors and the electrolytic capacitor

(C9-C11) in place as shown. The

.01uF capacitor may be marked

"103". The mylar capacitor is red.

Observe polarity of electrolytic ca-

pacitor. C11 is connected from the

tab of C7 to ground.

n. Cut a brass strap 3/16 x 1

inch (approx.), and solder it down to

complete the stripline from the base

of Q1 to the hole under the position

of C2 on the diagram. (This pc board

was originally designed for another

PA which had a driver transistor

which is not used in this model.)

o. Bend the tabs of variable

mica capacitor C12 as shown, and

solder it in the exact position shown,

on a diagonal from the center contact

of J2 to the end of the collector

stripline. Its leads are bent out away

from the capacitor to reach.

p. Prepare the three piston ca-

pacitors by cutting off the two narrow

lugs from the bottom of the main body

of each capacitor. On C1 and C2,

bend the narrow lugs at the end of

the rotor straps over at a 90-degree

angle away from the capacitor.

q. Set C2 in place on the board

as shown and tack solder in place. It

will be necessary to bend the rotor

strap out away from the capacitor

body at an angle to straddle the large

hole in the board. The capacitor it-

self can be installed on a slight an-

gle, and the strap will be at an angle.

Tack solder the lugs at the bottom of

the main body of the capacitor first

and then the rotor strap.

r. Likewise, set C1 in place and

solder to the board with the two lugs

at the bottom of the body of the ca-

pacitor soldered to the stripline, and

the rotor strap soldered to the ground

plane.

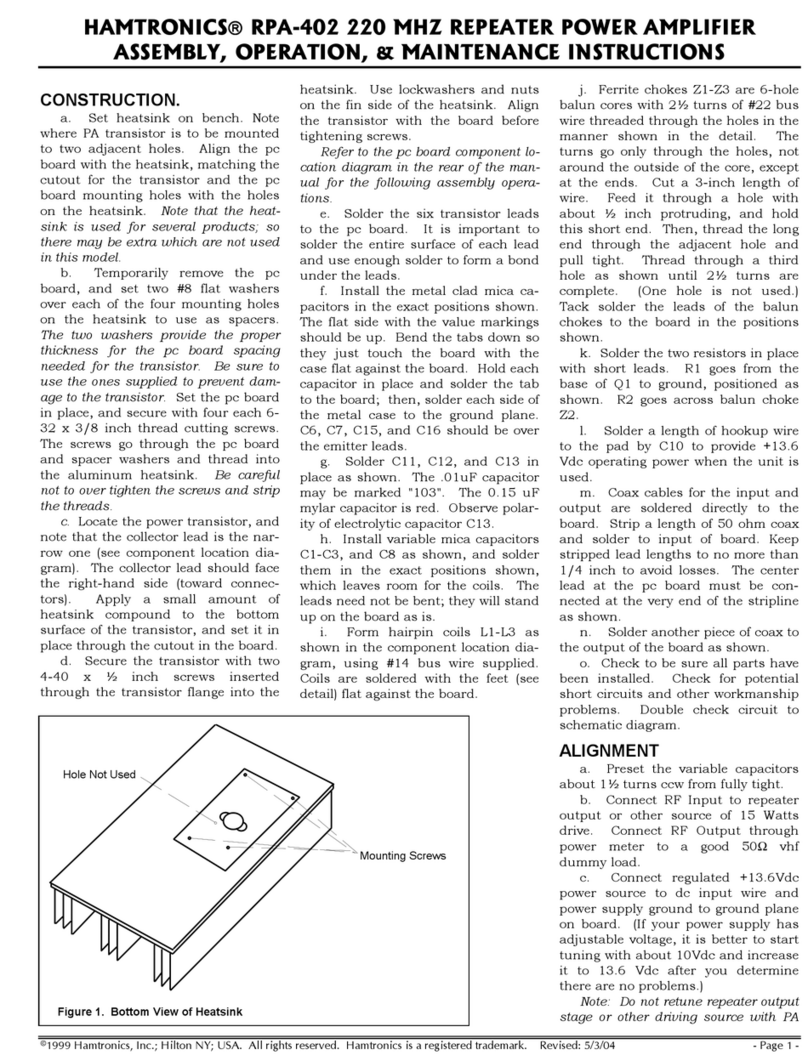

s. Refer to the detail drawing to

the right of C13 in the component lo-

cation drawing. Note that the rotor

strap must be bent up at an angle

away from the body of the capacitor.

The excess should be trimmed off.

Install C13 on the board with the

lugs at the bottom of the body sol-

dered to the ground plane next to the

mounting screw, and the rotor strap,

routed as directly as possible, laying

on top of the lug from C12 above the

connector pin. Tack solder thor-

oughly.

t. Wind coil L1 as shown in the

diagram from #18 bus wire supplied.

It is 1/4 inch inside diameter; so it

can be formed around a 1/4 inch drill

bit or other rod. L1 has three turns

barely spaced. Solder L1 leads from

the tab of C7 to the stripline in the

position shown. The bottom of the

coil should be just above the board.

u. Ferrite chokes Z1 and Z2 are

6-hole balun cores with 1-1/2 turns

of #22 bus wire threaded through the

holes in the manner shown in the

diagram. The turns go only through

the holes, not around the outside of

the core, except at the ends. Cut a

3-inch length of wire. Feed it

through a hole with about 1/2 inch

protruding, and hold this short end.

Then, thread the long end through

the adjacent hole and pull tight.

Thread through a third hole as

shown until 1/1-2 turns are com-

plete. (Three holes are not used.)

Tack solder the leads of the balun

chokes to the board in the positions

shown. One end of Z2 is soldered to

the tab of C7.

v. Solder Z1 in place, with short

leads, from the base of Q1 to ground,

positioned as shown.

w. Strip and solder short length

of hookup wire from B+ land area on

pc board to feedthru capacitor C14.

x. Cut an 8 inch length of

miniature coax. Strip it and solder to

input of board and uhf receptacle J1.

Keep stripped lead lengths to no

more than 1/4 inch to avoid losses.

The center lead at the pc board must

be connected at the very end of the

stripline as shown.

y. Solder a short, direct piece of

3/16 inch wide brass strap from the

ground lug on J2 to the pc board

ground plane directly below J2, as

shown in the diagram. Keep the

strap as short and direct as possible

for low inductance.

z. Cut the leads of a 10pf disc

capacitor to about 1/8 inch. Care-

fully tack solder this capacitor to the

front side of piston capacitor C2 as

shown in the parts location diagram.

aa. Check to be sure all parts

have been installed. Check for po-

tential short circuits and other