©1999 Hamtronics, Inc.; Hilton NY; USA. All ri

hts reserved. Hamtronics is a re

istered trademark. Revised: 12/11/02 - Pa

e 2 -

RF Choke, Ferrite Beads, and Re-

sistors.

a. Ferrite choke Z2 is threaded

with 2½ turns of #22 bus wire, as

shown in the detail, by feeding the

wire through opposite holes and pull-

ing tight. One hole will not be used.

Be sure to wind the wire around and

around through the holes as shown.

Do not thread the wire through in a

zig-zag fashion. The choke is

mounted flat against the pc board,

and the leads are tack soldered to the

board.

b. Install resistor R2 across Z2 as

shown.

c. Cut the bus wire off the ferrite

bead close to one end of the bead and

discard the leads.

d. The following procedure in-

stalls a power lead of the proper

length for our repeater. If you have a

different installation, you can do

something similar. Cut a 3 inch

length of red hookup wire. Strip one

end ¼ inch and the other end 5/8

inch. Tack solder the ¼inch end to

the pc board power trace as shown.

Be careful to apply fresh solder over

the wire so you don't get a cold solder

joint from simply reheating solder al-

ready on the trace. Slide the ferrite

bead over the long end, and bend the

wire at a slight angle to hold the bead

in place until you solder the lead to

the feedthrough capacitor in the re-

peater.

e. Twist together and tack solder

one lead each of rf choke L2 and re-

sistor R1. Trim the other lead of each

part to about ¼ inch and form down

to reach the board. Then, tack solder

these leads to the board as shown,

with the lead of L2 to the pad area for

the base of the transistor and the

lead of R1 to the ground plane.

f. For 220 MHz, install R3 and

R4 with very short leads exactly as

shown. Tack solder to traces and

ground plane.

Coil Forming and Placement.

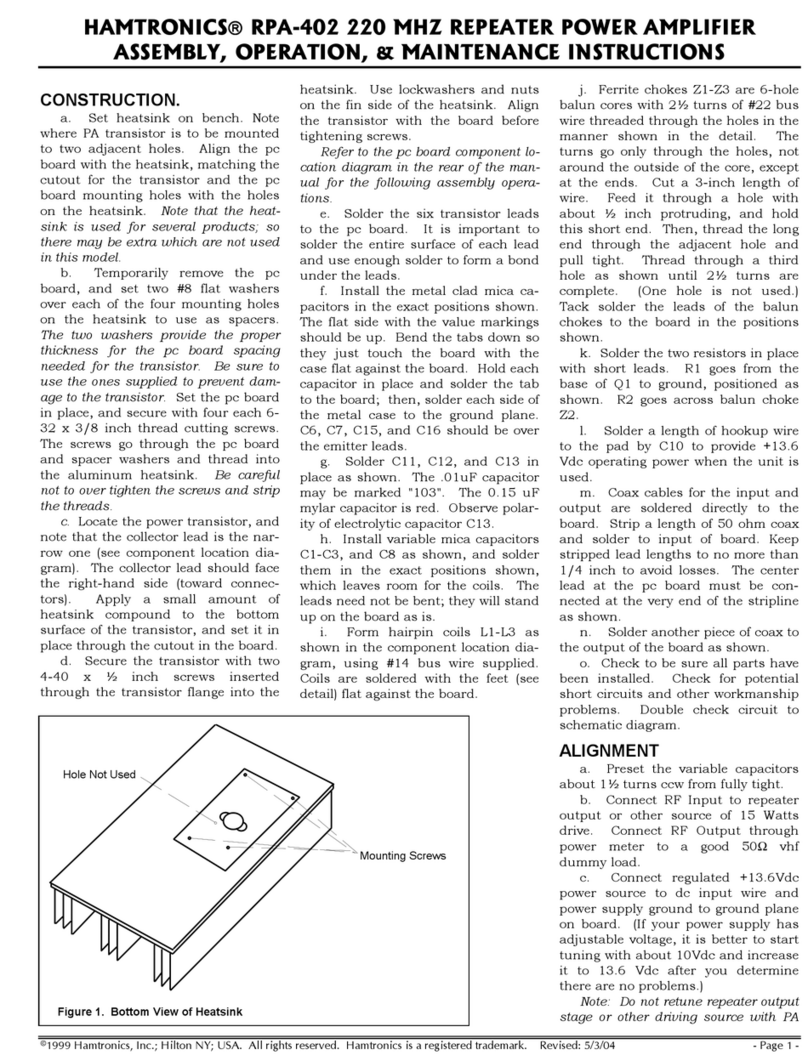

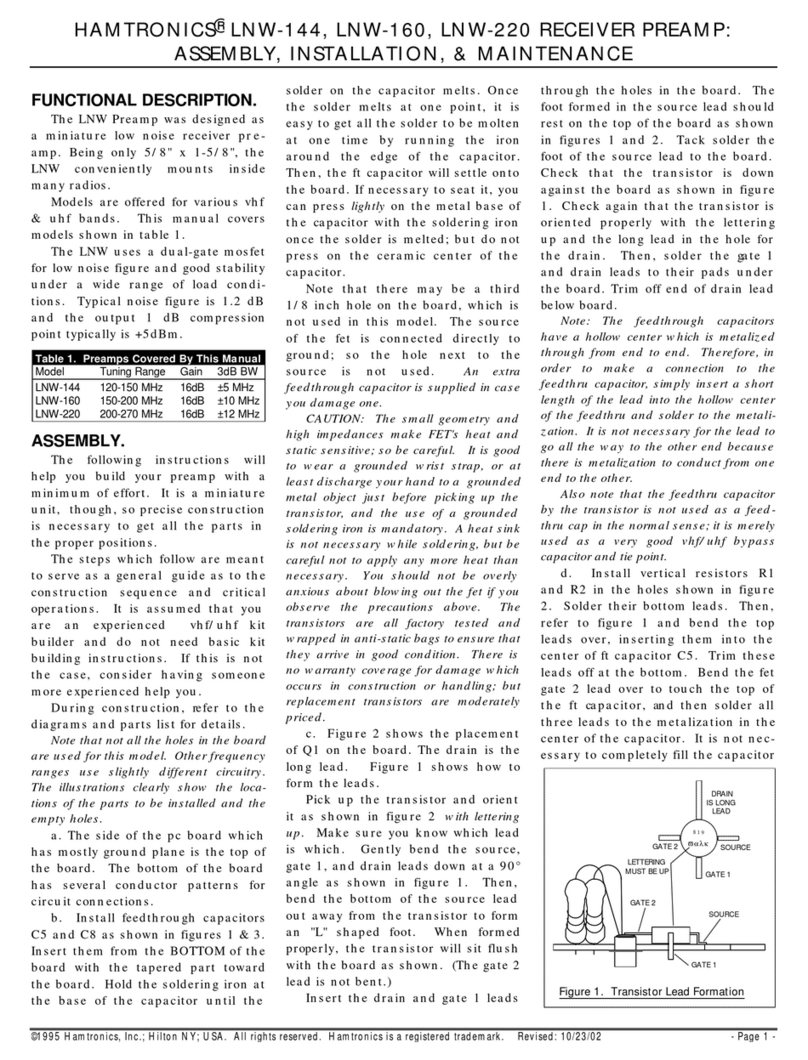

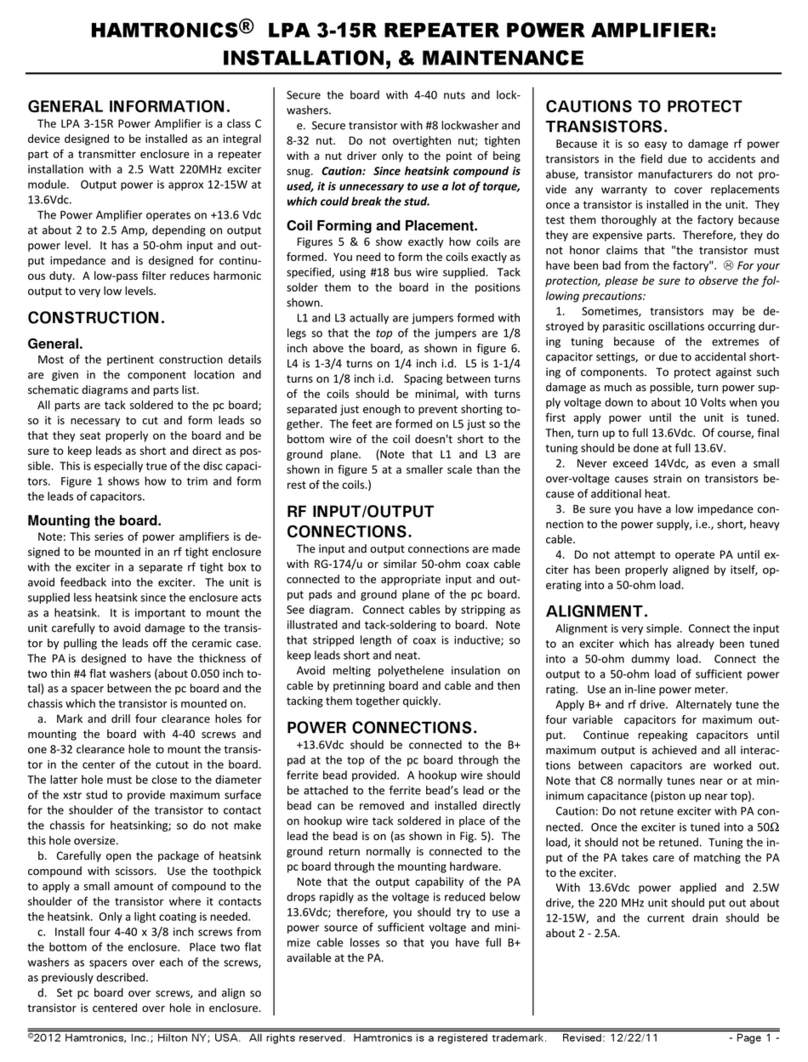

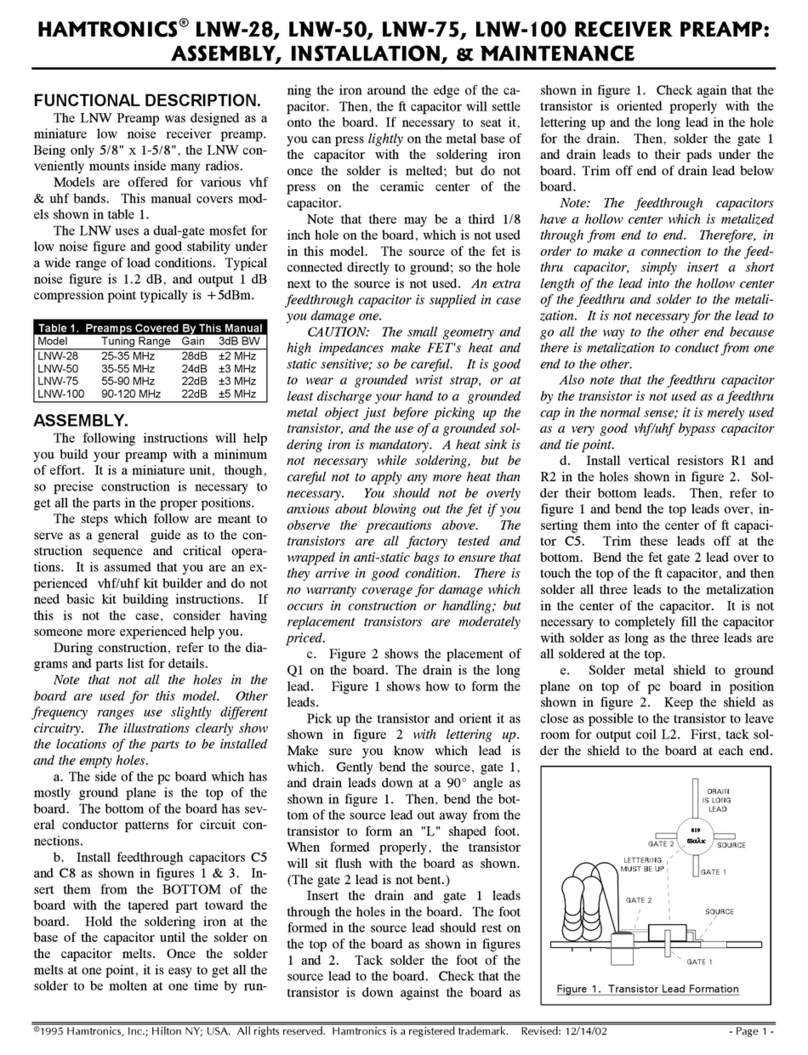

Figures 2 & 3 and 5 & 6 show ex-

actly how coils are formed for the 144

and 220 MHz versions of the PA, re-

spectively. If you have the 6 meter

version, separate drawings are pro-

vided for that unit.

You need to form the coils exactly

as specified, using #18 bus wire sup-

plied. Tack solder them to the board

in the positions shown.

Any rod of the proper diameter

(such as the shank of a drill bit) can

be used as a forming tool for coil

winding. It is important that they not

only be wound the proper inside di-

ameter but that the leads be the

proper length. Any extra lead length

adds to the inductance and will affect

performance. You don't need to be

super precise, but do form them to

resemble the detailed drawings as

closely as you can.

Remember that the finished coils

should fit on the pc traces as shown;

so that will help you check that you

formed the coils properly.

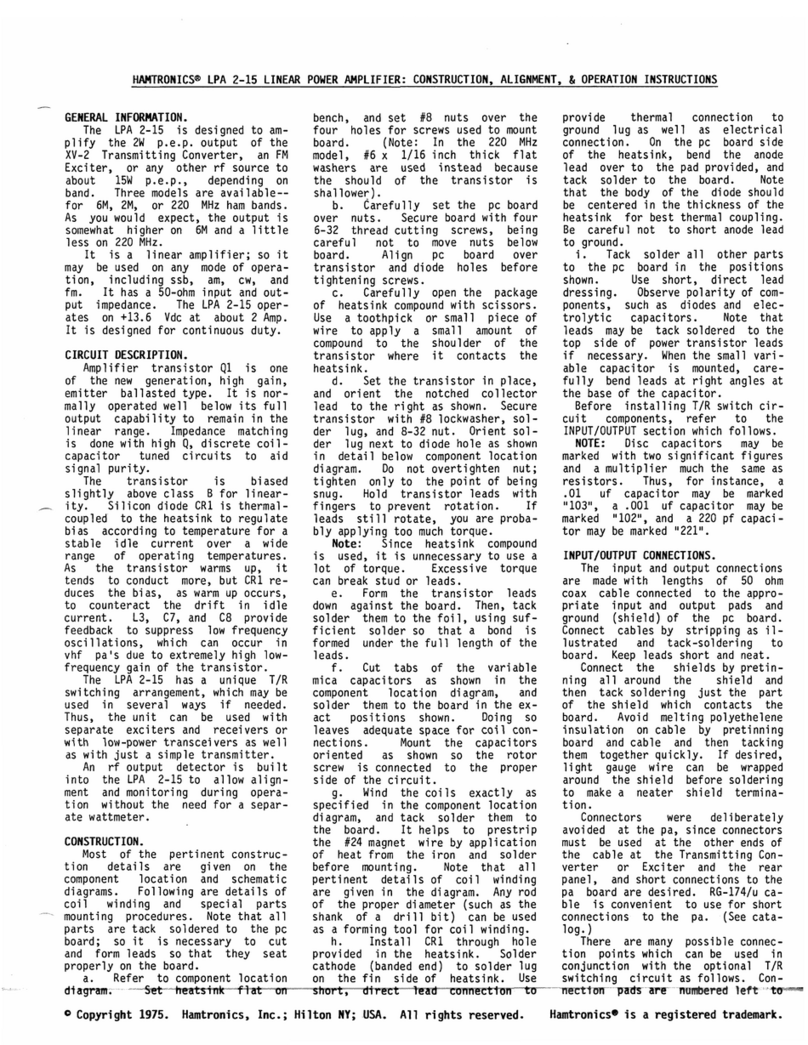

For 144 MHz, the coils are all ei-

ther 1/8 or 1/4 inch inside diameter.

Spacing between turns of the coils

should be minimal, with turns sepa-

rated just enough to prevent shorting

together.

L1 is 1/8 inch i.d. and 1-1/4

turns. The feet are formed just so the

bottom wire of the coil doesn't short

to the ground plane. The feet should

be only about 1/16 inch high. The

other three coils are 1/4 inch i.d. L3

is 1-1/4 turns. L4 is 3-3/4 turns.

L5 is 1-3/4 turns.

For 220 MHz, L1 and L3 actually

are jumpers formed with legs so that

the top of the jumpers are 1/8 inch

above the board, as shown in figure

6. L4 is 1-3/4 turns on 1/4 inch i.d.

L5 is 1-1/4 turns on 1/8 inch i.d.

Spacing between turns of the coils

should be minimal, with turns sepa-

rated just enough to prevent shorting

together. The feet are formed on L5

just so the bottom wire of the coil

doesn't short to the ground plane.

(Note that L1 and L3 are shown in

figure 5 at a smaller scale than the

rest of the coils.)

Inspection.

This completes assembly. Check

to be sure all parts are installed ac-

cording to parts list. Look for any

short circuits or bad solder joints. RF

power transistors are expensive to re-

place; so now is the time to find prob-

lems, before power is applied.

RF INPUT/OUTPUT

CONNECTIONS.

The input and output connections

are made with RG-174/u 50-ohm

coax cable connected to the appro-

priate input and output pads and

ground plane of the pc board.

The following lengths assume that

PA will be installed in REP-200 Re-

peater. The input cable should be 5½

inches long and the output cable

should be 3 inches long, measured

before stripping the ends.

Connect cables by stripping and

tack-soldering to board as illustrated.

Note that stripped length of coax is

inductive; so keep pigtail leads as

short as possible.

Connect the shields by pretinning

the shield and then tack soldering

the end which contacts the board.

Avoid melting polyethylene insulation

on cable by pretinning board and ca-

ble and then tacking them together

quickly.

POWER CONNECTIONS.

+13.6Vdc should be connected to

the B+ pad at the top of the pc board.

When installed in an REP-200 Re-

peater, a hookup wire should be at-

tached to the B+ pad as shown, using

a ferrite bead on the far end, which

attaches to the feedthrough capacitor

in the PA compartment. The ground

return normally is connected to the

pc board through the mounting

hardware.

The cable should be #18 or larger

wire to minimize voltage drop. A 6

Amp, quick acting fuse should be

connected in the positive supply line

for protection.

A well regulated power supply

should be used. Current drain of the

PA at full output is about 4 to 5 Amp,

sometimes slightly higher (but no

more than 6 Amp), depending on

power level.

Note that the output capability of

the PA drops rapidly as the voltage is

reduced below 13.6Vdc; therefore,

you should try to use a power source

of sufficient voltage and minimize ca-

ble losses so that you have full B+

available at the PA.

CAUTIONS TO PROTECT

TRANSISTORS.

Because it is so easy to damage rf

power transistors in the field due to

accidents and abuse, transistor

manufacturers do not provide any

warranty to cover replacements once

a transistor is installed in the unit.

They test them thoroughly at the fac-

tory because they are expensive

parts. Therefore, they do not honor

claims that "the transistor must have

been bad from the factory". /For

your protection, please be sure to ob-

serve the following precautions:

1. Sometimes, transistors may be

destroyed by parasitic oscillations oc-

curring during tuning because of the

extremes of capacitor settings, or due

to accidental shorting of components.

To protect against such damage as