©1995 Hamtronics, Inc.; Hilton NY; USA. All rights reserved. Hamtronics is a registered t

FUNCTIONAL DESCRIPTION.

The LNW Preamp was designed as

a miniature low noise receiver pre-

amp. Being only 5/8" x 1-5/8", the

LNW conveniently mounts inside

many radios.

Models are offered for various vhf

& uhf bands. This manual covers

models shown in table 1.

The LNW uses a dual-gate mosfet

for low noise figure and good stability

under a wide range of load condi-

tions. Typical noise figure is 1.2 dB

and the output 1 dB compression

point typically is +5dBm.

Table 1. Preamps Covered By This Manual

Model Tuning Range Gain 3dB BW

LNW-144 120-150 MHz 16dB ±5 MHz

LNW-160 150-200 MHz 16dB ±10 MHz

LNW-220 200-270 MHz 16dB ±12 MHz

ASSEMBLY.

The following instructions will

help you build your preamp with a

minimum of effort. It is a miniature

unit, though, so precise construction

is necessary to get all the parts in

the proper positions.

The steps which follow are meant

to serve as a general guide as to the

construction sequence and critical

operations. It is assumed that you

are an experienced vhf/uhf kit

builder and do not need basic kit

building instructions. If this is not

the case, consider having someone

more experienced help you.

During construction, refer to the

diagrams and parts list for details.

Note that not all the holes in the board

are used for this model. Other frequency

ranges use slightly different circuitry.

The illustrations clearly show the loca-

tions of the parts to be installed and the

empty holes.

a. The side of the pc board which

has mostly ground plane is the top of

the board. The bottom of the board

has several conductor patterns for

circuit connections.

b. Install feedthrough capacitors

C5 and C8 as shown in figures 1 & 3.

Insert them from the BOTTOM of the

board with the tapered part toward

the board. Hold the soldering iron at

the base of the capacitor until the

solder on the capacitor melts. Once

the solder melts at one point, it is

easy to get all the solder to be molten

at one time by running the iron

around the edge of the capacitor.

Then, the ft capacitor will settle onto

the board. If necessary to seat it, you

can press lightly on the metal base of

the capacitor with the soldering iron

once the solder is melted; but do not

press on the ceramic center of the

capacitor.

Note that there may be a third

1/8 inch hole on the board, which is

not used in this model. The source

of the fet is connected directly to

ground; so the hole next to the

source is not used. An extra

feedthrough capacitor is supplied in case

you damage one.

CAUTION: The small geometry and

high impedances make FET's heat and

static sensitive; so be careful. It is good

to wear a grounded wrist strap, or at

least discharge your hand to a grounded

metal object just before picking up the

transistor, and the use of a grounded

soldering iron is mandatory. A heat sink

is not necessary while soldering, but be

careful not to apply any more heat than

necessary. You should not be overly

anxious about blowing out the fet if you

observe the precautions above. The

transistors are all factory tested and

wrapped in anti-static bags to ensure that

they arrive in good condition. There is

no warranty coverage for damage which

occurs in construction or handling; but

replacement transistors are moderately

priced.

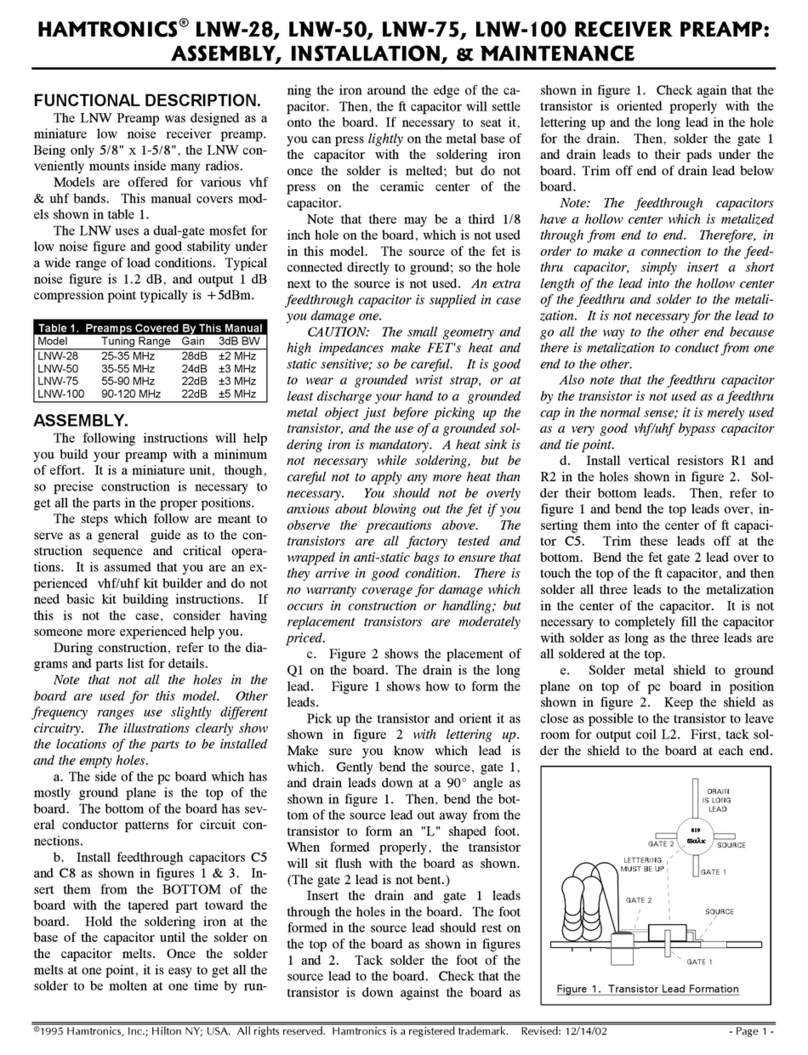

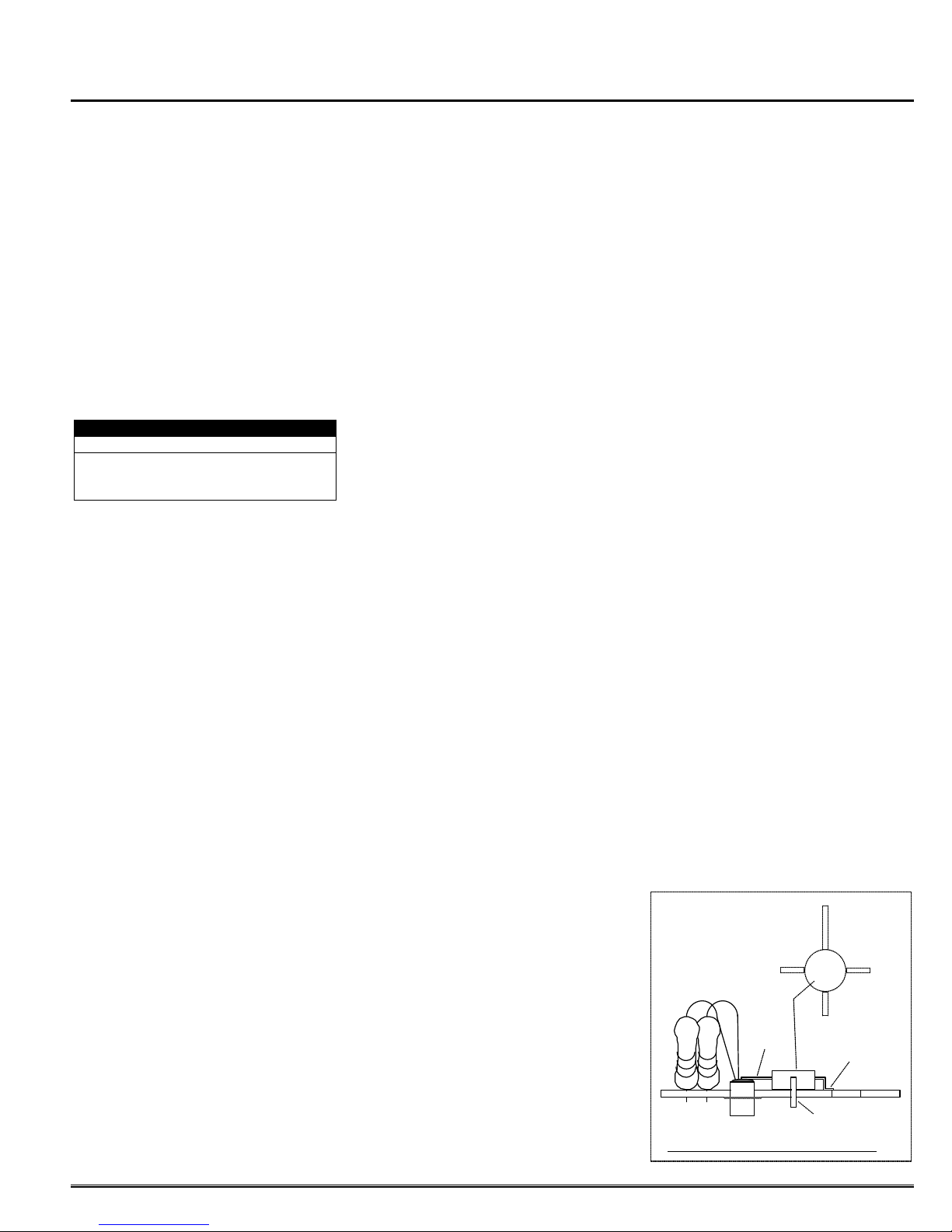

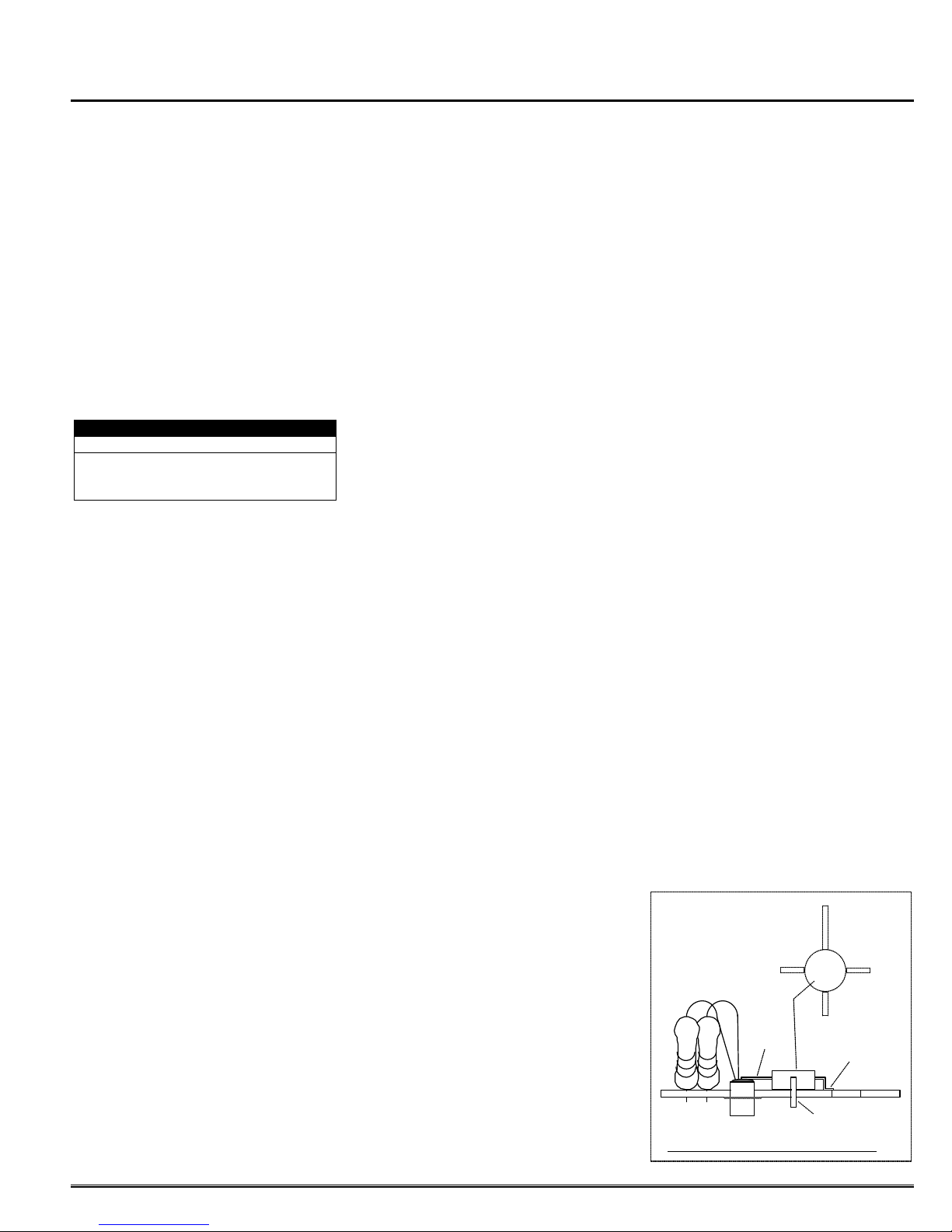

c. Figure 2 shows the placement

of Q1 on the board. The drain is the

long lead. Figure 1 shows how to

form the leads.

Pick up the transistor and orient

it as shown in figure 2 with lettering

up. Make sure you know which lead

is which. Gently bend the source,

gate 1, and drain leads down at a 90°

angle as shown in figure 1. Then,

bend the bottom of the source lead

out away from the transistor to form

an "L" shaped foot. When formed

properly, the transistor will sit flush

with the board as shown. (The gate 2

lead is not bent.)

Insert the drain and gate 1 leads

through the holes in the board. The

foot formed in the source lead should

rest on the top of the board as shown

in figures 1 and 2. Tack solder the

foot of the source lead to the board.

Check that the transistor is down

against the board as shown in figure

1. Check again that the transistor is

oriented properly with the lettering

up and the long lead in the hole for

the drain. Then, solder the gate 1

and drain leads to their pads under

the board. Trim off end of drain lead

below board.

Note: The feedthrough capacitors

have a hollow center which is metalized

through from end to end. Therefore, in

order to make a connection to the

feedthru capacitor, simply insert a short

length of the lead into the hollow center

of the feedthru and solder to the metali-

zation. It is not necessary for the lead to

go all the way to the other end because

there is metalization to conduct from one

end to the other.

Also note that the feedthru capacitor

by the transistor is not used as a feed-

thru cap in the normal sense; it is merely

used as a very good vhf/uhf bypass

capacitor and tie point.

d. Install vertical resistors R1

and R2 in the holes shown in figure

2. Solder their bottom leads. Then,

refer to figure 1 and bend the top

leads over, inserting them into the

center of ft capacitor C5. Trim these

leads off at the bottom. Bend the fet

gate 2 lead over to touch the top of

the ft capacitor, and then solder all

three leads to the metalization in the

center of the capacitor. It is not nec-

essary to completely fill the capacitor

HAMTRONICS

LNW-144, LNW-160, LNW-220 RECEIVER PREAMP:

ASSEMBLY, INSTALLATION, & MAINTENANCE

GATE 1

SOURCE

GATE 2

Figure 1. Transistor Lead Formation

LETTERING

MUST BE UP

GATE 2 SOURCE

GATE 1

DRAIN

IS LONG

LEAD

ϖαλκ

819