©1998 Hamtronics, Inc.; Hilton NY; USA. All ri

hts reserved. Hamtronics is a re

istered trademark. Revised: 12/11/02 - Pa

e 2 -

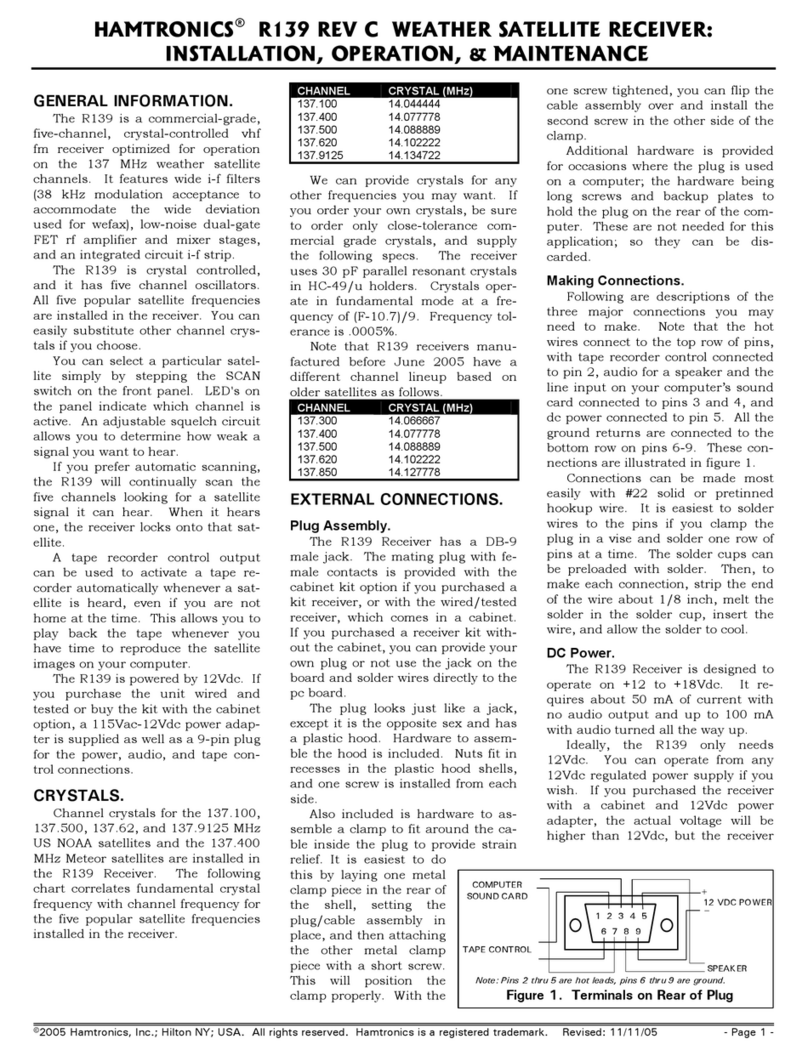

Antenna Connections.

The antenna connection should be

made to the receiver with an RCA plug

of the low-loss type made for rf. We

have them available if you need one.

If you want to extend the antenna

connection to a panel connector, we

recommend using a short length of

RG-174/u coax and a good RCA plug

with cable clamp (see catalog).

We do not recommend trying to

use direct coax soldered to board or

another type of connector. The

method designed into the board re-

sults in lowest loss practical. When

soldering the cable, keep the stripped

ends as short as possible.

0We recommend you always use

antennas with a matching network

which provides a dc ground on the

driven element. This reduces chances

of static buildup damaging the input

stage of the receiver as well as provid-

ing safety for the building and other

equipment.

OPTIONS.

Repeater Use.

E5 provides a COS (carrier oper-

ated switch) output which may be

connected to a COR module to turn a

transmitter on and off. The output

level is about 8V unsquelched and 0V

squelched. There is a resistor in se-

ries with the output to limit current.

Therefore, the voltage that appears at

the COR board will depend on the

load resistance at the input of that

board. For best results, be sure that

the input resistance of the COR board

is at least 47K. If the input resistance

is too low, no damage to the receiver

will occur; but the squelch circuit hys-

teresis will be affected.

If your repeater controller uses

discriminator audio, rather than the

speaker output, filtered discriminator

audio is available at E4. The level is

about 2V p-p. Note that discriminator

audio is not de-emphasized or

squelched. If you need audio which is

squelched, take it from Repeater Au-

dio terminal E1.

If your controller uses low level

audio and has a high input imped-

ance (20K or higher), squelched audio

can be obtained from E1 independent

of the VOLUME control.

Discriminator Meter.

If you wish to use a discriminator

meter and you are handy in designing

with op-amps, you can run a sample

of the dc voltage at DISCRIMINATOR

output terminal E4 to one input of an

op-amp and tie the other input to a

voltage divider pot set to provide a ref-

erence voltage of about +3.3Vdc.

S-Meter.

There is no s-meter function, as

such, available in i-f amplifier ic's

made for professional receivers; how-

ever, a signal strength indication is

available at test point TP-5. This volt-

age is a function of the noise level de-

tected in the squelch circuit. It also

varies with SQUELCH control setting.

With the SQUELCH set to where the

squelch just closes, the dc voltage at

TP-5 is about -0.5V with no signal

and +0.75 with full quieting signal.

You can tap off this test point with a

high-impedance circuit, such as an

op-amp, to drive a meter or a comput-

erized repeater controller.

Subaudible Tone Decoder.

To use our TD-5 Subaudible Tone

Decoder or a similar module, connect

its audio input to DISCRIMINATOR ter-

minal E4. If you want to use it to

mute the audio (instead of inhibiting a

repeater transmitter as is normally

done), connect the mute output of the

TD-5 to E1 on the receiver.

ADJUSTMENTS.

Frequency Netting.

All crystals age a little over a long

period of time; so it is customary to

tweak any receiver back onto the pre-

cise channel frequency once a year

during routine maintenance. This ad-

justment is called “netting”, which is a

term going back to days when all sta-

tions on a network would initially ad-

just their VFOs to all be on the same

exact frequency before operating as a

net.

Because modern solid state

equipment doesn’t require much rou-

tine maintenance, many receivers

don’t get their oscillators tweaked as a

matter of routine any more, but they

should.

The adjustment should be done

using an accurate service monitor or

frequency counter. Of course, make

sure the test equipment is exactly on

frequency first by checking it against

WWV or another frequency standard.

The channel frequency is trimmed

precisely on frequency with a small

variable capacitor, which is accessible

through a hole in the top of the shield

can on the TCXO. The proper tool is a

plastic wand with a small metal bit in

the end. (See A2 Alignment Tool in

our catalog.)

To perform this adjustment, it is

first necessary to verify that the dis-

criminator is properly adjusted. Do

this by connecting a dc voltmeter to

TP6. Connect a signal generator set

for 10.700 MHz to TP4, and set the

level for a relatively strong signal so

there is very little white noise. Adjust

discriminator coil T2 for 3.3Vdc.

Then, reconnect the signal generator

to antenna connector J1, and set it for

the precise channel frequency. You

can also use a strong signal on the air

if you are sure it is right on frequency.

Adjust the TCXO capacitor for 3.3Vdc

(to match the voltage obtained with

the 10.700 MHz signal).

Setting Channel Frequency.

The channel frequency is deter-

mined by frequency synthesizer cir-

cuits, which use a dip switch in

conjunction with programming in a

microcontroller to set the channel.

The microcontroller reads the dip

switch information and does mathe-

matics, applying serial data to the

synthesizer ic whenever power is ap-

plied. Following is a discussion of

how to set the dip switch to the de-

sired channel frequency.

☞

☞☞

☞NOTE: If the frequency is

changed more than about 1 MHz, a

complete alignment of the receiver

should be performed, as described in

later text. Optimum operation only oc-

curs if the synthesizer is adjusted to

match the frequency switch setting and

all the tuned amplifier circuits are

peaked for the desired frequency.

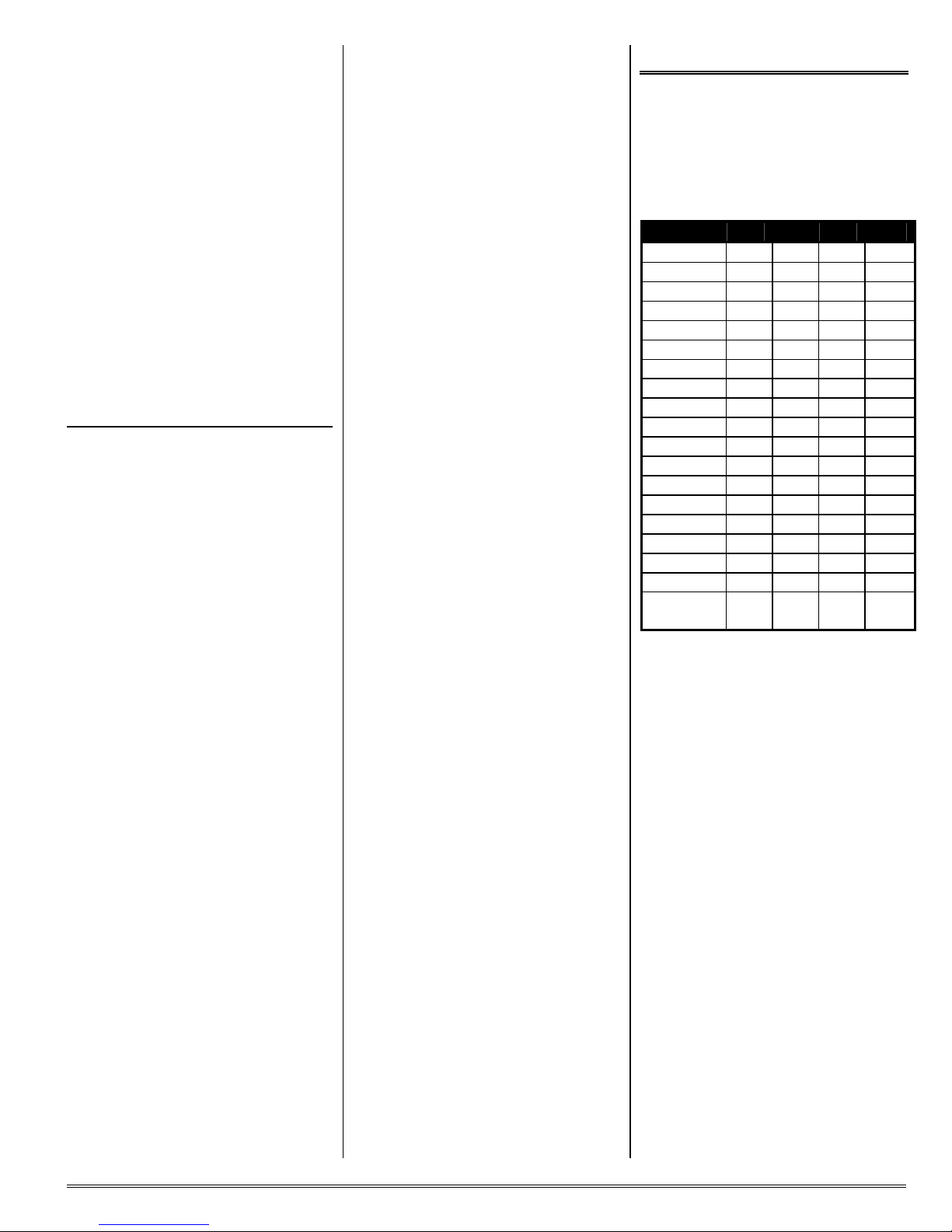

To determine what channel fre-

quency to use, the microcontroller

adds the frequency information from

the dip switch to a “base” frequency

stored in eprom used for microcontrol-

ler programming. Each model of the

R301 Receiver has a particular base

frequency. For example, the R301-2

has a base frequency of 144.000 MHz,

as shown in Table 1.

Dip switch settings are binary,

which means each switch section has

a different weighting, twice as great as

the next lower section. Sections have

weights such as 5 kHz, 10 kHz, etc.,

all the way up to 2.56 MHz. (See Ta-

ble 2 or the schematic diagram for

switch values.) For very large incre-

ments, there is even a jumper which

can be added to the board between E6

and E7 for a 5.12 MHz increment, al-

though this is rarely used.

The system sounds cumbersome,

but it really is fairly simple, and you

don’t need to do this frequently. A