H&H AI-002 User manual

www.hh.com.hk

t = 852.24813068

f = 852.24813727

Room 1117, 11/F, Asia Trade Centre, 79 Lei Muk Road, Kwai Chung, N.T., Hong Kong

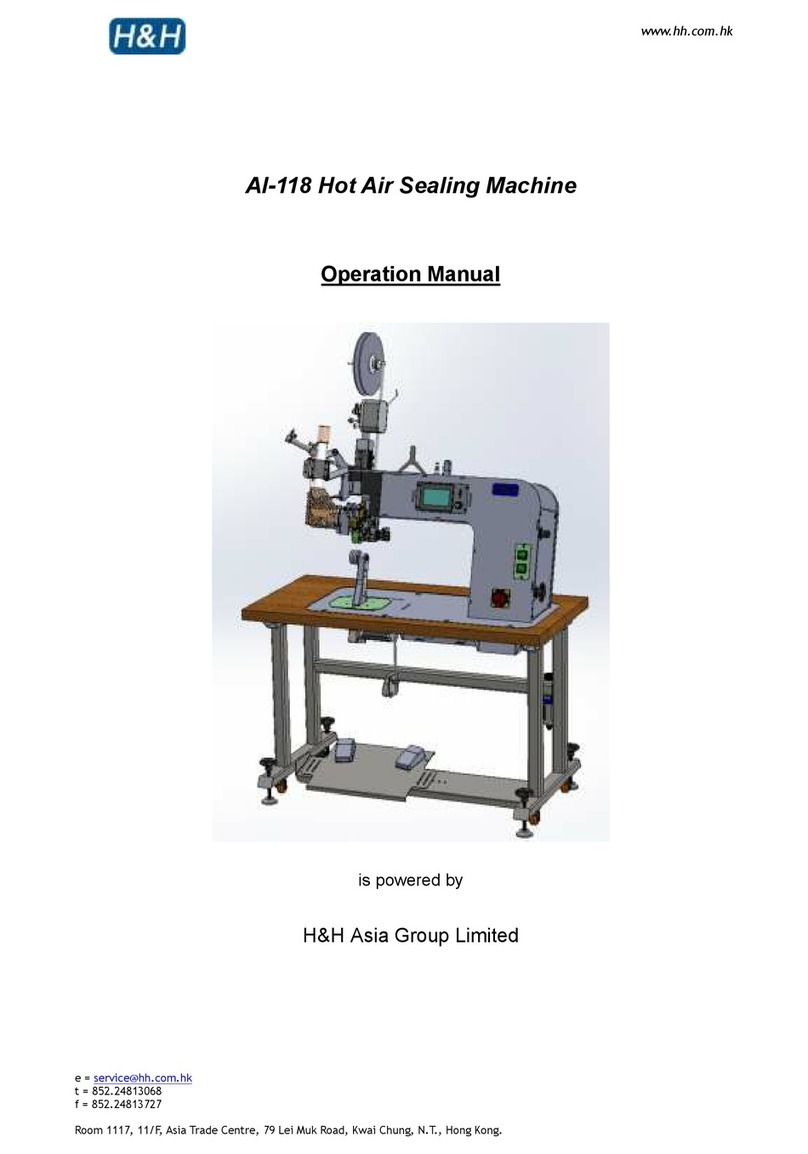

AI-002 Hot Air Sealing Machine

Operation Manual

is powered by

H&H Asia Group Limited

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 1 of 59

Table of Content

> Precautions Regarding to Safety..........................................................................................3

> Name Plate...................................................................................................................................5

> Introduction.................................................................................................................................6

> Specifications.............................................................................................................................7

> Features .......................................................................................................................................8

> Identification of Components.................................................................................................9

>> Front View .........................................................................................................................9

>> Cutter Assembly............................................................................................................10

>> Heater Positioning Assembly (front)........................................................................10

>> Heater Positioning Assembly (rear) .........................................................................11

>> Touch Screen Control Panel & Pressure Adjustment Panel .............................12

> Principle of Seam Sealing.....................................................................................................13

> Preparation for Installation ...................................................................................................14

> Control Method.........................................................................................................................15

>> Touch Screen Control Panel ......................................................................................15

>> Foot Switch.....................................................................................................................15

>> Control Menu Navigation ............................................................................................16

>> Pressure Adjustment....................................................................................................19

> Start Up and Shut Down Procedures .................................................................................20

>> Start up Procedures......................................................................................................20

>> Shut down Procedures................................................................................................23

> Basic Operation .......................................................................................................................24

>> Procedures of Seam Sealing......................................................................................25

>> Tape Cutting....................................................................................................................25

>> Tape Loading..................................................................................................................26

>> Nozzle...............................................................................................................................27

> Advance Operation .................................................................................................................28

>> Personality 1...................................................................................................................29

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 2 of 59

>> Advance Mode................................................................................................................30

>> Differential Speed..........................................................................................................31

>> Electronic Nozzle Position Adjustment...................................................................32

>> Memory ............................................................................................................................34

>> Individual Program for Start/ Middle/ End of Tape ...............................................35

>> Digital Tensioner............................................................................................................36

>> Alarm.................................................................................................................................37

> Maintenance..............................................................................................................................38

>> Preventative....................................................................................................................38

>> Procedures for Replacing Parts................................................................................39

> Trouble Shooting.....................................................................................................................41

Appendix A . Nozzle Air Flow Cross Reference Table.......................................................42

Appendix B . Penumatic Scheme...........................................................................................43

Appendix C . Wiring Scheme...................................................................................................44

Appendix D . Tape Start, Tape Middle, Tape End Parameters.........................................45

> Tape Start Program .........................................................................................................45

> Tape Middle Program......................................................................................................51

> Tape End Program...........................................................................................................56

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 3 of 59

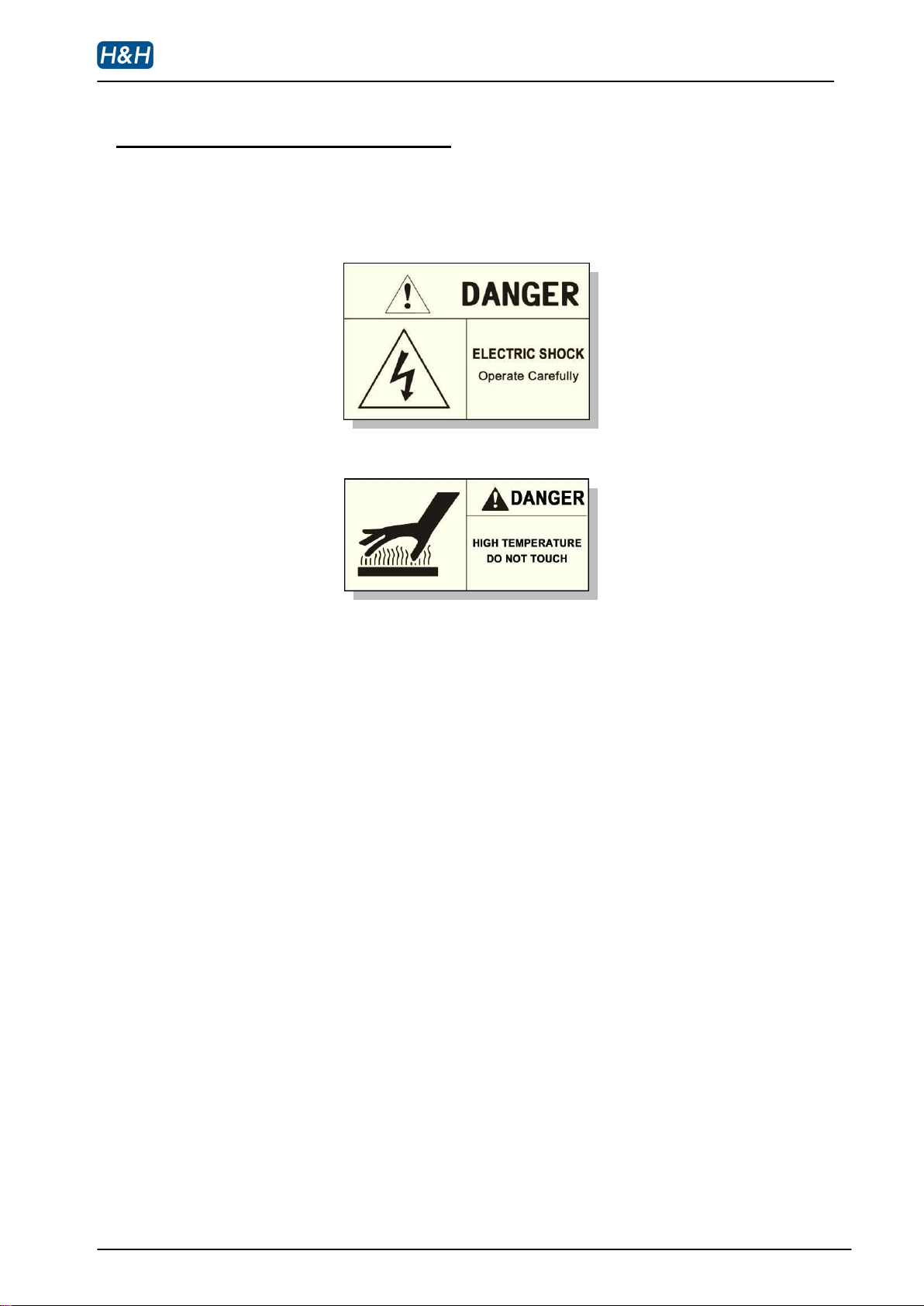

> Precautions Regarding to Safety

Please observe these safety tips for a safe, efficient, and injury free operation of your equipment. By

strictly following all instructions contained in this manual you will certainly obtain an excellent

performance from the use of this equipment for many years.

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 4 of 59

> Precautions Regarding to Safety (cont.)

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 5 of 59

> Name Plate

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 6 of 59

> Introduction

Thank you for choosing AI-002 hot air sealing machine by H&H.

The hot air sealing machine described in this manual is one of the most sophisticated machines in the

market today. Built on pure digital platform and designed for the professional users, AI-002

incorporated many new features that makes seam sealing much easier than before. Operators are

recommended to have basic knowledge and skill in seam sealing operation before using this machine.

In order to fully understand how to use this machine properly, and avoid damage to both the machine

and operating personnel, please read this manual carefully and keep it safe for future reference.

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 7 of 59

> Specifications

Model : AI-002

Voltage : AC 220 V

Frequency : 50/60 Hz

Power Consumption : 3600 W

Compressed Air : 0.4- 0.6 Mpa

Air Consumption : 100 L/min max

Sealing Speed : 1-28, 36–60 ft/min

Nozzle Temperature : 50 C –800 C

Nozzle Unit : 22.0 mm standard, other optional

Upper Roller Width : 25.4 mm

Lower Roller Width : 31.0 mm

Overall Dimensions : 1200 mm (L) x 660 mm (W) x 1800 mm (H)

Overall Weight : 130 kg

Note : due to continuous improvement, specifications are subjected to change without prior

notification

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 8 of 59

> Features

Real time variable speed sealing for non-stop long seam, ideal for narrow tape running on curve

as well as improving waterproof on crossed seam.

Differential speed for top and bottom rollers, ideal for reducing stretch fabric puckering.

Electronic nozzle positioning adjustment by control panel entries, ensuring 100% repeatability.

“Remember” function to store multi-nozzle position to be recall at a later time.

Digital tape length counter, ideal for costing calculation.

Multi-function foot pedal for easy one-footed control operation.

Multi-lingual support for touch screen display interface.

Heat press emulator function to simulate the function of heat press machine

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 9 of 59

> Identification of Components

>> Front View

1

3

4

5

6 7

8

2

9

10

1. tape spool

2. tape dispenser

3. heater

4. upper roller

5. lower roller

6. left foot pedal

7. right foot pedal

8. water filter assembly

9. power switch

10. emergency stop switch

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 10 of 59

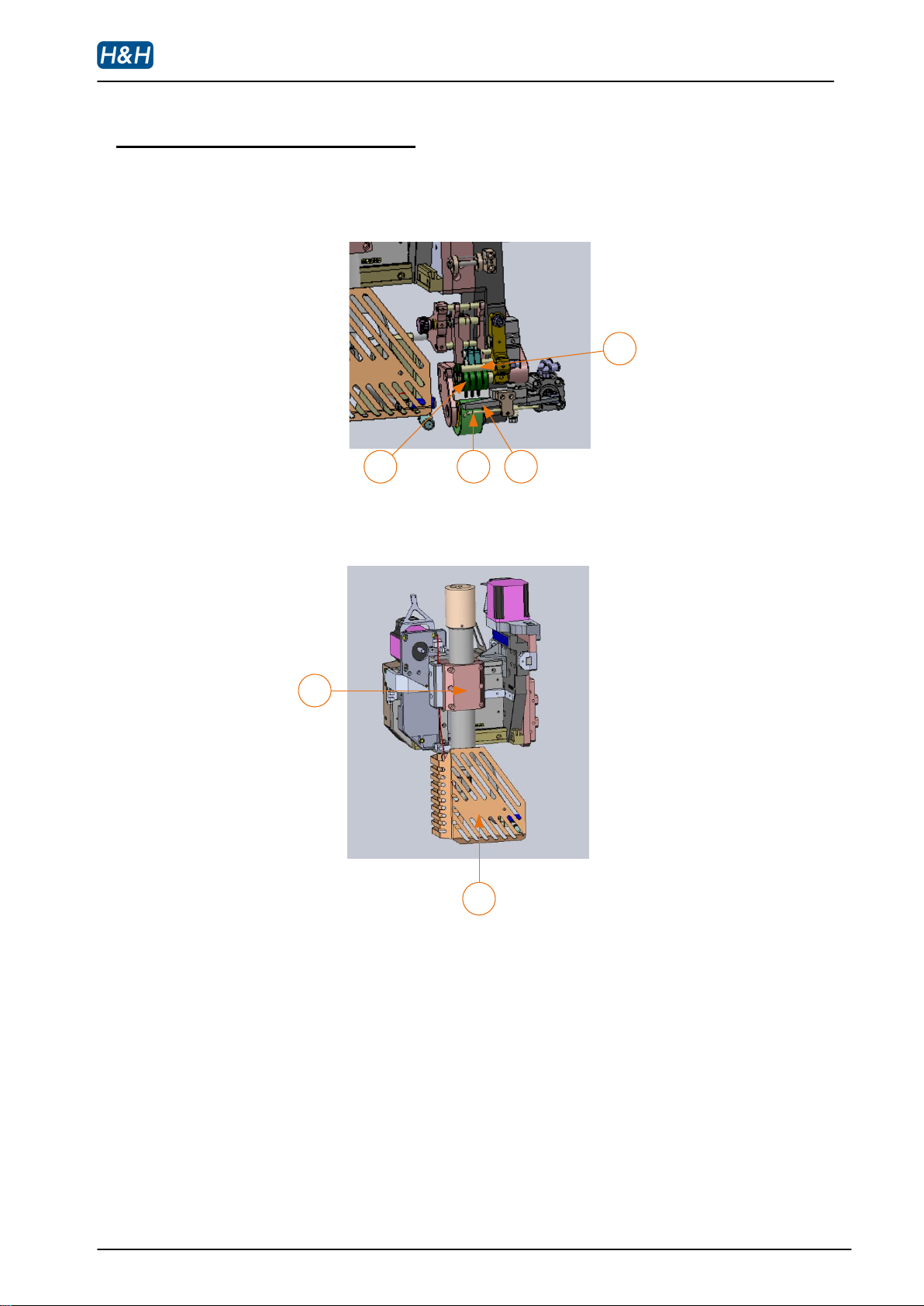

> Identification of Components (cont.)

>> Cutter Assembly

21 3

4

>> Heater Positioning Assembly (front)

5

6

1. presser roller

2. blow forward

3. tape cutter

4. tape feed blowing

5. heater holder

6. heater shroud

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 11 of 59

> Identification of Components (cont.)

>> Heater Positioning Assembly (rear)

1

3

2

1. hot air deflector

2. temperature sensor

3. air nozzle

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 12 of 59

> Identification of Components (cont.)

>> Touch Screen Control Panel & Pressure Adjustment Panel

1

3

4

25

6

7

8

1. touch screen control panel

2. digital nozzle pressure display

3. nozzle air pressure regulator

4. nip roller pressure regulator

5. digital nip roller pressure display

6. data lock

7. USB socket

8. heater power outlet

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 13 of 59

> Principle of Seam Sealing

When seam tape is heated up, the adhesive on the tape is activated. This activated tape is applied on

the water proof coating or lamination of the fabric seam under pressure. When cooled, a strong bond

is formed between the tape and the seam. This bond is so strong that it will prevent pressurized water

from penetrating the sewn seam. As a result, a water proof seam is produced.

A hot air machine, like AI-002, produces hot air with precisely controlled temperature to directly heat

up the adhesive of seam tape. The heated tape and the fabric are feeding into two oppositely rotating

rollers under pressure called nip rollers. The linear speed of the nip rollers is called sealing speed.

During sealing, hot air is being blown out from the nozzle. The hot air that actually reaches the surface

of the tape is a mixture of hot air from the nozzle and surrounding air, hence the actual temperature

that appeared on the tape is somewhat lower than the nozzle temperature. The farther the distance

between the nozzle and the tape, the higher the percentage of surrounding air becomes. On the other

hand, a higher hot air flow rate will reduce the percentage of surrounding air causing the hot air

temperature appeared on the tape to be higher. So both the nozzle position and hot air flow rate are

very important factors.

So, the major factors that can affect the seam sealing are as follows:

Hot air temperature

Sealing speed

Nozzle air pressure

Air flow rate

Nozzle position

When a consistent product is required, the combination of the above factors have to be set precisely

as their effects towards a proper sealing are all interconnecting.

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 14 of 59

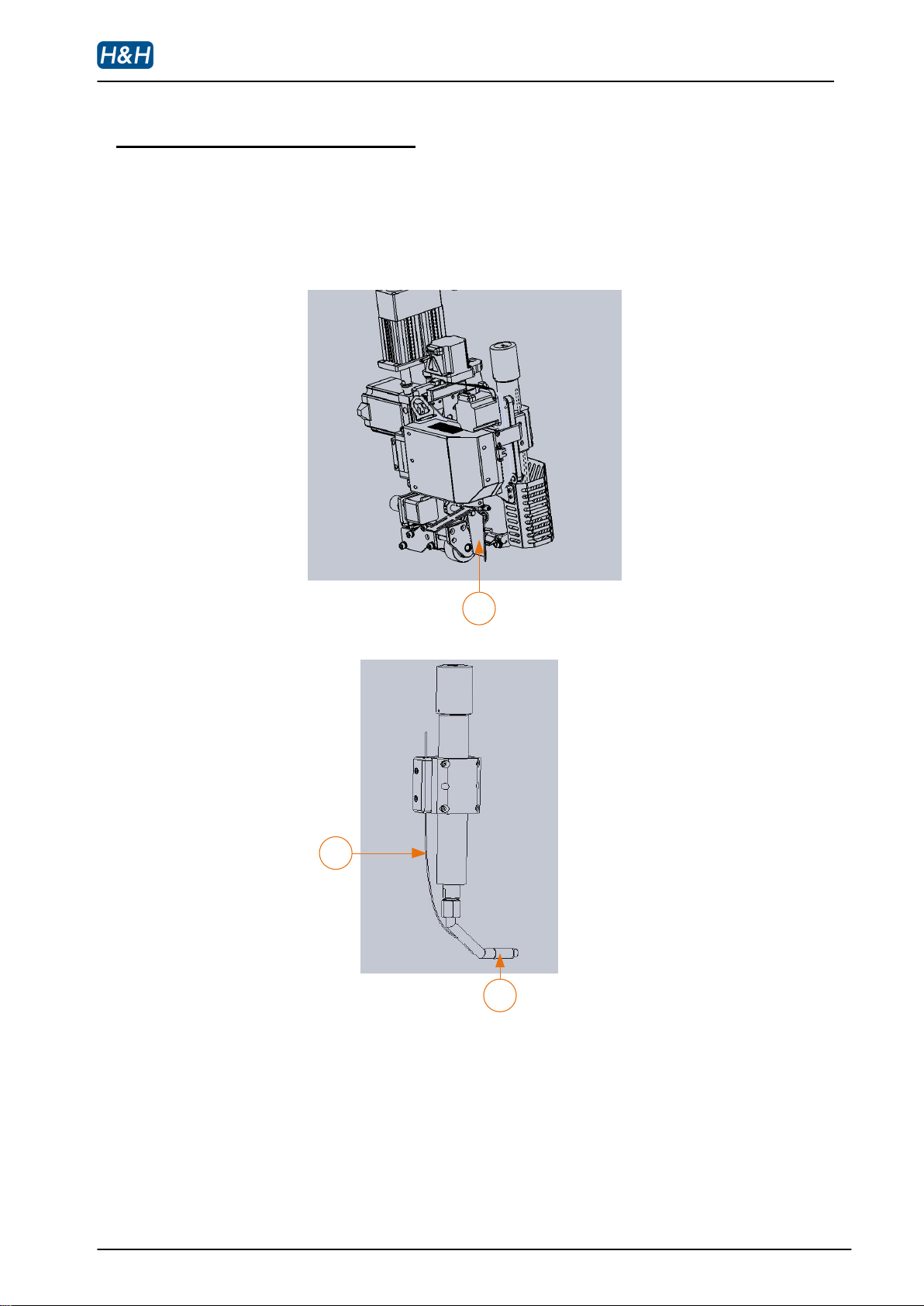

> Preparation for Installation

Installation must be carried out by authorized personnel. Follow the steps below:

1. Position the machine on a flat surface and allow at least 50cm clearance on both sides as well as

the back side, this is essential for the hot air deflector to work properly and also to allow enough

room for carrying out necessary service and maintenance

2. Adjust the foot stand so that the machine is level and stable.

3. Cut loose all packing cable ties and materials in order to free up all machine movements.

4. Connect the power plug to a suitable outlet with at least 15A capacity.

5. Locate the air hose supplied with the machine. Connect one end to the inlet of the water filter at

the back side of the machine; connect the other end to a compressed air supply such as air

compressor or central air supply. Make sure the compressed air supply has at least 0.6 Mpa (6 bar)

of pressure and a flow rate of no less than 100L/min.

6. Install the tape dispenser assembly at the top of the machine and align the tape spool at right

angle to the width of the machine. (see diagram below)

Install tape

7. Install a roll of seam tape with the adhesive side facing the operator (refer to the section on tape

loading).

8. The machine is now ready for operation.

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 15 of 59

> Control Method

>> Touch Screen Control Panel

Almost all settings and timing control of the machines can be input from the touch screen control

panel. Use you finger tip to touch the parameter to be modified. Switch to different pages to modify

other parameters (refer to section on control menu navigation). The screen has a protective cover

to prevent the surface from damage and scratch, however, avoid using excessive force when

touching the panel. You can also change the contrast of the display so as to obtain the best picture

when viewing at a different angle.

>> Foot Switch

There are 2 foot pedals for the machine. The design of these pedals is such that they can be

operated either individually or in combination to achieve a number of preset tasks by the

operator‟s feet only. As a result, the operator‟s hands are free to manipulate the processing fabric.

Left foot pedal

The left pedal is a multi function pedal. You can use it to raise the upper roller and start sealing .

To raise the upper roller - heel back the left foot pedal.

To start sealing - press forward.

Right foot pedal

The right pedal is a simple switch. It performs different function according to the timing.

During idle –jog function that makes the rollers rotate forward without the nozzle coming in.

During idle –cut function that cuts the tape if left pedal is in heel back position.

During sealing –cut function that cuts the tape

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 16 of 59

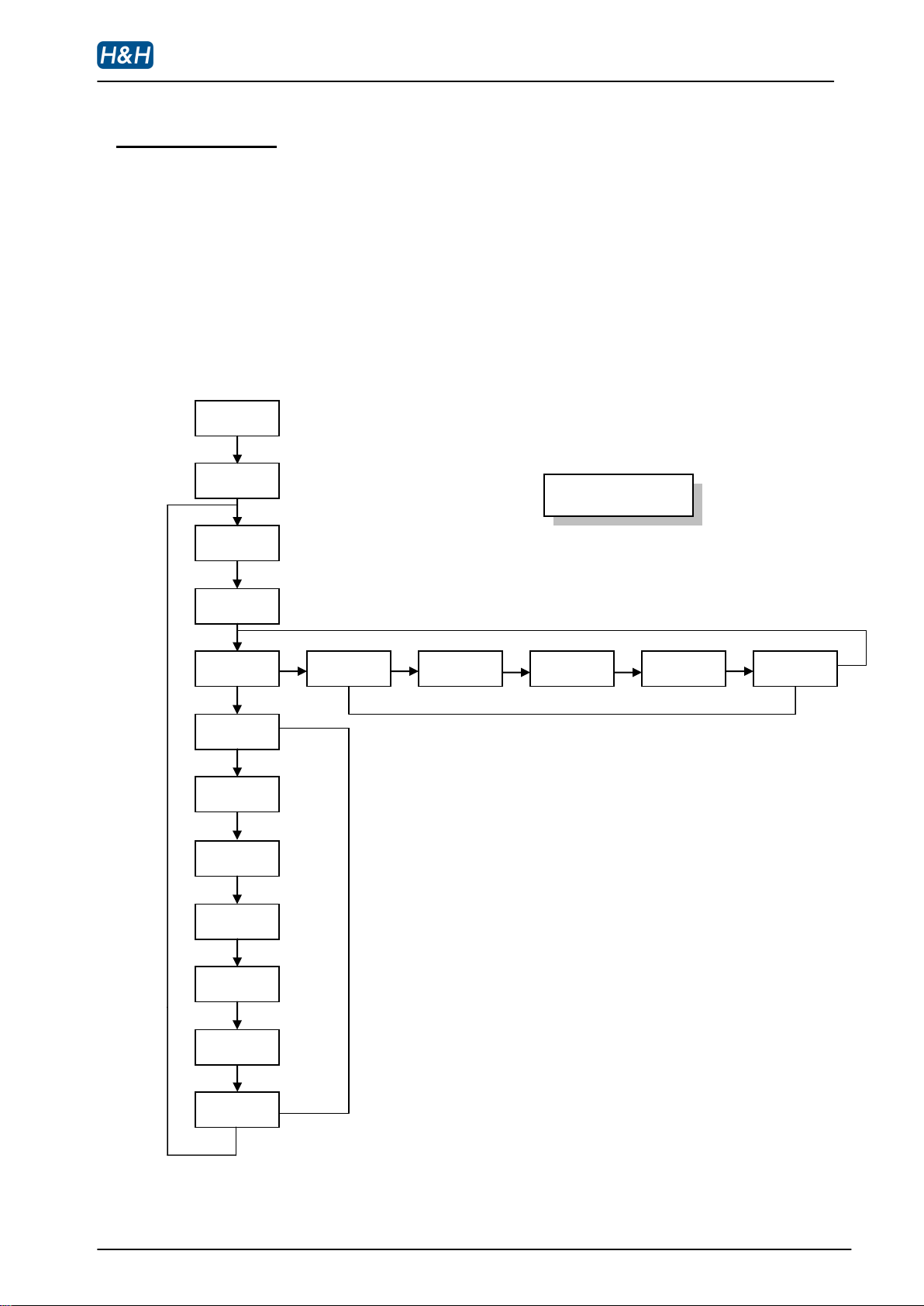

> Control Method (cont.)

>> Control Menu Navigation

The AI-002 has many parameters that can be adjusted according to the operational situations.

These parameters are arranged in different menu pages on the touch screen control panel

according to their functionality. The structure of the menu page arrangement is represented in the

following diagram.

AI-002 Menu Structure

H&H

contact

information

software

information

language

main

tape start

tape middle

tape end

nozzle adjust

memory

write & read

personality 1

personality 2

statistics

heat press

tensioner

alarm

Operation Menu Group

Support Menu Group

tools

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 17 of 59

> Control Method (cont.)

>> Control Menu Navigation (cont.)

The followings are typical menu pages, all of them have names at the top left corner for easy

identification. Right arrow buttons are for navigating in the operation menu group. Down arrow

buttons are for navigating in the support menu group. Please note that page „main‟ is the hub of

the menu network so only this page has navigation buttons for both operation and support menu

groups.

1

4

2

1

3

2

5

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 18 of 59

1

4

6

5

1. page name

2. next page in the operation menu group

3. previous page in the operation menu group

4. next page in the support menu group

5. hot key to return to page “main”

6. previous page in the support menu group

AI-002 operation manual

Issue 1 21.09.09 display version 13 . main controller version 69 . servo version 61 P. 19 of 59

> Control Method (cont.)

>> Pressure Adjustment

To adjust corresponding pressure, pull out the adjusting knob by one notch, turn the knob

clockwise or anti-clockwise to increase or decrease the neede d pressure accordingly. When

finished, lock the air regulator pressure by pushing the adjusting knob toward the regulator.

Nip roller pressure regulator

Nozzle pressure regulator

Table of contents

Other H&H Food Saver manuals