Operating manual

Pressure compensation valve (COMBI)

12605

BA_012605.04_EN

1 / 7 Albert Handtmann Armaturenfabrik GmbH & Co. KG 2017-09-14

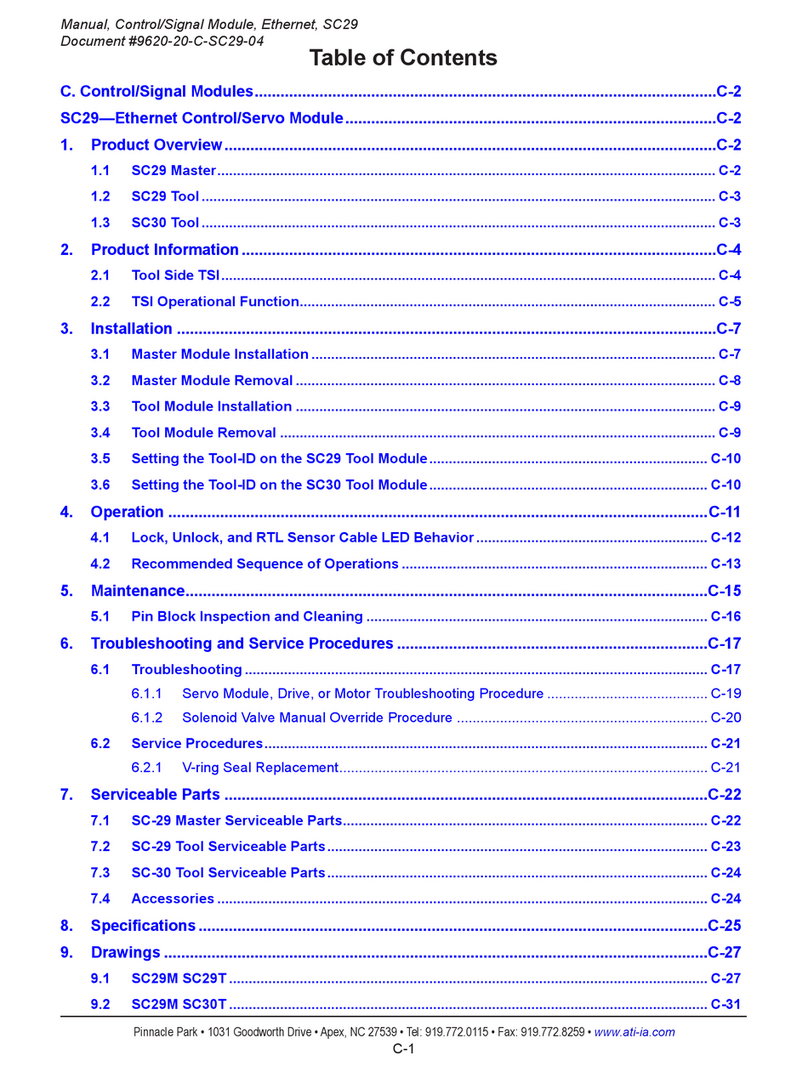

1General.............................................................................................................................................................1

2Safety Information............................................................................................................................................2

3Delivery, Completeness, Storage ......................................................................................................................3

4Installation, Operation, Maintenance ...............................................................................................................3

1General

1.1 Manufacturer

Albert Handtmann Armaturenfabrik GmbH & Co. KG

Arthur-Handtmann-Str. 11; D-88400 Biberach

Tel.: +49(0) 73 51/3 42-0; Fax: +49(0) 73 51/3 42-44 80

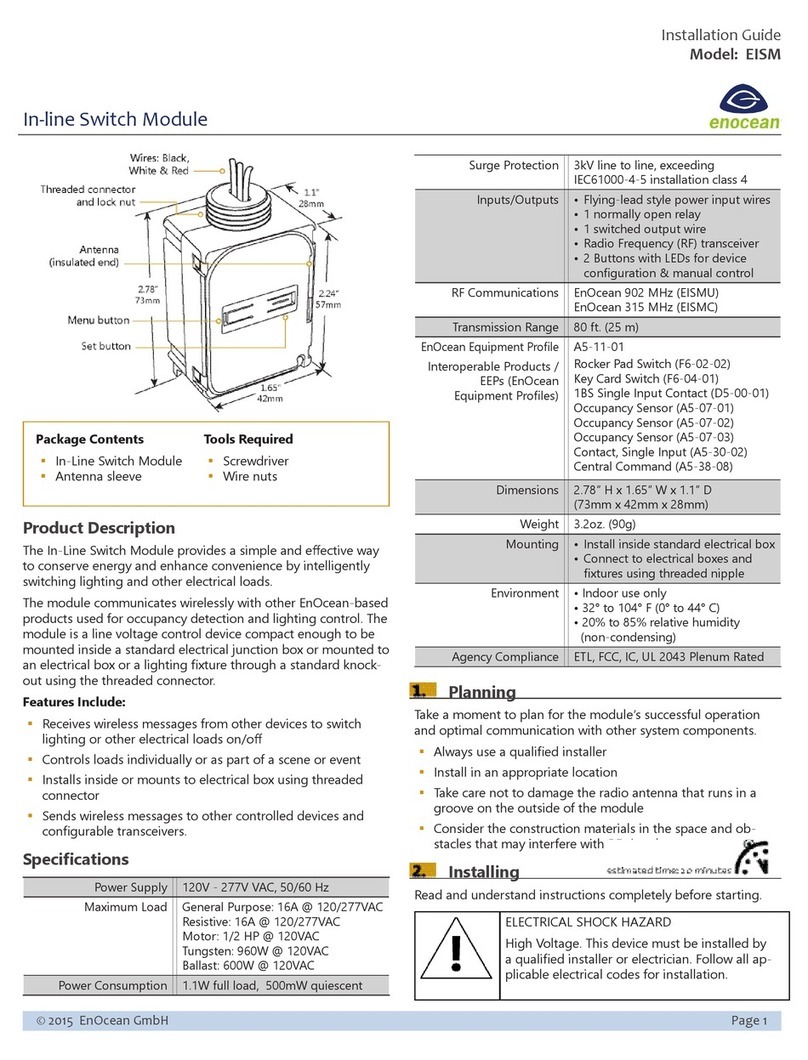

1.2 Proper application

Pressure relief valves are used in the food and beverages industry. They are used for

protection against vacuum/overpressure in tanks and other closed systems. They do not

meet the criteria for a safety valve according to the pressure equipment directive (PED.

During installation, operation and maintenance please pay attention to the generally

accepted safety regulations as well as to the operating instructions.

1.3 Misuse

Misuse is

Misuse is:

•Application in different operating conditions as intended for the specific type.

•Installation, operation and maintenance by unqualified staff.

•Any unauthorized modification of the valve or a valve component.

•On-observance of the operating instructions.

Any misuse will automatically lead to a loss of right to claim under guarantee as well as

any liability.

1.4 Duties of operator

The operator has to make sure that:

•The valve/component is operated properly and only in functional condition.

•The legal requirements are kept during operation and maintenance.

•Only sufficiently qualified and authorized staff maintain the valve/component.

•The staff responsible for operation and maintenance know and obey the

operating instructions and in particular the safety advice.

•The safety and warning signs remain on the valve/component and are

always legible.