handtmann FLOWmag 12020 User manual

Operating manual

Non-return valve

FLOWmag (type 12020 / 12021)

BA 012020.01 EN

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

2 / 14

Table of Contents

Page

Page

1. General 3

Valve Types 7

Proper Application 3

Technical Data 9

Incorrect Application 3

Performance Data 9

The User's Duty to Exercise Diligence 3

5. Assembly and Disassembly 10

2. Safety Information 4

Safety and Assembly Instructions 10

Symbols 4

Single Assemblies, Spare Parts 12

Safety Instructions 4

6. Maintenance 14

3. Delivery and Performance, Storage 4

Maintenance Instructions 14

4. Function and Operation 6

Troubleshooting 14

Valve Description 6

Spare Parts 14

Valve Operation 6

Safekeeping and Completeness

•The operating manual is part of the valve delivery package and must be available

to authorised personnel at all times.

•It is impermissible to delete chapters from this manual. If the operating manual

or pages thereof are missing, they must be replaced immediately.

Updating Service

This documentation is not subject to the updating service of Albert Handtmann Armaturenfabrik

GmbH & Co. KG. Amendments to this document may be carried out without prior notification.

Copyright

This documentation contains copyrighted information. It should only be used

in connection with the valve application.

Manufacturer

Albert Handtmann Armaturenfabrik GmbH & Co. KG

Arthur-Handtmann-Str. 11; D-88400 Biberach, Germany

Tel.: +49(0) 73 51/3 42-0; Fax: +49(0) 73 51/ 3 42-44 80

E-mail: sales.fittings@handtmann.de

Operating manual edition

C 01/2013

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

3 / 14

1. General

This operating manual must be read and observed by everyone involved with the installation, commissioning, operation

and maintenance of the non-return valve.

This operating manual applies to the following valve versions:

Types Equipment

FLOWmag 12020

Magnetic non-return valve

with weld ends or threaded pipe connections

FLOWmag 12021

Magnetic non-return valve in intermediate flange design

with weld ends

Proper Application

•The non-return valve is used in the food and beverage industry and the pharmaceutical and chemical industry.

•Non-return valves prevent return flow in the direction opposite flow or prevent

connected pipe systems from flowing through. The valve is normally closed.

•The valve may be used for the intended purpose only. Pay close attention

to the installation situation and/or flow direction, the specified pressure and temperature range

and the flow media.

•Applicable and generally recognised safety rules as well as the operating manual instructions must be

followed during assembly and disassembly, in operation and during maintenance.

Incorrect Application

The following are examples of incorrect application:

•Operating conditions other than those specified in the operating manual are present.

•Liquid media different to that envisaged in the operating manual flow through the valve.

•The safety information is disregarded during operation, assembly and maintenance.

•Independent modifications or changes to the valve are carried out that

restrict safety or functionality.

•Valves are used although they are not functional.

The User's Duty to Exercise Diligence

The user must especially ensure that:

•The installation of the valves is carried out in accordance with the instructions.

•The valves are operated according to their intended purpose and are in a fully functional state.

•The statutory requirements for operation, assembly and maintenance are observed.

•Only sufficiently qualified and authorised personnel maintain the valves.

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

4 / 14

2. Safety Information

2.1 Symbols

Risk of injuries!

Indicates an immediate hazardous situation!

•Non-observance may result in serious injury or death.

Caution – danger zone warning!

Indicates a potentially hazardous situation!

•Non-observance may result in minor to moderate

injury

Functional impairment or material damage!

Indicates a possible functional impairment or material damage:

Note

Important additional information, tips and recommendations.

2.2 Safety Instructions

Note

The following safety information must be considered as an addition to the relevant

applicable national accident prevention requirements and laws.

Current standards of good engineering practice must be observed when planning the

application and operation of the device.

Please pay attention to the relevant rules and safety regulations in other countries.

Basic safety instructions

to prevent injuries and to ensure correct functioning:

•Transportation and storage are carried out correctly in accordance with the operating

manual.

•Installation and maintenance tasks as well as operating actions should

only be carried out by appropriately authorised and qualified personnel with suitable

tools.

•The device should only be installed and operated when in efficient working order and

in accordance with the operating manual.

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

5 / 14

Risk of injuries!

•The valve must be switched off in the case of

noticeable malfunctions.

•The area of the line where the valve is located

must be locked within the system.

•Disassembling the valve from the piping

system without relieving the system pressure

first may result in burns, scalding or chemical

burns.

•If the valve in a system is operated with acidic

or alkaline media, your hands and fingers may

suffer chemical burns when disassembling the

valve.

•If the valve in a piping system is operated

with hot media, the surface temperature of

the valve can also reach this value.

•There is a risk of crushing due to moving

parts.

oFaults must be eliminated

immediately.

oUnintentional commissioning

must be prevented.

oMake sure that the piping system

pressure has been relieved.

oMake sure that the piping system

has been flushed and emptied.

oMake sure that the piping system

has cooled to a value below 50°C.

oNever reach into the switching

section of the valve.

3. Delivery and Performance, Storage

•Check the information on the delivery note for correctness and check the delivery for

completeness. Later complaints will not be accepted.

•Conduct a visual inspection for transport damage. The forwarding agent must be informed of any visible damages

immediately (comment on the waybill).

•Claims due to transport damage not visible right away must be made to the forwarding agent within a week.

•Store the delivery in dry rooms and, if possible, in the original packaging to protect it against external factors.

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

6 / 14

4. Function and Operation

4.1 Valve Description

These non-return valves are for low-bacteria/sterile processes in the beverage and food industry as well as in the

chemical-pharmaceutical sector

The non-return valve is equipped with a permanent magnet. Because the pressure spring was eliminated, other

components installed in the product area are also eliminated, which makes cleaning and sterilising considerably easier.

The valve types 12020 / 12021 are characterised by:

•open flow, gentle product handling

•flow with almost no pressure loss

•secure closing, no backflow

•hygienically designed shutter and product area

•patented, magnetic functional principle

4.2 Valve Operation

The conventional pressure spring has been replaced with an external magnetic field. If the flow of liquid is

interrupted, the shutter is pushed against the valve seat, thus preventing backflow.

If the liquid pressure exceeds the force of the magnetic field, the valve opens.

The liquid can then flow through the product area unhindered.

Risk of injuries!

See Chapter 2.2 - Safety Information

Note

Installation position of the valve or draining of the pipeline and flow direction in the valve.

Non-return valves should be cleaned within a defined time period (cleaning schedule).

Generally this is done during pipe cleaning / flow.

Note

Only use cleaning agents which are appropriate for stainless steel and the seals. Please

refer to the safety data sheets of the cleaning agents.

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

7 / 14

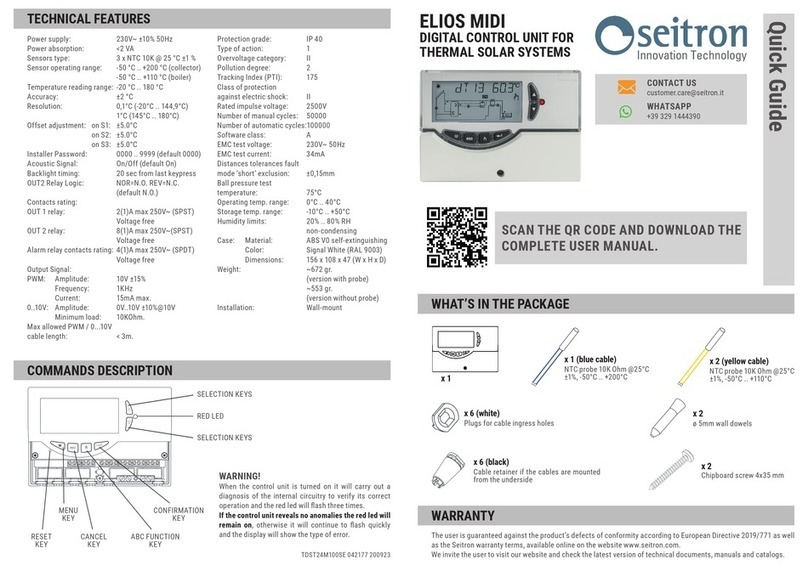

4.4 Valve Types

FLOWmag 12020

Housing

The non-return valve consists of 4 main parts and has a weld end on both sides.

Different weld-on connections are available. The preferred installation position is

vertical.

Valve design

1

2

3

4

Flange

Housing

Shutter

Flange

Dimensions

012020

DN

a

[mm]

b

[mm]

c

∅

[mm]

a*

[mm]

10 51 41 13 55

15 60 54 19 65

25 80 72 29 85

40 100 90 41 105

3

2

4

1

a

b

c

a*

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

8 / 14

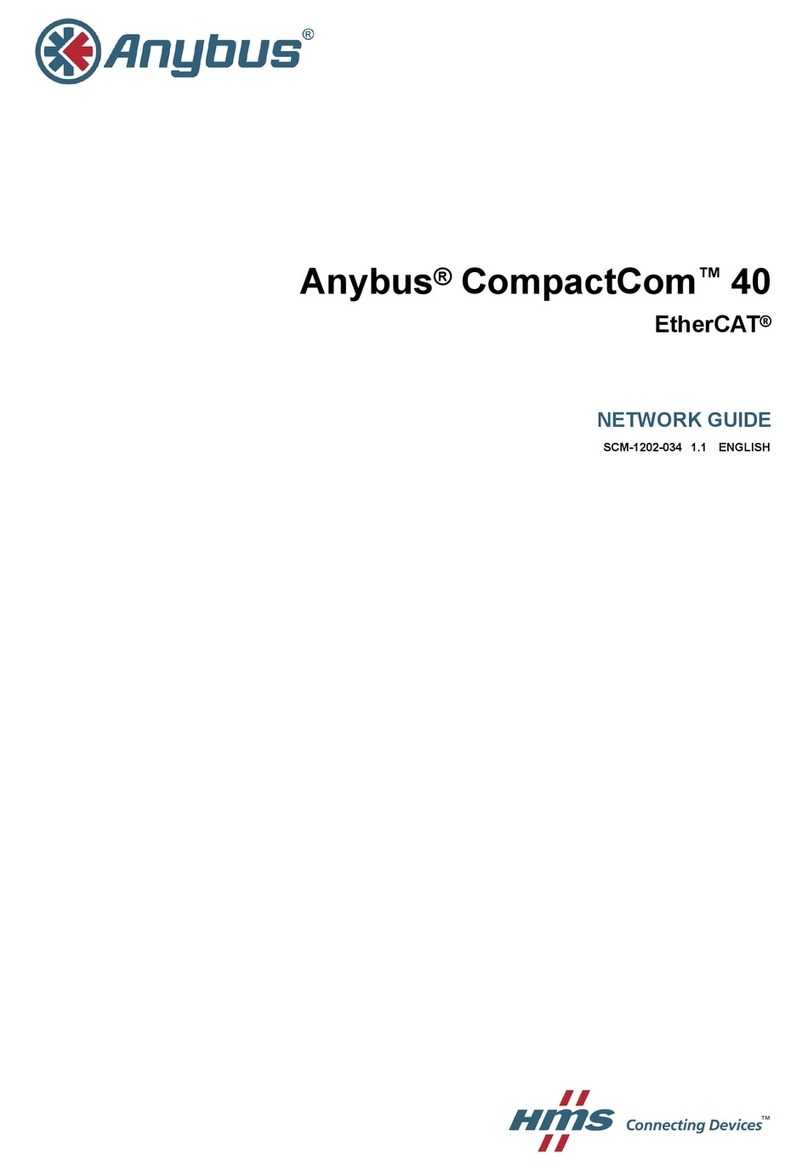

FLOWmag 12021

Housing in intermediate flange design

The non-return valve consists of a two-part housing and 2 flanges on the ends. The housing with all functional parts can be

removed from the end flanges for maintenance work.

Valve design

1

2

3

4

5

Housing part 1

Housing part 2

Flanges

Shutter

Magnetic half-rings

Dimensions

012021

DN

a

[mm]

b

[mm]

c

∅

50 112 94 53

65 122 117 70

80 144 134 85

100 156 155 104

c

b

a

1

2

3

4

5

3

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

9 / 14

4.5 Technical Data

Surface (Ra)

≤ 0.8 µm

Nominal sizes (DN)

10, 15, 20, 25, 40

Nominal sizes ZF (DN)

50, 65, 80, 100

Nominal sizes (OD)

1“, 1 ½“, 2“, 2 ½“, 3“, 4“

Production / CIP

Flow media

Liquids and gases, (non toxic, less aggressive)

CIP media

Commercially available alkaline and acidic

solutions

Operating pressure

0 - 10 bar

4.6 Performance Data

Product range

Materials

Stainless steel 1.4404, DUPLEX

Seals

EPDM, FDA proof

Other parts

Materials

Stainless steel 1.4307

Surface

Precision-turned

Opening pressure

0.05 - 0.1 bar

Temperature CIP / SIP

0 - 95°C / 140°C

line pressure (bar)

Flow capacity (m

3

/h)

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

10 / 14

5. Assembly and Disassembly

5.1 Safety and Assembly Instructions

Risk of injuries!

Permanent magnet

•All electronic objects can be damaged by the magnetic field or their function can be

impaired.

This also applies to medical/electrical devices, for example heart pace makers,

hearing aids, etc.

•To exclude possible risks, the valves should only be maintained by personnel who are

instructed in devices of this type.

Risk of injuries!

See Chapter 2.2 - Safety Information

Caution – danger zone warning! (also see Chapter 2)

Please pay attention to the following prior to installation and commissioning:

•Check the valve for visible external and internal damage.

•Check the valve housing inside for residues.

•Check the current system status (pressure, temperature, medium).

Please pay attention to the following if malfunctions occur and prior to disassembly:

•The valve must be switched off in the case of malfunction.

•Check the current system status (pressure, temperature, medium).

Caution – functional impairment or material damage!

Installation instructions:

•Valves for welding in must be previously disassembled or the magnet and

seals must be removed. The housing cannot be welded in with a magnet installed!

•Weld the housing into the piping system free of tension with sufficient free space.

•Remove welding residue from the piping system.

•The welding work (TIG, welding gas) should only be carried out by qualified welders (EN

287-1).

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

11 / 14

Caution – functional impairment or material damage!

Assembly instructions:

•Do not damage the valve insert, sliding surfaces or sealing surfaces.

Only use suitable tools and tensioning devices.

•Only use suitable and approved spare parts from the manufacturer.

•Slightly grease seals and insert them evenly into the groove.

(Only use grease approved for the field of food processing)

•Bolts, slightly grease threads. Tighten parts evenly.

•Carry out a manual functional check – activate the shutter.

Caution – functional impairment or material damage!

Permanent magnet:

•Do not remove the magnet unless it is absolutely necessary.

•A safety clearance must be observed between the magnet and all electrical/electronic

objects and parts of equipment. It is possible these objects could be damaged or their

functionality could be impaired.

•If the magnet is damaged by an impact or shock small broken pieces with sharp edges

may form.

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

12 / 14

5.2 Disassembly / Assembly

FLOWmag 12020

O-ring seal

Flange

Housing

Screws

A

B

Remove screws, take front flange off of

housing,

remove/replace O-ring seal

C

D

Remove seal ring, magnetic half rings

can be removed (normally not

necessary)

Seal ring

Magnetic half-

rings

Shutter part 1

Shutter part 2

Housing

Remove screws, take rear flange off of

housing,

remove/replace O-ring seal

O-ring seal

Flange

Housing

Screws

O-ring seal

Remove shutter from housing and screw

on,

remove/replace O-ring seal

1

Screws

2

Screws

3

Shutter part 1

4

Shutter part 2

5

Housing

6

Flange (valve inlet)

7

Flange (valve outlet)

8

Magnetic half-rings

9

Seal

10

O-ring seal

11

O-ring seal

12

O-ring seal

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

13 / 14

FLOWmag 12021

Flange

Housing

Screws

A

B

Remove screws

E

Remove front and rear flange from housing

O-ring seals accessible

Remove shutter from housing and screw on,

O-ring seal accessible

C

D

Separate housing parts

Remove sealing ring and magnetic half rings

(normally not necessary)

Shutter

Sealing ring

Housing part 1

Remove screws

Housing can be disassembled

O-ring seals accessible

Flange

Flange

Housing

Flange

Housing part 2

Screws

Magnetic half-

rings

Housing part 1

Housing part 2

Shutter part 2

Shutter part 1

O-ring seals

F

Operating manual

Non-Return Valve FLOWmag

12020 / 12021

BA_012020.01_EN

Albert Handtmann Armaturenfabrik GmbH & Co. KG

2015-09-07

14 / 14

6. Servicing

6.1 Maintenance Instructions

Caution – functional impairment or material damage!

Inspection and maintenance intervals:

•Visual inspections must be carried out continuously every 4 weeks.

•To ensure that the valve is ready for operation and functionally reliable, it should be

checked every year within the scope of the general internal maintenance procedure.

>> Maintenance intervals must be set by the user

•After maintenance, always remove protective devices and reconnect the feed and drain

lines to the valve.

•Ensure that a function test is always performed on the valve

following maintenance work.

6.2 Troubleshooting

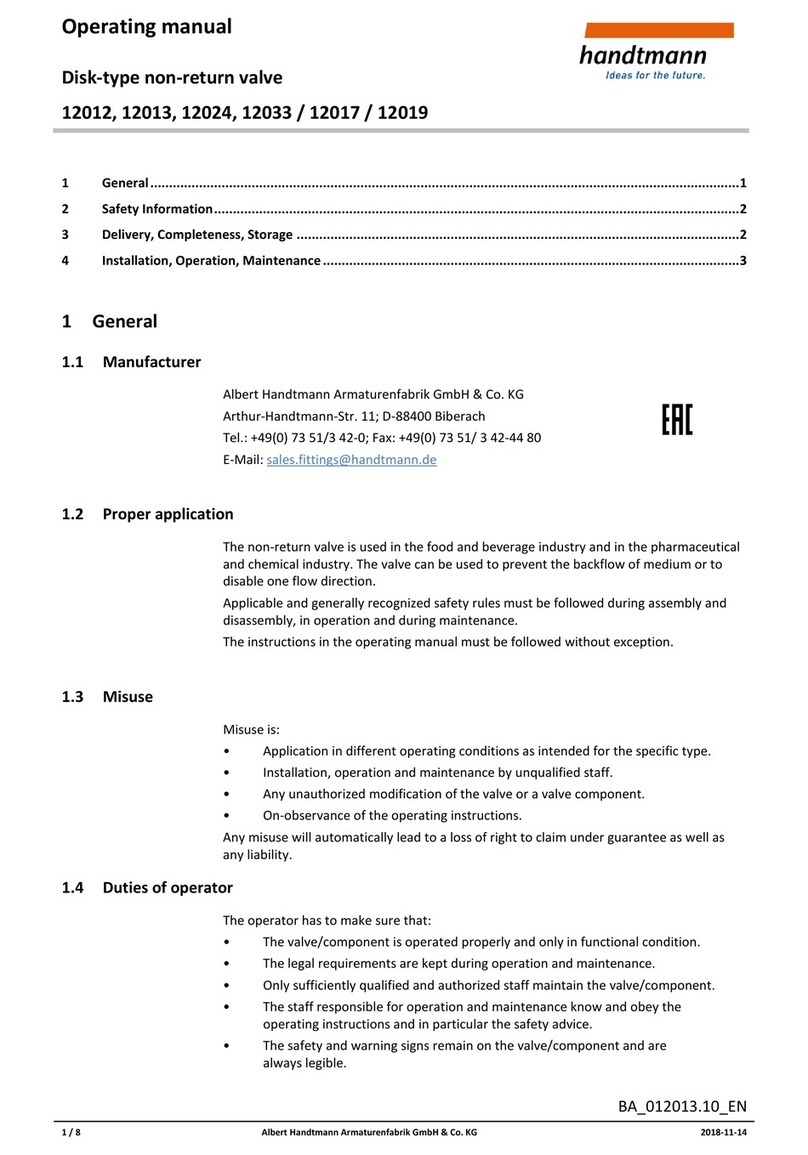

Malfunction Possible causes Measures

Leak

(external)

•O-ring seals between

flange and housing damaged

•Screws have come loose

•Process pressure too high

•Replace seals

•Test tightening torque

•Check pressure

Leak/backflow

(internal)

•O-ring seal between taper and shutter

damaged

•Seal area damaged

•Shutter blocked

•Replace seals

•Check seating area and taper for

mechanical damage

•Manual functional check, remove

shutter

Noise generation •Uneven flow/cavitation •Check process conditions,

change installation position

6.3 Spare Parts

Seal / Position DN 10 DN 15 DN 20 DN 25 DN 40

Seal set for: 012020. 00010 00015 00020 00025 00040

Seal / Position DN 50 DN 65 DN 80 DN 100

Seal set for: 012021. 00050 00065 00080 00100

Seal replacement - please note the following points:

•Use a suitable tool (dig hook) to remove the seals

•The gasket grooves should be cleaned thoroughly before installing the new seals.

•Slightly grease the seals (only use grease approved for the field of food processing)

•Insert seals evenly into the gasket grooves

This manual suits for next models

1

Table of contents

Other handtmann Control Unit manuals

handtmann

handtmann 491 User manual

handtmann

handtmann 75100 User manual

handtmann

handtmann 12012 User manual

handtmann

handtmann 12501 User manual

handtmann

handtmann INOVA User manual

handtmann

handtmann 12504 User manual

handtmann

handtmann 33501 User manual

handtmann

handtmann 12503 User manual

handtmann

handtmann 12605 User manual

Popular Control Unit manuals by other brands

Honeywell

Honeywell SM152 Series installation instructions

EPS

EPS SK202 Series manual

Toptech Systems

Toptech Systems MultiLoad II user guide

Emerson

Emerson Daniel 788DVC user manual

VAT

VAT 655 Series Installation, operating, & maintenance instructions

VAT

VAT 670 Series Installation, operating, & maintenance instructions