handtmann 12012 User manual

This manual suits for next models

5

Table of contents

Other handtmann Control Unit manuals

handtmann

handtmann INOVA User manual

handtmann

handtmann 491 User manual

handtmann

handtmann 33501 User manual

handtmann

handtmann 75100 User manual

handtmann

handtmann 12501 User manual

handtmann

handtmann 12605 User manual

handtmann

handtmann 12503 User manual

handtmann

handtmann FLOWmag 12020 User manual

handtmann

handtmann 12504 User manual

Popular Control Unit manuals by other brands

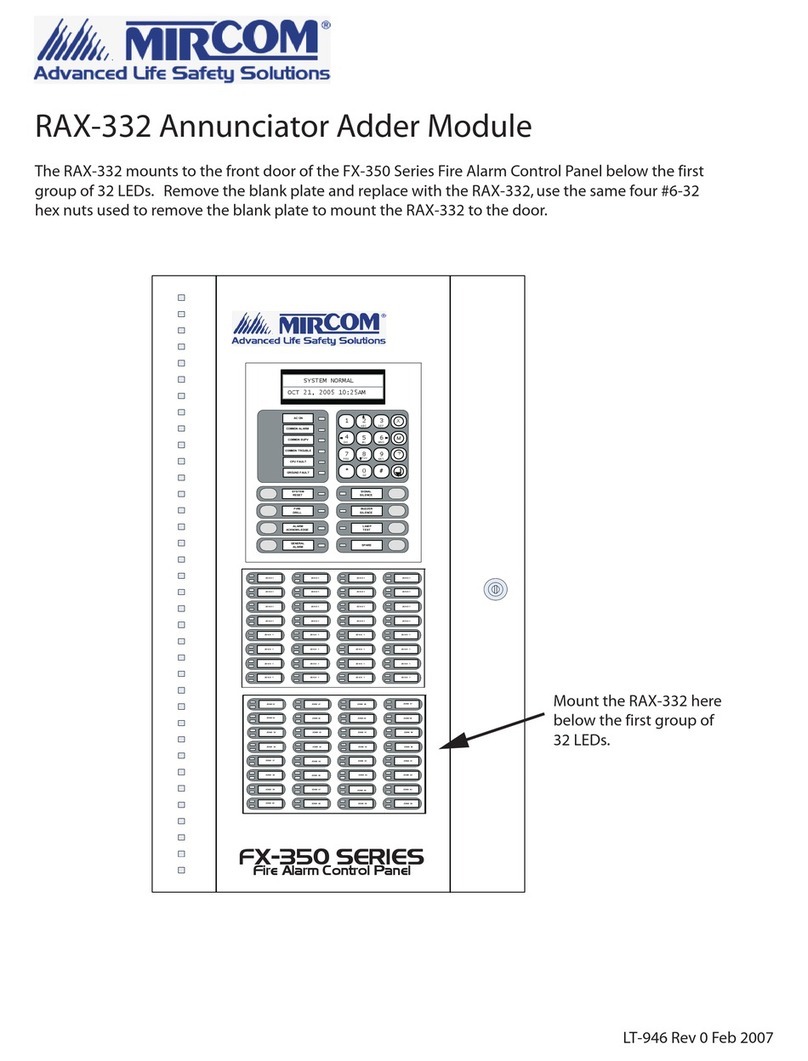

Mircom

Mircom RAX-332 quick start guide

Orbinox

Orbinox EX Installation, operation & maintenance manual

AVK

AVK 145 Series Installation, operation and maintenance manual

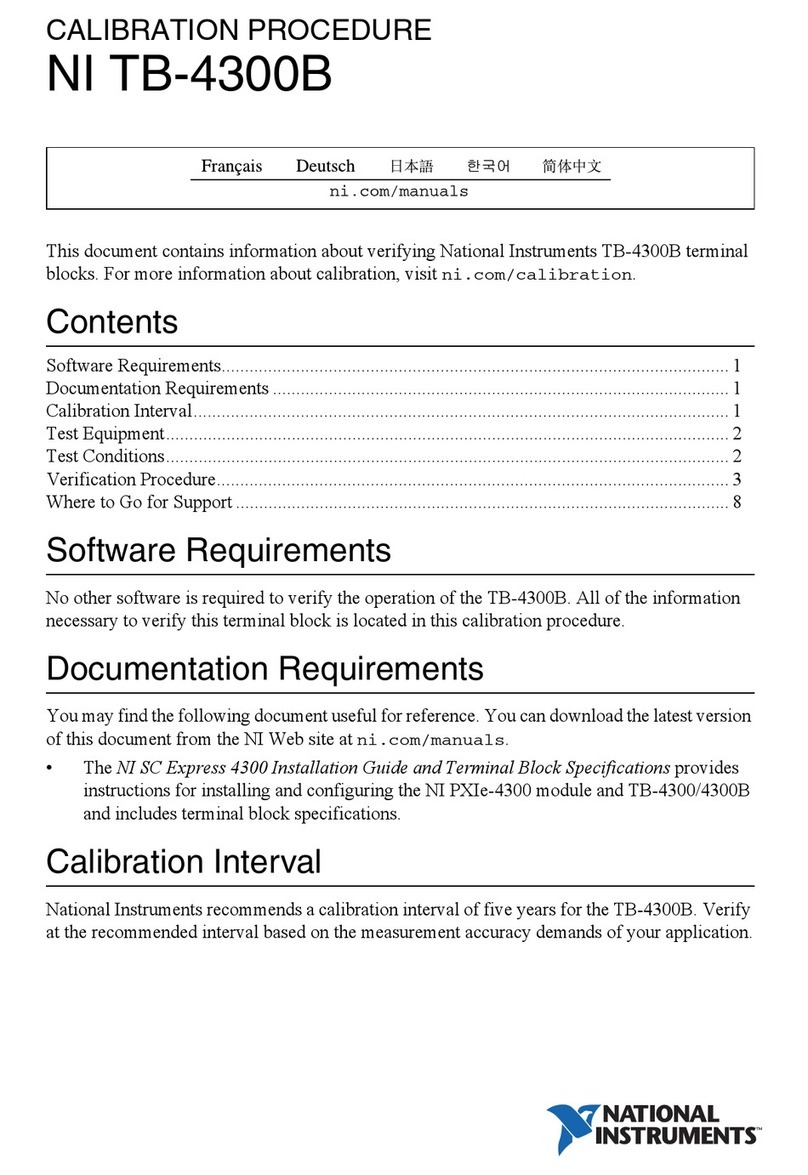

National Instruments

National Instruments NI TB-4300B CALIBRATION PROCEDURE

ITT

ITT SKOTCH TRIFECTA T1005 Installation, operation and maintenance instructions

Watts

Watts iDROSET CSD Series installation instructions

Viessmann

Viessmann VITOTRONIC 200 Service instructions

Giacomini

Giacomini KTD3 manual

SolarEdge

SolarEdge PV530-R72LGML installation guide

Event Lighting

Event Lighting DMXRTWALL user manual

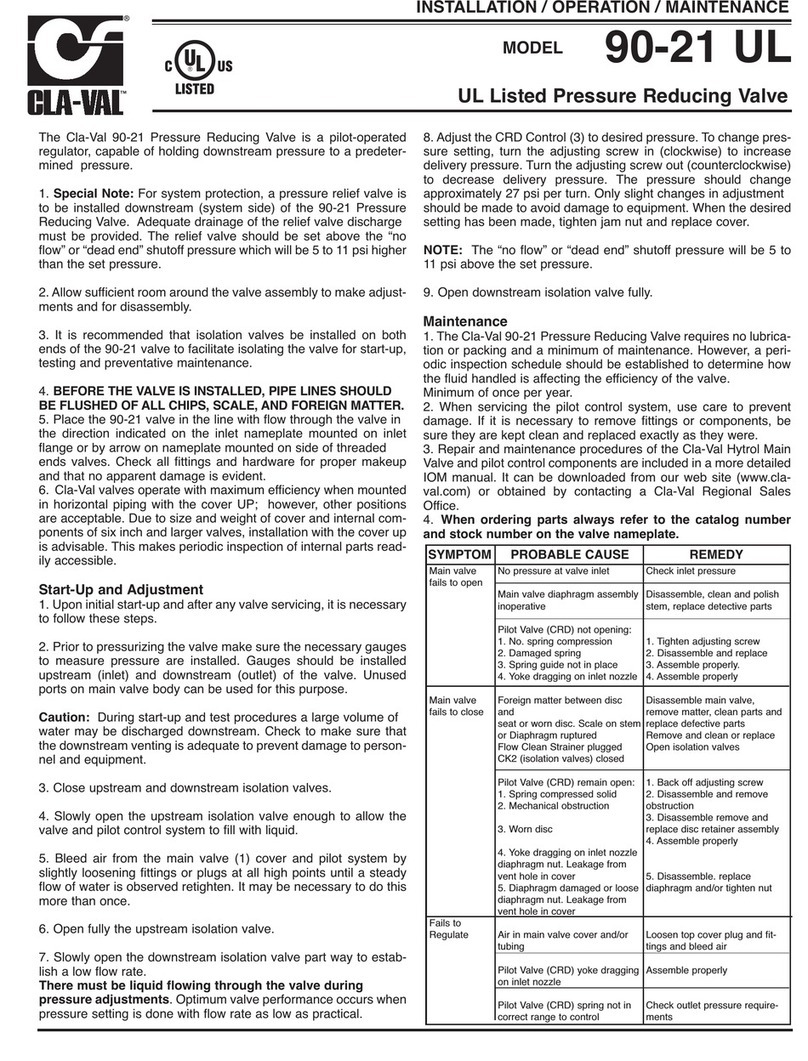

CLA-VAL

CLA-VAL 90-21 UL Installation, operation & maintenance manual

Maker Factory

Maker Factory MAKEVMP400 user manual

Pepperl+Fuchs

Pepperl+Fuchs VAA-2E2A-KE1-S/E2 instruction manual

Albalá Ingenieros, S.A.

Albalá Ingenieros, S.A. AEM3000C01 manual

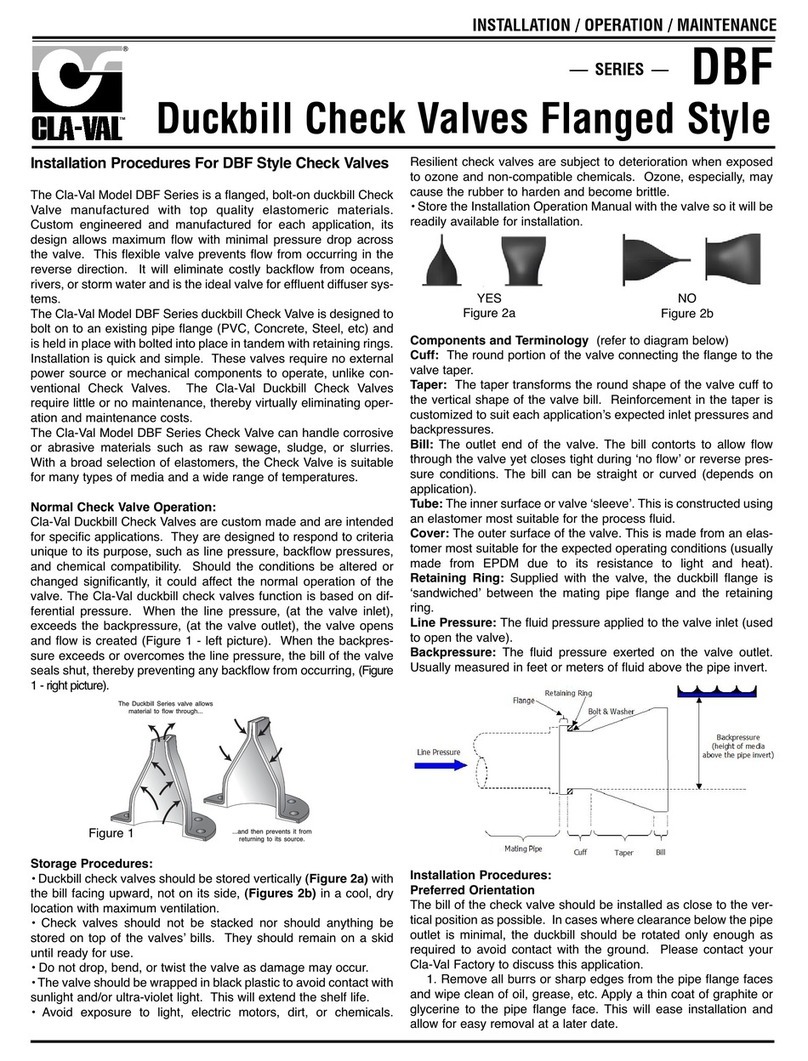

CLA-VAL

CLA-VAL DBF Series Installation operation & maintenance

Telit Wireless Solutions

Telit Wireless Solutions GC864-QUAD V2 Hardware user's guide

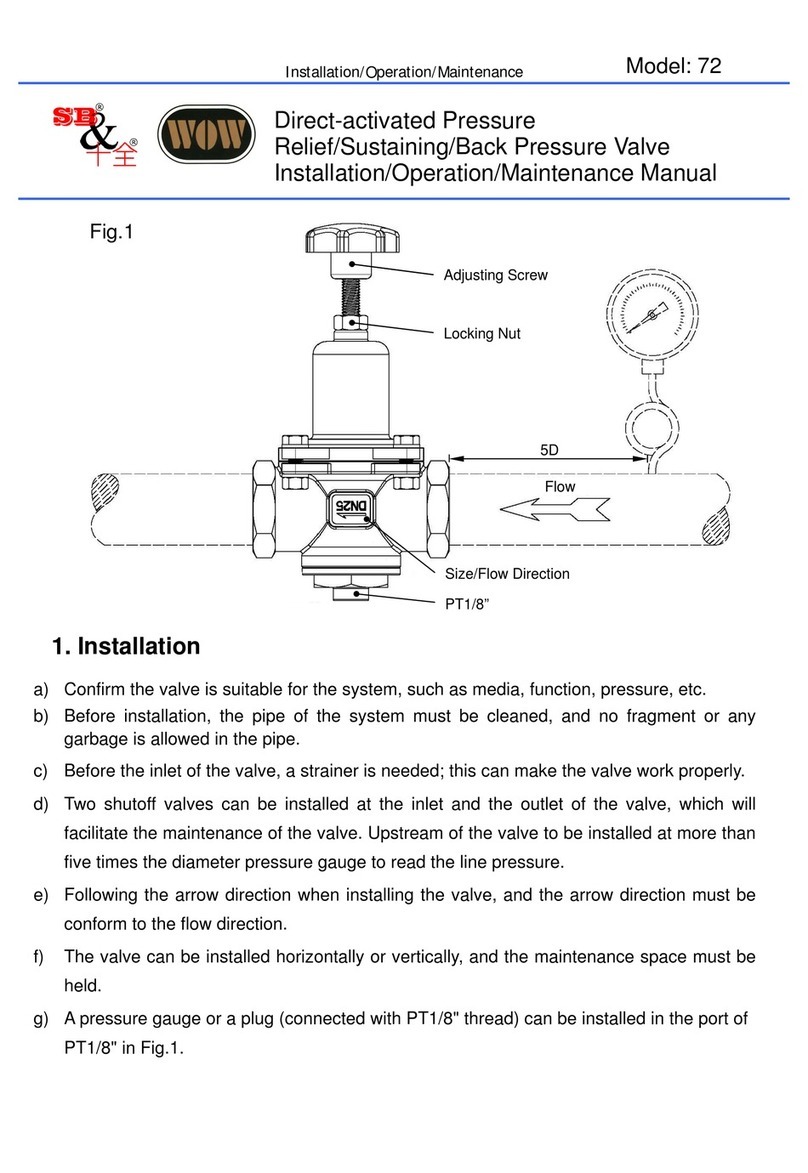

King Technology

King Technology 72 Installation operation & maintenance

Milltronics

Milltronics EnviroRanger ERS500 Programming reference guide