handtmann 491 User manual

OPERATING MANUAL

DOUBLE-SEAT VALVE

(Type 491)

BA 049100.06 EN

© 2006

Albert Handtmann Armaturenfabrik GmbH

& Co. KG

Technical Documentation

All copy rights regarding this technical documentation and all

drawings submitted to the receiver in person remain at all

times with Albert Handtmann Armaturenfabrik GmbH & Co.

KG, Biberach, Germany.

They must not be copied or reproduced without prior written

authorization.

Handtmann Worldwide

Technology for a Prosperous Future

The Handtmann Armaturenfabrik can look

back over a long and successful tradition.

Today it is part of the globally operating

Handtmann Group of Companies.

The Handtmann Armaturenfabrik is one of

the leading suppliers of armatures and

process systems for the beverage industry.

Increasingly positive activities can also be

seen in the fields of biotechnology and the

pharmaceuticals industry.

Our ambitious goals can only be realized

with a highly qualified and motivated team.

We are not looking for short-term

successes but rather the creation of a long-

term partnership with our customers.

Albert Handtmann Armaturenfabrik GmbH & Co. KG · Arthur-Handtmann-Strasse 11 · D-88400 Biberach an der Riss

Telephone +49- (0) 7351-342-0 · Fax +49- (0) 7351-342- 4480 · sales.fittings@handtmann.de · www.handtmann.de

Contents

4 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

0Contents

0Contents ...........................................................................................................................................................4

1Foreword ..........................................................................................................................................................5

2Safety ...............................................................................................................................................................6

2.1 General Information .......................................................................................................................................... 6

2.2 Proper Application ............................................................................................................................................. 6

2.3 Improper Application......................................................................................................................................... 6

2.4 The User's Duty to Exercise Diligence................................................................................................................ 6

2.5 Symbols.............................................................................................................................................................. 7

2.6 Basic Safety Advice ............................................................................................................................................ 8

3Delivery ..........................................................................................................................................................10

3.1 Transport ......................................................................................................................................................... 10

3.2 Instructions for Delivery and Performance...................................................................................................... 10

3.3 Storage Instructions......................................................................................................................................... 10

3.4 Disposal of Packaging....................................................................................................................................... 10

4Description of Function...................................................................................................................................11

4.1 Valve Types ...................................................................................................................................................... 11

4.1.1 Process Integration, Mechanical 13

4.1.2 Process Integration, Electrical 13

5Technical Data ................................................................................................................................................14

6Operation/ Use...............................................................................................................................................16

6.1 Valve Switching Functions ............................................................................................................................... 16

6.1.1 Production – Valve Closed 16

6.1.2 CIP or Production Valve Open 16

6.1.3 Cleaning – Balancer (B) 17

6.1.4 Cleaning – Leakage Chamber (L) 17

6.2 CIP Cleaning ..................................................................................................................................................... 18

6.3 Leakage Detection ........................................................................................................................................... 18

7Installation and Commissioning ......................................................................................................................19

7.1 Installation of the Valve Housing..................................................................................................................... 19

7.2 Installation of the Valve Inset .......................................................................................................................... 19

8Disassembly/ Assembly ..................................................................................................................................21

8.1 Disassembly of the Valve Inset ........................................................................................................................ 21

8.2 Disassembly of the Valve inset/Seat sealings .................................................................................................. 22

8.3 Disassembly of the Spring Closing Unit............................................................................................................ 23

8.4 Auxiliary tools for Assembly / Disassembly ..................................................................................................... 24

8.5 Valve assembly ................................................................................................................................................ 25

9Repair .............................................................................................................................................................26

10 Maintenance / Cleaning..................................................................................................................................28

10.1 Preparation for Maintenance .......................................................................................................................... 28

10.2 General Maintenance Intervals ....................................................................................................................... 28

10.3 Inspection Intervals.......................................................................................................................................... 29

10.4 Cleaning Parameters........................................................................................................................................ 29

10.5 Seal change ...................................................................................................................................................... 29

10.6 Types of Seal .................................................................................................................................................... 30

10.7 Spare Parts List................................................................................................................................................. 31

11 Disposal ..........................................................................................................................................................32

11.1 Disposal of Packaging....................................................................................................................................... 32

11.2 Disposal of the Valve Parts .............................................................................................................................. 32

12 Index...............................................................................................................................................................33

Forewor

d

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 5 / 34

1Foreword

This operating manual is for the information of the service personnel, the user and if

necessary specialist personnel. It is part of the valve delivery. No chapter from this manual

may be deleted. A missing operating manual or missing pages are to be replaced

immediately.

An understanding of the double-seat valve's function is a prerequisite for a smooth

operation.

Every person charged with the valve’s installation, commissioning, operation,

maintenance and repair must have read this manual and especially the chapter on safety

and have understood both the content and the terminology.

If necessary, in-house instruction taking into account the specialist qualifications of the

respective persons must take place.

In order to avoid operating errors and to ensure the correct implementation of the

required testing measures, this operating manual must be available at all times to the

operating personnel.

The Handtmann Armaturenfabrik assumes no responsibility for damages or operating

faults resulting from the non-compliance with this operating manual!

This documentation may be amended by the updating service of Albert Handtmann

Armaturenfabrik GmbH & Co. KG. Amendments to this document may be carried out

without prior notification.

Safety

6 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

2Safety

2.1 General Information

All persons involved with the installation, commissioning, operation and maintenance of

the double-seat valve must carefully read and observe the following instructions. Your

safety is at stake.

2.2 Proper Application

Double-seat valves are used in the food and beverage industry and the pharmaceutical

and chemical industry. They are used as single valves or in the valve group (valve knot).

Double-seat valves form the point of intersection between two separate piping systems

with different liquid media. Due to their function, they safely separate the liquid media

from each other or transfer the media from one piping system to the other.

2.3 Improper Application

Improper application occurs if:

•Liquid media different to that envisaged in the operating manual are conducted

through the valves.

•Operating conditions different to those envisaged in the operating manual apply.

•The safety instructions are disregarded in the operation, assembly and

maintenance.

•Independent modifications or changes to the double-seat valve are carried out that

restrict safety or functionality.

2.4 The User's Duty to Exercise Diligence

Both operator and user must ensure that only authorized and trained personnel work with

the double-seat valve.

The user must especially ensure that:

•The double-seat valve’s installation is carried out in accordance with the

instructions.

•The double-seat valves are used in accordance with their purpose and only in a

functional state.

•Only qualified and authorized personnel use and maintain the double-seat valves.

•The legal requirements of the operating safety regulations are adhered to.

Safety

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 7 / 34

2.5 Symbols

Below are the explanations for the symbols used.

Warning - Danger from electrical current!

This symbol indicates that there is a danger to the life and health of persons due to

electric voltage.

Warning - Danger to persons!

This symbol indicates that there is a danger to the life and health of persons.

Caution – Damage to components!

This symbol indicates that special care should be taken.

Note

This symbol indicates an environmentally friendly process or disposal.

Note

This symbol refers to special instructions.

Safety

8 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

2.6 Basic Safety Advice

Warning - Danger to persons!

Adhere to the following safety instructions in order to avoid dangers to life and health.

Endangerment to service personnel

Explanations Measures

Squeezing danger to fingers, hands and feet

Unintentional opening and closing of the valve must be prevented

during maintenance work.

Do not place your hands in the valve housing or the seat area of

the valve disk.

The valve weighs several kilograms.

Bruising injuries can arise during transport, assembly or in

maintenance work.

Disconnect the electrical connection to the

valve.

Disconnect the pneumatic connection to

the valve.

(Compressed air hose)

Always wear safety shoes and protective

gloves.

Secure the valve against slipping and falling

during assembly, disassembly and in

maintenance work.

Blow and impact danger

Low spring tension

Before taking out the valve inset and loosening the screws, the

valve can be pneumatically lifted.

When carrying out maintenance work the piping system should be

made pressure-free or drained beforehand in the area concerned.

The piping area awaiting maintenance should be sealed off from

the other piping system.

Apply compressed air to the main drive.

Before removing the valve inset, check

which liquid medium was in the piping. If

necessary, rinse the piping again

beforehand with water.

Check the piping pressure before the valve

inset is removed from the housing.

Danger of burning, scalding and causticization

If the piping system is subjected to higher media temperatures the

surface temperature of the valve housing can also reach this

value.

If the liquid medium is drained from the system, this can lead to

burns, scalding or causticization for the operating and

maintenance personnel.

Detergent can leak from the leakage outlet during CIP cleaning.

Attach warning signs.

Rinse the piping system with cold water

before carrying out maintenance work.

Install collecting tubs or a collecting piping

system for controlled pressure-free

drainage of the CIP media.

Make sure, if during the maintenance work

the CIP is activated, that no-one is standing

in the danger area of the leakage outlet.

Safety

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 9 / 34

Malfunction due to incorrect handling

Explanations Measures

The valve should be made inoperative if malfunctions occur. Disconnect the electrical connection to the

valve.

Solve faults immediately.

The valve should be installed in such a way that the complete

valve inset can be removed.

Make sure that there is sufficient space

above the drive.

The valve should be installed so that a complete draining by

gravity of the product or leakage chamber is ensured.

Install the valve in a vertical position in

horizontal piping.

The valve’s switching function is defective or takes place jerkily.

The valve has not been properly installed during assembly.

Install the valve housing free from tension

in the piping system.

Residues from welding or assembly can disturb the switching

function.

Remove welding residues and other

contaminants from the valve housing.

The function can be put out of action or considerably disturbed if

faulty or non-specified parts are assembled or exchanged on the

valve.

This can also lead to injuries to the operating and maintenance

personnel.

Only use accepted parts from the

manufacturer.

If the valve is not checked or maintained at regular intervals, this

can lead to malfunction or major disturbance.

Check the valve within the framework of

the fixed operating maintenance cycles.

When in strong demand the seals in the

product chamber should be changed more

regularly.

Malfunction through improper use

The valve’s operating area is envisaged for certain operating states

(pressure, temperature, media).

The valve’s function can be disturbed greatly by different

operating conditions.

Make sure of proper utilization.

Transport

Deli

very

10 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

3Delivery

3.1 Transport

The double-seat valves or prefabricated valve units should remain in the delivered packing

systems until assembly.

After unpacking the goods and before assembling them the operating manual must be

read.

Warning - Danger to persons!

Possibly supplied foil packings are airtight. Therefore never pull packing material over

the head. Otherwise, there is a danger of suffocation!

Warning - Danger to persons!

Lifting equipment or aids that are too weak can break.

Always make sure of sufficient carrying capacity when selecting lifting equipment or

aids!

Only use tested and approved lifting equipment and aids such as:

Shackles e.g. complying with DIN 82101

Slinging chains e.g. complying with DIN 5687 Quality Class 8

3.2 Instructions for Delivery and Performance

•Check the delivery note data for factual correctness.

•Check the delivery for completeness. Later complaints will not be accepted.

•Carry out a visual inspection of the packing system for external transport damages.

These should be brought to the attention of the forwarder immediately.

Complaints for unrecognizable transport damages should be made within a week.

3.3 Storage Instructions

The goods should be stored in dry, closed rooms if possible in the original packaging. UV

radiation and direct sunlight should be avoided. The maximum air moisture should be no

higher than 60%; the maximum storage temperature should not exceed 40%.

3.4 Disposal of Packaging

Note

The packaging should be disposed of in a proper and environmentally friendly way.

National regulations should be adhered to.

Description of Function

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 11 / 34

4Description of Function

Double-seat valves are installed at critical connection points of two process pipings. The

different liquid media flowing through the pipings are sealed twice (double) against each

other in the valve’s seat area through the upper and lower valve disk.

The leakage chamber is formed between both valve disks. Should a leakage occur at one

of the two valve disks, then the respective medium can flow out through the leakage

chamber to the outside.

The leakage-free switching function is characteristic for the double-seat valve:

1. The lower valve disk moves in the valve seat’s sealing area against the upper

valve disk. At the same time, the leakage chamber is completely closed.

2. The valve disks now lying against each other move from the upper valve seat

area into the open valve position.

3. When the valve is closed, the adjacent valve disks now move into the upper

valve seat area.

The leakage chamber is still closed.

4. The lower valve disk moves in the valve seat’s sealing area to its final

position and at the same time slowly opens the leakage chamber.

Due to the piston-like valve rods, the double-seat valve is insensitive to pressure impacts.

The lower balancer is also at the same time the actuator piston i.e. the valve does not

possess a separate actuator cylinder.

The upper and lower valve disk are integrated into the respective balancer. During the

switching function, the balancers move between product chamber and the upper or lower

flushing chamber.

The sealing between the product chamber and the flushing chamber is effected through a

gap-free tensioned lip sealing.

4.1 Valve Types

The current valve type 481 has been updated. The new valve type 491 is in the product

area identical to the EHEDG tested valve type 580.

The valve type 491 has, however, no seat lifting but is therefore equipped with leakage-

chamber cleaning.

The follow-on type 491 is characterized by:

•Separate upper and lower valve disks, easier sealing change

•Form seals (EPDM) above and below in the seat area

•Updated seat design with controlled cleaning gap

•One-piece housing execution, hygienically formed product chamber

Description of Function

12 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

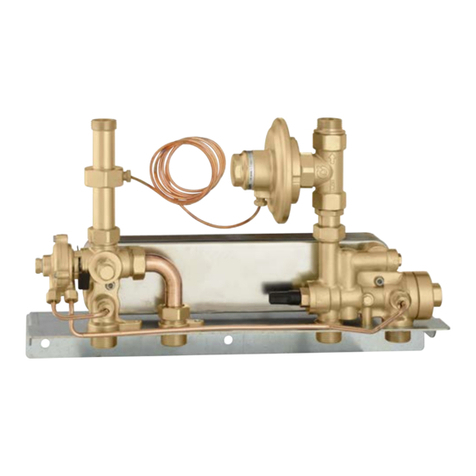

02

Fig.1: Double-seat valve type 491

1Electric feedback

2Upper venting bore hole (leakage display quad ring)

3CIP piping

4Flush pipe connection (pipe ∅8 mm)

5Leakage chamber outflow (leakage display seat sealings)

6Lower venting bore hole (leakage display quad ring)

7Air connection (PK 4 ∅6/4 mm)

8Flushing chamber outflow (leakage display lip sealing)

3

4

7

5

1

2

6

8

Technical Data

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 13 / 34

Transport

4.1.1 Process Integration, Mechanical

Four standard housing executions are offered for the integration of the double-seat valves

in the piping system (standard execution in bold print). The other housing executions are

available on request.

03

Fig. 2: Form of execution

A Form II (e.g. execution 49101-II)

B Form X (e.g. execution 49104-X)

Note

In the housing form Xthe line-evens are moved by 90°; in the housing execution II these run

parallel to each other. The broad line in the symbol display indicates the upper line-even.

Order No. Execution X Order No. Execution II

49101

49102

49103

49104

4.1.2 Process Integration, Electrical

There are various control units available for the integration of the double-seat valves in

the automated production CIP process:

Types

Valve position

Control valves

BUS system

S

1/2

--

S0 /S0-A

1/2

0/1

ASI

S3 / S3-A

2

1

ASI

•Proximity switch for position (S)

•Control unit for position and function check (SO)

•Control unit for switching, position and function check (S3)

A

B

Technical Data

14 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

5Technical Data

Product range

Materials Stainless steel 1.4301 (or 1.4404)

Seals EPDM, FDA conform

Surface area ≤0.8 µm

Other parts

Materials Stainless steel 1.4301

Seals EPDM / HNBR

Surface area polished, matte

Production

Operating pressure 0 - 10 bar

Temperature 0 -95 °C

Pressure impact safety 40 bar tested

Control air 5 -8 bar

Cleaning

CIP operating pressure 2 -5 bar

CIP pressure for flush

connection

0.4 -0.6 bar

Flushing chamber

pressure

< 0.5 bar

Temperature 0 – 95 °C / 140 °C

CIP amount for leakage

chamber

approx. 20l / min

Noise emissions

Operator position noise < 70 dB(A)

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 15 / 34

04

Fig. 3: Valve dimensions [mm]

DN ab c d e

50 100 85 184 53 491

65 115 100 205 70 542

80 130 116 251 85 643

100 140 136 261 104 680

125 180 165 312 129 813

150 180 190 369 154 916

Kvs value [m3/h]

DN Passage above Valve seat Passage below Air consumption

[Bcm3/lift]

50 80 65 85 140

65 135 100 150 200

80 200 150 230 370

100 310 215 395 390

125 390 370 460 1310

150 505 430 605 1310

16 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

6Operation/ Use

6.1 Valve Switching Functions

The double-seat valve’s function is characterized through the following described

switching statuses.

6.1.1 Production – Valve Closed

•The various process media flow through the upper and lower piping system

or valve housing.

•Both valve disks are in the final position in the seat area and seal the piping

systems against each other.

•The leakage chamber, which is connected with the free environment, is

formed between both valve disks.

•When there are sealing problems in the seat area, the respective medium

can flow through the leakage chamber and the leakage outlet to the

outside.

05 06

Fig. 4: Valve closed Valve open

6.1.2 CIP or Production Valve Open

•Through the compressed air supply at Pos. 7 (page 12, Fig. 1) the lower valve

disk moves from its final position against the upper valve disk. At the same

time, the seat sealing is maintained. The double-seat valve switches leak-

free.

•The leakage chamber between the now adjacent valve disks is sealed via the

leakage chamber sealing.

The valve disks travel into the opened valve position.

•When the valve is closed, the valve disks now travel against the upper valve

seat.

•The lower disk, maintaining its seat sealing, travels into the final position

and at the same time continually opens the leakage chamber.

Operation/ Use

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 17 / 34

6.1.3 Cleaning – Balancer (B)

07

Fig. 5: Cleaning methods

In hygienically sensitive processes we recommend connecting the flushing

chambers to the CIP circuit via controllable valves.

•During the valve switching process the balancers move between the product

chamber and the adjacent upper and lower flushing chambers.

•The cleaning medium flows through the flushing chambers via a stationary

inflow and outflow.

•The balancers’ upper and lower product-affected area are thus integrated

into the cleaning process.

6.1.4 Cleaning – Leakage Chamber (L)

•In the valve’s closed and open position, the leakage chamber between the

two valve disks is sealed all the way to the piping system.

•Through a stationary supply pipe, cleaning medium can be injected from

above into the leakage chamber.

•The cleaning medium is guided outdoors through the leakage outlet.

(B)

(L)

Operation/ Use

18 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

6.2 CIP Cleaning

To clean the valve seat it is advantageous to open the double-seat valve at intervals if both

piping systems are located in the CIP cycle

(see also Chapter 10.4, Page 29).

The cleaning of the flushing chambers and the leakage chamber takes place at the same

time (or separately) via a flush pipe. This can be supplied with cleaning fluid directly at the

CIP flow or also separately.

Both flushing chambers are rinsed from below to the top. At the discharge an overflow

pipe drawn downwards is attached (the chamber is thus always filled).

The leakage chamber and the cylindrical valve seat are rinsed by a radially emitted liquid

stream between both valve disks. The liquid flows away through the leakage pipe to the

outside.

The cleaning liquid emitted from the flushing chambers or the leakage chamber is recycled

via a collecting tub or flows into the drains.

6.3 Leakage Detection

It is essential that the form seals in the separate valve disks are protected from

mechanical damage during operation and maintenance.

A leakage in the area of the product and flushing chamber can be recognized as described

below:

•In the case of defective form seals of a valve disk, liquid flows out from the

respective pipe at the leakage outlet in a closed valve position.

•In the case of defective sealing of the leakage chamber, liquid runs out at

the leakage outlet with an opened valve.

•In the case of defective inner sealing of the flushing chambers (lip seals),

liquid flows into the upper or lower flushing chambers. As this is normally

filled with flushing water from the last CIP cleaning, liquid flows away

immediately at the respective CIP outflow.

•In the case of defective exterior sealing of the flushing chambers (quad ring),

liquid flows out at the guide bush’s upper or lower venting bore hole.

Installation and Commissioning

29.06.2016

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 19 / 34

7Installation and Commissioning

Before starting the installation and commissioning:

•Check the current system status (pressure, temperature, medium, operating

conditions).

•Check the valve for external and internal damages.

•Check the valve housing in the area of the valve disk for dirt contamination.

Note

Read the chapter "Basic Safety Advice".

The double-seat valve’s function should always be checked after carrying out any work.

The functional safety should also be checked before the system’s first commissioning and

after every disassembly and assembly of the valve.

7.1 Installation of the Valve Housing

•The valve inset, the lower bushing and the housing seals are to be taken out

before the valve housing is welded into the piping system.

•There must be sufficient space above the installed valve for the

assembly/disassembly.

•The valve housing should be welded in a tension-free state between the

supply and the outlet pipe. This also applies when the pipes are subject to

thermal load.

•The welding work (TIG) may only be carried out by qualified welders (EN

287-1). Welding gas should always be used.

•The valve housing should be located in the piping system so that the assembled

valve is vertical and the leakage outlet is pointing downwards.

Requirements of the piping system

•The supply and outflow pipes must be installed in a way favorable to flow.

•The pipe cross-section of the supply and outflow pipes should at least

correspond to those of the valve’s inflow and outflow.

•A complete draining by gravity of the valve housing must be carried out.

•The leakage outlet should take place as far as possible without pressure and

danger in the corresponding outflow or collecting systems.

Operating the valve

•Check the valve housing for possible dirt residues.

•Inspect the valve-seat area for surface quality.

•Lightly grease the thread and seals.

•Locate the valve inset free of tension in the housing.

7.2 Installation of the Valve Inset

Please note the following instructions for assembling the valve inset so that the later

functionality of the valve is ensured.

Installation and Commissioning

20 / 34

DOUBLE-SEAT VALVE (Type 491)

BA 049100.06 EN 29.06.2016

08

Fig. 6: Representation of the valve inset

Serial No. Type of activity

1 Locate the bushing below [9] with actuator piston [6] and seals (Ch. 10.6) and

screw these together with the valve housing.

Position the bushing after the connection nipple for CIP collecting pipe [8].

2 Locate the complete valve inset [3] tension-free in the valve housing.

Position the valve inset after connection for CIP collecting pipe

[8]. Turn only in a clockwise direction.

3 Screw the valve inset [3] complete with the valve housing.

4 Tighten the collecting pipe [8] and the overflow pipe [7];

if necessary screw on the external CIP supply pipe.

5 Attach the electrical connections to the control unit.

6 Carry out a seal and function check.

7 Direct control through compressed air pipe at the compressed air connection

G1/8" [5] or if available at the control head.

5

8

3

1

9

6

4

7

2

Table of contents

Other handtmann Control Unit manuals

handtmann

handtmann 12503 User manual

handtmann

handtmann 33501 User manual

handtmann

handtmann FLOWmag 12020 User manual

handtmann

handtmann INOVA User manual

handtmann

handtmann 75100 User manual

handtmann

handtmann 12501 User manual

handtmann

handtmann 12504 User manual

handtmann

handtmann 12012 User manual

handtmann

handtmann 12605 User manual

Popular Control Unit manuals by other brands

elsner elektronik

elsner elektronik RF-MSG-DST Technical specifications and installation instructions

LG

LG V-Net PQDSBNGCM1 installation manual

Danfoss

Danfoss EV250B NC Mounting guide

ICP DAS USA

ICP DAS USA M-7067D quick start guide

Keofitt

Keofitt SESAME series user manual

Rehau

Rehau NEA SMART 2.0 Quick install