BA(k)_033501.06_EN

2023-07-27 Albert Handtmann Armaturenfabrik GmbH & Co. KG 3 / 30

0Foreword ..........................................................................................................................................................5

1General.............................................................................................................................................................6

1.1 Manufacturer.....................................................................................................................................................6

1.2 Proper application .............................................................................................................................................6

1.3 Improper application .........................................................................................................................................6

1.4 Duties of operator..............................................................................................................................................6

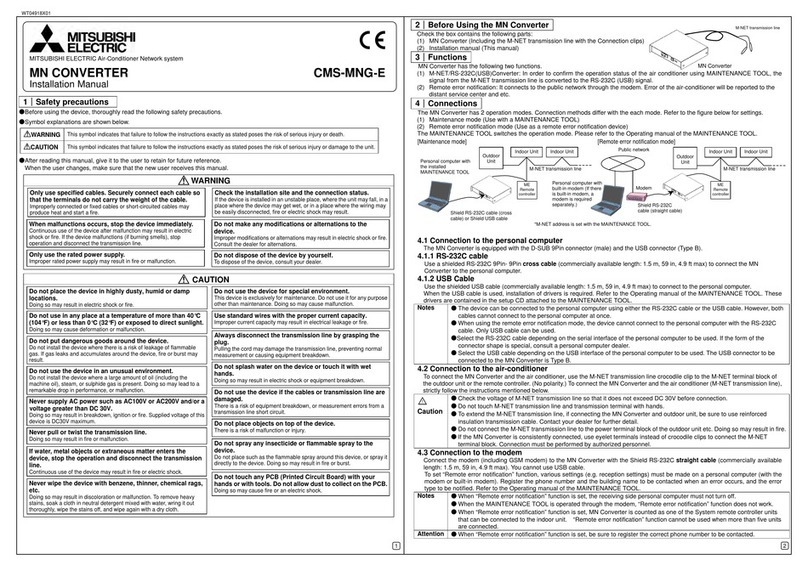

2Safety Information............................................................................................................................................7

2.1 Symbols..............................................................................................................................................................7

2.2 Hazards and Safety Instructions ........................................................................................................................7

3Notes ................................................................................................................................................................9

3.1 Notes on transport.............................................................................................................................................9

3.2 Instructions for Delivery and Performance......................................................................................................10

3.3 Storage Instructions.........................................................................................................................................10

4Technical Description......................................................................................................................................11

4.1 Technical Data..................................................................................................................................................11

4.2 Identification of components .......................................................................................................................... 12

4.3 Valve types.......................................................................................................................................................13

5Perfomance Data ............................................................................................................................................14

6Operation .......................................................................................................................................................16

6.1 Valve actuator..................................................................................................................................................16

6.2 Valve Tightness / Leak ..................................................................................................................................... 16

6.3 Operating Characteristics ................................................................................................................................17

6.4 Valve cleaning / CIP.......................................................................................................................................... 17

7Disassembly....................................................................................................................................................18

7.1 Assembly instructions......................................................................................................................................18

7.2 Disassembling manual safety relief valves - Types 33501, 33502, 33503, 33521 ...........................................19

7.3 Disassembling pneumatic safety relief valves - Types 33601, 33602, 33603, 33621 ......................................19

8Installation and Commissioning......................................................................................................................21

8.1 Installation Instructions ................................................................................................................................... 21

8.2 Assembly.......................................................................................................................................................... 22

9Trouble shooting.............................................................................................................................................23

10 Maintenance...................................................................................................................................................24

10.1 Maintenance....................................................................................................................................................24

10.2 Inspection and Maintenance Intervals ............................................................................................................24

10.3 Function Checks............................................................................................................................................... 25

10.4 Seals.................................................................................................................................................................26

10.5 Spare parts.......................................................................................................................................................27

11 Additional Equipment.....................................................................................................................................28

11.1 Heating insets .................................................................................................................................................. 28

12 Disposal ..........................................................................................................................................................29