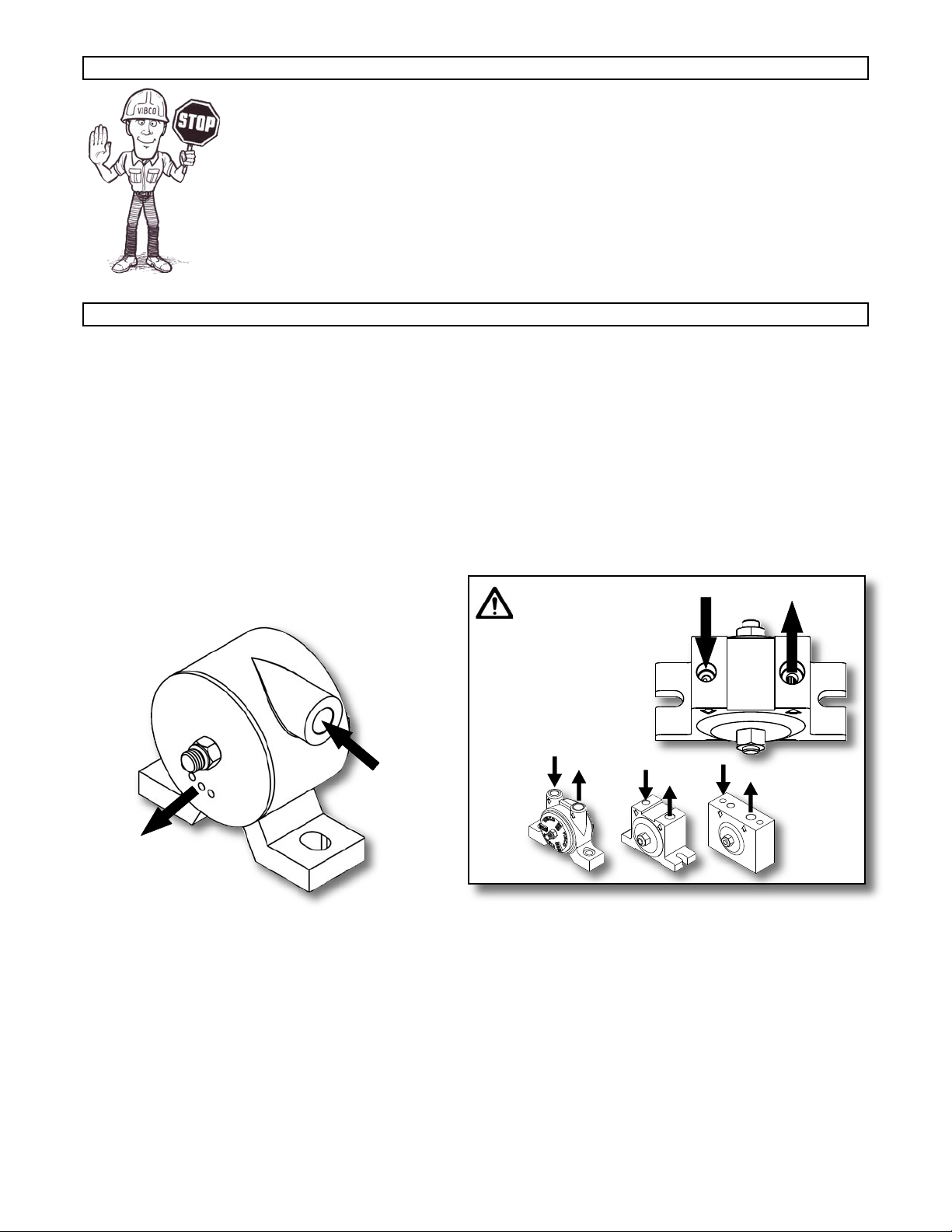

Mounting Plate

For force up to 100 lbs. use a 1/4 in. thick plate, 100 to 500 lbs. use a 3/8 in. to 1/2 in. thick plate and over

500 lbs. use a 1/2 in. thick plate.(See Table).

Mounting Channel

Never place the vibrator directly onto the skin of the bin. It should be mounted to either a plate or a piece

of channel iron that has been welded to the bin. The proper mounting method is to use either 3 in. or 4

in. channel iron. This will help to stiffen the structure to be vibrated as well as spread the vibration over a

larger surface, increasing the overall efciency and diminishing the possibilities of fatigue cracks in the bin

material.

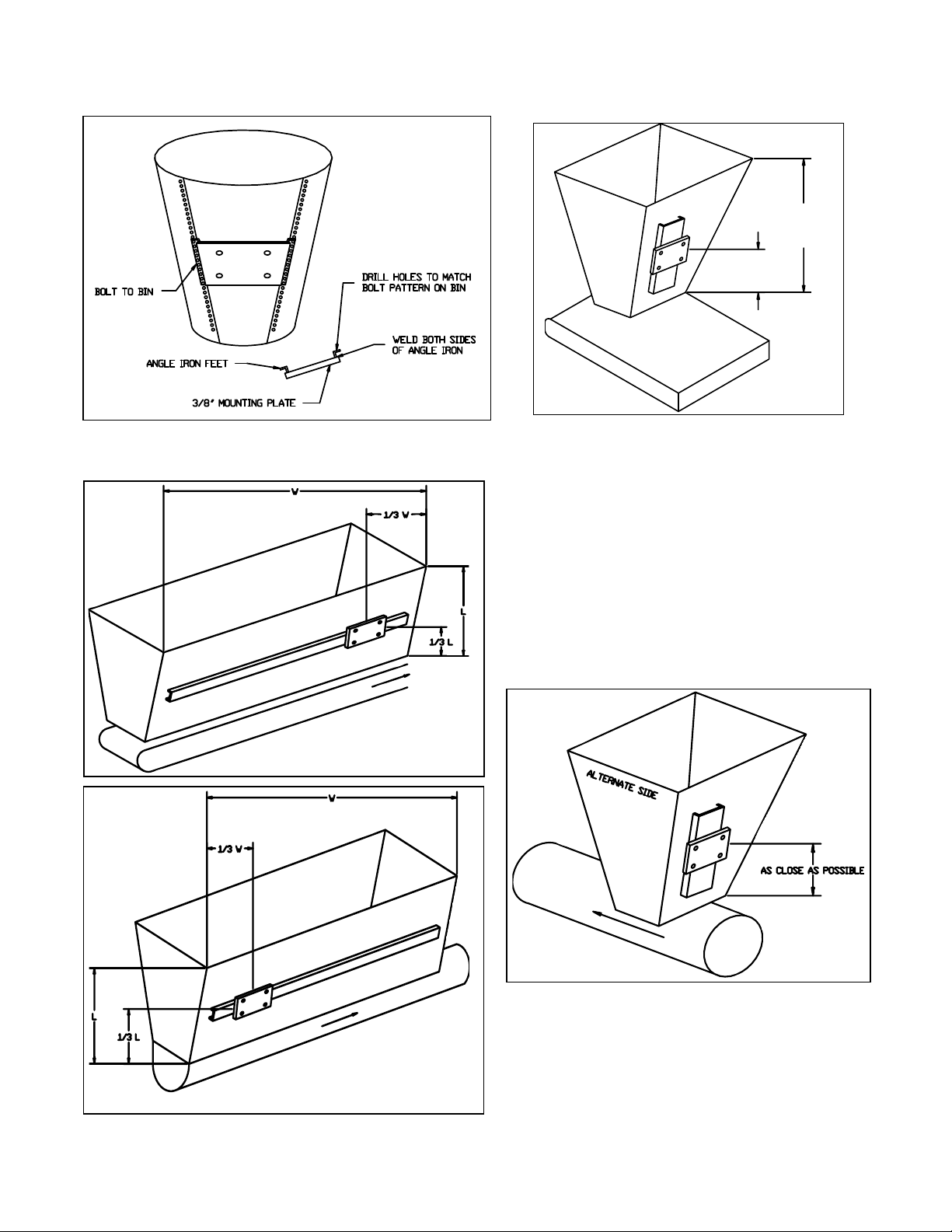

The length of the channel iron is determined by the thickness of the bin plate. For vibrators with a force up

to 500 lbs. and a bin plate under 3/16” the 4 in. channel iron should extend 18 to 36 inches on both sides

of the vibrator. For smaller vibrators with a force of up to 100 lbs. and a bin thickness of 3/16 in. to 1/4 in.

the length of the 3 in. channel iron should extend 3 to 4 inches on both sides of the vibrator. For vibrators

with a force between 100 and 500 lbs. and a bin thickness of 3/8 in. to 1/2 in. the length of the 3 in. or 4

in.channel iron should extend 6 to 8 inches on both sides of the vibrator. (See Table).

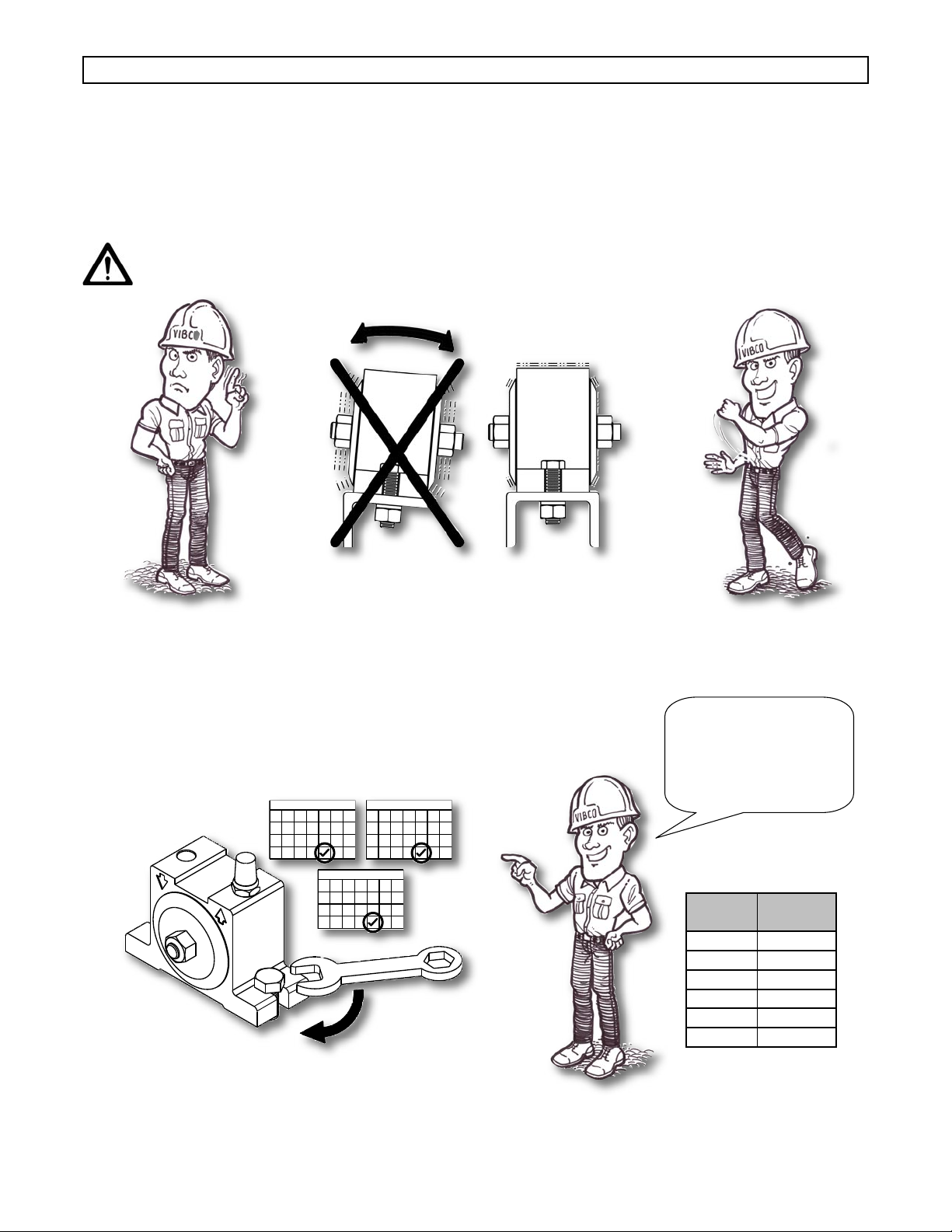

Warranty is void if vibrator is not properly installed. During installation follow and check off the

following steps and your vibrator should provide you with years of trouble-free service.

� Determine the length of the channel iron.

� Select thickness of vibrator mounting plate and method of mounting.

� STITCH weld mounting plate to channel iron.

� Determine where vibrator should be placed on the bin.

� STITCH weld channel iron to bin.

� Place vibrator on mounting plate. It is important that you check the

mounting plate for any warping. Secure vibrator rmly.

� Install safety chain or wire.

� Connecting pneumatics.

� Continuous vs. intermittent operation.

� FILL OUT WARRANTY CARD!!!

Mounting Instructions Checklist

3

PHONE ORDER: 1-800-633-0032 FAX: 1-401-539-2584

LBS. OF FORCE PLATE THICKNESS

up to 100 lbs. 1/4" plate

100 to 500 lbs. 3/8" to 1/2" plate

over 500 lbs. 1/2" plate

CORRECT MOUNTING PLATES

SUGGESTED CHANNEL LENGTH

LBS. OF FORCE/BIN WALL WIDTH CHANNEL IRON WIDTH CHANNEL IRON LENGTH

up to 100 lbs / bin wall < 3/16" (thin) 3" channel iron 18" to 36" on both sides of vibrator

up to 500 lbs / bin wall = 3/16" to 1/4" 4" channel iron 3" to 4" on both sides of vibrator

over 500 lbs / bin wall = 3/8" to 1/2" 4" channel iron 6" to 8" on both sides of vibrator

If you have any questions consult the Mounting Instruction section of this manual or call

VIBCO’s Technical Support at (800) 633-0032.

MOUNTING INSTRUCTIONS