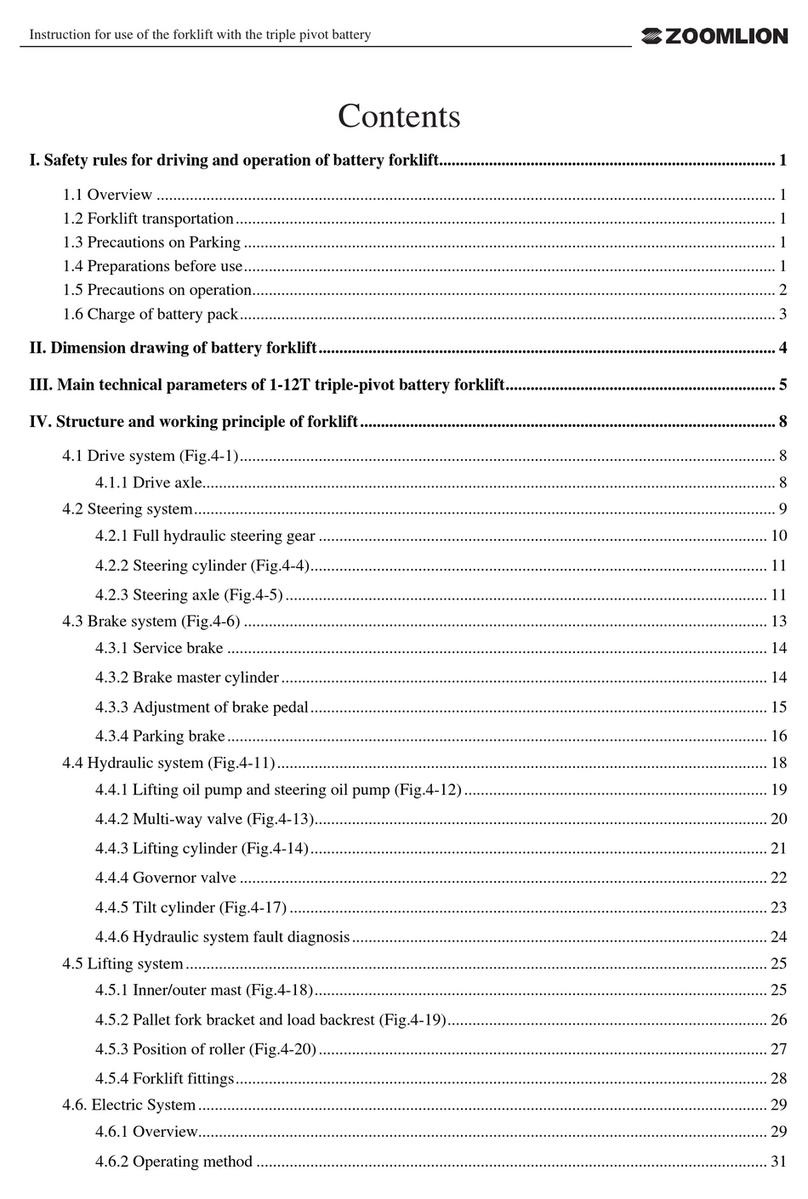

Content

1 TRUCK INTRODUCTION ...........................................................................................................1

1.1 SUMMARY...................................................................................................................................1

1.2 USE OCCASIONS AND CONDITIONS ...............................................................................................2

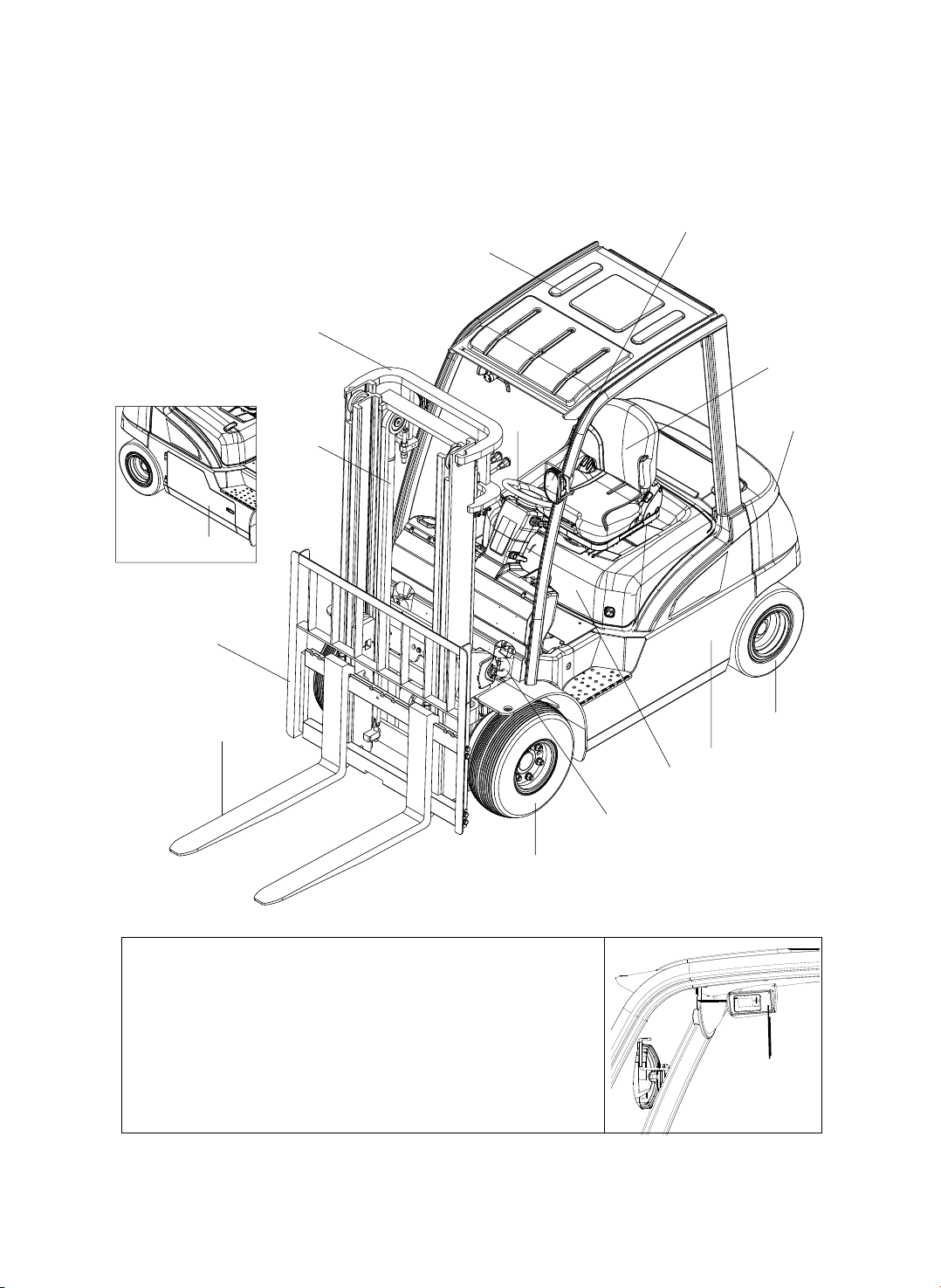

1.3 APPEARANCE AND MAIN PART......................................................................................................3

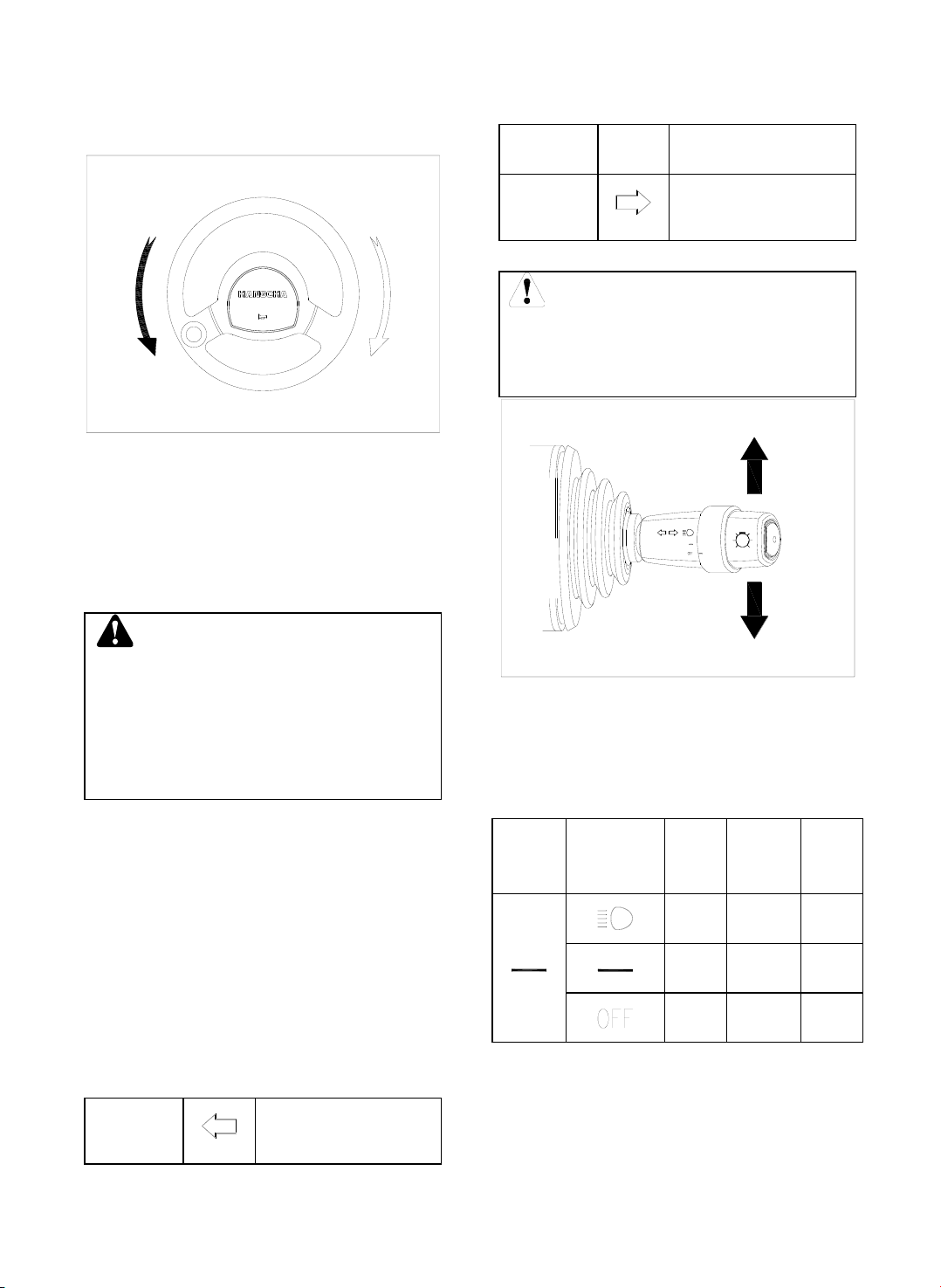

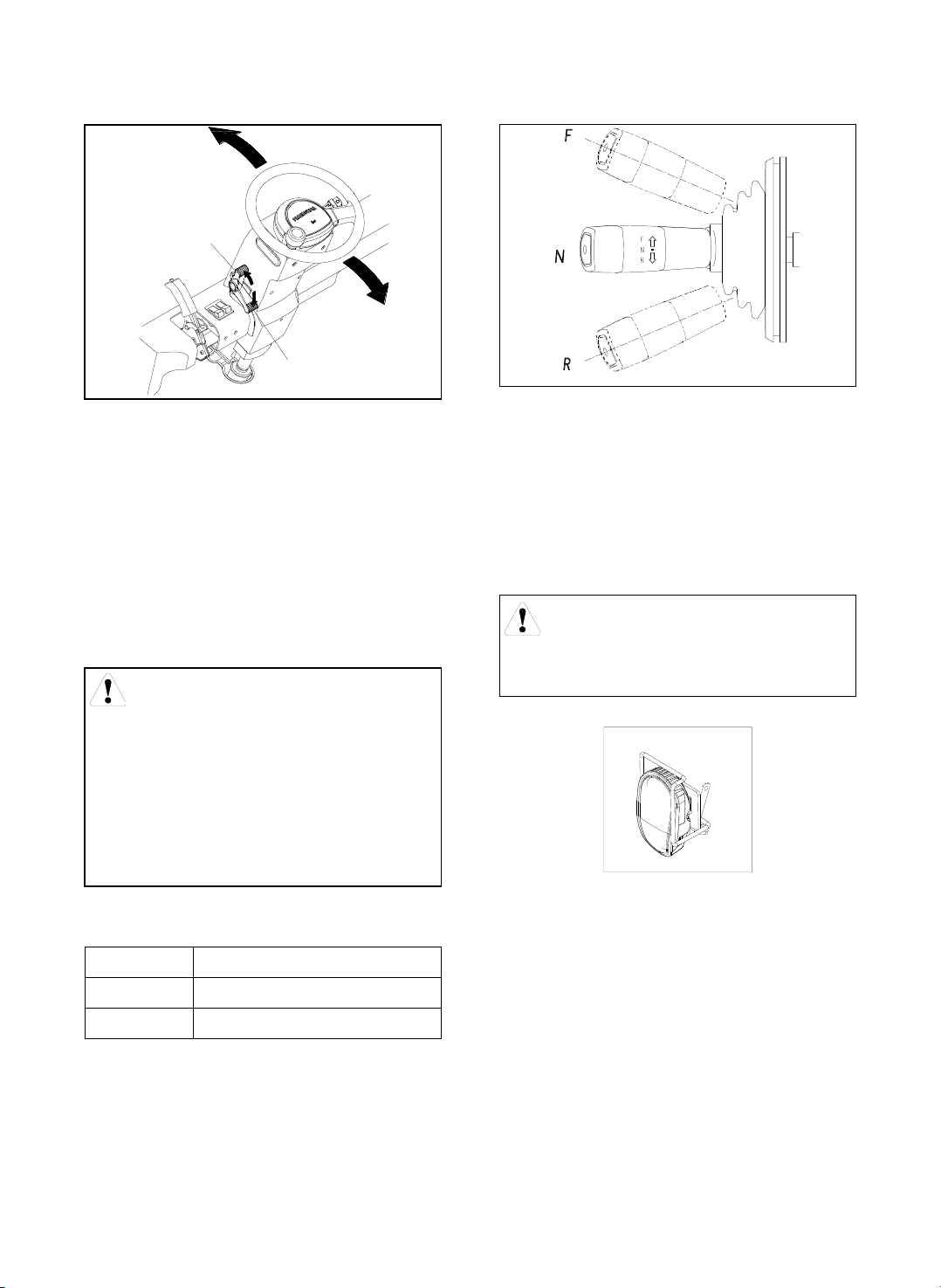

1.4 DISPLAYS AND CONTROLS ...........................................................................................................4

1.5 DISPLAY METER.........................................................................................................................13

1.6 LITHIUM BATTERY CHARGING PORT STRUCTURE AND ITS SIDE DOOR..............................................26

1.7 LITHIUM BATTERY REPLACEMENT AND INSTALLATION ....................................................................27

1.8 TRUCK BODY AND OTHERS...........................................................................................................28

1.9 ADJUST AND REPLACE FORKS ......................................................................................................33

1.10 OPERATOR PRESENCE SENSING (OPTION).................................................................................35

1.11 NAMEPLATE AND WARNING LABEL ..............................................................................................37

1.12 STRUCTURE AND STABILITY OF TRUCK........................................................................................39

2 SAFETY INSTRUCTIONS...........................................................................................................43

3 OPERATION AND SAFETY PRECAUTIONS FOR THE ELECTRIC FORKLIFT LITHIUM

BATTERY........................................................................................................................................50

4 TRUCK LIFTING, CARRYING AND TOWING ...........................................................................53

4.1 LIFTING.......................................................................................................................................53

4.2 CARRYING...................................................................................................................................55

4.3 TOWING ......................................................................................................................................56

5 LITHIUM BATTERY.....................................................................................................................57

5.1 SAFETY NOTICE...........................................................................................................................57

5.2 INSTALLATION INSTRUCTIONS.......................................................................................................57

5.3 BASIC TERMS OF LITHIUM-ION POWER BATTERY............................................................................58

5.4 USAGE NOTICE............................................................................................................................58

5.5 DAILY MAINTENANCE....................................................................................................................59

5.6 EMERGENCY PLAN.......................................................................................................................59

5.7 DIMENSION/WEIGHT ...................................................................................................................60

5.8 CHARGING OF LITHIUM BATTERIES................................................................................................61

6 OPERATING INSTRUCTIONS....................................................................................................75

6.1 DURING RUNNING-IN....................................................................................................................75

6.2 CHECK AND ADJUST BEFORE OPERATION..................................................................................75

6.3 OPERATION .............................................................................................................................81