HANKISON SPX FLOW HES Series User manual

HES Series

Energy Saving Refrigerated Type Compressed Air Dryers

Models: HES800, HES1000, HES1250, HES1500, HES1750, HES2000, HES2500, HES3000

FORM NO.: 5001364 REVISION: 12/2017 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

CONTENTS

GENERAL SAFETY INFORMATION....................................................................... 1

RECEIVING, MOVING, AND UNPACKING............................................................ 1

1.0 INSTALLATION

1.1 Location ................................................................................................................. 2

1.2 Mounting ................................................................................................................. 3

1.3 Piping Connections ................................................................................................. 3

1.4 Electrical Connections ............................................................................................ 3

1.5 Electronic Demand Drain......................................................................................... 3

2.0 OPERATION

2.1 Minimum/Maximum Operating Conditions............................................................... 4

2.2 Start-Up.................................................................................................................... 4

2.3 Using the RS-485 Port Connector (J8) .................................................................... 6

2.4 Using the USB Host Feature (J7) ............................................................................ 6

2.5 Using the Ethernet Feature (J3)............................................................................... 8

3.0 MAINTENANCE

3.1 Monthly Maintenance............................................................................................... 14

3.2 Annual Maintenance ................................................................................................ 14

4.0 TROUBLESHOOTING GUIDE.......................................................................... 16

5.0 REFERENCE

Sizing ....................................................................................................................... 17

Engineering Data Table............................................................................................ 18, 19

Dryer Set Point Table ............................................................................................... 20

Dryer Alarm Table .................................................................................................... 21

Controller Screen Shots

Status Menu Screens .......................................................................................... 22

Setup Menu Screens ........................................................................................... 23

Network Menu Screens ....................................................................................... 24

6.0 DIMENSIONS / WEIGHTS ................................................................................. 25

7.0 ELECTRICAL SCHEMATIC

Model 800 ................................................................................................................ 26, 27

Models 1000 and 1250 ............................................................................................ 28, 29

Models 1500 and 1750 ............................................................................................ 30, 31

Models 2000 and 2500 ............................................................................................ 32, 33

Model 3000 .............................................................................................................. 34, 35

575-460/3/60 Transformer Pack .............................................................................. 36

230-460/3/60 Transformer Pack .............................................................................. 37

8.0 REPLACEMENT PARTS

Air-Cooled Units....................................................................................................... 38, 39

Water-Cooled Units.................................................................................................. 40, 41

Cabinet Panels......................................................................................................... 42

WARRANTY.................................................................................................................. 45

1

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

This shipment has been thoroughly checked, packed and

inspected before leaving our plant. It was received in good

condition by the carrier and was so acknowledged.

Check for Visible Loss or Damage. If this shipment shows

evidence of loss or damage at time of delivery to you, insist

that a notation of this loss or damage be made on the delivery

receipt by the carrier’s agent.

B. UNPACKING

Check for Concealed Loss or Damage. When a shipment

has been delivered to you in apparent good order, but

concealed damage is found upon unpacking, notify the carrier

immediately and insist on his agent inspecting the shipment.

Concealed damage claims are not our responsibility as our

terms are F.O.B. point of shipment.

C. MOVING

In moving or transporting dryer, do not tip dryer onto its side.

D. STORAGE/SHUT DOWN

Dryer should not be stored outside (either packed

or unpacked) or exposed to the weather. Damage to electrical

and control components may result.

IMPORTANT: WATER-COOLED UNITS - If unit is shut down

in below freezing temperatures, the water-cooled condenser

may freeze and cause permanent damage. Condenser must be

drained when the unit is shut down.

IMPORTANT: Do not store dryer in temperatures above 130°F

(54°C).

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES

This equipment is a pressure containing

device.

• Do not exceed maximum operating

pressure as shown on equipment serial

number tag.

• Makesureequipmentisdepressurizedbeforeworkingon

or disassembling it for service.

2. ELECTRICAL

This equipment requires electricity to

operate.

• Installequipmentincompliancewithall

applicable electrical codes.

• Standardequipmentissuppliedwithelectricalenclosures

not intended for installation in hazardous environments.

• Disconnectpowersupplytoequipmentwhenperforming

any electrical service work.

3. BREATHING AIR

• Air treated by this equipment may

not be suitable for breathing without

furtherpurication.

Refer to applicable standards and

specications for the requirements

for breathing quality air.

2

IMPORTANT: READ PRIOR TO STARTING THIS EQUIPMENT

1.0 INSTALLATION

1.1 Location

A. For typical placement in a compressed air system, see draw-

ing.

B. Air compressor intake – Locate air compressor so that con-

taminants potentially harmful to the dryer (e.g. ammonia) are

not drawn into the air system.

C. Dryer should be installed in a moderately heated, well ven-

tilated area. Avoid locations immediately adjacent to cold

exterior windows or walls, or adjacent to high temperature

ovens or boilers.

D. Clearances:Freeairow

Front 37.3/8 inches (950 mm)

Back 37.3/8 inches (950 mm)

Left Side 37.3/8 inches (950 mm)

Right Side 6 inches (153 mm)

Top 25.5/8 inches (650 mm)

Service - To facilitate maintenance leave 37.3/8 inches (950

mm) of clearance in front of dryer.

E. Standard units are designed to operate in ambients:

Air-cooled: 40 to 110°F (4 to 43°C).

Water-cooled: 40 to 130°F (4 to 54°C).

F. Dryer is designed to operate at all altitudes - no adjustment

for altitude is required.

G. Theinstallationofaexibleconnectionpriortothedryeris

recommended to prevent possible damage from vibration.

NOTE: Outdoor installation – Standard units are designed for

indoor installation. Contact manufacturer if installing outdoors.

Aftercooler

Separator

Dryer

Compressor

COOLING WATER

INLET

COOLING WATER

OUTLET

COOLING WATER

OUTLET

COOLING WATER

INLET

DETAIL ‘A’

Cooling Water Connection Ports for

Models 800, 1000, 1250, 1500

DETAIL ‘B’

Cooling Water Connection Ports for

Models 1750, 2000, 2500, 3000

COOLING AIR FLOW

COOLING AIR FLOW

CONDENSATE DRAIN

(OPTIONAL)

CONDENSATE DRAIN

CONDENSATE DRAIN

LEFT SIDE VIEW

CONTROL PANEL

FRONT SIDE VIEW

SEE DETAILS ‘A’ AND ‘B’

FOR WATER CONNECTION

PORT IDENTIFICATION

3

1.2 Mounting

Mount the dryer on a level solid surface. Holes are provided in the

dryerbasetopermanentlymountthedryertotheoor.

1.3 Piping Connections

A. Air Inlet - Connect compressed air line from air source to air

inlet.

Refer to Serial Number Tag for maximum working

pressure. Do not exceed dryer’s Maximum Working Pressure.

NOTE: Install dryer in air system at highest pressure possible

(e.g. before pressure reducing valves).

NOTE: Install dryer at coolest compressed air temperature

possible. Maximum inlet compressed air temperature: 120°F

(49°C). If inlet air exceeds this temperature, precool the air with

an aftercooler.

B. Air Outlet - Connect air outlet to downstream air lines.

C. Bypass piping - If servicing the dryer without interrupting the

air supply is desired, piping should include inlet and outlet

valves and an air bypass valve.

D. Water-cooled models - cooling water inlet and outlet

1. Connect cooling water supply to cooling water inlet.

2. Connect cooling water return line to cooling water outlet

connection.

NOTE: Strainer and water regulating valve are supplied on water-

cooled models. Also, it is recommended to add water inlet/outlet

temperature and pressure gauges to the water piping.

1.4 Electrical Connections

IMPORTANT: Use copper supply wires only.

A. Dryer is designed to operate on the volt-

age, phase, and frequency listed on the

serial number tag.

B. Electrical entry is through a hole in the

top of the cabinet. Route wires through

the bottom of the electrical enclosure.

Connect power source to the terminal strip in the electrical

enclosure as shown on the electrical schematic included with

the dryer.

NOTE: Refrigeration condensing unit is designed to run

continuously and should NOT be wired to cycle on/off with the

air compressor.

1.5 Electronic Demand Drain

A. An automatic electric demand drain (EDD)

discharges condensate removed by the

separator.

B. All dryer models are supplied with one

EDD. Models with the additional (optional)

oilremovallteraresuppliedwithasecond

EDD.

C. Thedrainsarepipedtottingsinthelegoftheunit.Con-

densateshouldbepipedfromthisttingtoanopenvented

oordrainorsump.

NOTE: Discharge is at system pressure. Drain line should be

anchored.

NOTE: Condensate may contain oil. Comply with applicable laws

concerning proper disposal.

D. Verify that isolation valves are open. If the drain fails to

discharge after the valve is energized, the electronic control

circuit will repeatedly energize the valve in an attempt to clear

the discharge port. If, after 60 seconds, the drain still fails

to discharge, the control circuit then switches to the alarm

mode. In this mode the valve is de-energized and the red

alarm light is activated on the drain and the dryer controller.

The valve is then automatically energized every 80 seconds

for 60 seconds. Check the drain operation. Push drain

(push-to-test) button on the Energy Management Monitor

controlboardtoenergizedrain.Aowofcondensateand/

or air should be present at the drain outlet. The alarm mode

automatically clears after the drain returns to normal opera-

tion.

E. Description of Operation:Thecondensateowsthrough

the feed line (1) into the condensate drain and accumulates

in the housing (2). A capacitive sensor (3) continuously reg-

isterstheliquidlevel.Assoonasthecontainerislled,a

xedwaitingperiodbeginsduringwhichmorecondensate

accumulates. After the waiting time has expired the pilot valve

(4) is then activated and the diaphragm (5) opens the outlet

line (6) for discharging the condensate.

When the condensate drain has been emptied, the outlet

line is closed again quickly and tightly without wasting com-

pressed air.

2.0 OPERATION

Basic theory of operation: This energy saving dryer has a

completely new compressor technology at the heart of its

operation. This is the Digital Scroll. This compressor has a

unique mechanism that allows it to be completely “unloaded”.

This is accomplished internally, using a piston to “pull”

the upper scroll apart from the lower scroll. This stops the

compression of the refrigerant. At the same time: the electric

motor unloads and continues to turn, providing lubrication to the

mechanism. This greatly reduces power consumption from the

loaded state. At 100% load the compressor runs fully loaded,

with no noticeable difference between this compressor at full load

and the standard scroll compressor. The solenoid controlling the

loading and unloading cycles open and closed in response to the

temperature of the refrigerant and thereby the load on the system.

NOTE: The compressor sound changes noticeably between

the loaded and unloaded state, this occurs every ten to twenty

seconds.

4

1. Temperature Indicator

2. Operator Interface Display

3. Power-on Light

4. Compressor-on Light

5. Alarm / Service Light

6. Schedule On/Off and Enter Button

a. In Display Mode: Press to toggle between

SCHEDULED MODE and MANUAL MODE.

b. In Program Mode:

i. Press to move to a lower level menu.

ii. Press to accept a value that has been edited.

7. Program Mode (i) and Esc

a. In Display Mode: Press and hold to enter program

mode.

b. In Program Mode: Press to move to a higher level

menu.

8. Up Arrow

a. In Display Mode: Press to cycle to next Display

screen.

b. In Program Mode:

i. Press to view the next item in a list or to

decrement a variable to a higher value.

ii. When the top of the list (or highest value) is

displayed, pressing the up button will cause

the display to wrap to the bottom of the list (or

lowest value).

9. Down Arrow

a. In Display Mode: Press to cycle to previous

Display screen

b. In Program Mode:

i. Press to view the previous item in a list or to

decrement a variable to a lower value.

ii. When the bottom of the list (or lowest value) is

displayed, pressing the down button will cause

the display to wrap to the top of the list (or

highest value).

10. 1/0: Press at any time to turn the dryer on/off.

11. Drain test: Press at any time to momentarily open the

drains.

12. Reset: Press at any time to clear the alarm/service

message (if shown) and the alarm LED.

CONTROL PANEL

1 2 3 4 5

67 8 9 10 11 12

2.1 Minimum/Maximum Operating Conditions

A. Maximum inlet air pressure: refer to dryer serial number tag

B. Minimum inlet air pressure: 30 psig (2.1 barg)

C. Maximum inlet air temperature: 120°F (49°C)

D. Maximum ambient temperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 40°F (4°C)

2.2 Start-Up

A. Energize Dryer. Green power on light will illuminate.

IMPORTANT: Energize dryer for 24 hours before refrigeration

compressor is started! Never use the disconnect switch to

shutdown the dryer for an extended period of time (except

for repair). Failure to follow these instructions may result in

a non-warrantable compressor failure.

B. Program Monitor

Press and hold Program Mode button until Main Menu screen

appears. Use the Up and Down arrow buttons to scroll through

the list of sub-menu choices. Press Enter button to view the

sub-menu that is displayed. Press ESC to exit the Main Menu

and return to Display mode.

1. Language Selection

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the list of languages (choice of 13 available: English,

Spanish, French, German, Portuguese, Italian, Polish,

Danish, Dutch, Norwegian, Finnish, Swedish and Czech).

b. Press ‘Enter’ button to select the language that is

displayed.

c. Push ‘ESC’ at any time to return to the Main Menu.

2. Setting Date & Time

a. Press ‘Enter’ to edit value.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set year (00 to

99 representing 2000 to 2099). Press ‘Enter’ to accept

new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set month (1-

12). Press ‘Enter’ to accept new value.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set day (01 to

maximum for the month and year selected). Press ‘Enter’

to accept new value.

e. Use the ‘Up’ and ‘Down’ arrow buttons to set hours (00

to 23). Press ‘Enter’ to accept new value.

f. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes (00

to 59). Press ‘Enter’ to accept new value.

g. Press ‘Enter’ to accept new value. Push ‘ESC’ at any

time to return to the Main Menu.

5

3. Setting Schedule

a. Use the ‘Up’ and ‘Down’ arrow buttons to select desired

“Day of week + on/off”. Press ‘Enter’ to adjust time.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hour (00 to

23). Press ‘Enter’ to accept new value.

NOTE: If the hour setting is ‘--:--’, Press ‘Enter’ again to

move the cursor under the “Day of week + on/off”.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00, 10, 20, 30, 40, 50; not shown if hour setting is ‘--:--’).

Press ‘Enter’ to accept new value and return to “Day of

week + on/off”. Repeat steps a through c as needed.

d. Push ‘ESC’ at any time to return to the Main Menu.

4. Hours To Service

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the range of permissible values (0 to 9999) before service

reminderisinitiated.Press‘Enter’tomovetonexteld.

(Only hours that refrigeration compressor is operating

are counted).

b. Press ‘ESC’ at any time to return to the Main Menu.

NOTE: On dryers with air-cooled condensers, regular

condenser cleaning is recommended. Dirtiness of

ambient air at installation site will determine frequency

of service. Typically once a month is recommended.

NOTE: All dryers contain an integral 3 micron lter.

As the lter element accumulates solid contaminants,

differential pressure increases. Solid particulate load in

the compressed air supply will determine frequency of

service. Typically element changeout is recommended

at least annually.

5. Alarm History

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll through

the last twenty (20) alarms beginning with the most recent

alarm.

b. Press ‘ESC’ at any time to return to the Main Menu.

c. To clear the alarm history, press and hold the ‘Enter’

button then press the ‘Up’ arrow button. Release both

buttons.

6. Energy Cost

a. Use the ‘Up’ and ‘Down’ arrow buttons to select the

desired currency ($ or €). Press ‘Enter’ to accept new

value.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set the energy

cost. Press ‘Enter’ to accept new value.

c. Press ‘ESC’ at any time to return to the Main Menu.

7. Push ESC button to exit program mode.

C. Starting Dryer

IMPORTANT: Dryer must be energized 24 hours before starting

refrigeration compressor.

NOTE: It is recommended that dryer be started 15 minutes before

compressedairowbegins.

1. On water-cooled models: after 24 hours and before starting

dryer,begincoolingwaterow.

2. Check for proper electrical voltage.

3. Slowly pressurize unit air side by opening inlet isolation valve.

Check for leaks.

4. After 15 minutes, open outlet isolation valve slowly.

5. Close air bypass valve.

6. Dryer may be operated in Manual or scheduled modes.

NOTE: Check for correct phasing of unit. On air-cooled models:

check fan rotation (air must be pulled through the condenser).

Fans may not start immediately or may cycle on and off. If rotation

is in the wrong direction follow the procedure below. On water-

cooled models: After starting dryer, if an unusual noise is heard

and the discharge line does not get hot, stop the dryer, reverse

two power leads, restart, and verify discharge line gets hot.

a. Manual Mode - push ‘On/Off’ button - refrigeration com-

pressor will start and run, green Compressor-on light will

illuminate. In this mode compressor will run continuously

and will not be turned on and off by the monitor. MANUAL

MODE will appear on interface panel.

b. Scheduled Mode - push ‘Schedule On/Off and Enter’

button. SCHEDULED MODE will appear on the inter-

face panel. The compressor will then turn on or off as

programmed.

NOTE: Dryer may be returned to the manual mode at any time

using the ‘Schedule On/Off and Enter’ button or by pressing

On/Off button. MANUAL MODE will appear on interface panel.

To reinstitute Schedule, push the ‘Schedule On/Off and Enter’

button again.

NOTE: Restart after the power interruption. Unit will be in

MANUAL MODE, refrigeration compressor, off when power is

restored after power interruption.

7. To reinstitute SCHEDULE RUNNING: push ‘Schedule On/

Off and Enter’ button.

IMPORTANT: Dryer must be energized 24 hours before

refrigeration compressor is started.

D. Operating Check Points

1. Check that green Power-on light is illuminated.

2. Check that green Compressor-on light is illuminated if dryer

is on in the manual mode or it is a scheduled on time.

IMPORTANT: Refrigeration compressor must be restarted after

power interruption.

3. Check interface panel.

NOTE: Interface panel will scroll through three screens (Current

Time/Operating Status, Hours to Service, and Total Operating

Hours).

a. Verify that current time is correct.

b. Check HRS TO SERVICE: this indicates time remaining

until service is required; allow time for required

maintenance items to be ordered.

c. Check operating status:

MANUAL MODE - Dryer is either running continuously

(not being controlled by the scheduled on/off times) or

the refrigeration compressor has been shut off using the

‘On/Off’ button.

SCHEDULED MODE - Refrigeration compressor

is being turned on and off by the monitor per-programmed

schedule (see B.3. to set schedule).

d. Check Temperature indicator - indicator should read in

the green area.

6

e. Check Alarm/Service light. If illuminated, check Interface

panel.

1) If SERVICE DRYER appears, scheduled maintenance

time has elapsed (HRS TO SERVICE is 0). Perform

needed service and reset service interval (see B.4.).

2) If ALARM appears, a dryer fault is indicated; see

Troubleshooting Guide for possible remedies. After

fault correction push Reset button to turn Fault alarm

off.

Type of FAULTS:

HIGH DISCHARGE TEMPERATURE - refrigerant

discharge temperature is above the set point.

LOW PRESSURE - the refrigeration compressor

control circuit has opened because of low suction

pressure.

HIGH PRESSURE - the refrigeration compressor

control circuit has opened because of high head

pressure. The high pressure switch must be reset

manually once the fault is corrected. Red reset button

is located on pressure switch inside unit.

HIGH EVAPORATOR TEMPERATURE - compressed

air temperature is above the set point.

COMPRESSOR - normally open (NO) auxiliary

contact on the compressor contactor is open when

the dryer is on.

HEATER - normally closed (NC) auxiliary contact on

the compressor contactor is open when the dryer is

off.

TEMP SENSOR - occurs if the temperature sensor

circuit is open or shorted. If open, none of the LED’s

in the temperature display will be illuminated. If

shorted, all the LEDs in the temperature display will

be illuminated.

DRAIN - electric drain contains a high water level

alarm that activates if drain fails to discharge.

f. Check drain operation - push Drain (push-to-test) button

toenergizeelectricdrain.Aowofcondensateand/or

air should be present at the drain outlet.

2.3 Using the RS-485 Port Connector (J8)

This connector provides RS-485 compatible signals from the

internal master microprocessor. Using jumpers on the headers

supplied near the connector (J12), 120 ohm termination resistors

can be connected and the system can be connected for either

two-wire or four-wire operation (half or full duplex). To connect

the termination resistors, install jumpers on J12 in the direction

shown by the white bars printed above the connector.

If the jumpers are removed no termination of the RS-485 bus is

in effect. Usually, these jumpers must be in position for proper

operation of the bus.

J10 contains the two-wire/four-wire jumper. If the jumper is set

in W2 place, the circuit is set up for two-wire operation. If the

jumper is set in W4 place, the circuit is set up for four-wire op-

eration. Selection of jumper settings must be determined by the

customer’s system. The jumpers are supplied as standard and

are installed as shown at the factory. Be sure to set the jumpers

properly for your system.

RS-485 Pinout

Following is the pinout for J8, the RS-485 communications con-

nector.

1 A

2 B

3 Z

4 Y

When connected in two-wire mode, the bus wires may be

connected to pins 1 & 2. Also note that when in two-wire mode,

one termination resistor jumper should be removed to prevent the

termination from being too low in value. It may be stored on the top

set of pins on J12. Those pins are not connected. Please make

sure that your connections are properly made. This connector is

a 4-pin terminal block. Mating connectors are not supplied. The

electrical signals supplied by this connector are TIA/EIA-485A

compliant. A good cable should be used to transmit signals such

as Belden 3109A or equivalent.

Communication Parameters:

RS-485 Parameters

Baud Rate 19200

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Modbus Drop I/O Factory Default = 1

(user adjustable 1 - 247 )

2.4 Using the USB Host Feature (J7)

The EMM connect is equipped with a USB Host port located at

J7 on the control board which allows for the connection of a USB

ashdrive.TheUSBashdrivecanbeusedfordatalogging,

event history, and installing software updates.

1. USB Data Logging

WhenaUSBashdriveisinstalledinthecontrolleritwillbeginto

automatically record key dryer operating parameters: timestamp,

dryer status, service timer, total compressor run timer, discharge

temperature, evaporator inlet temperature, evaporator outlet

temperature, and dryer % load.

7

These values will be written every 10 seconds to a comma

separatedvaluelestoredintherootfolderoftheUSBashdrive.

Eachdayanewcommaseparatedvaluelewillbecreatedfor

storingthesamplesforthatday.Commaseparatedvalueles

older than 60 days will be automatically deleted.

2. USB Event History

WhenaUSBashdriveisinstalledinthecontrolleritwillbegin

to automatically log all dryer events: power loss, power recovery,

alarms, state (standby/running), and mode (manual/scheduled/

remote).

Events are timestamped and recorded in the EVENT.TXT le

storedintherootfolderoftheUSBashdrive.

3. USB Bootloader

Firmware updates for the EMM connect can be performed via the

USBashdrive.Inordertoperformarmwareupdate;placethe

image.hexandlang.hexlesprovidedbySPXintherootfolder

of a USB thumb drive.

WiththedryercontrollerpoweredoffinstalltheUSBashdrive

in the USB host port on the EMM connect. Then while holding

the enter button on the front panel apply power to the controller.

Once the power LED begins blinking rapidly you can release

the enter button. The controller will reboot when the update is

complete.Onstartupthecurrentrmwareversionwillbeshown

on the text display.

Version x.x

8

2.5 Using the Ethernet Feature (J3)

The EMM connect is equipped with an Ethernet port located at

J3 on the control board which allows the customer to connect the

dryer to a local area network. The customer can then monitor the

dryer status and performance via Web Interface or ModbusTCP.

1. Web Interface

After assigning an IP address to the dryer the IP address can be

entered into the address bar of any web browser to connect to

the web interface.

Therstpagedisplayedisthehomescreen.Displayedonthis

page are the dryers operating status, operating mode, current

dryer load, evaporator inlet temperature, evaporator outlet tem-

perature, discharge temperature, energy savings, and any active

alarms. The navigation bar at the top of this page can be used to

view event history, dryer scheduler, and dryer settings.

Energy savings is shown as the estimated annual energy savings

based on the actual energy cost (entered on the settings page)

and the average dryer load over the last 30 days.

Figure 1: Home Screen

The event history page shows the last 64 timestamped events that

have occurred on the dryer. These events include power failure/

recovery, dryer mode changes, dryer status changes, and alarms.

Figure 2: Event History

The dryer scheduler page allows the customer to view/edit the

daily start/stop times that will be used when operating the dryer

in scheduled mode.

Figure 3: Schedule

9

The dryer settings screen allows the customer to view/edit various

dryer set points and setup E-mail alerts that will send an e-mail to

up to 3 different e-mail addresses whenever an alarm or warning

occurs on the dryer.

Figure 4: Settings

2. Modbus TCP

The Modbus TCP connection allows you to continuously monitor

the dryer from a DCS system which implements a Modbus TCP

master. The dryer controller implements a ModbusTCP server

on port 502. The following Modbus register table provides a list

of data that is available.

10

Modbus Registers

Holding Register

Reference Address Name Units Description

40001 0x0000 DRYER_STATUS Status ID Status ID for the dryer

40002 0x0001 ALARM_STATUS Flag Bits Alarm flag bits

40003 0x0002 WARNING_STATUS Flag Bits Warning flag bits

40004 0x0003 RESERVED N/A Reserved

40005 0x0004 SERVICE_TIMER Hours Timer to service

40006 0x0005 TOTAL_TIMER Hours Total operating hours

40007 0x0006 EVAPORATOR_INLET_TEMP 1/10 Degree Celsius Evaporator inlet temperature

40008 0x0007 DISCHARGE_TEMP 1/10 Degree Celsius Discharge temperature

40009 0x0008 DRYER_LOAD % Dryer load

40010 0x0009 SAVINGS Dollars / Euros Energy savings

40011 0x000A EVAPORATOR_OUTLET_TEMP 1/10 Degree Celsius Evaporator outlet temperature

40012 0x000B

40013 0x000C

40014 0x000D

40015 0x000E

40016 0x000F

40017 0x0010 DRYER_MODEL Model_ID Dryer model

40018 0x0011 DRYER_MODE Mode_ID Dryer mode

40019 0x0012 SERVICE_INTERVAL Hours Service interval

40020 0x0013 AUTO_RESTART Boolean Auto-restart (0=Disabled, 1=Enabled)

40021 0x0014 UI_LANGUAGE Language_ID User interface language

40022 0x0015 RESERVED N/A Reserved

40023 0x0016 RESERVED N/A Reserved

40024 0x0017 ENERGY_COST Integer Energy cost (Cost / kWh)

40025 0x0018 AUDIBLE_ALARM Boolean Audible Alarm (0=Disabled, 1=Enabled)

40026 0x0019 MODBUS_ADDRESS Integer Modbus Address

40027 0x001A FULL_POWER Watts Full load power

40028 0x001B

40029 0x001C

40030 0x001D

40031 0x001E

40032 0x001F

40033 0x0020 ALARM_MSG_1 Integer Alarm message #1 phrase id

40034 0x0021 ALARM_MSG_2 Integer Alarm message #2 phrase id

40035 0x0022

40036 0x0023

40037 0x0024

40038 0x0025

40039 0x0026

40040 0x0027

40041 0x0028 INPUT_STATUS Flag Bits Digital Input Status

40042 0x0029 OUTPUT_STATUS Flag Bits Digital Output Status

40043 0x002A ANALOG[0] 1/10 Degree Celsius Analog Input [0]

40044 0x002B ANALOG[1] 1/10 Degree Celsius Analog Input [1]

40045 0x002C ANALOG[2] 1/10 Degree Celsius Analog Input [2]

40046 0x002D PV 1/10 Degree Celsius Process value

40047 0x002E P Integer P Term

40048 0x002F I Integer I Term

40049 0x0030 D Integer D Term

40050 0x0031 FIXED_LOAD Seconds Fixed cycle load period

40051 0x0032 FIXED_UNLOAD Seconds Fixed cycle unload period

40052 0x0033 FIXED_TIME Seconds Fixed mode timeout period

40053 0x0034 DELTA_PID_CALC 1/10 Degree Celsius PID calculation set point

40054 0x0035 DELTA_PID_CTRL 1/10 Degree Celsius PID control set point

11

Modbus Register Details

Page 1 of 3

Dryer Status

Register 40001

Decimal Hex Description

0 0x0000 Standby

1 0x0001 Fixed

2 0x0002 PID

3 0x0003 Reserved

4 0x0004 Reserved

5 0x0005 Reserved

6 0x0006 Reserved

7 0x0007 Reserved

Dryer Alarm Flags

Register 40002

Bit Mask Description

0 0x0001 High Discharge Temperature

1 0x0002 High Refrigerant Pressure

2 0x0004 Low Refrigerant Pressure

3 0x0008 Compressor #1

4 0x0010 Compressor #2

5 0x0020 Oil Protection #1

6 0x0040 Oil Protection #2

7 0x0080 Phase Reversal

8 0x0100 Phase Loss

9 0x0200 Evaporator Temperature Sensor Failure

10 0x0400 Glycol Temperature Sensor Failure

11 0x0800 Evaporator Outlet Temperature Sensor Failure

12 0x1000 Discharge Temperature Sensor failure

13 0x2000 High Super Heat

14 0x4000 Reserved

15 0x8000 Reserved

Dryer Warning Flags

Register 40003

Bit Mask Description

0 0x0001 High Evaporator Temperature

1 0x0002 High Glycol Temperature

2 0x0004 Heater #1

3 0x0008 Heater #2

4 0x0010 Drain #1

5 0x0020 Drain #2

6 0x0040 Filter #1

7 0x0080 Filter #2

8 0x0100 Reserved

9 0x0200 Reserved

10 0x0400 Reserved

11 0x0800 Reserved

12 0x1000 Reserved

13 0x2000 Reserved

14 0x4000 Reserved

15 0x8000 Reserved

12

Modbus Register Details

Page 2 of 3

Dryer Model

Register 40017

Decimal Hex Description

0 0x0000 Non-Cycling MRD

1 0x0001 Non-Cycling LRD

2 0x0002 ES-MRD 90

3 0x0003 ES-MRD 120

4 0x0004 ES-MRD 140

5 0x0005 ES-MRD 190

6 0x0006 ES-MRD 245

7 0x0007 ES-MRD 280

8 0x0008 ES-MRD 360

9 0x0009 ES-MRD 450

10 0x000A ES-MRD 540

11 0x000B ES-MRD 675

12 0x000C DEMM 800

13 0x000D DEMM 1000

14 0x000E DEMM 1250

15 0x000F DEMM 1500

16 0x0010 DEMM 1750

17 0x0011 DEMM 2000

18 0x0012 DEMM 2500

19 0x0013 DEMM 3000

20 0x0014 Reserved

21 0x0015 Reserved

22 0x0016 Reserved

23 0x0017 Reserved

24 0x0018 Reserved

25 0x0019 Reserved

26 0x001A Reserved

27 0x001B Reserved

28 0x001C Reserved

29 0x001D Reserved

30 0x001E Reserved

31 0x001F Reserved

Dryer Mode

Register(s) 40018

Decimal Hex Description

0 0x0000 Manual Mode

1 0x0001 Scheduled Mode

2 0x0002 Remote Mode

3 0x0003 Reserved

4 0x0004 Reserved

5 0x0005 Reserved

6 0x0006 Reserved

7 0x0007 Reserved

13

Modbus Register Details

Page 3 of 3

UI Language

Register(s) 40021

Decimal Mask Description

0 0x0000 English

1 0x0001 Spanish

2 0x0002 French

3 0x0003 German

4 0x0004 Portuguese

5 0x0005 Italian

6 0x0006 Polish

7 0x0007 Danish

8 0x0008 Dutch

9 0x0009 Norwegian

10 0x000A Finnish

11 0x000B Swedish

12 0x000C Czech

13 0x000D Reserved

14 0x000E Reserved

15 0x000F Reserved

14

3.0 MAINTENANCE

3.1 Monthly Maintenance

A. Air-Cooled:Cleanrefrigerantcondenser.Blowthensofthe

condenser clean with compressed air, if necessary, remove

heavier soiling with a suitable cleansing agent.

B. Water-cooled - clean strainer monthly, more often if required.

Shut off water, remove small plug to relieve pressure, then

remove large plug to remove strainer. Clean strainer and

replace.

C. Check the condensate drains by pressing the Drain Test

button on the control panel (see page 5 for description and

location). Visually check to assess whether condensate is

separated and discharged.

D. Check the dew point temperature on the control panel.

E. Check the inlet compressed air temperature and the ambient

temperature (or inlet cooling water temperature) to assure

they are within the operational limits.

Ref: 3.2, C., 2., e through h

3.2 Annual Maintenance

A. Check all terminals in the switchgear cabinet and tighten

them up if necessary.

Check to be sure the unit is de-energized.

B. Maintenance/Cleaning of the condensate drain.

1. To facilitate service, maintenance kits are available.

C. Replacetheltercartridgesinthelter.(Allnecessaryservice

parts can be ordered in a service kit – See Parts List.)

1. When to replace the Separator/Filters

Replacelterelementwhenpressuredropacrossdryer

is excessive or annually.

When removing liquids at rated ow conditions, the

pressure drop will be 5 psi (0.35 bar), or less, across

the entire dryer. An increase in pressure drop will occur

onlyastheseparator/lterelementsbecomeloadedwith

solidparticles.Itisrecommended,formaximumltration

efciency,theseparator/lterelementsbereplacedwhen

the pressure drop across the dryer exceeds 10 psi (0.7

bar),orevery12months,whicheveroccursrst.

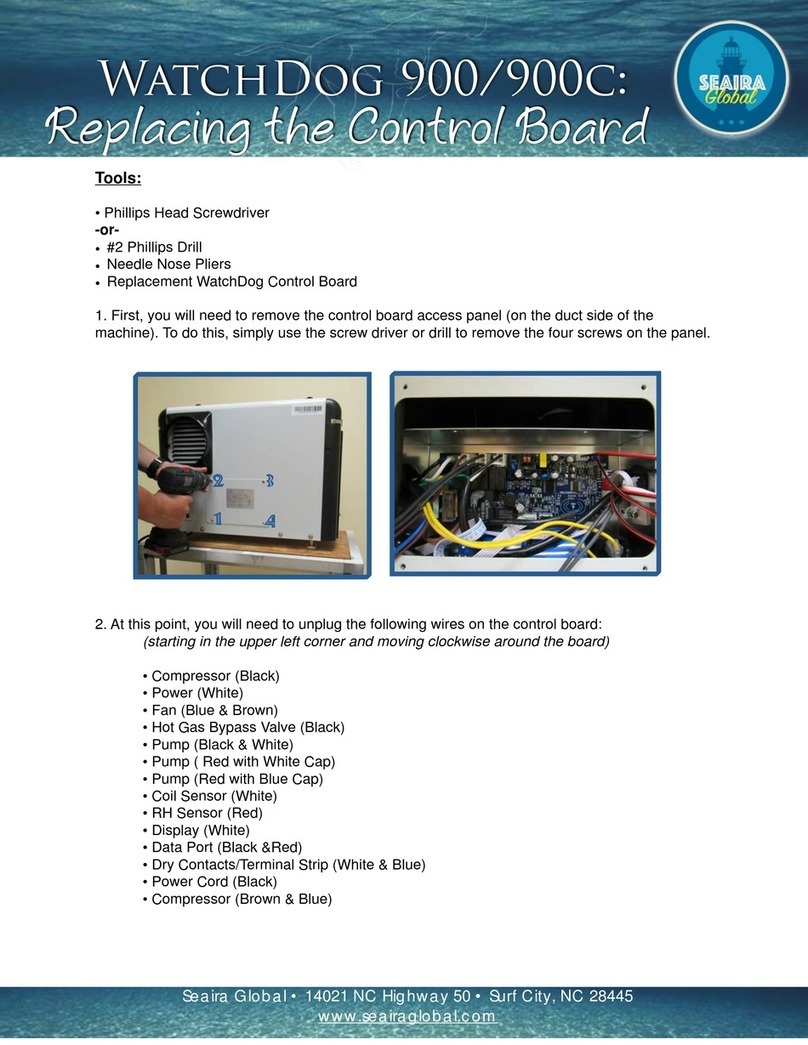

2. Replacement of the Separator/Filters

Depressurize the unit before servicing.

Failure to do this may result in injury.

a. Open the bypass between compressed air inlet and

outlet. (if equipped)

b. Close the shut-off devices at the compressed air inlet

and outlet.

c. Press the Drain Test button on the control panel (see

page 5 for description and location) until the system

is depressurized.

d. Switch off the dryer.

e. Remove the insulation [1].

1

2 3 4

15

f. Loosenthescrews[2]ofthelterhousing.Caution

is necessary as the system may still be under slight

residual pressure.

g. Removeallscrewsexceptoneandswingange[3]

to the side.

h. Pull out the old cartridges [4].

i. Push new cartridges on to the mounting posts in the

bottom of the separator vessel.

NOTE: Do not touch the foam sleeves of the

cartridgeswithyourngers.

j. Close housing in reverse order.

k. Put on insulation.

l. Switch on the dryer.

m. Repressurize the dryer by slowly opening the

compressed air inlet valve.

n. Slowly open the compressed air outlet valve.

o. Slowly close the compressed air bypass valve (if

equipped).

16

4.0 TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A) Water downstream of dryer 1. Residual free moisture remaining in downstream

pipelines.

2. Air bypass system is open.

3. Inlet and Outlet connections are reversed.

4. Air lines downstream of dryer are exposed to

temperatures below the dew point.

5. Excessive free moisture (bulk liquid) at dryer

inlet.

6. Condensate not being drained.

7. Dryer overloaded resulting in elevated dew point.

8. Refrigeration system not functioning.

1. Blow out system with dry air.

2. Check valve positions.

3. Check for correct connection.

4. Insulate or heat trace air lines exposed to low

ambients or dry air to lower dew point.

5. Install separator ahead of dryer.

6. See C below.

7. See C below.

8. See C below.

B) High pressure drop across dryer 1. Excessive air flow.

2. Freezing of moisture in evaporator because of

refrigeration system fault.

3. Filter loaded with solid particulates.

1. Check flow rate.

2. See C below.

3. Replace filter element.

C) Checkpoint faults

1. Power on light off

2. Compressor on light off

3. Alarm/Service alert light on -

check Display for active conditions

SERVICE DRYER

HIGH DISCHARGE TEMPERATURE

LOW PRESSURE

HIGH PRESSURE

NOTE: If high refrigerant pressure

occurs, switch must be manually reset

HIGH EVAPORATOR TEMPERATURE

(also observed as high reading on

temperature indicator)

DRAIN

COMPRESSOR

HEATER

TEMP SENSOR

1. Power failure; open circuit.

1. Compressor commanded off by manual switch or

programmed schedule.

2. Open circuit.

3. Control circuit open on high or low pressure

cutout.

1. Service interval specified has elapsed.

1. Air-cooled - Ambient temperature too high,

clogged condenser fins, obstructed flow across

condenser, faulty fan motor or fan control switch.

Water-cooled - Cooling temperature too high,

flow too low, clogged strainer, faulty water

regulating valve.

2. Low refrigerant charge.

1. Control system error.

2. Low on refrigerant/refrigerant leak.

1. Lack of condenser cooling.

Air-cooled - Ambient temperature too high,

clogged condenser fins, obstructed flow across

condenser, faulty fan motor or fan control switch.

2. Water-cooled - Cooling temperature too high,

flow too low, clogged strainer, faulty water

regulating valve.

1. Dryer overloaded.

2. Refrigeration system off or not cooling

sufficiently.

1. Drain line restricted or frozen.

2. Drain mechanism faulty.

1. Faulty compressor contactor.

2. Faulty N.O. auxiliary contact on compressor

contactor.

1. Faulty compressor contactor.

2. Faulty N.C. auxiliary contact on compressor

contactor.

3. Faulty heater.

1. Temperature sensor or wiring to sensor is open

(none of the LED’s in the temperature display will

be illuminated).

2. Temperature sensor or wiring to sensor is shorted

(all of the LEDs in the temperature display will be

illuminated).

1. Check for power to dryer.

1. Check current command status.

2. Check power to compressor.

3. Check display for fault.

1. Perform scheduled service.

1. Check air temperature 6” in front of condenser;

Clean condenser and check for free air flow;

Check fan and switch operation.

Check cooling medium temperature and flow,

clean strainer, check valve operation.

2. Check system pressures/temperatures.

1. Contact qualified technician or manufacturer’s

service department.

1. Check air temperature 6” in front of condenser;

Clean condenser and check for free air flow;

Check fan and switch operation.

2. Check cooling medium temperature and flow,

clean strainer, check valve operation.

1. Check compressed air inlet flow, temperature,

and pressure.

2. Check power to unit, power to compressor, Low

or High pressure faults. Have qualified technician

evaluate system.

1. Open drain line.

2. Check drain by pressing “Push to Test” button

on control panel. If faulty, isolate drain. Rebuild

automatic drain.

1. Check wiring and operation of contactor.

2. Check wiring and operation of auxiliary contact.

1. Check wiring and operation of contactor.

2. Check wiring and operation of auxiliary contact.

3. Check heater element for continuity.

1. Replace sensor or repair wiring.

2. Replace sensor or repair wiring.

NOTE: After fault correction, press reset button to clear display

17

5.0 REFERENCE

Sizing

Determining dryer capacity at actual operating conditions.

Todeterminethemaximuminletowcapacityofadryeratvarious

operating conditions, multiply the rated capacity from Table 1 by

the multipliers shown in Table 2.

Example: How many scfm can a 60 Hz air-cooled model 1000

handle when compressed air to be dried is at 200 psig and 100°F;

ambient air temperature is 80°F?

Answer: 1,000 x 1.22 x 1.12 = 1,366 scfm.

TABLE 1

Rated capacity (scfm) @ 100 psig inlet pressure, 100°F inlet

temperature, and 100°F ambient temperature.

MODEL 800 1000 1250 1500 1750 2000 2500 3000

Rated capacity

of air-cooled

models (scfm)

60 Hz

50 Hz

800

672

1000

830

1250

1050

1500

1250

1750

1460

2000

1670

2500

2080

3000

2500

TABLE 2

Air capacity correction factors (Multipliers)

INLET COMPRESSED AIR CONDITIONS

INLET INLET TEMPERATURES

PRESSURES 80°F 90°F 100°F 110°F 120°F

psig barg 27°C 32°C 38°C 43°C 49°C

50

80

100

125

150

175

200

3.4

5.5

6.9

8.6

10.3

12.1

13.8

1.35

1.50

1.55

1.63

1.70

1.75

1.80

1.05

1.17

1.23

1.31

1.37

1.42

1.47

0.84

0.95

1.00

1.07

1.13

1.18

1.22

0.69

0.79

0.82

0.91

0.95

0.99

1.03

0.56

0.66

0.70

0.74

0.80

0.84

0.89

COOLING MEDIUM*

AMBIENT

TEMPERATURE MULTIPLIER

°F °C

80

90

100

110

27

32

38

43

1.12

1.06

1.00

0.94

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling water is

below 95°F (35°C).

18

Model 800 1000 1250 1500 1750 2000 2500 3000

Air System Data

Rated Air Flow at 100°F & 100 psig Inlet, 100°F Ambient (scfm) 60 Hz, a-c 800 1000 1250 1500 1750 2000 2500 3000

60 Hz, w-c 920 1150 1438 1725 2013 2300 2875 3450

Rated Air Flow at 95°F & 100 psig Inlet, 77°F Ambient (scfm) 50 Hz, a-c 848 1060 1325 1590 1855 2120 2650 3180

50 Hz, w-c 856 1070 1338 1605 1873 2140 2675 3210

Minimum / Maximum Inlet Compressed Air Pressure 30 / 232 psig (2.1 / 16.0 barg)

Minimum / Maximum Inlet Compressed Air Temperature 40° / 120°F (4° / 49°C)

Minimum / Maximum Ambient Temperature a-c 40° / 110°F (4° / 43°C)

w-c 40° / 130°F (4° / 54°C)

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigeration System Data

Compressor Type Hermetic, Digital Scroll Hermetic, Digital Scroll + Standard Scroll

Refrigeration Compressor Horsepower 4 6 6 4 + 4 4 + 4 6 + 4 6 + 6 6 + 6

Refrigeration Capacity @ Rated Flow (BTU/hr)* 60 Hz, a-c 40,800 47,000 58,800 69,000 80,500 98,500 118,800 141,300

50 Hz, a-c 41,000 47,200 59,000 70,500 82,300 100,300 119,500 143,400

Refrigerant Type R-404A

Refrigerant Charge See Data Tag on Dryer

Suction Pressure Setting (nominal operating range) 75 - 85 psig (5.2 - 5.9 barg)

Compressor Pressure Switch Setting (cut out / cut in) High, a-c 450 / 350 psig (31.0 / 24.1 barg)

High, w-c 320 / 250 psig (22.1 / 17.2 barg)

Low 47 / 64 psig (3.2 / 4.4 barg)

Air-Cooled Condensers

Air Flow Across Condenser (cfm) 60 Hz 4,200 4,200 4,200 7,300 7,300 7,300 7,300 14,600

50 Hz 3,500 3,500 3,500 6,100 6,100 6,100 6,100 12,200

Condenser Fan Switch Setting (cut in / cut out) Fan 1 300 / 230 psig (20.7 / 15.9 barg)

Fan 2 N/A 325 / 255 psig (22.4 / 17.6 barg)

Water-Cooled Condensers

Water Regulating Valve Setting 255 psig (17.6 barg)

Minimum Water Pressure Differential 40 psig (2.8 barg)

Cooling Water Flow with 85°F (gpm)* 60 Hz 4.7 6.7 9.1 11 14 16 21 26

50 Hz 4.4 6.2 8.5 10 13 15 20 24

Notes

* 60 Hz: 35°F Evaporator & 100°F Ambient; 50 Hz: 35°F Evaporator & 77°F Ambient

Engineering Data Table

Sheet 1 of 2

This manual suits for next models

8

Table of contents

Other HANKISON Dehumidifier manuals

HANKISON

HANKISON PR500 User manual

HANKISON

HANKISON HPRP 200 User manual

HANKISON

HANKISON SPXFLOW HSHD Series User manual

HANKISON

HANKISON HPRplus Series User manual

HANKISON

HANKISON H Series User manual

HANKISON

HANKISON HPRD 0.50-500 User manual

HANKISON

HANKISON HPR Series User manual

HANKISON

HANKISON HPRplus HPRP1000 User manual

HANKISON

HANKISON HPRP 25 User manual

HANKISON

HANKISON SPX HES Series User manual