HANKISON PR500 User manual

1

7610.483.4B 8/01

INSTRUCTION MANUAL

Contents

GENERAL SAFETY INFORMATION ................................. 2

RECEIVING, MOVING, UNPACKING ............................... 2

1.0 INSTALLATION ........................................................ 3

2.0 OPERATION ........................................................... 6

3.0 MAINTENANCE ...................................................... 8

SIZING ........................................................................... 9

ENGINEERING DATA ..............................................10, 11

ELECTRICAL SCHEMATICS ......................................12, 13

CONTROL TRANSFORMER CONNECTIONS.................. 14

DIMENSIONS / WEIGHTS ............................................. 15

TROUBLESHOOTING .................................................... 16

PARTS LIST .............................................................17, 18

WARRANTY................................................................. 20

Models: PR500, PR600, PR700, PR800,

PR1000, PR1200, PR1600,

PR2000, and PR2300

SERVICE DEPARTMENT: (724) 746-1100

REFRIGERATED

TYPE

COMPRESSED

AIR DRYERS

®

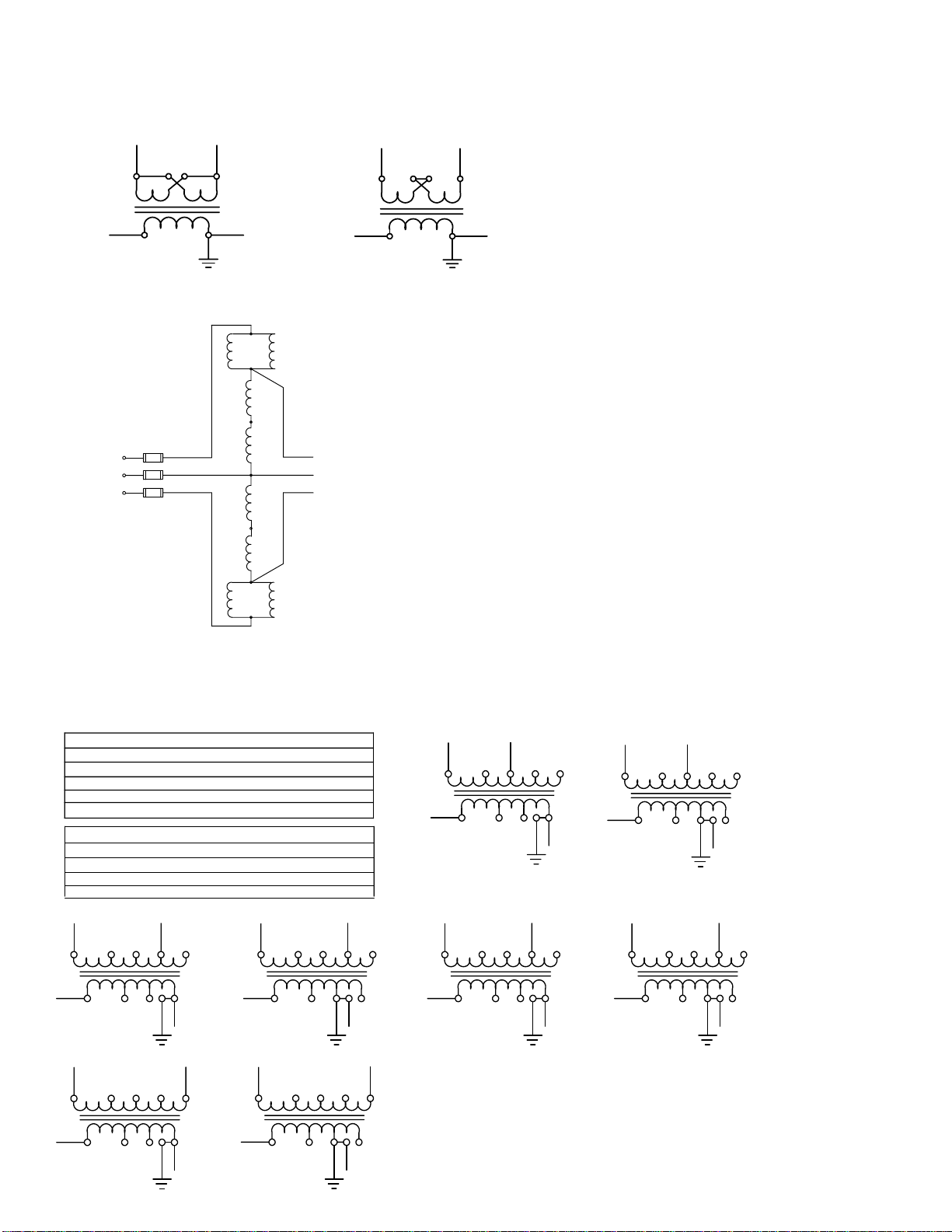

IMPORTANT - 380-420V/3ph/50Hz models - control

transformer is wired to operate on a voltage range of 391

to 418. For voltages outside this range rewire transformer

as shown on page 12.

M

M

2

RECEIVING, MOVING, AND UNP ACKING

A. RECEIVING

This shipment has been thoroughly checked, packed

and inspected before leaving our plant. It was received

in good condition by the carrier and was so acknowl-

edged.

Check for Visible Loss or Damage.If this shipment

shows evidence of loss or damage at time of delivery

to you, insist that a notation of this loss or damage be

made on the delivery receipt by the carrier’s agent.

B. UNPACKING

Check for Concealed Loss or Damage. When a ship-

ment has been delivered to you in apparent good

order, but concealed damage is found upon unpack-

ing, notify the carrier immediately and insist on his

agent inspecting the shipment. Concealed damage

claims are not our responsibility as our terms are F.O.B.

point of shipment.

C. MOVING

In moving or transporting dryer, do not tip dryer

onto its side.

All dryers are shipped to accomodate a fork lift truck.

When installing this unit, move it by means of a fork

lift or other suitable means. Never lift unit by hooking

on to the air inlet and outlet connections. Serious

damage may result.

D. STORAGE/SHUT-DOWN

IMPORTANT - WATER-COOLED UNITS - if unit is shut down in

below freezing temperatures, the water-cooled condenser

may freeze and cause permanent damage.

Condenser must be drained using drain cocks located on

the condenser when unit is shut down.

IMPORTANT - Do not store dryer in temperatures above

130°F, 54.4°C.

GENERAL SAFETY INFORMA TION

1. PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Do not exceed maximum operating

pressure as shown on equipment serial number tag.

• Make sure equipment is depressurized before

working on or disassembling it for service.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Install equipment in compliance

with all applicable electrical codes.

• Standard equipment is supplied with electrical

enclosures not intended for installation in hazard-

ous environments.

• Disconnect power supply to equipment when

performing any electrical service work.

3. BREATHING AIR:

• Air treated by this equipment may

not be suitable for breathing

without further purification. Refer

to applicable standards and

specifications for the requirements

for breathing quality air.

3

NOTE: Outdoor installation: Standard dryers are designed

for indoor installation. Contact manufacturer if installing

outdoors.

1.0 INST ALLATION

1.1 Location

A. For typical placement in a compressed air system, see

drawing at right.

B. Air compressor intake - Locate air compressor so that

contaminants potentially harmful to the dryer (e.g.

ammonia) are not drawn into the air system.

C. Air-cooled units - Free air flow - Ambient air should be

free to flow across the refrigeration condenser. Do not

block either side of the cabinet. Leave at least 36 inches

(915 mm) clearance for free air flow.

COMPRESSOR AFTERCOOLER

SEPARATOR RECEIVER

TANK

DRYER

OIL

REMOVAL

FILTER

AUTOMATIC

DRAINS

1.2 Mounting

A. Mount dryer on firm level surface.

B. Dryers are furnished with removable shipping pads.

Remove prior to installation if desired. Dryers may be

bolted to the floor if desired.

IMPORTANT - Read prior to starting this equiptment.

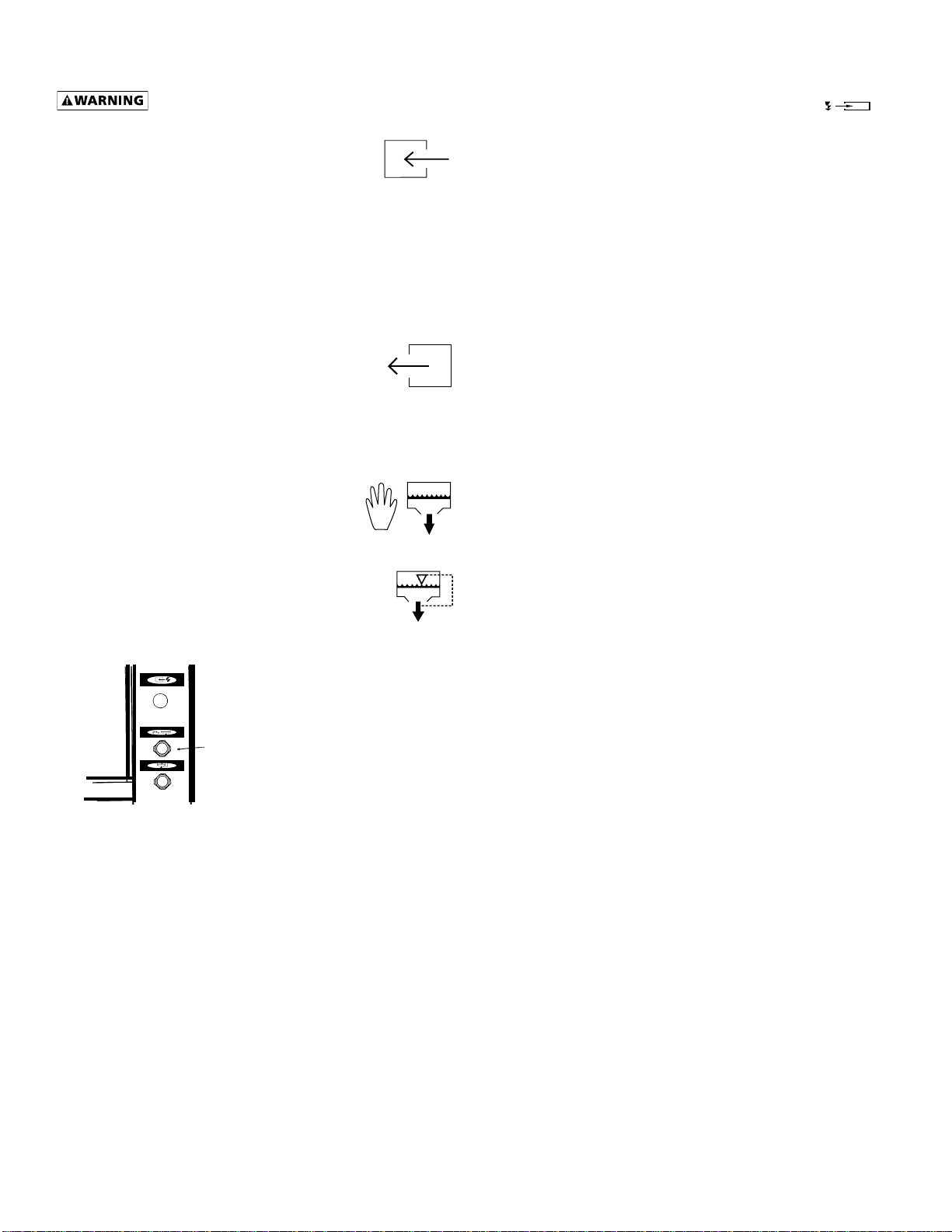

LEFT SIDE VIEW FRONTVIEW RIGHT SIDEVIEW

AIR OUT AIR IN

DRAIN

ASSY.

(2)

MANUAL

DRAIN

AUTOMATIC

DRAIN ELECTRICAL

ENCLOSURE

ELECTRICAL

ENTRY

MANUAL

DRAIN

AUTOMATIC

DRAIN

CONTROL PANEL

SERIAL TAG

INSTRUCTION TAG

CONDENSER

BLOW OFF GUN

FOR CONDENSER CLEANING

4

1.3 Piping connections

If welding above unit make certain that

sparks are kept from contacting insulation around inlet

and outlet piping.

A. Air Inlet - Connect compressed air line from

air source to air inlet.

IMPORTANT: Refer to Serial Number Tag for maximum

working pressure. Do not exceed dryer’s Maximum

Working Pressure

NOTE: Install dryer in air system at highest pressure possible

(e.g. before pressure reducing valves)

NOTE: Install dryer at coolest compressed air temperature

possible. Maximum inlet compressed air temperature: 120°F

(49°C). If inlet air exceeds this temperature, precool the air

with an aftercooler.

B. Air Outlet - Connect air outlet to down-

stream air lines.

C. By-pass piping - If servicing the dryer

without interrupting the air supply is desired,

piping should include inlet and outletvalves and

an air by-pass valve.

D. Condensate Drain

1. Manual Drains - Petcocks (2) for manual

draining are attached to the manual drain

lines in the cabinet. Remove petcocks and

install into manual drain couplings. Make

sure petcocks are closed.

2. Automatic Drains - Drain lines can be run

from Automatic Drain outlets (2) to the plant

drainage system.

NOTE: Condensate may contain oil. Comply with

applicable laws concerning proper disposal.

NOTE: Discharge is at system pressure. Anchor drain line.

E. Water cooled models - cooling water inlet and outlet

1. Connect cooling water supply to cooling water inlet

coupling.

2. Connect cooling water return line to cooling water

outlet coupling.

NOTE: Strainer and water regulating valve are supplied on

water cooled models.

1.4 Electrical connections

IMPORTANT - Use copper supply wires only.

A. Unit is designed to operate on the voltage,

phase, and frequency listed on serial number tag.

B. Electrical entry is through hole in cabinet and

into electrical enclosure. Connect power source to

terminal strip in electrical enclosure as shown on

Electrical Schematic attached to dryer.

NOTE: Refrigeration condensing unit is designed to run

continuously and should NOT be wired to cycle on/off with

the air compressor.

PETCOCK

INSTALLED

5

1

22

45

MIN.

1

7

15

SEC..

manual

overide

POWER

ON

ELECTRIC DRAIN

(Optional with Three Light Control Panel)

ISOLATION VALVE

RESERVOIR WITH

INTERNAL

STRAINER

TIMER

MANUAL DRAIN

TUBE

SET TIME VALVE OPENS

SET TIME BETWEEN

OPERATIONS

(VALVE CLOSED)

VALVE

ENERGIZED

LIGHT

TIMER ENERGIZED

LIGHT

DRAIN TEST BUTTON

1.5 Automatic condensate drains

A. Models with electric drains

1. Verify that isolation valves are open.

2. Verify time settings.

After dryer is operating, verify that valve remains open

long for all condensate to be ejected from the system.

If all condensate is not ejected during valve open time,

shorten time between operations.

a. MODELS WITH STANDARD CONTROL PANEL AND

ELECTRIC DRAIN - Drain timers (2) are factory set

for 5 minutes between operations (valve closed)

and 5 seconds valve open time

b. MODELS WITH DIGITAL CONTROL PANEL - TIME

BETWEEN OPERATIONS (valve closed) is factory set

for 2.5 minutes, valve open time is not adjustable.

See instructions under 2.3 to adjust time.

B. Models with mechanical drains

1. Verify that isolation valves are open.

MECHANICAL DRAIN

ISOLATION

VALVE

MANUAL DRAIN

AUTOMATIC

DISCHARGE

MANUAL DRAIN

AUTOMATIC DRAIN

ISOLATION VALVE

SOLENOID VALVE

RESERVOIR WITH

INTERNAL STRAINER

ELECTRIC DRAIN

(Supplied with digital control panel)

6

2.3 Operating check points – Check the following on

a periodic basis:

A. Power-on light glows indicating power to the dryer.

B. Compressor-on light (green) glows indicating the

refrigerator compressor is operating.

C. Standard Panels

1. High air temperature warning light is out. The high air

temperature warning light will illuminate when unit is

energized. Light should go out approximately 15

minutes after start-up. If light remains lit after 30

minutes or lights again after going out, refer to

Troubleshooting Guide.

2. Refrigerant pressure cut out light is out.

D. Digital panels - Check for alarms - compressor on light -

red indicating compressor off because of refrigerant

pressure cut out. High temperature alarm. High level

alarm (optional).

E. Suction pressure gauge indicates proper low side

refrigerant pressure. (Refer to engineering data)

F. Outlet pressure gauge - Compare with pressure at inlet

to dryer to determine if a higher than normal pressure

drop exists.

G. Inlet temperature gauge (supplied on models with

Standard Control Board) - inlet temperature should read

below 120°F (49°C).

H. Condensate is discharging from drain

2.0 OPERA TION

2.1 Minimum/maximum operating conditions

A. Maximum inlet air pressure: refer to unit serial

number tag

B. Minimum inlet air pressure: 20 psig (1.4 kgf/cm2)

C. Maximum inlet air temperature: 120°F (49°C)

D. Maximum ambient temperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 35°F (2°C)

2.2 Start-up

NOTE: Start unit before introducing air flow. High

pressure switch has a manual reset. If refrigerant pressure

cut-out (compressor off light) illuminates during start-up,

reset switch.

A. Control Panel

1. After making sure that on/off switch is off (“O” ),

energize dryer. Green power-on light will glow.

2. On water-cooled units - after 24 hours start flow

of water through condenser.

3. After 24 hours, energize compressor by positioning

the on/off switch in the on ("I") position. Green

compressor-on light will glow.

NOTE: COMPRESSOR ROTATION - Model 800 thru 2300

only - ensuring proper compressor rotation - Dryer contains

a scroll compressor which must rotate in the proper

direction. If after starting dryer an unusual noise is heard

and the suction pressure fails to drop into the normal range,

stop dryer, reverse two power leads, restart, and verify that

suction pressure is reading as stated on serial no. tag.

B. Alarms

1. High temperature alarm - If the Lowest Air Tempera-

ture exceeds the alarm set point, the red high

temperature warning light will glow.

2. Refrigerant pressure cut out alarm - If the high or low

refrigerant pressure set points have been exceeded,

the dryer will shut down. The green compressor-on

light will turn off and the red refrigerant pressure cut

out light will glow.

NOTE: High refrigerant pressure switch has a manual

reset. After correcting fault, manually reset switch to

resume operation.

C. Drain Test Button (models with electric drains)

Standard Control Panel: Push test button on drain valve

to manually activate. Drain energized light will glow.

Digital Control Panel: Push test button on digital board.

2.4 Using the Digital Panel

A. Function Lights

1. Power-on light - indicates power to dryer

2. Compressor-on light - indicates power to

control circuit, refrigeration compressor should

be running

3. Drain energized light - indicates power to solenoid

valve, drain should be open

B. Numeric Display - When the on/off switch is placed in

the ON position, the Numeric Display indicates Lowest Air

Temperature. Additional temperatures, alarm setpoints,

and electric drain adjustment are available by pressing

the mode selector button in the following sequence:

1. Display indicates Outlet Air Temperature. Outlet

temperature light glows.

2. Display indicates Ambient Temperature. Ambient

temperature light glows.

3. Display indicates Inlet Temperature Alarm set point.

Green light glows in Temperature Alarm box. Set point

may be changed by pushing up and down arrows.

4. Display indicates Lowest Air Temperature Alarm set

point. Green light glows in Temperature Alarm box. Set

point may be changed by pushing up and down arrows.

5. Used on models with Electric Drains (if dryer is not

equipped with electric drain sequence through this

step) Display indicates Electric Drain Closed time in

minutes and tenths of a minute. Green light in drain

time box glows. Time between valve openings may be

changed by pushing up and down arrows.

6. Display indicates inlet air temperature. Inlet

temperature light glows.

-

IMPORTANT: Energize dryer disconnect switch 24 hours

before refrigeration compressor is started! Never use

the disconnect switch to shut-down the dryer for a

extended period of time (except for repair). Failure to

follow these instructions may result in a non-warrant-

able compressor failure.

7

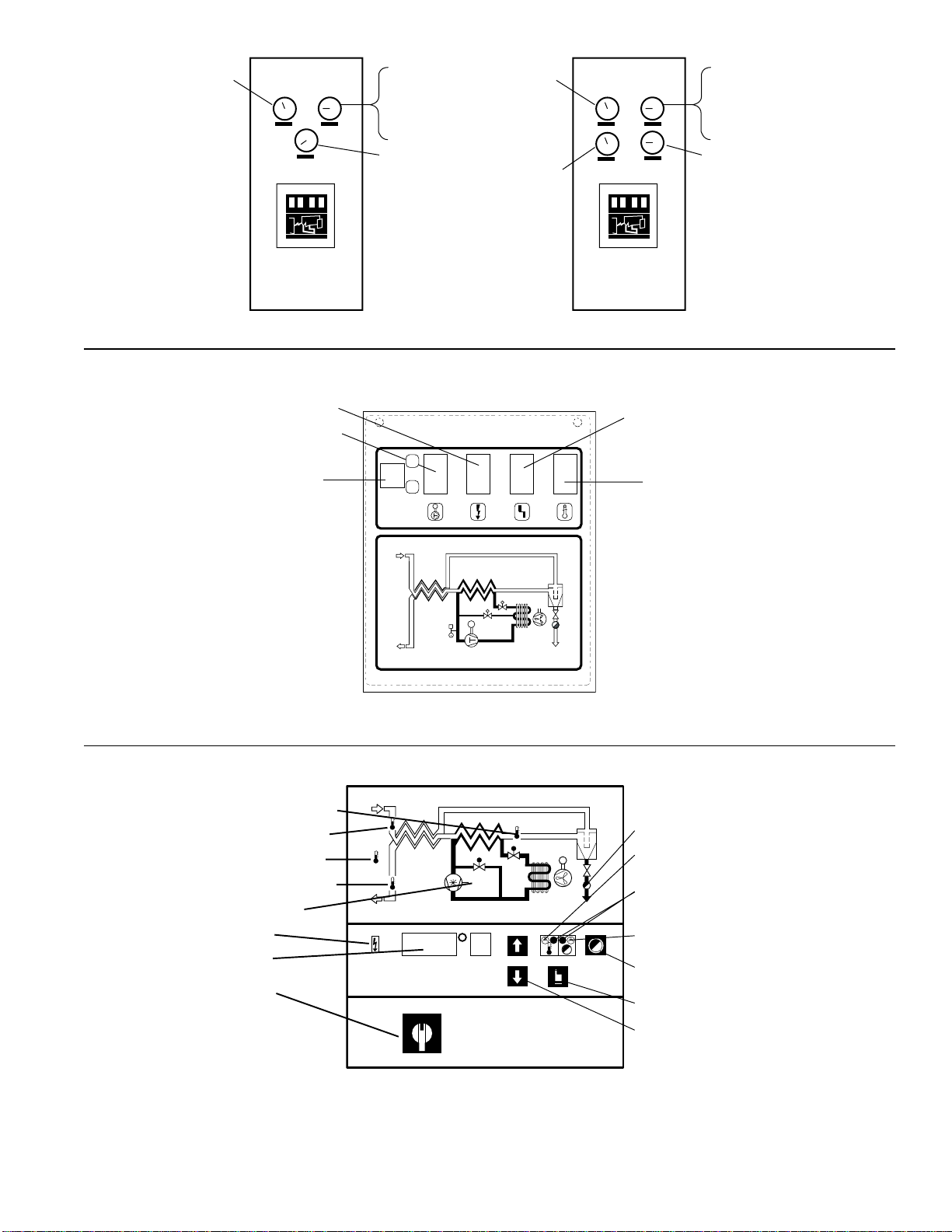

PRESSURE

OUT GAUGE

DIGITAL PANEL-

Pressure In Gauge

or

STANDARD PANEL-

Temperature In Gauge

REFRIGERANT SUCTION

PRESSURE GAUGE

PRESSURE

OUT GAUGE

HEAD

PRESSURE

GAUGE

DIGITAL PANEL-

Pressure In Gauge

or

STANDARD PANEL-

Temperature In Gauge

REFRIGERANT SUCTION

PRESSURE GAUGE

CONTROL PANEL FOR MODELS 1600, 2000, 2300CONTROL PANEL FOR MODELS 500 TO 1200

* Green - compressor on

Red - compressor off because of

refrigerant pressure cut out

COMPRESSOR ON LIGHT (GREEN)

POWER ON LIGHT (GREEN)

STANDARD CONTROL PANEL

ON/OFF SWITCH

M

I

O

M

PI

M

REFRIGERANT PRESSURE CUT

OUT LIGHT (RED)

HIGH TEMPERATURE

WARNING LIGHT (RED)

M

M

DRAIN ENERGIZED LIGHT

HIGH TEMPERATURE

ALARM LIGHT (RED)

MODE INDICATOR (GREEN)

OPTIONAL HIGH

WATER LEVEL ALARM

ELECTRIC DRAIN TEST BUTTON

MODE SELECTOR

ALARM/SET TEST BUTTONS

DIGITAL CONTROL PANEL

LOWEST AIR TEMPERATURE LIGHT

AIR INLET TEMPERATURE LIGHT

AMBIENT TEMPERATURE LIGHT

AIR OUTLET TEMPERATURE LIGHT

COMPRESSOR ON LIGHT*

POWER ON LIGHT

DIGITAL DISPLAY

ON/OFF SWITCH

8

2.5 Shutdown and Restart

A. Shutdown

1. Turn on/off switch to off "O". Leave dryer energized

unless servicing.

B. Restart

NOTE: Dryer should be energized 24 hours prior to start-up.

1. Make certain air inlet and outlet isolation valves

are closed.

2. Turn on/off switch to on "I"

3. After 15 minutes, slowly open isolation valves and close

by-pass valve.

3.0 MAINTENANCE

3.1 Air-cooled models

A. Condenser coil - Clean off accumulated dust and dirt

monthly.

NOTE: A blow-gun is supplied with dryer for this purpose.

Remove condenser screen to access blow gun.

3.2 Water-cooled models

A. Strainer - Clean strainer periodically to prevent

restriction of water flow

3.3 Automatic condensate drains

A. Check daily to be sure automatic drain is discharging.

B. Manually drain separator weekly by opening

manual drain.

C. Electric drains - periodically clean strainer in

drain reservoirs.

D. Mechanical drains - Rebuild drain mechanisms annually.

Use repair parts kit - 05.7501-03.

9

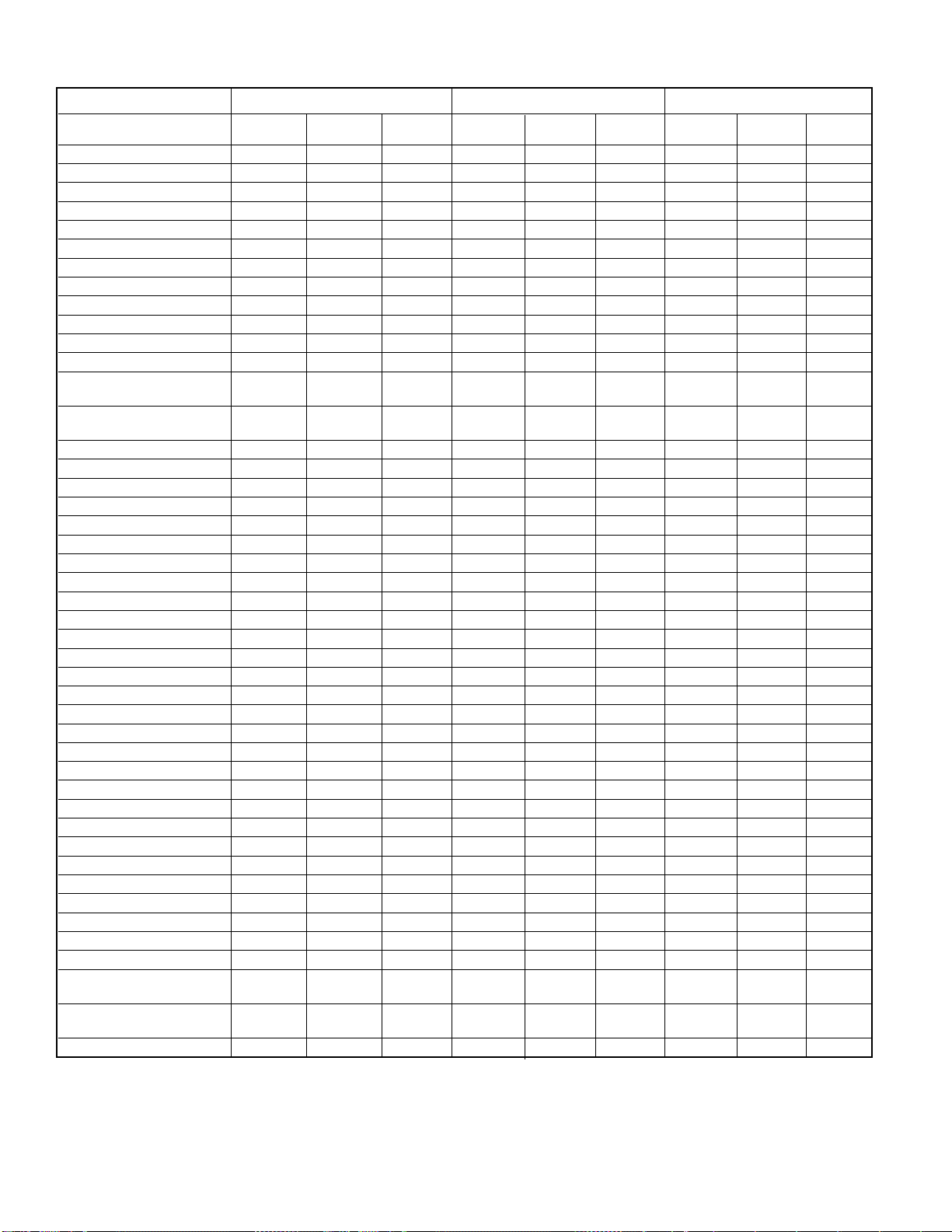

OPERATING PRESSURE psig / kg/cm2

AIR FLOW 60 / 4.2 100 / 7 180 / 12.6 200 / 14.0

2.0 x rated flow 5.4 3.5 2.1 1.9

1.5 x rated flow 3.2 2.1 1.2 1.1

1.2 x rated flow 2.1 1.4 0.8 0.7

OUTLET DEWPOINT

DEW POINT

TEMPERATURE MULTIPLIER

°F°C

38 3 1.0

40 4 1.1

45 7 1.2

50 10 1.3

COOLING MEDIUM*

AMBIENT

TEMPERATURE MULTIPLIER

°F°C

80 27 1.12

90 32 1.06

100 38 1.00

110 43 0.94

INLET COMPRESSED AIR CONDITIONS

INLET INLET TEMPERATURES

PRESSURES 80°F90°F 100°F 110°F 120°F

psig kg/cm227°C32°C38°C 43°C49°C

50 3.5 1.35 1.05 0.84 0.69 0.56

80 5.6 1.50 1.17 0.95 0.79 0.66

100 7.0 1.55 1.23 1.00 0.82 0.70

125 8.8 1.63 1.31 1.07 0.91 0.74

150 10.5 1.70 1.37 1.13 0.95 0.80

175 12.3 1.75 1.42 1.18 0.99 0.84

200 14.0 1.80 1.47 1.22 1.03 0.89

scfm x 0.0286 = m3/min

TABLE 2

Air capacity correction factors (multipliers) TABLE 3

Pressure drop correction factors (multipliers)

* Air-cooled models; water-cooled models use 1.15 multiplier if cooling

water is below 95°F, 35°C

TABLE 1

Rated capacity and Pressure @ 100 psig inlet pressure,

100°F inlet temperature, and 100°F ambient temperature

MODEL 500 600 700 800 1000 1200 1600 2000 2300

scfm scfm scfm scfm scfm scfm scfm scfm scfm

Rated Capacity of 60 Hz 500 600 700 800 1000 1200 1600 2000 2300

Air-Cooled Models (scfm) 50 Hz 500 560 580 745 830 1000 1330 1660 1910

Pressure Drop (psi) 60 Hz 3.2 3.6 4.0 3.6 4.2 4.1 3.9 4.7 5.0

50 Hz 3.2 3.2 2.9 3.2 3.0 2.9 2.8 3.4 3.6

n

SIZING

Determining dryer capacity at actual operating conditions

To determine the maximum inlet flow capacity of a dryer at various operating conditions, multiply the rated capacity from

Table 1 by the multipliers shown in Table 2.

EXAMPLE: How many scfm can a model 1000 handle when the compressed air to be dried is at 80 psig and 90°F; ambient air

temperature is 80°F; and a 38°F dew point temperature is desired?

ANSWER: 1000 x 1.17 x 1.12 x 1.0 = 1310 scfm.

Pressure Drop

To determine pressure drop at increased flows, multiply the pressure drop at rated conditions from Table 1 by the multiplier

shown in Table 3 for the appropriate air flow rate and operating pressure.

EXAMPLE: What is the pressure drop across a model 1000 when flowing 1500 scfm at 200 psig ?

ANSWER: 1500/1000 = 1.5; multiplier below at 1.5 and 200 psi = 1.1; 1.1 x 4.2 psi = 4.6 psi.

10

ENGINEERING DA TA

MODELS 500 600 700 800 1000

MINIMUM- MAXIMUM OPERATINGCONDITIONS

Max. Inlet Air Pressure ( compressed air @ inlet dryer Std. 200 psig (14 bar)

Optional 300 psig (21 bar)

Max. Inlet Air Temperature (compressed air @ inlet dryer) 120°F (49°C)

Min.- Max. Ambient Temperature (Air Cooled) 35°F (1.7°C) -110°F (43°C)

Min.- Max. Ambient Temperature (Water Cooled) 35°F (1.7°C) -130°F (54°C)

REFRIGERATIONSYSTEM DATA

Condensing Unit Mfg. Copeland

Compressor Type Hermetic - Non-Cycling Hermetic Scroll / Non-cycling

Refrigeration Compressor Horsepower 3 3 3 4 4

BTU/HR - Refrigeration Only @ 35°F (1.7°C) Evaporator

& 100°F (38°C) Ambient 60/50 Hz 28592 / 23827 28592 / 23827 28592 / 23827 42140 / 35117 42140 / 35117

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigerant Type R-134A R-134A R-134A R-404A R-404A

Refrigerant Charge See dryer serial number tag

Suction Pressure Setting psig (bar) 30.5 (2.1) 30.5 (2.1) 30.5 (2.1) 78 (5.4) 78 (5.4)

Compressor Control Ranges (out/in) (psig) A/C High 281 - 190 281 - 190 281 - 190 450 - 350 450 - 350

A/C Low 24 - 34 24 - 34 24 - 34 67 - 84 67 - 84

Compressor Control Ranges (out/in) (psig) W/C High 200 - 160 200 - 160 200 - 160 320 - 280 320 - 280

W/C Low 22 - 34 22 - 34 22 - 34 67 - 84 67 - 84

Condenser Fan Switch Setting (in/ out) (psig) Fan 1 113 - 78 113 - 78 113 - 78 300 - 230 300 - 230

(air-cooled models only) Fan 2 183 - 124 183 - 124 183 - 124 - -

Air Flow Across Condenser (cfm) 60/50 Hz 2650 / 2208 2650 / 2208 2650 / 2208 3400 / 2833 3400 / 2833

CONDENSERCOOLING WATERREQUIREMENTS

(water cooled models)

Recommended Water Pressure psig (bar) * -40 (2.8) Min. - 120 (8.4) Max.

gpm of water @ 85°F cooling water 60/50 Hz 6 / 5 7 / 6 8 / 7 9 / 8 12 / 10

ELECTRICALDATA

Nominal Voltage 208-230/3/60 208-230/3/60 208-230/3/60 208-230/3/60 208-230/3/60

Max. - Min. Voltage 253 - 187 253 - 187 253 - 187 253 - 187 253 - 187

Amperage Draw Total Full Load ** 22.9 22.9 22.9 19.1 19.1

Compressor Rated Load (amps) 20.7 20.7 20.7 15 15

Compressor Locked Rotor (amps) 90 90 90 99 99

Unit Protection Fuse Size (amps) ** 25 25 25 20 20

Branch Circuit Fuse Size (amps) Max. *** 45 45 45 35 35

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 3600 3600 3600 5020 5020

Resistance (ohms) Three phase (total) 0.853 0.853 0.853 - -

Nominal Voltage 460/3-60 460/3-60 460/3-60 460/3-60 460/3-60

Max. - Min. Voltage 506 - 414 506 - 414 506 - 414 506 - 414 506 - 414

Amperage Draw Total Full Load ** 11 11 11 10.3 10.3

Compressor Rated Load (amps) 9.9 9.9 9.9 8.2 8.2

Compressor Locked Rotor (amps) 45 45 45 49.5 49.5

Unit Protection Fuse Size (amps) ** 12-1/2 12-1/2 12-1/2 12-1/2 12-1/2

Branch Circuit Fuse Size (amps) Max. *** 20 20 20 20 20

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 3600 3600 3600 5020 5020

Resistance (ohms) Three phase (total) .0.853 0.853 0.853 - -

Nominal Voltage 200-220/3/50 200-220/3/50 200-220/3/50 200-220/3/50 200-220/3/50

Max. - Min. Voltage 242 - 180 242 - 180 242 - 180 242 - 180 242 - 180

Amperage Draw Total Full Load ** 22.9 22.9 22.9 19.1 19.1

Compressor Rated Load (amps) 20.7 20.7 20.7 15 15

Compressor Locked Rotor (amps) 90 90 90 99 99

Unit Protection Fuse Size (amps) ** 25 25 25 20 20

Branch Circuit Fuse Size (amps) Max. *** 45 45 45 35 35

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 2929 2929 2929 4183 4183

Resistance (ohms) Three phase (total) 0.853 0.853 0.853 - -

Nominal Voltage 400/3/50 400/3/50 400/3/50 400/3/50 400/3/50

Max. - Min. Voltage 462 - 342 462 - 342 462 - 342 462 - 342 462 - 342

Amperage Draw Total Full Load ** 11 11 11 10.3 10.3

Compressor Rated Load (amps) 9.9 9.9 9.9 8.2 8.2

Compressor Locked Rotor (amps) 45 45 45 49.5 49.5

Unit Protection Fuse Size (amps) ** 12-1/2 12-1/2 12-1/2 12-1/2 12-1/2

Branch Circuit Fuse Size (amps) Max. *** 20 20 20 20 20

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 2929 2929 2929 4183 4183

Resistance (ohms) Three phase (total) 0.853 0.853 0.853 - -

Nominal Voltage 575/3/60 575/3/60 575/3/60 575/3/60 575/3/60

Max. - Min. Voltage 632 - 518 632 - 518 632 - 518 632 - 518 632 - 518

Amperage Draw Total Full Load ** 11 11 11 9.8 9.8

Compressor Rated Load (amps) 9.9 9.9 9.9 8.2 8.2

Compressor Locked Rotor (amps) 45 45 45 40 40

Unit Protection Fuse Size (amps) ** 12-1/2 12-1/2 12-1/2 12-1/2 12-1/2

Branch Circuit Fuse Size (amps) Max. *** 20 20 20 20 20

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 3600 3600 3600 5020 5020

Resistance (ohms) Three phase (total) 0.853 0.853 0.853 --

* Allows continued operation with some restriction in the water strainer, * * Air cooled models only, * * * HACR type per NEC

11

MODELS 1200 1600 2000 2300

MINIMUM- MAXIMUM OPERATINGCONDITIONS

Max. Inlet Air Pressure ( compressed air @ inlet dryer ) Std. 200 psig (14 bar)

Optional 300 psig (21 bar)

Max. Inlet Air Temperature (compressed air @ inlet dryer) 120°F (49°C)

Min.- Max. Ambient Temperature (Air Cooled) 35°F (1.7°C) -110°F (43°C)

Min.- Max. Ambient Temperature (Water Cooled) 35°F (1.7°C) -130°F (54°C)

REFRIGERATIONSYSTEM DATA

Condensing Unit Mfg. Copeland

Compressor Type Hermetic Scroll / Non-cycling

Refrigeration Compressor Horsepower 6 7-1/2 10 12

BTU/HR - Refrigeration Only @ 35°F (1.7°C) Evaporator

& 100°F (38°C) Ambient 60/50 Hz 57310 / 47758 69370 / 57808 92550 / 77125 106090 / 88408

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigerant Type R-404A R-404A R-404A R-404A

Refrigerant Charge See dryer serial number tag

Suction Pressure Setting psig (bar) 78 (5.4) 78 (5.4) 78 (5.4) 78 (5.4)

Compressor Control Ranges (out/in) (psig) A/C High 450 - 350 450 - 350 450 - 350 450 - 350

A/C Low 67 - 84 67 - 84 67 - 84 67 - 84

Compressor Control Ranges (out/in) (psig ) W/C High 320 - 280 320 - 280 320 - 280 320 - 280

W/C Low 67 - 84 67 - 84 67 - 84 67 - 84

Condenser Fan Switch Setting (in/out) (psig) Fan 1 300 - 230 300 - 230 300 - 230 300 - 230

(air-cooled models only) Fan 2 325 - 255 325 - 255 325 - 255 325 - 255

Air Flow Across Condenser (cfm) 60/50 Hz 4230 / 3525 5300 / 4417 4900 / 4083 4900 / 4083

CONDENSER COOLING WATER REQUIREMENTS (watercooledmodels)

Recommended Water Pressure (psig) * 40 Min. - 120 Max.

gpm of water @ 85°F cooling water 60/50 Hz 14 / 12 21 / 18 27 / 23 35 / 30

ELECTRICALDATA

Nominal Voltage 208-230/3/60 208-230/3/60 208-230/3/60 208-230/3/60

Max. - Min. Voltage 253 - 187 253 - 187 253 - 187 253 - 187

Amperage Draw Total Full Load ** 26.9 39.3 53.1 62.8

Compressor Rated Load (amps) 23.9 30.9 44.9 54.4

Compressor Locked Rotor (amps) 156 189 278 350

Unit Protection Fuse Size (amps) ** 30 45 60 70

Branch Circuit Fuse Size (amps) Max. *** 50 70 100 125

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 7540 9630 14370 17490

Resistance (ohms) Three phase (total) - - - -

Nominal Voltage 460/3-60 460/3-60 460/3-60 460/3-60

Max. - Min. Voltage 506 - 414 506 - 414 506 - 414 506 - 414

Amperage Draw Total Full Load ** 11.1 20 25.5 29.6

Compressor Full Load (amps) 9.3 16.2 21.7 25.8

Compressor Locked Rotor (amps) 70 94 127 158

Unit Protection Fuse Size (amps) ** 15 25 30 35

Branch Circuit Fuse Size (amps) Max. *** 20 40 50 60

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 7540 9630 14370 17490

Resistance (ohms) Three phase (total) - - - -

Nominal Voltage 200-220/3/50 200-220/3/50 200-220/3/50 200-220/3/50

Max. - Min. Voltage 242 - 180 242 - 180 242 - 180 242 - 180

Amperage Draw Total Full Load ** 26.9 39.3 53.1 62.8

Compressor Rated Load (amps) 23.9 30.9 44.9 54.4

Compressor Locked Rotor (amps) 156 189 278 350

Unit Protection Fuse Size (amps) ** 30 45 60 70

Branch Circuit Fuse Size (amps) Max. *** 50 70 100 125

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 6283 8025 11975 14575

Resistance (ohms) Three phase (total) - - - -

Nominal Voltage 400/3/50 400/3/50 400/3/50 400/3/50

Max. - Min. Voltage 462 - 342 462 - 342 462 - 342 462 - 342

Amperage Draw Total Full Load ** 11.1 20 25.5 29.6

Compressor Rated Load (amps) 9.3 16.2 21.7 25.8

Compressor Locked Rotor (amps) 74 99 127 167

Unit Protection Fuse Size (amps) ** 15 25 30 35

Branch Circuit Fuse Size (amps) Max. *** 20 40 50 60

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 6283 8025 11975 14575

Resistance (ohms) Three phase (total) - - - -

Nominal Voltage 575/3/60 575/3/60 575/3/60 575/3/60

Max. - Min. Voltage 632 - 518 632 - 518 632 - 518 632 - 518

Amperage Draw Total Full Load ** 9.3 15.2 20 24

Compressor Rated Load (amps) 7.9 11.8 16.6 20.6

Compressor Locked Rotor (amps) 54 74 100 125

Unit Protection Fuse Size (amps) ** 12-1/2 17-1/2 25 30

Branch Circuit Fuse Size (amps) Max. *** 15 25 40 50

Watts @ 35°F (1.7°C) Evaporator & 100°F (38°C) Ambient 7540 9630 14370 17490

Resistance (ohms) Three phase (total) - - - -

* Allows continued operation with some restriction in the water strainer, * * Air cooled models only, * * * HACR type per NEC

ENGINEERING DA TA

12

L1

4HP THRU 12HP 575 VOLT UNITS

3HP THRU 12HP 230/460 VOLT AND

(1) CUSTOMER ELECTRICAL CONNECTIONS (TERMINAL STRIP)

(1)

(1)

(1)

L3 L3

L2

L3 L3 L2 L1

(1)

L1

L1

8FU

(1) CUSTOMER ELECTRICAL CONNECTION (ENTRY ENCLOSURE)

3HP 575 VOLT UNITS ONLY

(1)

(1)

(1) 9FU

(1) 7FU

6FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

CON 4LT

3LT

4. DISCHARGE TEMPERATURE SWITCH IS ONLY USED ON

3. SOLID STATE MOTOR PROTECTOR IS ONLY USED ON

1. REMOVE FAN MOTORS AND FAN SWITCHES FOR WATER

2. 4HP UNITS HAVE ONLY ONE (1) FAN MOTOR.

4HP AND 6HP UNITS.

7-1/2HP THRU 12HP UNITS.

COOLED UNITS.

NOTES

LOW AMBIENT

(OPTIONAL)

2SOL

1SOL

TDR

PBS

CR

DTS

SSMP HPS

TDR

LPS

CON

HTS

R

R

CR-1

CR-5

LOW AMBIENT

TIME DELAY

(OPTIONAL)

CR-9

ALARM CONTACT RATINGS

7A @ 240VAC

7.5A @ 30VDC

7.5A @ 120VAC

CR

CR

ALARM CONTACTS (OPTIONAL)

TAS - THERMOSTAT

TDR - TIME DELAY RELAY

2T - LOW AMBIENTTRANSFORMER

2HTR - LOW AMBIENT HEAT TAPE

3HTR - LOW AMBIENT HEAT TAPE

CONTACTS

SEE NOTES 3

SEE NOTES 4

(OPTIONAL)

ALARM

2LT

1LT

230/400/460/575 VOLT

L2

5FU

2T

TAS 3HTR

TAS 2HTR

6FU

1

XX

GND

2

115V

CONNECTIONS

575 VOLT SEE TRANSFORMER

FOR 3HP UNITS

4FU

L3

1T

CON

1FU

1X

GND

2

115V

X

G

SSMP

G

3FU

2FU

SEE TRANSFORMER

DETAILS FOR

CONNECTIONS

1FPS

2FPS

USE COPPER

SUPPLY WIRE ONLY

L1 CON

CON 1HTR

MTR

5FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

4FU - FUSE, LITTELFUSE, FLM 1-1/4, 250V

CR - CONTROL RELAY

OPTIONAL FEATURES BELOW

4LT - REFRIGERANT FAULT LIGHT

2SOL - ELECTRIC DRAIN VALVE

1SOL - ELECTRIC DRAIN VALVE

SSMP - SOLID STATE MOTOR PROTECTOR

DTS - DISCHARGE TEMPERATURE SWITCH

SEE NOTE 3

FM - FAN MOTOR

CON - CONTACTOR

MTR - COMPRESSOR

1LT - POWER ON LIGHT

1T - CONTROL TRANSFORMER

3LT - HIGH TEMPERATURE LIGHT

2LT - COMPRESSOR ON LIGHT

HTS - HIGH TEMPERATURE SWITCH

FPS - FAN PRESSURE SWITCH

LPS - LOW PRESSURE SWITCH

1FM SEE NOTE 1

SEE NOTE 2

2FM

3FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

2FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

1FU - FUSE, LITTELFUSE, FLM 6/10, 250V

1HTR - CRANKCASE HEATER

HPS - HIGH PRESSURE SWITCH

PBS - DRYER-ON/OFF SWITCH

LEGEND

(OPTIONAL)

(OPTIONAL)

ELECTRICAL CONNECTIONS

WIRING DIAGRAM (ST ANDARD CONTROL P ANEL)

13

SUPPLY WIRE ONLY

USE COPPER

FOR 3HP UNITS

575 VOLT SEE TRANSFORMER

CONNECTIONS

230/400/460/575 VOLT

COOLED UNITS.

7-1/2HP THRU 12HP UNITS.

4HP AND 6HP UNITS.

2. 4HP UNITS HAVE ONLY ONE (1) FAN MOTOR.

1. REMOVE FAN MOTORS AND FAN SWITCHES FOR WATER

3. SOLID STATE MOTOR PROTECTOR IS ONLY USED ON

4. DISCHARGE TEMPERATURE SWITCH IS ONLY USED ON

OPTIONAL HIGH WATER LEVEL FLOAT SWITCHES 1FS & 2FS.

5. ALARM CONTACTS ARE CONTROLED BY T1 & T2 AND

TAS - THERMOSTAT

(OPTIONAL)

1SOL - ELECTRIC DRAIN VALVE

2SOL - ELECTRIC DRAIN VALVE

ALARM CONTACTS

7.5A @ 120VAC

7.5A @ 30VDC

7A @ 240VAC

ALARM CONTACT RATINGS

CON

T1

NOTES

14

10

F1

S1

89 16

15 4

CR

(OPTIONAL)

(OPTIONAL)

2S0L

T3T2

1S0L

T4

SEE NOTE 5

PCB

1817 2019

65 7

3

2221 23

11 12 13

2FS

1FS

CONTACTS

ALARM

TB-12

CR

1FS - FLOAT SWITCH

2FS - FLOAT SWITCH

TDR - TIME DELAY RELAY

TB-11

TB-13

T2 - EVAPORATOR TEMPERATURE SENSOR

T3 - AMBIENT TEMPERATURE SENSOR

T4 - OUTLET TEMPERATURE SENSOR

F1 - FUSE,WICKMANN TYPE TR5 250mA, 250V

T1 - INLET TEMPERATURE SENSOR

PBS - DRYER-ON/OFF SWITCH

HPS - HIGH PRESSURE SWITCH

1FU - FUSE, LITTELFUSE, FLM 6/10, 250V

2FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

3FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

LPS - LOW PRESSURE SWITCH

FPS - FAN PRESSURE SWITCH

HTS - HIGH TEMPERATURE SWITCH

1T - CONTROL TRANSFORMER

DTS - DISCHARGE TEMPERATURE SWITCH

SSMP - SOLID STATE MOTOR PROTECTOR

OPTIONAL FEATURES BELOW

4FU - FUSE, LITTELFUSE, FLM 1-1/4, 250V

5FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

3HTR - LOW AMBIENT HEAT TAPE

2HTR - LOW AMBIENT HEAT TAPE

2T - LOW AMBIENT TRANSFORMER

6FU - FUSE, LITTELFUSE, KLDR 1/2, 600V

MTR

L2

X

LOW AMBIENT

TAS 3HTR

TAS 2HTR

6FU

X1

GND

115V 2

1FU

X

PBS DTS

SSMP

GND

115V

12

X

L3

4FU

CONNECTIONS

2T

DETAILS FOR

SEE TRANSFORMER

1T

5FU 2FU 3FU

(OPTIONAL)

TIME DELAY

LOW AMBIENT

SEE NOTE 4

SEE NOTE 3

SEE NOTE 3

CON

TDR

HPS LPS SSMP

SEE NOTE 2

SEE NOTE 1

2FPS 2FM

1FPS 1FM

MTR - COMPRESSOR

CON - CONTACTOR

FM - FAN MOTOR

L1 CON

CON 1HTR

1HTR - CRANKCASE HEATER

LEGEND

WIRING DIAGRAM (DIGIT AL CONTROL P ANEL)

14

XX XXXXXXXXXX XXXX

X

H1

115V

115V 115V

575V/60Hz

2

X

12

X3X

H2H3H4

T

41

X

5

HH1H

493-506V/60Hz

110V

12

34 1

T

2

X3

X4

X

3

H4

H5

H

110V

23 4 1 324 115V

1234

391-418V/50Hz

LINE VOLTAGE RANGE PRIMARY TAPS SECONDARY TAPS

LINE VOLTAGE RANGE PRIMARY TAPS SECONDARY TAPS

1

H

342-360V/50Hz

414-440V/60Hz

110V

H

X

419-420V/50Hz

3

H

2

H4

H

T

H5HH1

493 - 506V

414 - 440V

441 - 492V H1/H5

H1/H4

H1/H4

T

3

H

245

HH H1H2

X1/X4

X1/X3

X1/X4

H1/H3

SELECTION TABLE

419 - 420V

361 - 390V

391 - 418V H1/H4

H1/H3

H1/H4

SELECTION TABLE

342 - 360V X1/X4

X1/X3

60 Hz

X1/X3

X1/X4

1

X

50 Hz

1

H2

H

441-492V/60Hz

T

4

H

3 5

H1

H2H3

H

T

H4H5

361-390V/50Hz

3

231

23

X4

X

T

1

X2

110V

X X

H

3

HH

45 HHH 54

4

X

T

HH

X

GND

X1115V 2

13H HH2

230V

4

T

H

GND

1

X115V 2

X

H2

H

H3

1

460V

H

2T

4

FOUR LEAD TRANSFORMER

230 & 460 V/ 3ph/60Hz

FIVE LEAD TRANSFORMER

380 - 420V/ 3hp/50Hz

460 & 575v/3hp/60Hz

CONTROL TRANSFORMER CONNECTIONS

7FU - FUSE, LITTELFUSE, CCMR15, 600V (SEE NOTE 2)

8FU - FUSE, LITTELFUSE, CCMR15, 600V (SEE NOTE 2)

9FU - FUSE, LITTELFUSE, CCMR15, 600V (SEE NOTE 2)

CUSTOMER CONNECTION

H2

3HP UNITS ONLY

X2

X4

X3 X1

4T

H1

SUPPLY WIRE ONLY

9FU

USE COPPER

L3

L2 8FU

L1 7FU

H4

H3

575V

H4

460V

3T H2

H3

X4 X2

H1

X3 X1

575 VOL T POWER TRANSFORMER CONNECTION FOR 3 HP UNITS

15

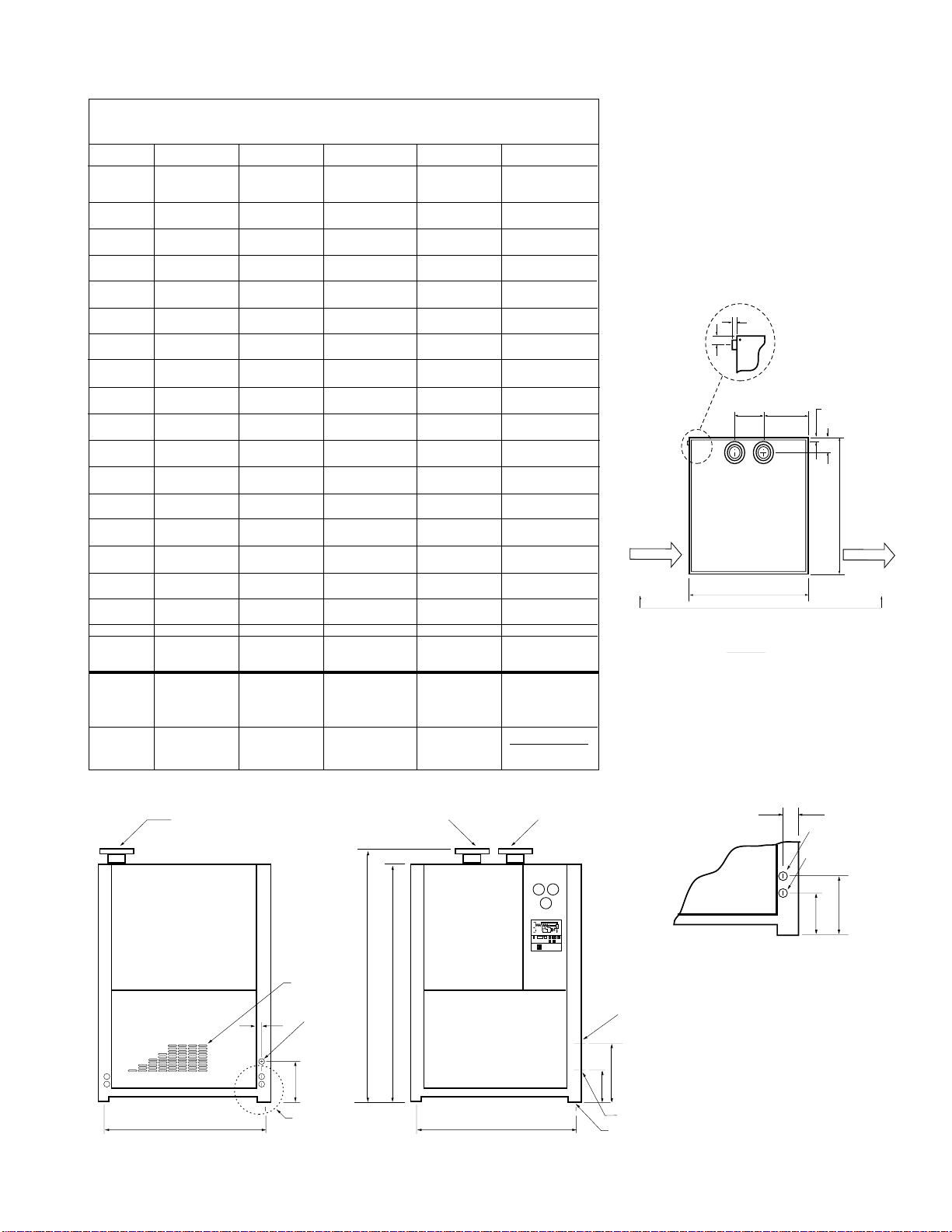

DIMENSIONS

inches [

mm

]

MODEL 500-600-700 800-1000 1200 1600 2000/2300

A 65-1/4 75-3/4 70-3/4 85 85

[

1657

][

1924

][

1797

][

2159

][

2159

]

B3838484848

[

965

][

965

][

1219

][

1219

][

1219

]

C4444505050

[

1118

][

1118

][

1270

][

1270

][

1270

]

D 68-1/2 79 74-1/4 87-3/4 87-3/4

[

1740

][

2007

][

1886

][

2229

][

2229

]

E 12-1/2 12-1/2 13-1/4 13-1/4 13-1/4

[

318

][

318

][

337

][

337

][

337

]

F 5-1/4 5-1/4 5-1/4 6-1/4 6-1/4

[

133

][

133

][

133

][

159

][

159

]

G 3" NPT or 3" NPT or 4" ANSI or 6" ANSI or 6" ANSI or

DN80 Flange DN80 Flange DN100 Flange DN150 Flange DN150 Flange

H 12-3/4 12-3/4 17-3/8 17-3/8 17-3/8

[

324

][

324

][

441

][

441

][

441

]

J 35-3/8 35-3/8 44-3/4 45-3/8 45-3/8

[

899

][

899

][

1137

][

1150

][

1150

]

K 41-3/8 41-3/8 45-3/4 47-3/8 47-3/8

[

1051

][

1051

][

1162

][

1203

][

1203

]

L 5/8 5/8 5/8 5/8 5/8

[

16

][

16

][

16

][

16

][

16

]

M2 222 2

[

51

][

51

][

51

][

51

][

51

]

N 10-3/4 10-3/4 9-1/2 10-1/4 10-1/4

[

273

][

273

][

241

][

260

][

260

]

P 16-3/4 16-3/4 15-1/2 16-3/4 16-3/4

[

426

][

426

][

394

][

425

][

425

]

Q2 222 2

[

51

][

51

][

51

][

51

][

51

]

R 7 7 5-3/4 5-3/4 5-3/4

[

178

][

178

][

146

][

146

][

146

]

S 9 9 7-3/4 7-3/4 7-3/4

[

229

][

229

][

197

][

197

][

197

]

T 1/2" 3/4" 3/4" 3/4" 3/4"

U 13-1/2 19 12-1/4 12-1/4 12-1/4

[

343

][

483

][

311

][

311

][

311

]

WEIGHTS 912 lbs [

414 kg

] 1288 lbs [

584 kg

] 1486 lbs 2173 lbs 2396 lbs. [

1087 kg

]

A/C 1024lbs [

465 kg

] 1365 lbs [

619 kg

][

675 kg

][

986 kg

] 2715 lbs [

1232 kg

]

1066 lbs [

484 kg

]

892 lbs [

404 kg

] 1230 lbs [

558 kg

] 1466 lbs 2153 lbs 2376 lbs [

1078 kg

]

W/C 1004 lbs [

455 kg

] 1305 lbs [

592 kg

][

666 kg

][

977 kg

]

1046 lbs [

474 kg

]

DIMENSIONS AND WEIGHTS

LEFT SIDE VIEW FRONT VIEW

TOP VIEW

NOTE: Dimensions and Weights are for reference only. Request certified

drawings for construction purposes.

M

M

M

3 mm

(1/8")

EH

F

Q

WATER

CONNECTIONS

B

C

AIR COOLED MODELS ONLY

914mm (36")

Minimum clearance for

free air flow both sides

All models 914mm (36")

minimum clearance should be

provided on

front and left side for maintenance

M

MANUAL DRAIN VALVE

1/4" NPT (F)

AUTOMATIC DRAIN

1/4" NPT (F)

G AIR CONNECTION

Flange standard on models 1200 and larger

K

MOUNTING CENTERS MOUNTING CENTERS

SCREEN

M

L

DIA. MTG. HOLES

(4 REQ'D)

29mm Dia.

(1-1/8")

ELECTRICAL

CONN. ENTRY

U

SEE DETAIL "A"

DETAIL "A"

Drain Location

M

M

T WATER INLET

T WATER OUTLET

N

P

AIR INLETAIR OUTLET

A

D

J

RS

FAN AIR FLOW

FAN AIR FLOW

16

TROUBLESHOOTING GUIDE

POSSIBLECAUSES

B) High pressure drop across

dryer

C) High Temperature Alarm

D) Refrigeration system not

functioning properly

1. Power on light off

2. Refrigerant Suction Pressure

Gauge in red area

3. Refrigerant Suction Pressure

Gauge in blue area

4. Refrigerant pressure cut out light

on (with on/off switch in on

position)

CORRECTIVE ACTION

Blow out system with dry air

Check valve positions

Check for correct connection

Insulate or heat trace air lines exposed

to low ambients or dry air to lower dew

point

Install separator ahead of dryer

Rebuild drain mechanism if inoperative

Open drain line

Electric drains - reset time so that all

liquid is discharged

Check inlet air temperature and pressure,

flow rate (compressor capacity) and

ambient air or water temperature.

See D below

Check flow rate

See D below

See A 7

See D below

Contact qualified refrigeration repair-

man or manufacturer’s service depart-

ment

Check power to unit

Close disconnect switch

Check for continuity

Have electrician check electrical

connections

Contact qualified refrigeration repairman

or manufacturer’s service department.

Check temperature

Check temperature

See special instructions Section 2.2.

Contact qualified refrigeration repairman

or manufacturer’s service department.

Check ambient temperature range

Clean condenser and check for free air

flow, if problem persists contact

qualified refrigeration repairman or

manufacturer’s service department.

Clean strainer, check water flow and

temperature, if problem persists contact

qualified refrigeration repairman or

manufacturer’s service department.

Manually reset and restart without load.

1. Residual free moisture remaining in

downstream pipelines

2. Air by-pass system is open

3. Inlet and Outlet connections are reversed

4. Temperatures surrounding air lines

downstream of dryer have dropped below

dryers dew point rating

5. Excessive free moisture (bulk liquid) at

dryer inlet

6. Condensate not being automatically

drained

Drain mechanism is clogged or inoperative.

Drain line is restricted or frozen.

Electric drains - timer not set to allow for

sufficient condensate removal

7. Dryer overloaded resulting in elevated

dew point.

8. Refrigeration system not functioning

properly resulting in elevated dew point.

1. Excessive air flow

2. Freezing of moisture in evaporator

because of refrigeration system

improperly functioning.

1. Dryer overloaded resulting in high air

outlet temperature.

2. Refrigeration system not functioning

properly resulting in high air outlet

temperature.

3. Unit functioning normally but thermostatic

switch is malfunctioning or not securely

mounted.

a. Power failure

b. Line disconnect switch open

c. Blown fuses, open breaker

d. Faulty wiring, loose terminals

a. Refrigeration compressor not running

b. High inlet air temperature

c. High ambient air temperature

d. 800-2300 models - compressor

rotation incorrect

a. Hot gas by-pass valve improperly set

b. Low on refrigerant

a. High or low ambient temperature

b. Air-cooled models - Dirty, clogged

condenser fins, obstructed air flow across

condenser, or non functioning fan motor

or fan control switch.

c. Water-cooled models - Cooling water

temperature too high, or flow too low,

faulty water regulating valve, clogged

water strainer.

d. Start-up - high pressure switch may

have tripped.

SYMPTOM

A) Water downstream of dryer

17

PAR TS LIST

Parts Description 500/600/700 800/1000 1200

Voltage 208 400/3/50 575/3/60 208 400/3/50* 575/3/60 208 400/3/50* 575/3/60

230/3/60 460/3/60 230/3/60 460/3/60 230/3/60 460/3/60

Condensing unit (Air-cooled) 4130.129.1 4130.129.2 4130.129.2 4130.129.3 4130.129.4 4130.129.5 4130.129.6 4130.129.7 4130.129.8

Compressor 4130.108.64 4130.108.65 4130.108.65 4130.106.57 4130.106.48 4130.106.58 4130.106.59 4130.106.49 4130.106.60

Crankcase Heater 5920.327.12 5920.327.13 5920.327.13 5920.330.18 5920.330.16 5920.330.19 5920.330.18 5920.330.16 5920.330.19

Contactor 5910.135.6 5910.135.4 5910.135.4 5910.135.19 5910.135.4 5910.135.4 5910.135.10 5910.135.4 5910.135.4

Aux Contactor NO 6110.101.13 6110.101.13 6110.101.13 6110.101.13 6110.101.13 6110.101.13 6110.101.13 6110.101.13 6110.101.13

Aux Contactor NC 6110.101.14 6110.101.14 6110.101.14 6110.101.14 6110.101.14 6110.101.14 6110.101.14 6110.101.14 6110.101.14

Aux Contactor NC\NO —-—-—-—-—-—-—-—-—-

Control Circuit Transformer 6120.092.11 6120.092.11 6120.092.11 6120.092.1 6120.092.1 6120.093.6 6120.092.1 6120.092.1 6120.093.6

Fuse, Control Circuit 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20

Fuse, Primany, Transformer 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19

Power Transformer —-—- 6120.277.1 —-—-—-—-—-—-

Fuse, Power Transformer —-—- 5920.274.34 —-—-—-—-—-—-

High Refrigerant Pressure Switch

(Air-cooled) 4130.138.25 4130.138.25 4130.138.25 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28

High Refrigerant Pressure Switch

(Water-cooled) 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2

Low Refrigerant Pressure Switch 4130.138.22 4130.138.22 4130.138.22 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29

Discharge Temperature Switch —-—-—- 5930.190.8 5930.190.8 5930.190.8 5930.190.8 5930.190.8 5930.190.8

Solid State Motor Protector —-—-—-—-—-—-—-—-—-

On/Off Switch 6110.706.9 6110.706.9 6110.706.9 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6

Light - Red 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12

Light - Green 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11

Hight Temperature Light Sensor 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1

Hot Gas By-pass Valve 4130.690.5 4130.690.5 4130.690.5 4130.690.18 4130.690.18 4130.690.18 4130.690.18 4130.690.18 4130.690.18

Thermal Expansion Valve 4130.829.14 4130.829.14 4130.829.14 4130.829.15 4130.829.15 4130.829.15 4130.829.16 4130.829.16 4130.829.16

Filter Dryer (liquid line) 4130.166.2 4130.166.2 4130.166.2 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4

Sight Glass 4130.725.3 4130.725.3 4130.725.3 4130.725.3 4130.725.3 4130.725.3 4130.725.4 4130.725.4 4130.725.4

De-Superheating Valve —-—-—-—-—-—-—-—-—-

Suction Filter —-—-—-—-—-—-—-—-—-

Condenser (Air-cooled) 4130.111.28 4130.111.28 4130.111.28 4130.113.11 4130.113.11 4130.113.11 4130.112.12 4130.112.12 4130.112.12

Condenser (Water-cooled) 4130.115.16 4130.115.16 4130.115.16 4130.115.11 4130.115.11 4130.115.11 4130.115.11 4130.115.11 4130.115.11

Cooling Water Regulating Valve 4130.145.23 4130.145.23 4130.145.23 4130.145.3 4130.145.3 4130.145.3 4130.145.3 4130.145.3 4130.145.3

Cooling Water Strainer 4731.735.1 4731.735.1 4731.735.1 4731.735.2 4731.735.2 4731.735.2 4731.735.2 4731.735.2 4731.735.2

Cooling Water Strainer Screen 4731.735.5 4731.735.5 4731.735.5 4731.735.7 4731.735.7 4731.735.7 4731.735.7 4731.735.7 4731.735.7

Fan Motor 6105.238.39 6105.238.40 6105.238.40 6105.238.46 6105.238.23 6105.238.47 6105.238.48 6105.237.14 6105.238.49

Fan Blade 4140.227.24 4140.227.24 4140.227.24 4140.227.14 4140.227.14 4140.227.14 4140.228.10 4140.228.10 4140.228.10

Fan Cut-out Switch (Fan 1) 4130.138.23 4130.138.23 4130.138.23 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26

Fan Cut-out Switch (Fan 2) 4130.138.24 4130.138.24 4130.138.24 —-—-—- 4130.138.27 4130.138.27 4130.138.27

Air Pressure Gauge 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1

Air Temperature Gauge 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6

Suction Pressure Gauge 6685.287.14 6685.287.14 6685.287.14 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3

Head Pressure Gauge —-—-—-—-—-—-—-—-—-

Digital Panel 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01

Sensor (set of 4) 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3

MECHANICAL DRAIN

Repair Rarts Kit 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03

ELECTRIC DRAIN

Timer 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4

Coil and Valve 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38

(*) For 400/3/50 use control transformer 6120.093.6

18

Parts Description 1600 2000 2300

Voltage 208 400/3/50 575/3/60 208 400/3/50* 575/3/60 208 400/3/50* 575/3/60

230/3/60 460/3/60 230/3/60 460/3/60 230/3/60 460/3/60

Condensing unit (Air-cooled) 4130.129.9 4130.129.10 4130.129.11 4130.129.12 4130.129.13 4130.129.14 4130.129.15 4130.129.16 4130.129.17

Compressor 4130.106.61 4130.106.50 4130.106.62 4130.106.63 4130.106.51 4130.106.64 4130.106.65 4130.106.52 4130.106.66

Crankcase Heater 5920.330.20 5920.330.17 5920.330.21 5920.330.20 5920.330.17 5920.330.21 5920.330.20 5920.330.17 5920.330.21

Contactor 5910.135.12 5910.135.19 5910.135.19 5910.135.16 5910.135.19 5910.135.19 5910.135.16 5910.135.19 5910.135.19

Aux Contactor NO —-—-—-—-—-—-—-—-—-

Aux Contactor NC —-—-—-—-—-—-—-—-—-

Aux Contactor NC\NO 6110.101.20 6110.101.20 6110.101.20 6110.101.20 6110.101.20 6110.101.20 6110.101.20 6110.101.20 6110.101.20

Control Circuit Transformer 6120.092.1 6120.092.1 6120.093.6 6120.092.1 6120.092.1 6120.093.6 6120.092.1 6120.092.1 6120.093.6

Fuse, Control Circuit 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20 5920.274.20

Fuse, Primany Transformer 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19 5920.274.19

Power Transformer —-—-—-—-—-—-—-—-—-

Fuse, Power Transformer —-—-—-—-—-—-—-—-—-

High Refrigerant Pressure Switch

(Air-cooled) 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28 4130.138.28

High Refrigerant Pressure Switch

(Water-cooled) 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2 4130.139.2

Low Refrigerant Pressure Switch 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29 4130.138.29

Discharge Temperature Switch —-—-—-—-—-—-—-—-—-

Solid State Motor Protector 5925.580.7 5925.580.7 5925.580.7 5925.580.7 5925.580.7 5925.580.7 5925.580.7 5925.580.7 5925.580.7

On/Off Switch 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6 6110.706.6

Light - Red 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12 6350.457.12

Light - Green 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11 6350.457.11

Hight Temperature Light Sensor 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1 5930.189.1

Hot Gas By-pass Valve 4130.690.19 4130.690.19 4130.690.19 4130.690.19 4130.690.19 4130.690.19 4130.690.19 4130.690.19 4130.690.19

Thermal Expansion Valve 4130.829.16 4130.829.16 4130.829.16 4130.829.17 4130.829.17 4130.829.17 4130.829.18 4130.829.18 4130.829.18

Filter Dryer (liquid line) 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4 4130.166.4

Sight Glass 4130.725.4 4130.725.4 4130.725.4 4130.725.4 4130.725.4 4130.725.4 4130.725.4 4130.725.4 4130.725.4

De-Superheating Valve 4130.829.19 4130.829.19 4130.829.19 4130.829.20 4130.829.20 4130.829.20 4130.829.20 4130.829.20 4130.829.20

Suction Filter 4130.246.1 4130.246.1 4130.246.1 4130.246.1 4130.246.1 4130.246.1 4130.246.1 4130.246.1 4130.246.1

Condenser (Air-cooled) 4130.111.16 4130.111.16 4130.111.16 4130.111.16 4130.111.16 4130.111.16 4130.111.16 4130.111.16 4130.111.16

Condenser (Water-cooled) 4130.115.12 4130.115.12 4130.115.12 4130.115.12 4130.115.12 4130.115.12 4130.115.12 4130.115.12 4130.115.12

Cooling Water Regulating Valve 4130.145.3 4130.145.3 4130.145.3 4130.145.5 4130.145.5 4130.145.5 4130.145.6 4130.145.6 4130.145.6

Cooling Water Strainer 4731.735.2 4731.735.2 4731.735.2 4731.735.3 4731.735.3 4731.735.3 4731.735.4 4731.735.4 4731.735.4

Cooling Water Strainer Screen 4731.735.7 4731.735.7 4731.735.7 4731.735.8 4731.735.8 4731.735.8 4731.735.9 4731.735.9 4731.735.9

Fan Motor 6105.238.50 6105.238.25 6105.238.51 6105.238.50 6105.238.25 6105.238.51 6105.238.50 6105.238.25 6105.238.51

Fan Blade 4140.227.15 4140.227.15 4140.227.15 4140.227.15 4140.227.15 4140.227.15 4140.227.15 4140.227.15 4140.227.15

Fan Cut-out Switch (Fan 1) 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26 4130.138.26

Fan Cut-out Switch (Fan 2) 4130.138.27 4130.138.27 4130.138.27 4130.138.27 4130.138.27 4130.138.27 4130.138.27 4130.138.27 4130.138.27

Air Pressure Gauge 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1 6685.279.1

Air Temperature Gauge 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6 6685.281.6

Suction Pressure Gauge 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3 6685.287.3

Head Pressure Gauge 6685.279.2 6685.279.2 6685.279.2 6685.279.2 6685.279.2 6685.279.2 6685.279.2 6685.279.2 6685.279.2

Digital Panel 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01 03.5817-01

Sensor (set of 4) 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3 6625.471.3

MECHANICAL DRAIN

Repair Parts Kit 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03 05.7501-03

ELECTRIC DRAIN

Timer 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4 5945.693.4

Coil and Valve 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38 4810.741.38

(*) For 400/3/50 use control transformer 6120.093.6

PAR TS LIST

19

NOTES

20

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY

BEFORE MATERIAL IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

WARRANTY

The manufacturer warrants the product manufactured by it, when properly installed, operated, applied, and maintained in accordance with procedures and

recommendations outlined in manufacturer's instruction manuals, to be free from defects in material and workmanship for a period of one (1) year from the

date of shipment to the buyer by the manufacturer or manufacturer's authorized distributor, or eighteen months from the date of shipment from the factory,

whichever occurs first (refrigerated dryers, models 25 thru 2300 scfm inclusive, for a period of two years from the date of shipment from the factory),

provided such defect is discovered and brought to the manufacturer's attention within the aforesaid warranty period.

The manufacturer will repair or replace any product or part determined to be defective by the manufacturer within the warranty period, provided such defect

occurred in normal service and not as a result of misuse, abuse, neglect or accident. Normal maintenance items requiring routine replacement are not

warranted. For refrigerated dryers model 25 thru 2300 scfm, the manufacturer will include parts and labor for 18 months from the date of shipment from the

factory and parts only for an additional six (6) months. On all other products, the warranty covers parts and labor for the warranty period. Repair or

replacement shall be made at the factory or the installation site, at the sole option of the manufacturer. Any service performed on the product by anyone

other than the manufacturer must first be authorized by the manufacturer.

Unauthorized service voids the warranty and any resulting charge or subsequent claim will not be paid.

Products repaired or replaced under warranty shall be warranted for the unexpired portion of the warranty applying to the original product.

The foregoing is the exclusive remedy of any buyer of the manufacturer's product. The maximum damages liability of the manufacturer is the original

purchase price of the product or part.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR STATUTORY, AND IS

EXPRESSED IN LIEU OF THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE MANUFACTURER SHALL NOT BE LIABLE FOR LOSS OR DAMAGE BY REASON OF STRICT LIABILITY IN TORT OR ITS NEGLI-

GENCE IN WHATEVER MANNER INCLUDING DESIGN, MANUFACTURE OR INSPECTION OF THE EQUIPMENT OR ITS FAILURE TO DISCOVER,

REPORT, REPAIR, OR MODIFY LATENT DEFECTS INHERENT THEREIN.

THE MANUFACTURER, HIS REPRESENTATIVE OR DISTRIBUTOR SHALL NOT BE LIABLE FOR LOSS OF USE OF THE PRODUCT OR OTHER

INCIDENTAL OR CONSEQUENTIAL COSTS, EXPENSES, OR DAMAGES INCURRED BY THE BUYER, WHETHER ARISING FROM BREACH OF

WARRANTY, NEGLIGENCE OR STRICT LIABILITY IN TORT.

The manufacturer does not warrant any product, part, material, component, or accessory manufactured by others and sold or supplied in connection with

the sale of manufacturer's products. 2/96

Division Of Hansen Inc.

Canonsburg, PA 15317-1700 U.S.A.

Tel 724-745-1555 Fax 724-745-6040

SERVICEDEPARTMENT:(724)746-1100

This manual suits for next models

8

Table of contents

Other HANKISON Dehumidifier manuals

HANKISON

HANKISON HBP Series User manual

HANKISON

HANKISON H Series User manual

HANKISON

HANKISON HPRP 1000 User manual

HANKISON

HANKISON SPX FLOW HES Series User manual

HANKISON

HANKISON HPRplus HPRP1000 User manual

HANKISON

HANKISON HPRP 200 User manual

HANKISON

HANKISON HPRD 0.50-500 User manual

HANKISON

HANKISON SPXFLOW HSHD Series User manual

HANKISON

HANKISON SPX HES Series User manual

HANKISON

HANKISON HPR Series User manual