HanleyLED Concorde Cabinet System User manual

12.18.18

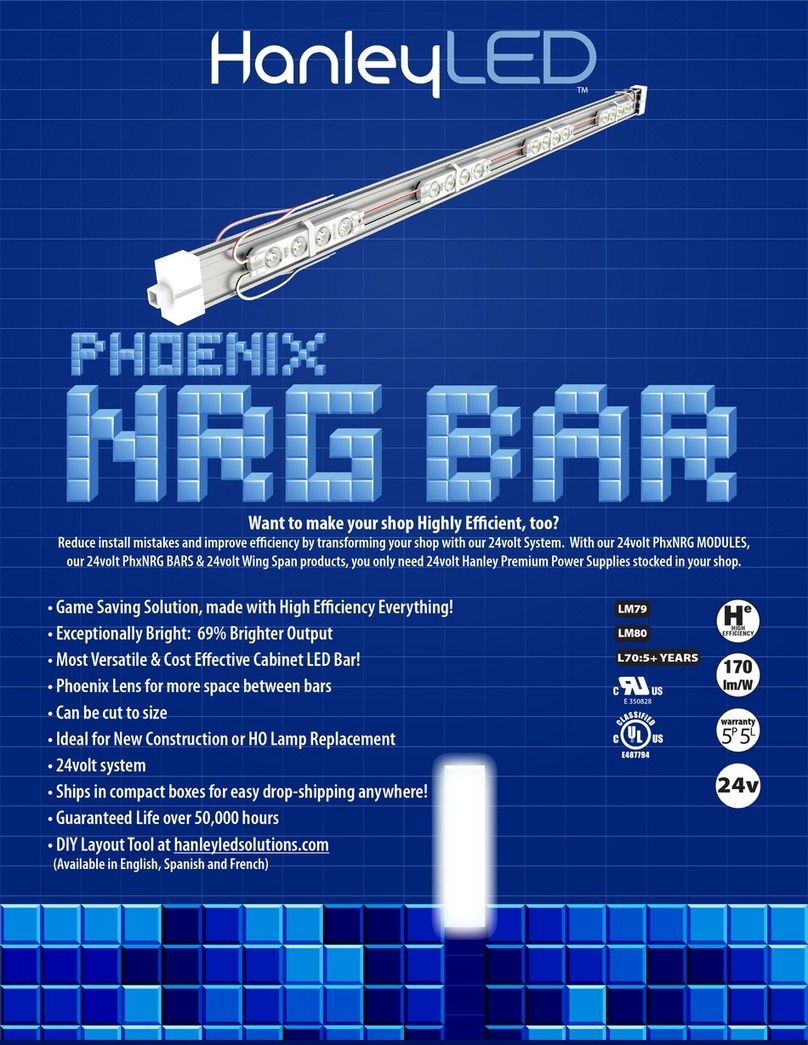

GENERAL PURPOSE

RETROFIT SIGN

CONVERSION

FOR USE ONLY IN

ACCORDANCE WITH KIT

INSTRUCTIONS

KIT IS COMPLETE ONLY WHEN ALL PARTS

REQUIRED BY THE INSTRUCTIONS ARE PRESENT

2

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY

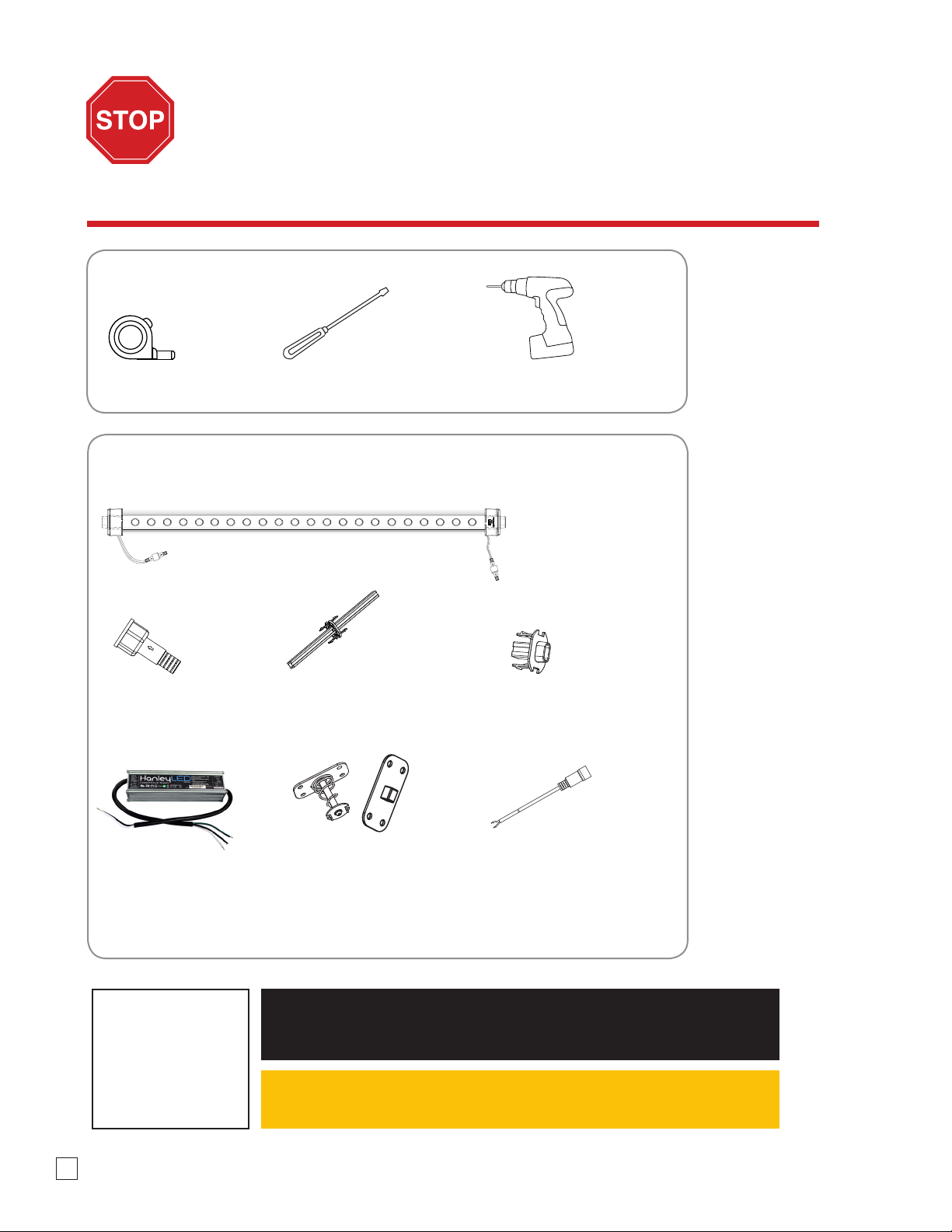

24v Power Supply Speed Spring Bracket Set

(Spring and stationary)

Optional

Concorde Cable Connectors

Optional

Retrot (RF) ConnectorWatertight End Cap Concorde Joint

Tools required:

Components:

NOTE:

All materials removed

must be disposed of

in accordance with

applicable local, state,

and federal laws.

WARNING check polarity: All connections must be WHITE-TO-RED (+) and BLACK-TO-BLACK (-).

Reverse polarity connections may damage the LEDs and will void product warranty.

Caution: Turn o power to sign before inspecting or removing existing light source.

Power must remain o while installing the Concorde Cabinet System.

Screwdriver Electric DrillTape Measure

BEFORE YOU BEGIN

Determine your light bar mounting method. Are you using pre-existing sockets to mount?

If so, Retrot Connectors are included. If not, be sure to purchase our Speed Spring Brackets

for fast and secure mounting.

Concorde Cabinet Bars

RETROFIT INSTALLATION GUIDE

This guide is designed to aid in the installation of HanleyLED’s Concorde Cabinet System. Skilled trades people that are familiar with

general construction, electrical, and sign installation techniques should do the installation. Licensed electricians should provide all

installation and hook-up of both the primary and secondary input/outputs of the HanleyLED power supply. All installation and hook-

up should be done in accordance with all National and Local codes and permits. In no way is this document intended to construe

warranty or tness of use of the products described, nor is it intended to provide safety instruction for those installing the product.

Step 1

Remove existing neon or uorescent bulbs by having a licensed electrician disconnect and remove the neon transformers or

uorescent ballasts. Remove existing neon and standos or uorescent lamps. Leave uorescent sockets in cabinets with leads

disconnected. This should leave an empty channel letter or cabinet.

Step 2

Using a non- oil based cleaner, clean the back surfaces of the channel letter or cabinet where the LED modules will be mounted.

This is an important step for good adhesion of HanleyLED modules mounting tape.

Step 3

Installer should examine all parts that are not intended to be replaced by the retrot kit for damage and replace any damaged

parts prior to installation of the retrot kit. Do not make or alter any open holes in an enclosure of wiring or electrical

components during kit installation. Any existing holes in the letters or cabinet that will not be used in the installation of HanleyLED

modules should be patched to avoid water damage. Openings smaller than ½”diameter may be sealed with the appropriate

amount of rated caulk or sealant. Openings larger than ½”should be patched using an aluminum or zinc coated steel patch with

rivets and sealant.

Step 4

Proceed with the appropriate HanleyLED module installation guide for your specic product.

THE FIELD INSTALLATION OF THIS RETROFIT SYSTEM INTO A SIGN IS SUBJECT TO THE

ACCECPANCE OF LOCAL INSPECTION AUTHORITY.

CAUTION: TURN OFF POWER TO THE SIGN BEFORE INSPECTING OR REMOVING EXISTING LIGHT

SOURCE. THE POWER MUST REMAIN OFF WHILE INSTALLING THE LED RETROFIT KIT.

NOTE: ALL MATERIALS REMOVED MUST BE DISPOSED OF IN ACCORDANCE WITH

APPLICABLE LOCAL, STATE AND FEDERAL LAWS.

Concorde Cabinet System

Prepping the Channel Letter or Cabinet

Tools Required:

• Wire cutter & strippers

• Measuring tape

• Marking pens

• Drill

• Standard hardware and supplies in addition to the HanleyLED modules

installation guides (UL listing may be required on certain items)

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

3

4

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

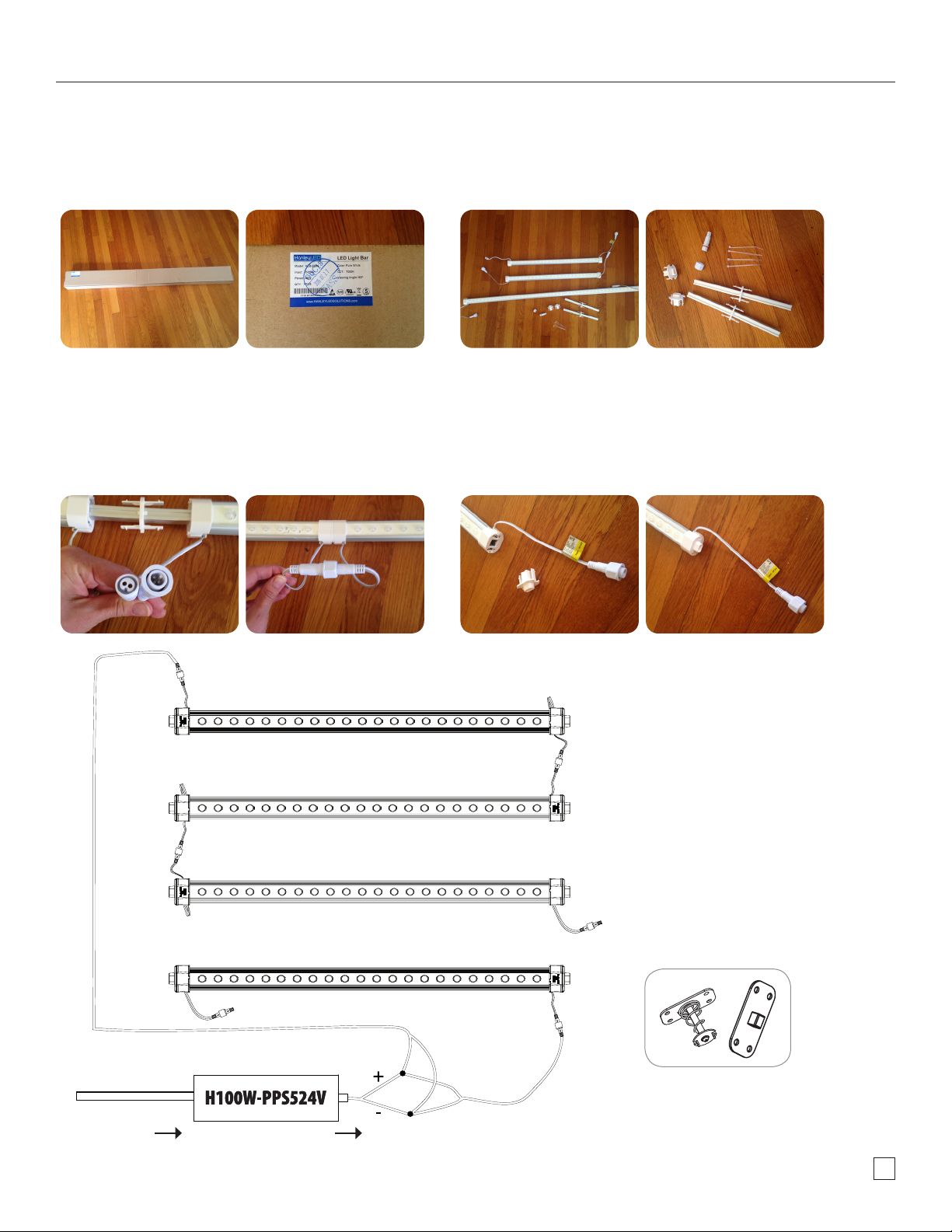

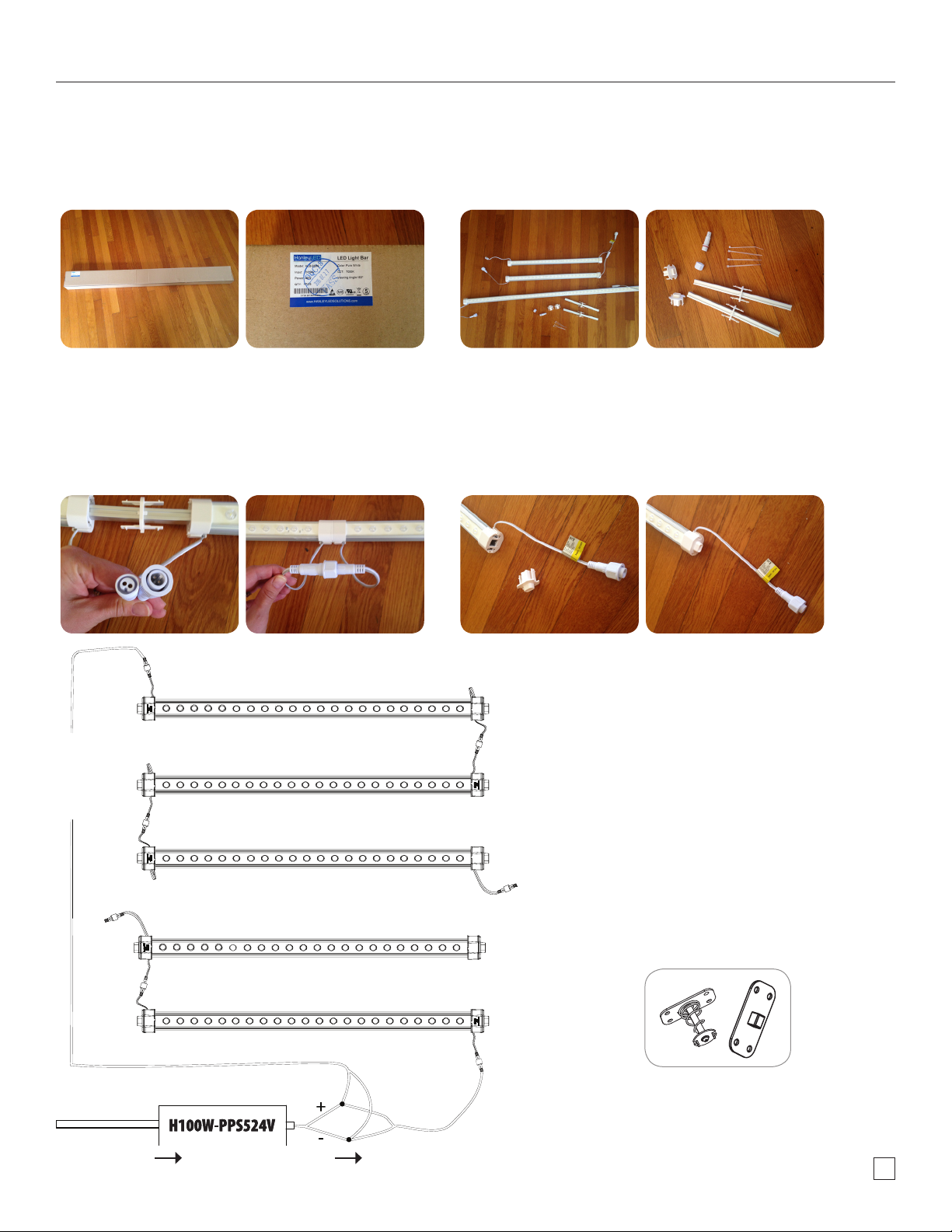

Concorde Cabinet System Quick Assembly

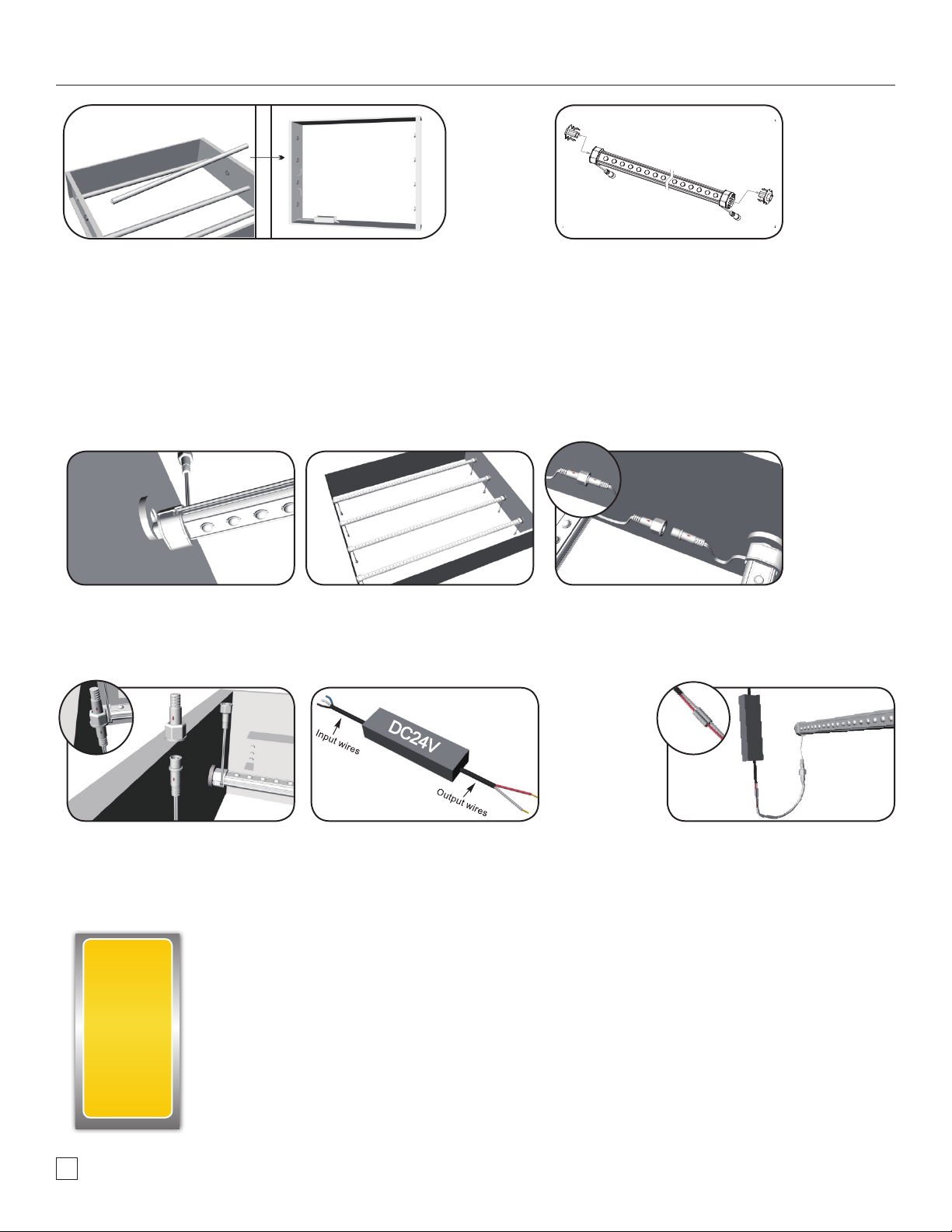

Step 1

Step 3

Step 2

Step 4

Order the size light bar just as you would order your replacement orescent

lamps. Pick the size you want. Everything you’ll need to assemble the bar will be

in the box. This guide shows how to assemble a 96” Concorde LED Bar System.

Connect all your Concorde pieces by using the Concorde Connector Joints.

Tighten the watertight wire ports.

** Pay attention to the male and female ends when assembling.

Make sure you have all your pieces for assembly. Take all the Concorde

components out of the box.

Place your Concorde Retrot (RF) Connectors on each side of the bar. The RF Connectors mount

straight into the HO sockets of your existing cabinet making this an easy retrot install. Screw

in Watertight End Cap to the unused wire port.

For new construction, the Conorde Speed

Spring brackets are available for purchase

Input Output

5

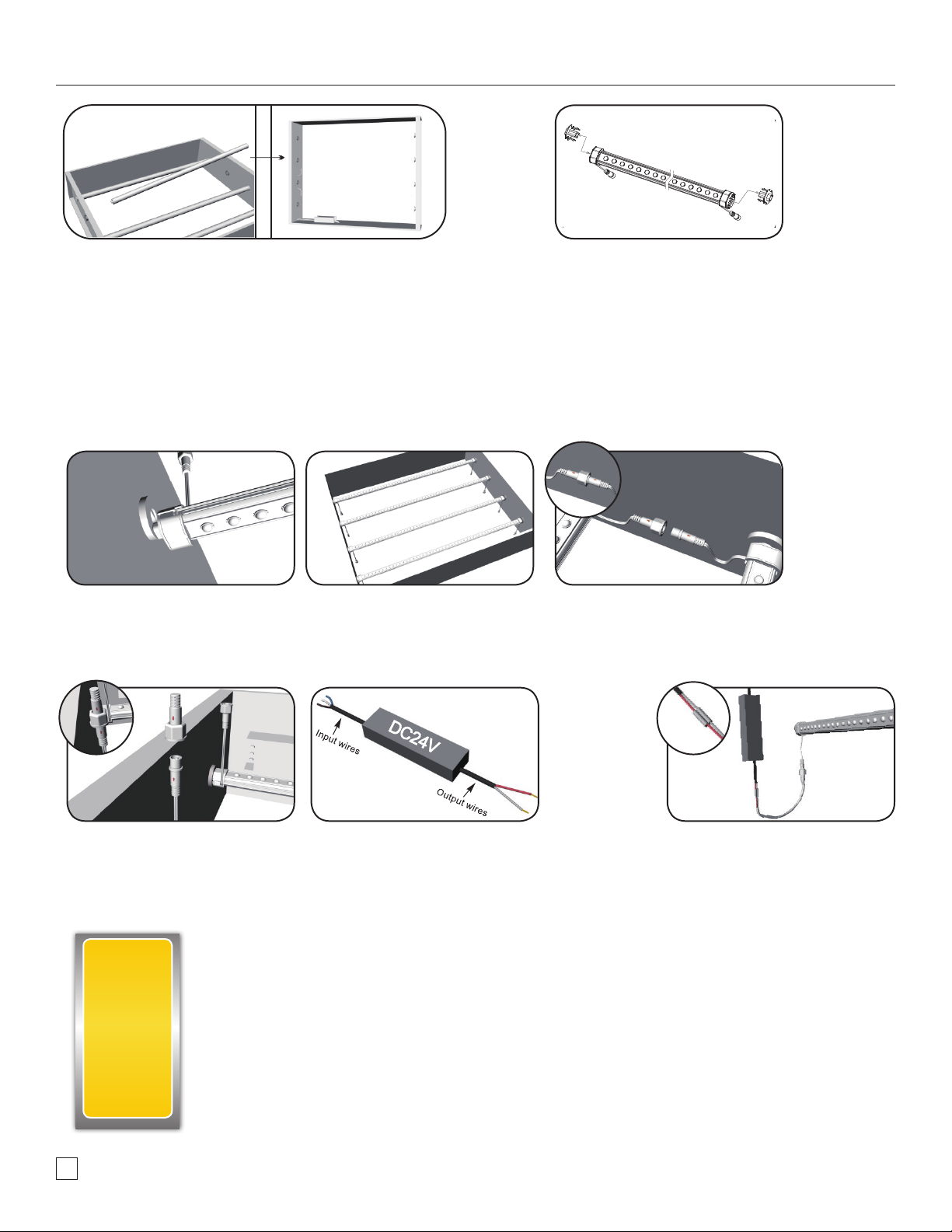

Retrot Installation For Use With Existing Fluorescent Box Signs

1. Remove Existing FluorescentTubes 2. Connect all light bar pieces, if necessary.

Install Retrot Connectors on each side of light bar.

• Make sure power is o. Have a licensed electrician disconnect and remove all ballasts.

• Remove existing uorescent tubes, leaving uorescent lamp holders in place.

• Installers should disconnect lamp holder leads and make new connections from the LED driver directly to the LED

lamps. Lamp holders are to be used only for the purpose of holding the LED lamps in place.

• (Existing Signs Only) If removal of the existing lighting equipment eliminates the disconnect switch, as required by

applicable local, state, or country electrical codes; a new disconnect switch must be installed.

• (Existing Signs Only) Make sure the removal of lighting equipment does not compromise the integrity of the sign body

(i.e. water intrusion). Fill in all holes 0.5 in. (13 mm) or smaller with the appropriate amount of rated caulk or sealant.

For holes greater than 0.5 in. (13 mm), use an aluminum or zinc coated steel patch with rivets and sealant.

4. Connections:Wire the Concorde bars with male and female connectors to make longer

cascade. (see Cascading Information Guidelines on page 7 to see how many bars can

be run in a series)

3. Insert Light bars into lamp-sockets

6. Mount power supply5. Unused wire ports should be capped with Watertight

End Cap provided in box, or use another extension cable

to tie the port back to the power supply.

7. Connect to power supply: Connect the white output

wire to the red Concorde cable wire and the black

output wire to the black cable wire. Connect female

cable end to male end coming o of Concorde bar and

tighten collar.

• Identify input and output secondary wires. Connect the power unit to the supply

in accordance with the applicable local, state, and country electrical codes, and the

instructions found in the power supply installation guide. All power supplies must be

installed in a raceway or suitable electrical enclosure.

• If required, the disconnect switch shall be installed by qualied personnel, in

accordance with applicable local, state, and country electrical codes.

• Spacing between LED power supplies shall be at least 25.4 mm (1 in) from end to end

and 101.6 mm (4 in) from side to side, in accordance with UL 48 Par. 4.2.3.2.3.1

8.This sign has been modied to operate LED lamps. Do not attempt to

install or operate uorescent lamps in this sign.The marking for item

shall have a minimum letter height of 2.4 mm (3/32 in) and shall be in

Universal Bold, Arial Bold, Helvetica Bold, or Zurich BT Bold or equivalent

font. Markings in this image shall be provided verbatim.

This sign

has been

modied

to operate

LED lamps.

Do not

attempt

to install

or operate

uorescent

lamps in

this sign.

6

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

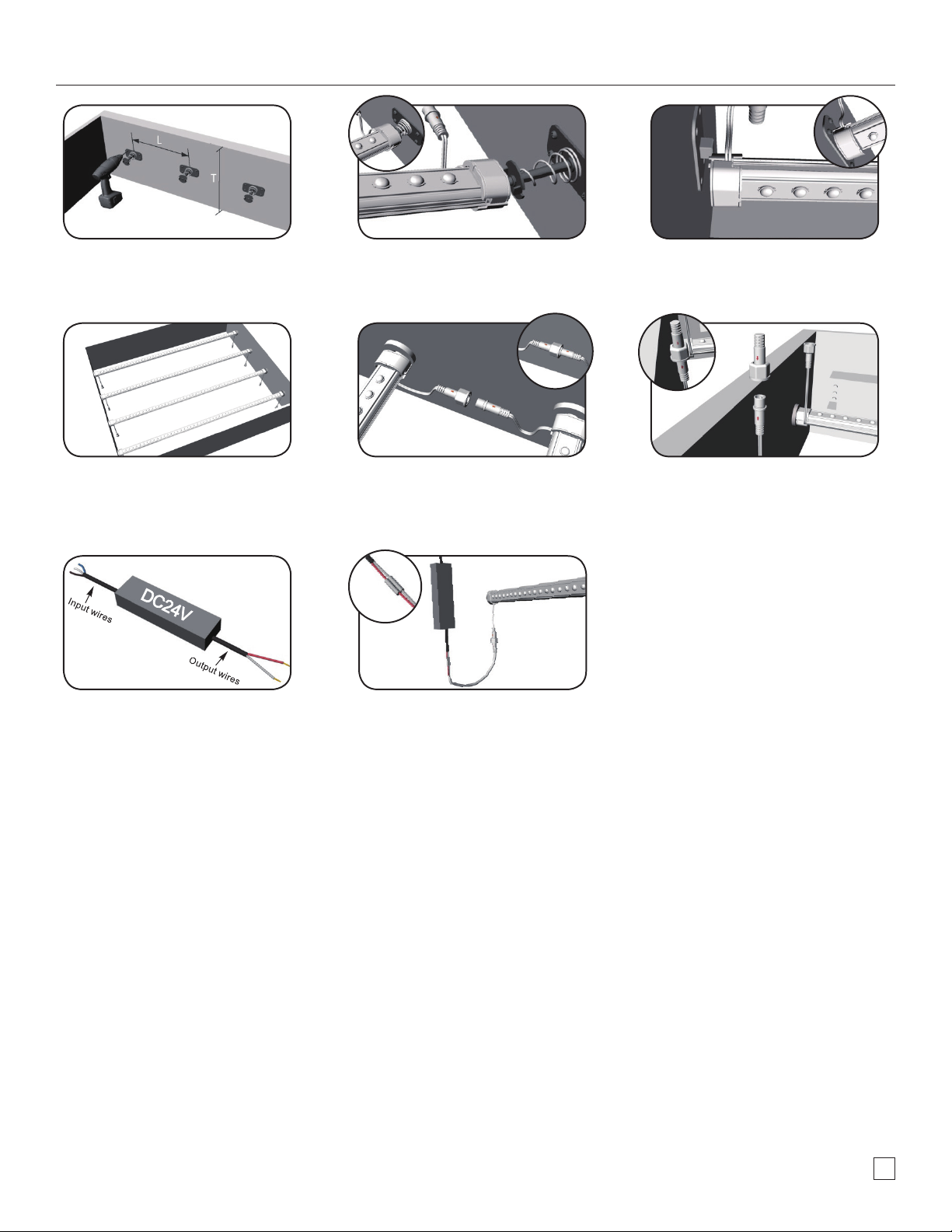

New Construction Installation

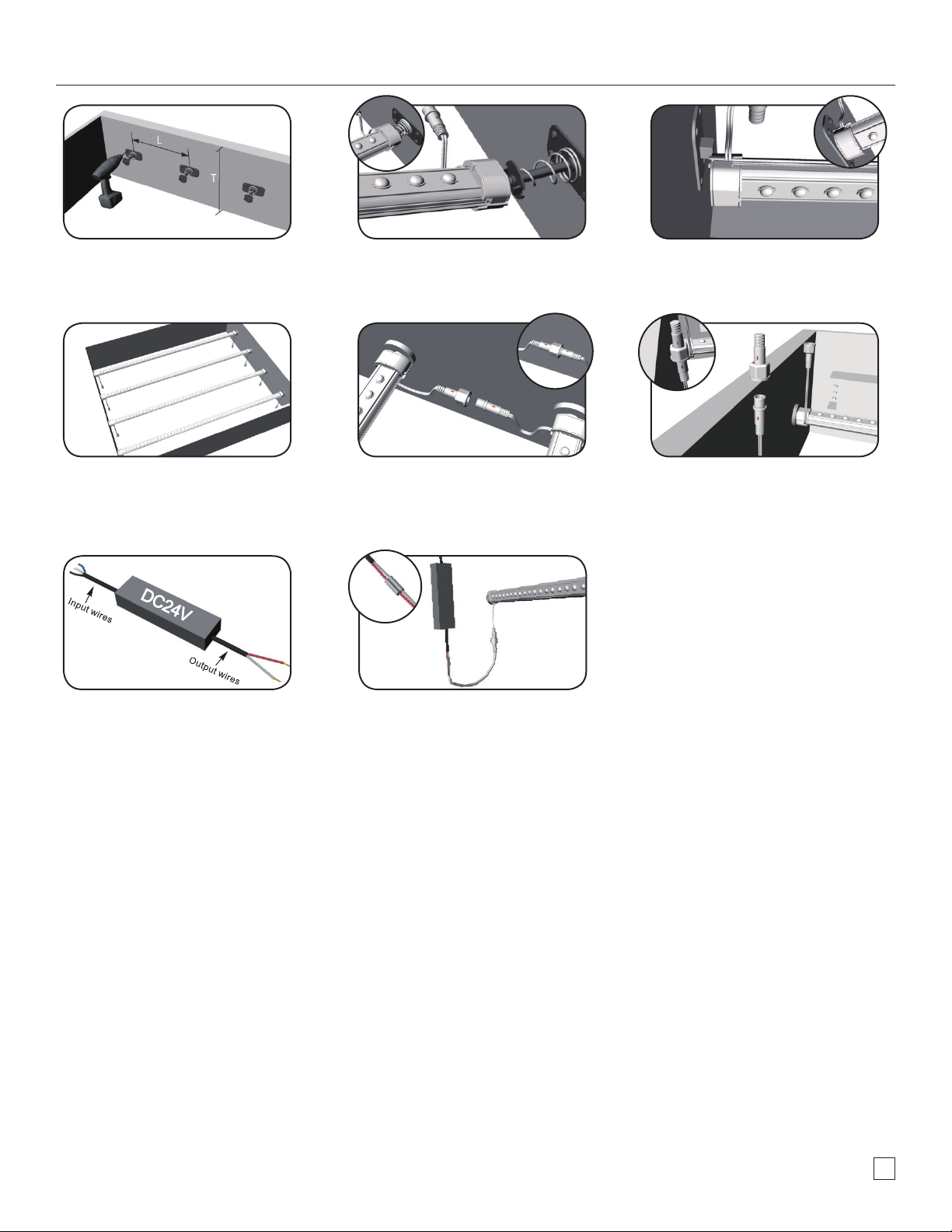

4.Verify all LEDs of light bars point to sign face. 5. Connections:Wire the Concorde bars with male and female

connectors to make longer cascade. (see Cascading

Information Guidelines on page 7 to see how many bars can

be run in a series)

6. Unused wire ports should be capped with Watertight End

Cap provided in box, or use another extension cable to tie

the port back to the power supply.

8. Connect to power supply: Connect the white output wire to

the red Concorde cable wire and the black output wire to the

black cable wire. Connect female cable end to male end

coming o of Concorde lamp and tighten collar.

9. Make sure all wire connections are ready and correct.

1. Mount Speed Spring Brackets and Stationary Brackets to each

side of sign box. (Mount bracket base parrallel to the direction

of your raceway)

2. lnsert Light bars onto Speed Spring Brackets rst. 3. Push the Concorde Bars down onto the Speed Spring Bracket,

then insert other end onto stationary bracket.

7. Mount power supply

• Identify input and output secondary wires. Connect the

power unit to the supply in accordance with the applicable

local, state, and country electrical codes, and the

instructions found in the power supply installation guide.

All power supplies must be installed in a raceway or suitable

electrical enclosure.

• If required, the disconnect switch shall be installed by

qualied personnel, in accordance with applicable local,

state, and country electrical codes.

• Spacing between LED power supplies shall be at least

25.4 mm (1 in) from end to end and 101.6 mm (4 in) from

side to side, in accordance with UL 48 Par. 4.2.3.2.3.1

7

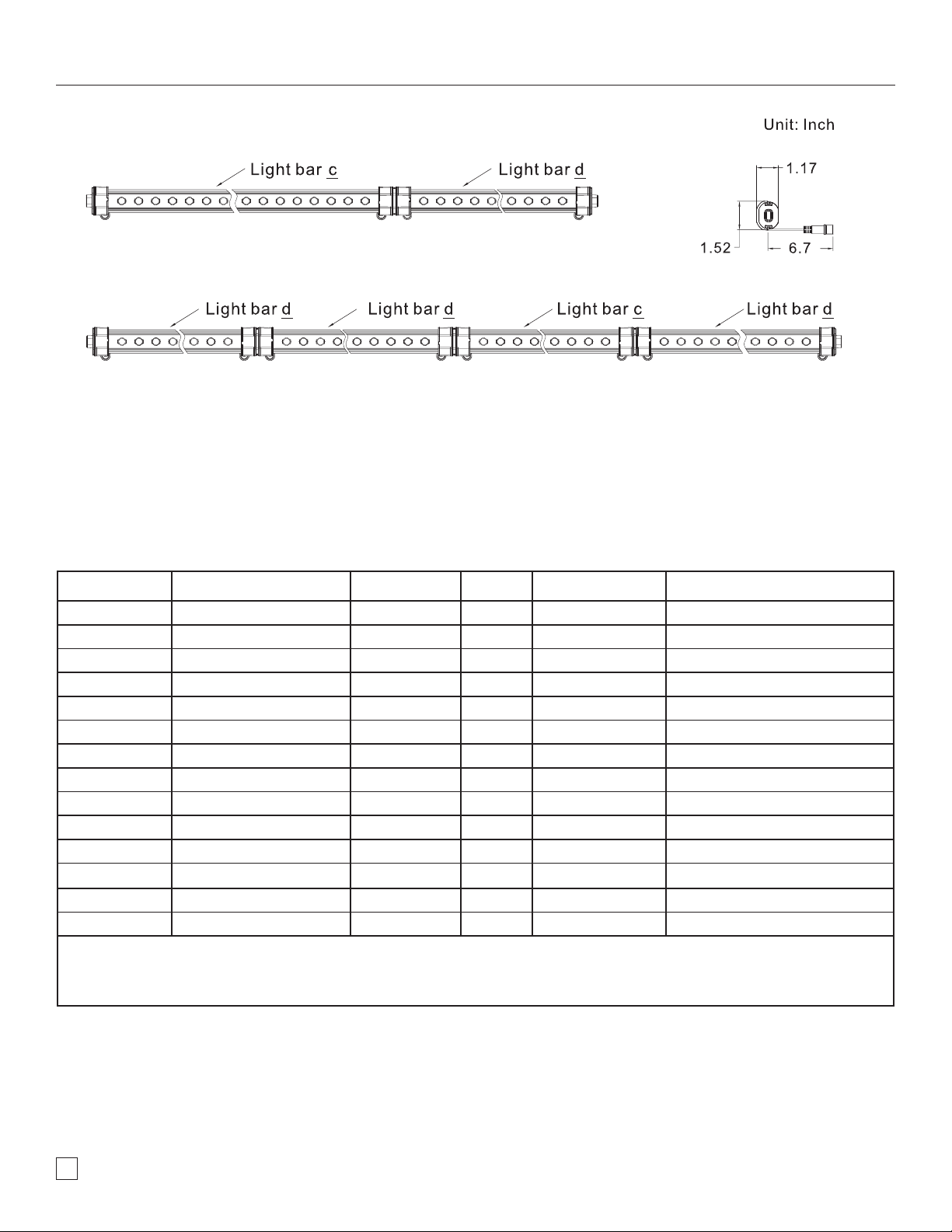

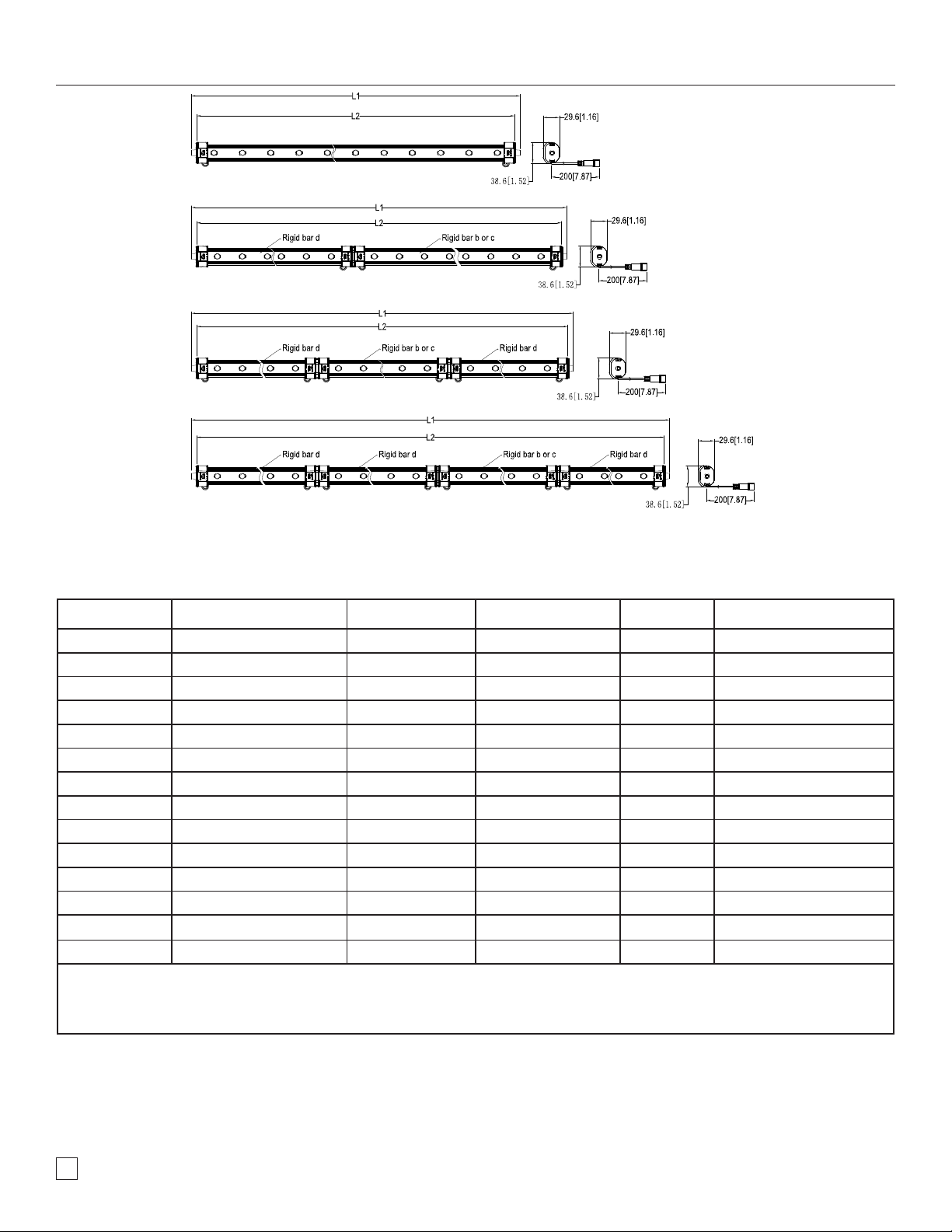

Light Bar Dimensions

All components needed to assemble your uorescent replacement length are included in the box. Pick the size you

want and you’ll receive everything you need to assemble the bar.

HLB-2S72 Example

HLB-2S120 Example

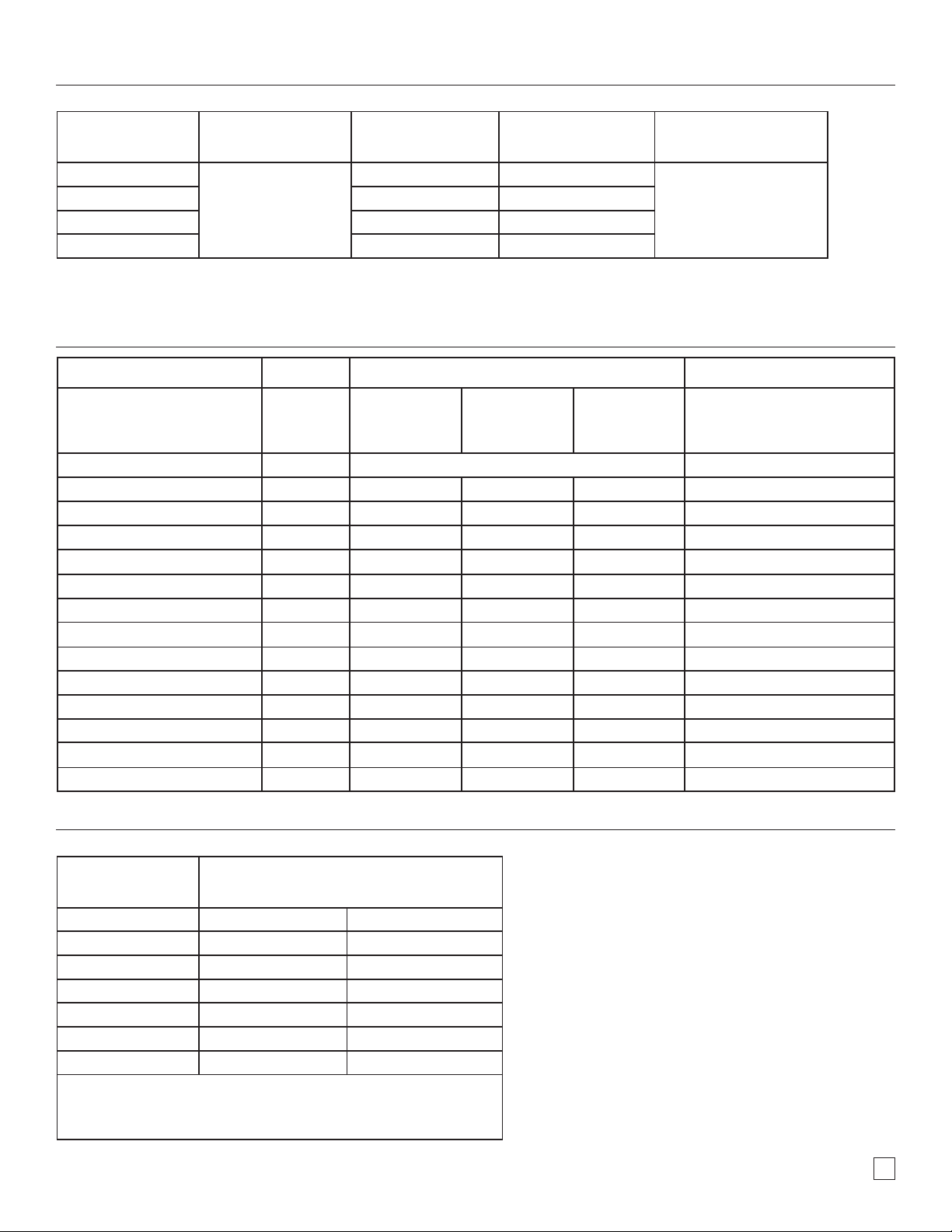

Item LED Lamp Cross Reference Components Watts (w) Lumens (lm) Actual assembled size (in)

HLB-2S24 F24HO a 8.2 800 21”

HLB-2S30 F30HO f 11.6 1300 27”

HLB-2S36 F36HO b 13.5 1350 33.1”

HLB-2S42 F42HO g 15.2 1800 39.1”

HLB-2S48 F48HO c 18.8 1900 45”

HLB-2S60 F60HO b + d 24 2300 57”

HLB-2S64 F64HO f + h 24.5 2650 61.1”

HLB-2S72 F72HO c + d 29.5 2850 69”

HLB-2S84 F84HO b + d + d 34.5 3250 81”

HLB-2S96 F96HO c + d + d 40 3800 93”

HLB-2S108 F108HO b + d + d + d 45 4150 105”

HLB-2S117 F117HO i + i + i 44 4650 114”

HLB-2S120 F120HO c + d + d + d 50.5 4750 117”

HLB-EQUALIZER d 10.8 900 23.9”

NOTE: a = 21.0625 inch; b = 33.0625 inch; c = 45.125 inch; d = 23.8125 inch; f = 27 inch; g = 39.1 inch; h = 34.1 inch; i = 37.9 inch

8

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

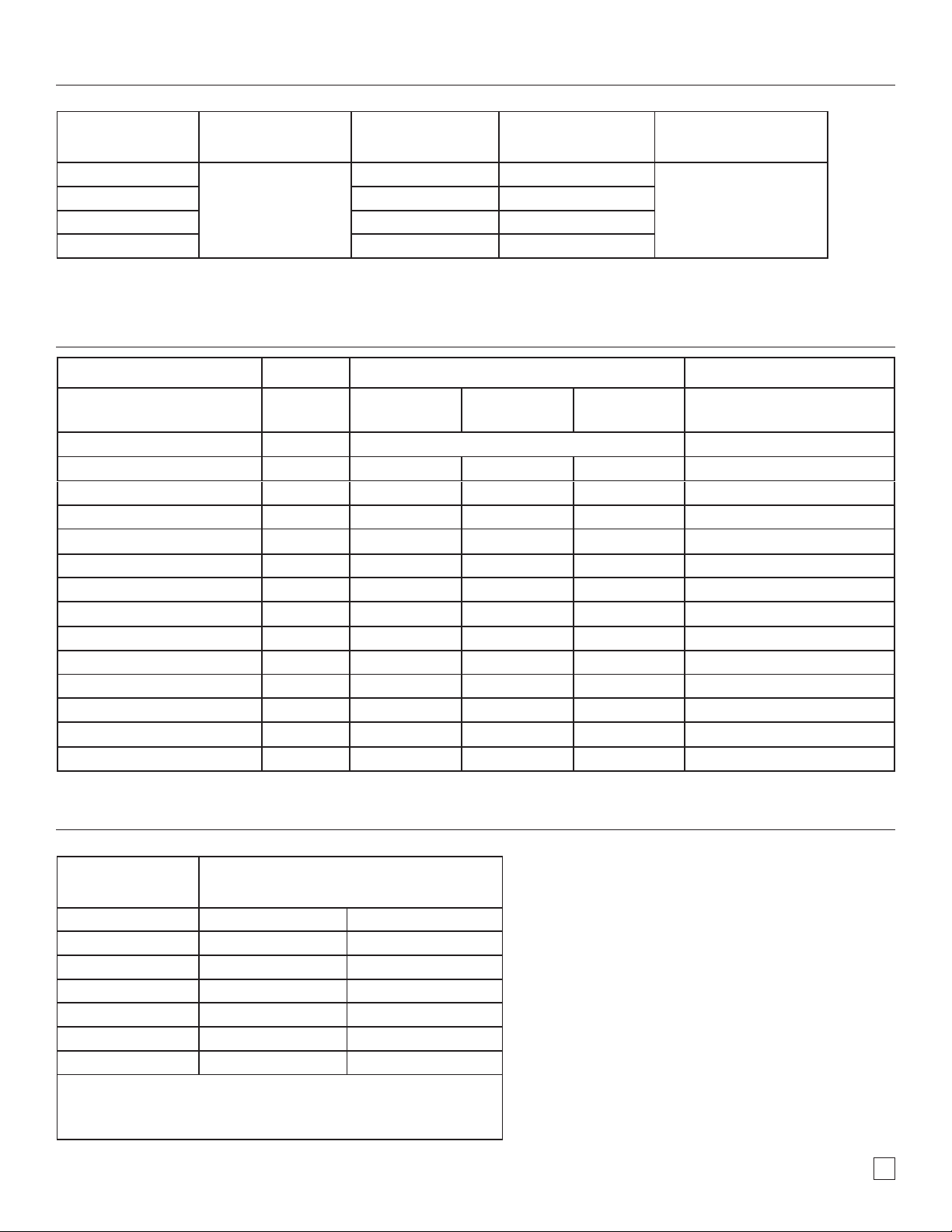

Layout Guidelines

Power Supply Wire Gauge Chart

Power Supply Load Chart & Cascading (bars in a series) Information Guidelines

Double-sided light

box depth (inch)

Item Maximum space

between bars (inch)

Illuminance ( lux )

- based on max spacing

Comments

9

Concorde Cabinet System

by HanleyLED

8 - 9 1600-2700 Lightbox size: 47”x 67”

Tested with 3/16”

7328 white acrylic

12 10-12 1000-2050

18 12-15 640-1150

24 12-19 500-950

Wire Size Maximum Distance

Gauge (AWG) 60W Power 100W Power

Feet Feet

18 6.4 /

16 10.2 1.6

14 16.3 2.6

12 26.0 4

10 41.0 6.5

NOTE: Distance from power supply to load at full capacity.

Item Watts/Bar Power Supplies (24v) Cascading/Run Information

60w

H60W-PPS524V

100w

H100W-PPS524V

150w

H150W-PPS524V Max Series Wired

Max Number of Concorde Bars Per Power Supply

HLB-2S24 (F24HO) 8.2w 7 12 18 5

HLB-2S30 (F30HO) 11.6w 5 8 12 4

HLB-2S36 (F36HO) 13.5w 4 7 11 4

HLB-2S42 (F42HO) 15.2 3 6 9 4

HLB-2S48 (F48HO) 18.8w 3 5 7 3

HLB-2S60 (F60HO) 24w 2 4 6 2

HLB-2S64 (F64HO) 24.5w 2 4 6 2

HLB-2S72 (F72HO) 29.5w 2 3 5 2

HLB-2S84 (F84HO) 34.5w 1 2 4 1

HLB-2S96 (F96HO) 40w 1 2 3 1

HLB-2S108 (F108HO) 45w 1 2 3 1

HLB-2S117 (F117HO) 44w 1 2 3 1

HLB-2S120 (F120HO) 50.5w 1 1 2 1

9

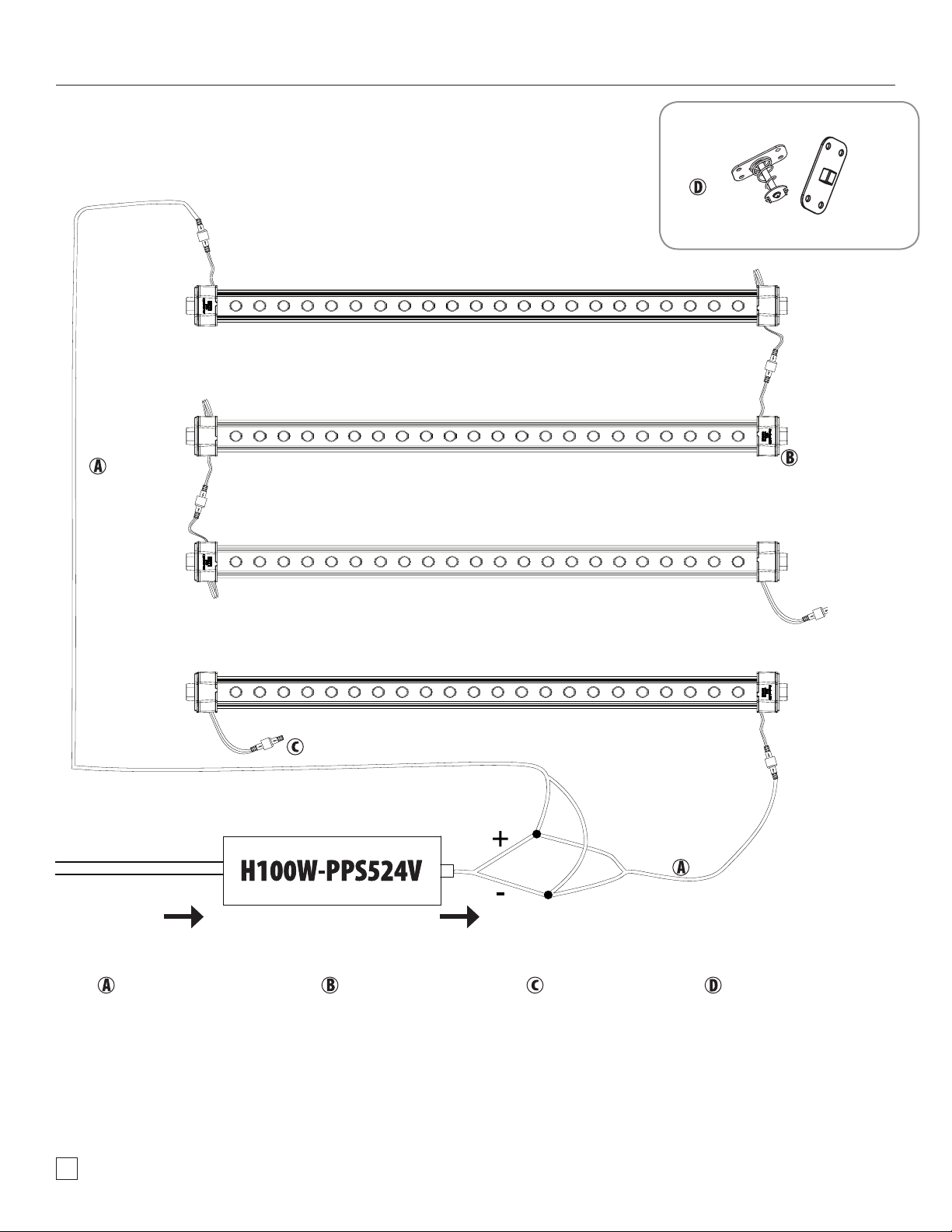

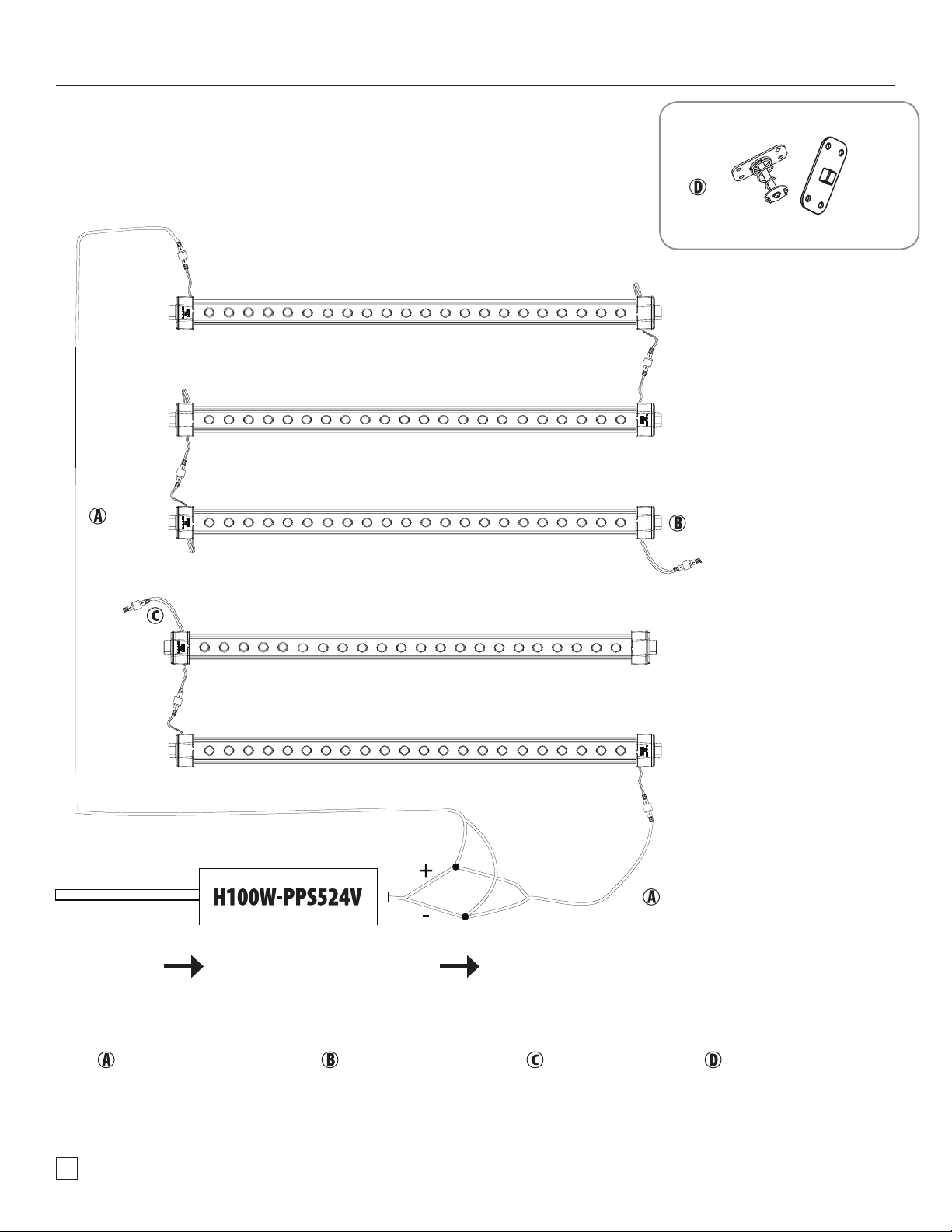

Speed Spring bracket (Spring and stationary)

18.8w

18.8w

18.8w

18.8w

Total: 75.2w

48” Concorde Cabinet Example (HLB-2S48)

Optional mounting method

Input Output

Concorde Cable Connector Retrot (RF) Connector

to mount in HO sockets

Watertight End Cap Speed Spring Bracket Set

for alternative mounting

method (sold separately)

10

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

Warranty

Cautions

Troubleshooting

Model No. Warranty Period

HLB-2S24 · HLB-2S30 · HLB-2S36 · HLB-2S42 · HLB-2S48 · HLB-2S60 · HLB-2S64

HLB-2S72 · HLB-2S84 · HLB-2S96 · HLB-2S108 · HLB-2S117 · HLB-2S120

5 year (product), 5 year (labor)

Note: Above warranty period is only for products which are used inside of waterproof light box, and valid only when used

as a system with HanleyLED Premium Power Supplies.

Cautions for installation and use:

- Make sure the installing surface is clean and suitable for sticking prior to installation

- Inadequately connecting the‘+’and‘-’of module to those of power supply output might ruin your product

- Full attention should be paid to wire polarity when connecting two or more strings of the product during installation

- The maximum cascade length is 142inch[3600mm]; not recommended to exceed this cascading length

- Standard operating temperature: -40° to 60°C

Cautions for selection of other parts:

- Please ensure that the output voltage of using power supply is DC (24±5%)V, and the rated power supply is recommended to underload by 20%.

(HanleyLED“PPS5”Power Supplies can be loaded to 100% if absolutely needed with no eect to warranty)

- During installation, please ask qualied person to count and select the suitable cable according to the diameter and length of wire when

the connecting cable needs to be extended, otherwise, low input voltage to product may occur, or re hazard due to overheated cable

- Prohibited to use any acid or alkaline glue to x this product

Malfunction & Solutions

Malfunctions Possible Causes Solutions

All LEDs

do not work

The power supply did not connect to

power grid Power on

No electricity due to short-circuit of

external power supply. Remove the malfunction caused by short-circuit, power on again

The wires of the bar connect to power

supply output reversely Check the connection and ensure the wires are connected correctly

Part of LEDs

do not work

Part of power supplies do not have output Check the power supply system

Part of the bar wires have malfunction

Brightness of LEDs

is weak or uneven

0verloaded power supply Replace it with higher power supply

The power loss of power circuit is huge or

the power loss to each existing circuit

Ensure working voltage of bars is within ±5%V of rated voltage.

(1.Shorten the length of wires between the rst bar and power

supply or replace with wires with bigger diameter; 2. Ensure the

cascading qty of string is less than or equal to the allowed maximum

cascading qty, and each bar cascading qty is well-balanced.)

Too many bars in series/cascade Lessen the cascading qty for bar and ensure the qty for each

electrical circuit is within the maximum cascading qty

LEDs are blinking Poor wiring connections Check all wiring connections immediatly

Failures in power supply Replace power supply

WARNING – Risk of re or electric shock. LED Retrot Kit installation requires knowledge of sign electrical systems. If not qualied, do not attempt installation.

Contact a qualied electrician.

WARNING – Risk of re or electric shock. Install this kit only in host signs that have been identied in the installation instructions and where the input rating of the

retrot kit does not exceed the input rating of the sign

WARNING – Risk of re or electric shock. Installation of this LED retrot kit may involve drilling or punching of holes into the structure of the sign. Check for

enclosed wiring and components to avoid damage to wiring and electrical parts.

WARNING – To prevent wiring damage or abrasion, do not expose wiring to edges of sheet metal or other sharp objects.

Do not make or alter any open holes in an enclosure of wiring or electrical components during kit installation.

Only those open holes indicated in the photographs and/or drawings may be made or altered as a result of kit installation.

Repair and seal any unused openings in the electrical enclosure. Openings greater than 12.7 mm (1/2 in.) diameter require a metal patch secured by screws or

rivets and caulked with non-hardening caulk. Smaller openings may be sealed with non-hardening caulk.

1.30.18

2

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY

24v Power Supply Speed Spring Bracket Set

(Spring and stationary)

Optional

Concorde Cable Connectors

Optional

Retrot (RF) ConnectorWatertight End Cap Concorde Joint

Tools required:

Components:

NOTE:

All materials removed

must be disposed of

in accordance with

applicable local, state,

and federal laws.

WARNING check polarity: All connections must be WHITE-TO-RED (+) and BLACK-TO-BLACK (-).

Reverse polarity connections may damage the LEDs and will void product warranty.

Caution: Turn o power to sign before inspecting or removing existing light source.

Power must remain o while installing the Concorde Cabinet System.

Screwdriver Electric DrillTape Measure

BEFORE YOU BEGIN

Determine your light bar mounting method. Are you using pre-existing sockets to mount?

If so, Retrot Connectors are included. If not, be sure to purchase our Speed Spring Brackets

for fast and secure mounting.

Concorde Bar II

RETROFIT INSTALLATION GUIDE

This guide is designed to aid in the installation of HanleyLED’s Concorde Bar II System. Skilled trades people that are familiar with

general construction, electrical, and sign installation techniques should do the installation. Licensed electricians should provide all

installation and hook-up of both the primary and secondary input/outputs of the HanleyLED power supply. All installation and hook-

up should be done in accordance with all National and Local codes and permits. In no way is this document intended to construe

warranty or tness of use of the products described, nor is it intended to provide safety instruction for those installing the product.

Step 1

Remove existing neon or uorescent bulbs by having a licensed electrician disconnect and remove the neon transformers or

uorescent ballasts. Remove existing neon and standos or uorescent lamps. Leave uorescent sockets in cabinets with leads

disconnected. This should leave an empty channel letter or cabinet.

Step 2

Using a non- oil based cleaner, clean the back surfaces of the channel letter or cabinet where the LED modules will be mounted.

This is an important step for good adhesion of HanleyLED modules mounting tape.

Step 3

Installer should examine all parts that are not intended to be replaced by the retrot kit for damage and replace any damaged

parts prior to installation of the retrot kit. Do not make or alter any open holes in an enclosure of wiring or electrical

components during kit installation. Any existing holes in the letters or cabinet that will not be used in the installation of HanleyLED

modules should be patched to avoid water damage. Openings smaller than ½”diameter may be sealed with the appropriate

amount of rated caulk or sealant. Openings larger than ½”should be patched using an aluminum or zinc coated steel patch with

rivets and sealant.

Step 4

Proceed with the appropriate HanleyLED module installation guide for your specic product.

THE FIELD INSTALLATION OF THIS RETROFIT SYSTEM INTO A SIGN IS SUBJECT TO THE

ACCECPANCE OF LOCAL INSPECTION AUTHORITY.

CAUTION: TURN OFF POWER TO THE SIGN BEFORE INSPECTING OR REMOVING EXISTING LIGHT

SOURCE. THE POWER MUST REMAIN OFF WHILE INSTALLING THE LED RETROFIT KIT.

NOTE: ALL MATERIALS REMOVED MUST BE DISPOSED OF IN ACCORDANCE WITH

APPLICABLE LOCAL, STATE AND FEDERAL LAWS.

Concorde Bar II System

Prepping the Channel Letter or Cabinet

Tools Required:

• Wire cutter & strippers

• Measuring tape

• Marking pens

• Drill

• Standard hardware and supplies in addition to the HanleyLED modules

installation guides (UL listing may be required on certain items)

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

3

4

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

Concorde Bar II System Quick Assembly

Step 1

Step 3

Step 2

Step 4

Order the size light bar just as you would order your replacement orescent

lamps. Pick the size you want. Everything you’ll need to assemble the bar will be

in the box. This guide shows how to assemble a 96” Concorde Bar II System.

Connect all your Concorde Bar II pieces by using the Concorde Connector

Joints. Tighten the watertight wire ports.

** Pay attention to the male and female ends when assembling.

Make sure you have all your pieces for assembly. Take all the Concorde

Bar II components out of the box.

Place your Concorde Retrot (RF) Connectors on each side of the bar. The RF Connectors mount

straight into the HO sockets of your existing cabinet making this an easy retrot install. Screw

in Watertight End Cap to the unused wire port.

For new construction, the Conorde Speed

Spring brackets are available for purchase

Input Output

5

Retrot Installation For Use With Existing Fluorescent Box Signs

1. Remove Existing FluorescentTubes 2. Connect all light bar pieces, if necessary.

Install Retrot Connectors on each side of light bar.

• Make sure power is o. Have a licensed electrician disconnect and remove all ballasts.

• Remove existing uorescent tubes, leaving uorescent lamp holders in place.

• Installers should disconnect lamp holder leads and make new connections from the LED driver directly to the LED

lamps. Lamp holders are to be used only for the purpose of holding the LED lamps in place.

• (Existing Signs Only) If removal of the existing lighting equipment eliminates the disconnect switch, as required by

applicable local, state, or country electrical codes; a new disconnect switch must be installed.

• (Existing Signs Only) Make sure the removal of lighting equipment does not compromise the integrity of the sign body

(i.e. water intrusion). Fill in all holes 0.5 in. (13 mm) or smaller with the appropriate amount of rated caulk or sealant.

For holes greater than 0.5 in. (13 mm), use an aluminum or zinc coated steel patch with rivets and sealant.

4. Connections:Wire the Concorde Bar II with male and female connectors to make longer

cascade. (see Cascading Information Guidelines on page 7 to see how many bars can

be run in a series)

3. Insert Light bars into lamp-sockets

6. Mount power supply5. Unused wire ports should be capped with Watertight

End Cap provided in box, or use another extension cable

to tie the port back to the power supply.

7. Connect to power supply: Connect the white output

wire to the red Concorde cable wire and the black

output wire to the black cable wire. Connect female

cable end to male end coming o of Concorde Bar II and

tighten collar.

• Identify input and output secondary wires. Connect the power unit to the supply

in accordance with the applicable local, state, and country electrical codes, and the

instructions found in the power supply installation guide. All power supplies must be

installed in a raceway or suitable electrical enclosure.

• If required, the disconnect switch shall be installed by qualied personnel, in

accordance with applicable local, state, and country electrical codes.

• Spacing between LED power supplies shall be at least 25.4 mm (1 in) from end to end

and 101.6 mm (4 in) from side to side, in accordance with UL 48 Par. 4.2.3.2.3.1

8.This sign has been modied to operate LED lamps. Do not attempt to

install or operate uorescent lamps in this sign.The marking for item

shall have a minimum letter height of 2.4 mm (3/32 in) and shall be in

Universal Bold, Arial Bold, Helvetica Bold, or Zurich BT Bold or equivalent

font. Markings in this image shall be provided verbatim.

This sign

has been

modied

to operate

LED lamps.

Do not

attempt

to install

or operate

uorescent

lamps in

this sign.

6

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

New Construction Installation

4.Verify all LEDs of light bars point to sign face. 5. Connections:Wire the Concorde Bar II with male and female

connectors to make longer cascade. (see Cascading

Information Guidelines on page 7 to see how many bars can

be run in a series)

6. Unused wire ports should be capped with Watertight End

Cap provided in box, or use another extension cable to tie

the port back to the power supply.

8. Connect to power supply: Connect the white output wire to

the red Concorde cable wire and the black output wire to the

black cable wire. Connect female cable end to male end

coming o of Concorde lamp and tighten collar.

9. Make sure all wire connections are ready and correct.

1. Mount Speed Spring Brackets and Stationary Brackets to each

side of sign box. (Mount bracket base parrallel to the direction

of your raceway)

2. lnsert Light bars onto Speed Spring Brackets rst. 3. Push the Concorde Bar II down onto the Speed Spring Bracket,

then insert other end onto stationary bracket.

7. Mount power supply

• Identify input and output secondary wires. Connect the

power unit to the supply in accordance with the applicable

local, state, and country electrical codes, and the

instructions found in the power supply installation guide.

All power supplies must be installed in a raceway or suitable

electrical enclosure.

• If required, the disconnect switch shall be installed by

qualied personnel, in accordance with applicable local,

state, and country electrical codes.

• Spacing between LED power supplies shall be at least

25.4 mm (1 in) from end to end and 101.6 mm (4 in) from

side to side, in accordance with UL 48 Par. 4.2.3.2.3.1

7

Light Bar Dimensions

All components needed to assemble your uorescent replacement length are included in the box. Pick the size you

want and you’ll receive everything you need to assemble the bar.

Item LED Lamp Cross Reference Components Watts (w) Lumens (lm) Actual assembled size (in)

HLB2-2S24 F24HO a 7.5 1100 21”

EQUALIZER d 9 1300 23.9”

HLB2-2S30 F30HO f 10.8 1550 27”

HLB2-2S36 F36HO b 13.4 1940 33.1”

HLB2-2S42 F42HO g 14.8 2150 39.1”

HLB2-2S48 F48HO c 17.9 2600 45”

HLB2-2S60 F60HO b + d 22.3 3200 57”

HLB2-2S64 F64HO f + h 24.2 3500 61.1”

HLB2-2S72 F72HO c + d 26.8 3900 69”

HLB2-2S84 F84HO b + d + d 31.2 4500 81”

HLB2-2S96 F96HO c + d + d 35.7 5170 93”

HLB2-2S108 F108HO b + d + d + d 40.2 5800 105”

HLB2-2S117 F117HO i + i + i 42.8 6200 114”

HLB2-2S120 F120HO c + d + d + d 44.6 6450 117”

NOTE: a = 21.0625 inch; b = 33.0625 inch; c = 45.125 inch; d = 23.8125 inch; f = 27 inch; g = 39.1 inch; h = 34.1 inch; i = 37.9 inch

8

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

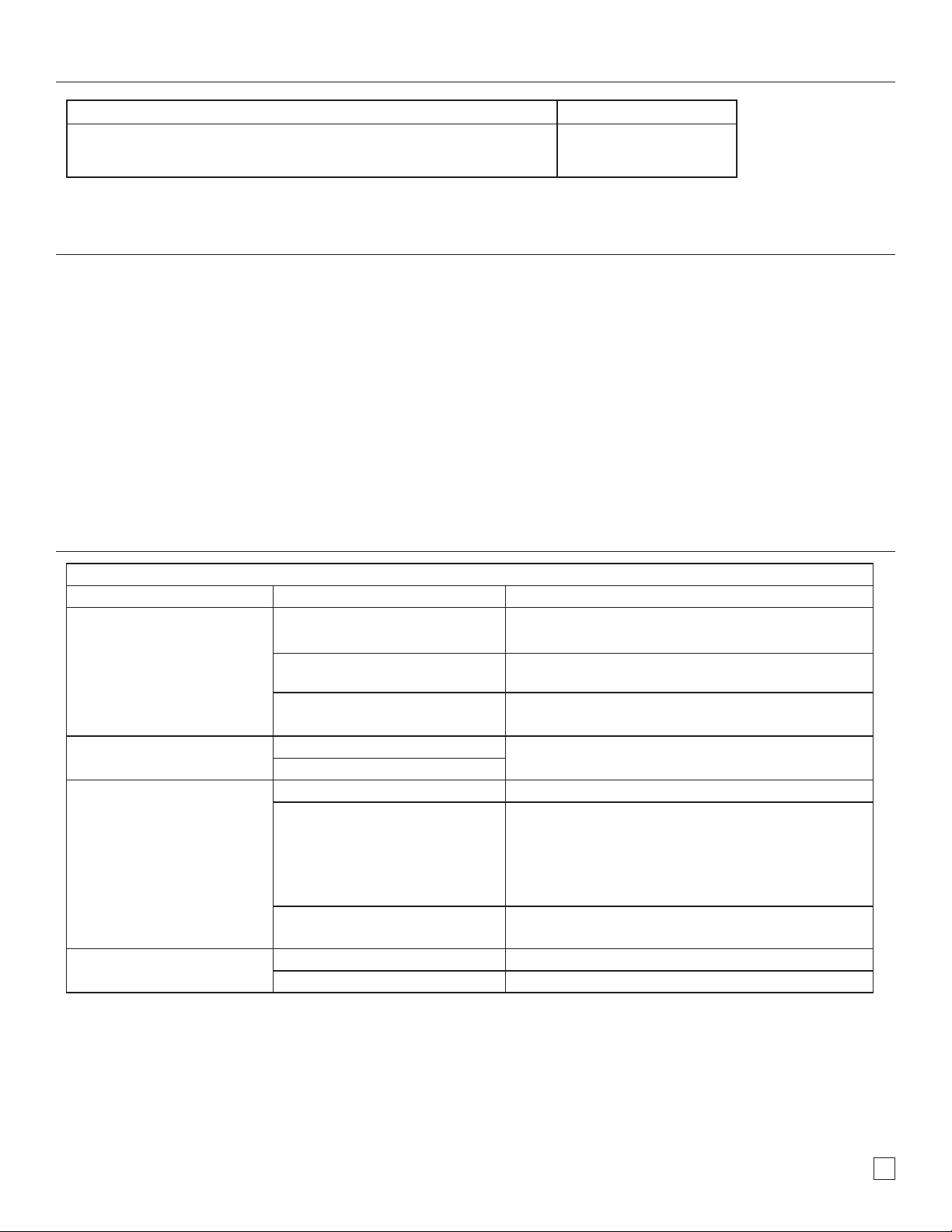

Layout Guidelines

Power Supply Wire Gauge Chart

Power Supply Load Chart & Cascading (bars in a series) Information Guidelines

Double-sided light

box depth (inch)

Item Maximum space

between bars (inch)

Illuminance ( lux )

- based on max spacing

Comments

9

Concorde Bar II

by HanleyLED

10 - 12 2144-3618 Lightbox size: 47”x 67”

Tested with 3/16”

7328 white acrylic

12 10-12 1340-2749

18 12-15 857-1541

24 12-19 670-1273

Wire Size Maximum Distance

Gauge (AWG) 60W Power 100W Power

Feet Feet

18 6.4 /

16 10.2 1.6

14 16.3 2.6

12 26.0 4

10 41.0 6.5

NOTE: Distance from power supply to load at full capacity.

Item Watts/Bar Power Supplies (24v) Cascading/Run Information

60w

H60W-PPS524V

H60W-PPSEM24V

100w

H100W-PPS524V

H100W-PPSEM24V

150w

H150W-PPS524V

H150W-PPSEM24V

Max Series Wired

Max Number of Concorde Bars Per Power Supply

HLB2-2S24 (F24HO) 7.5w 8 13 20 5

HLB2-2S30 (F30HO) 10.8w 5 9 13 4

HLB2-2S36 (F36HO) 13.4w 4 7 11 4

HLB2-2S42 (F42HO) 14.8w 3 6 9 4

HLB2-2S48 (F48HO) 17.9w 3 5 8 3

HLB2-2S60 (F60HO) 22.3w 2 4 6 2

HLB2-2S64 (F64HO) 24.2w 2 4 6 2

HLB2-2S72 (F72HO) 26.8w 2 3 5 2

HLB2-2S84 (F84HO) 31.2w 1 3 4 1

HLB2-2S96 (F96HO) 35.7w 1 2 4 1

HLB2-2S108 (F108HO) 40.2w 1 2 3 1

HLB2-2S117 (F117HO) 42.8w 1 2 3 1

HLB2-2S120 (F120HO) 44.6w 1 2 3 1

9

Speed Spring bracket (Spring and stationary)

17.9w

17.9w

17.9w

17.9w

Total: 89.5w

48” Concorde Cabinet Example (HLB2-2S48)

Optional mounting method

Input Output

Concorde Cable Connector Retrot (RF) Connector

to mount in HO sockets

Watertight End Cap Speed Spring Bracket Set

for alternative mounting

method (sold separately)

17.9w

10

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

Warranty

Cautions

Troubleshooting

Model No. Warranty Period

HLB2-2S24 · HLB2-2S30 · HLB2-2S36 · HLB2-2S42 · HLB2-2S48 · HLB2-2S60 · HLB2-2S64

· HLB2-2S72 · HLB2-2S84 · HLB2-2S96 · HLB2-2S108 · HLB2-2S117 · HLB2-2S120

5 year (product), 5 year (labor)

Note: Above warranty period is only for products which are used inside of waterproof light box, and valid only when used

as a system with HanleyLED Premium Power Supplies.

Cautions for installation and use:

- Make sure the installing surface is clean and suitable for sticking prior to installation

- Inadequately connecting the‘+’and‘-’of module to those of power supply output might ruin your product

- Full attention should be paid to wire polarity when connecting two or more strings of the product during installation

- The maximum cascade length is 142inch[3600mm]; not recommended to exceed this cascading length

- Standard operating temperature: -40° to 60°C

Cautions for selection of other parts:

- Please ensure that the output voltage of using power supply is DC (24±5%)V, and the rated power supply is recommended to underload by 20%.

(HanleyLED “PPS5” and“PPSEM”Power Supplies can be loaded to 100% if absolutely needed with no eect to warranty)

- During installation, please ask qualied person to count and select the suitable cable according to the diameter and length of wire when

the connecting cable needs to be extended, otherwise, low input voltage to product may occur, or re hazard due to overheated cable

- Prohibited to use any acid or alkaline glue to x this product

Malfunction & Solutions

Malfunctions Possible Causes Solutions

All LEDs

do not work

The power supply did not connect to

power grid Power on

No electricity due to short-circuit of

external power supply. Remove the malfunction caused by short-circuit, power on again

The wires of the bar connect to power

supply output reversely Check the connection and ensure the wires are connected correctly

Part of LEDs

do not work

Part of power supplies do not have output Check the power supply system

Part of the bar wires have malfunction

Brightness of LEDs

is weak or uneven

0verloaded power supply Replace it with higher power supply

The power loss of power circuit is huge or

the power loss to each existing circuit

Ensure working voltage of bars is within ±5%V of rated voltage.

(1.Shorten the length of wires between the rst bar and power

supply or replace with wires with bigger diameter; 2. Ensure the

cascading qty of string is less than or equal to the allowed maximum

cascading qty, and each bar cascading qty is well-balanced.)

Too many bars in series/cascade Lessen the cascading qty for bar and ensure the qty for each

electrical circuit is within the maximum cascading qty

LEDs are blinking Poor wiring connections Check all wiring connections immediatly

Failures in power supply Replace power supply

WARNING – Risk of re or electric shock. LED Retrot Kit installation requires knowledge of sign electrical systems. If not qualied, do not attempt installation.

Contact a qualied electrician.

WARNING – Risk of re or electric shock. Install this kit only in host signs that have been identied in the installation instructions and where the input rating of the

retrot kit does not exceed the input rating of the sign

WARNING – Risk of re or electric shock. Installation of this LED retrot kit may involve drilling or punching of holes into the structure of the sign. Check for

enclosed wiring and components to avoid damage to wiring and electrical parts.

WARNING – To prevent wiring damage or abrasion, do not expose wiring to edges of sheet metal or other sharp objects.

Do not make or alter any open holes in an enclosure of wiring or electrical components during kit installation.

Only those open holes indicated in the photographs and/or drawings may be made or altered as a result of kit installation.

Repair and seal any unused openings in the electrical enclosure. Openings greater than 12.7 mm (1/2 in.) diameter require a metal patch secured by screws or

rivets and caulked with non-hardening caulk. Smaller openings may be sealed with non-hardening caulk.

Table of contents

Other HanleyLED Lighting Equipment manuals