All rights are reserved. Reproduction in whole or in part is prohibited without the written consent of the copyright owner,

Hanna Instruments Inc., Woonsocket, Rhode Island, 02895, USA.

Hanna Instruments reserves the right to modify the design, construction, or appearance of its products without advance notice.

TABLE OF CONTENTS

1. Preliminary Examination ................................................................................................................3

2. Safety Measures............................................................................................................................3

3. General Description & Intended Use ................................................................................................3

4. Main Features...............................................................................................................................4

5. Series Configuration.......................................................................................................................4

6. Specifications................................................................................................................................5

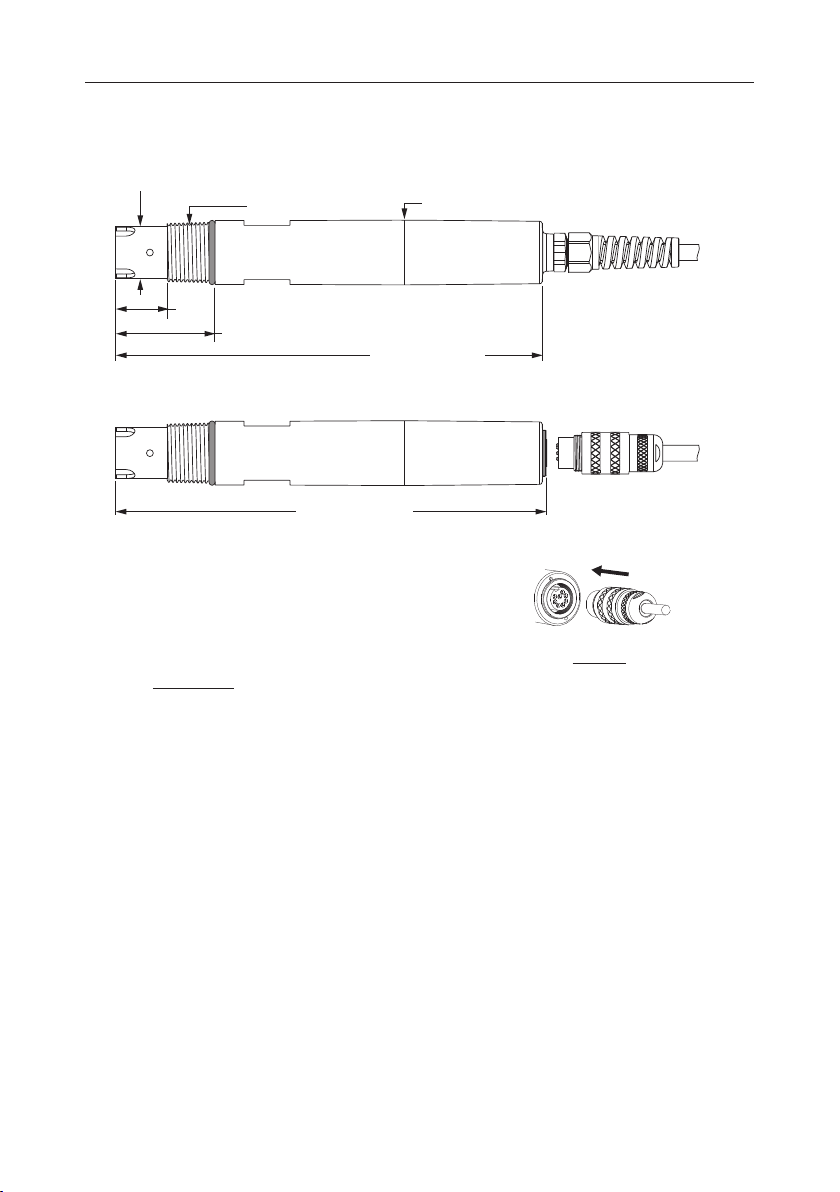

7. Probe Dimensions & Cable Connection.............................................................................................6

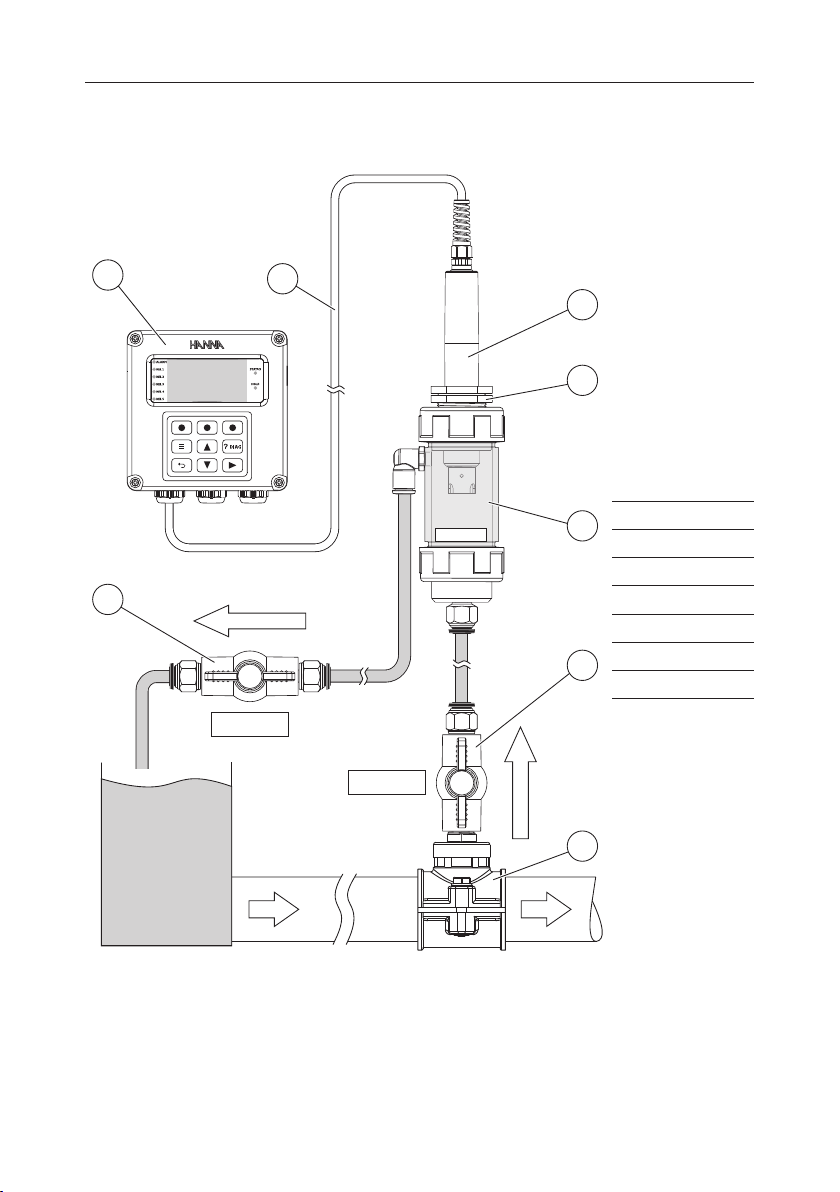

8. Installation ...................................................................................................................................6

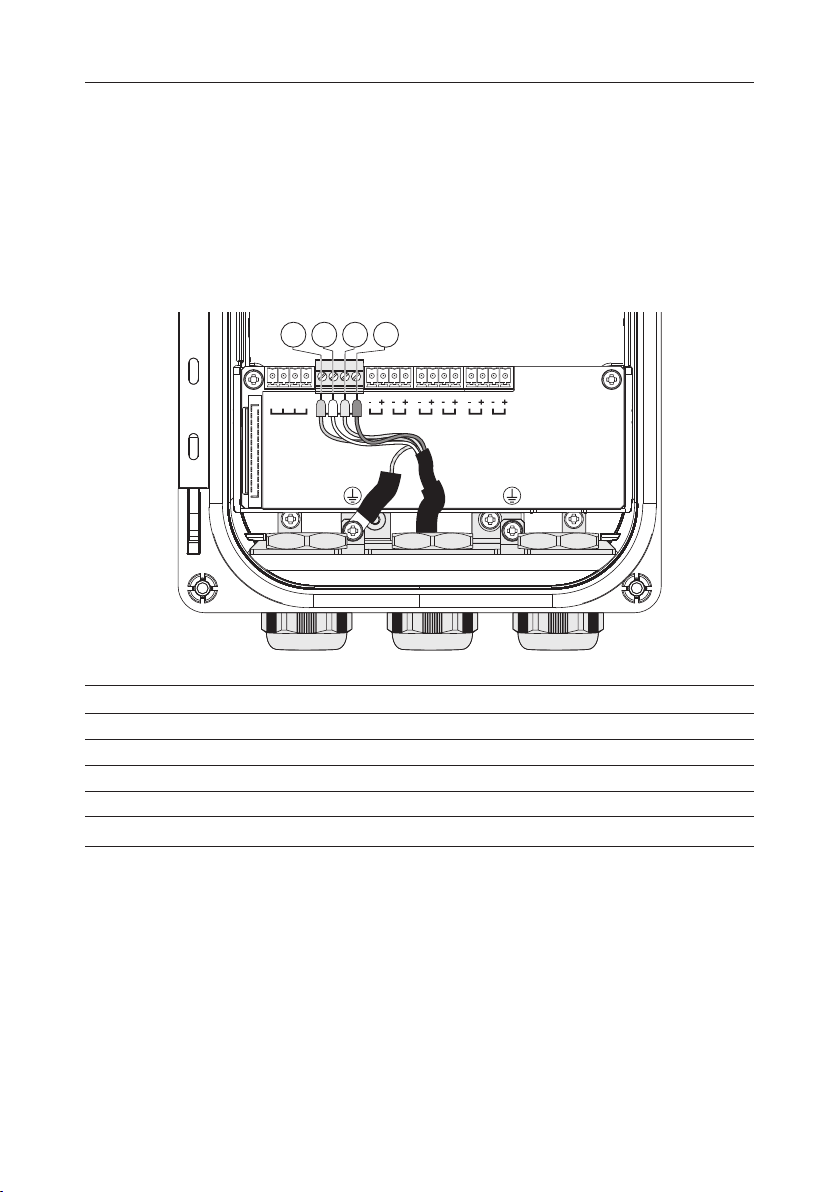

9. Wiring the Probe to the Controller..................................................................................................10

10. Calibration................................................................................................................................10

11. Maintenance & Conditioning.......................................................................................................11

12. Accessories................................................................................................................................12

13. Abbreviations............................................................................................................................13

Certification......................................................................................................................................14

Recommendations for Users...............................................................................................................14

Warranty .........................................................................................................................................14

Dear Customer,

Thank you for choosing a Hanna Instruments®product.

Please read this instruction manual carefully before using this instrument as it provides the necessary information

for correct use of this instrument as well as a precise idea of its versatility.

This release of the product manual contains information that applies to configuration, specification, installation,

and calibration of Hanna Instruments industrial ORP probes.

The HI510 controller is sold separately. Please refer to the controller manual for details on system configurations.

If

you

need

additional

technical

information,

do

not

hesitate

to

e-mail

us

at

[email protected].

Visit www.hannainst.com for more information about Hanna Instruments and our products.