Hansa C40 User guide

HANSA NEW ZEALAND

+64 7 849 4749 info@hansaproducts.co.nz

www.hansachippers.com

HANSA AUSTRALIA

1800 426 722 info@hansaproducts.com.au

www.hansaproducts.com.au

Operation, maintenance and safety manual

All operators must fully read and understand

this operator’s manual before using the chipper.

Keep this manual for future reference.

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

TABLE OF CONTENTS

WHAT CAN MY HANSA CHIPPER PROCESS?..................................................................................................................................1

INTENDED USES OF THE CHIPPER ...............................................................................................................................................................1

RECEIVING YOUR HANSA BRUSH CHIPPER....................................................................................................................................1

CHIPPER COMPONENTS........................................................................................................................................................................... 1

SAFETY .........................................................................................................................................................................................2

OPERATOR COMPETENCY.........................................................................................................................................................................2

IDENTIFYING HAZARDS AND RISKS ..............................................................................................................................................................2

TOWING SAFETY ....................................................................................................................................................................................3

OPERATION..................................................................................................................................................................................3

OUTLET CHUTE ADJUSTMENT....................................................................................................................................................................3

FEED ROLLER CONTROL ...........................................................................................................................................................................4

AUTOMATIC FEED CONTROLLER (AFC) ......................................................................................................................................................4

ENGINE LED PANEL................................................................................................................................................................................4

HOUR METER /TACHOMETER...................................................................................................................................................................5

CHECKLIST BEFORE OPERATION .................................................................................................................................................................5

SAFE SETUP PROCEDURES ........................................................................................................................................................................5

SAFE OPERATING PROCEDURES .................................................................................................................................................................6

STARTING PROCEDURE ............................................................................................................................................................................7

SHUTDOWN PROCEDURE .........................................................................................................................................................................8

TROUBLESHOOTING.....................................................................................................................................................................9

MAINTENANCE & SERVICE ......................................................................................................................................................... 10

KNIFE RE-SHARPENING AND KNIFE REPLACEMENT .......................................................................................................................................10

ANVIL ADJUSTMENT ............................................................................................................................................................................. 13

BELT TENSION .....................................................................................................................................................................................14

BELT TENSION ADJUSTMENT...............................................................................................................................................................14

BELT REPLACEMENT.............................................................................................................................................................................. 14

HYDRAULIC PUMP BELT ADJUSTMENT....................................................................................................................................................... 15

GREASING BEARINGS &PIVOT POINTS......................................................................................................................................................15

HYDRAULIC SYSTEM.............................................................................................................................................................................. 16

ENGINE SERVICING ...............................................................................................................................................................................16

OTHER SERVICING ................................................................................................................................................................................16

ROTOR BEARING REPLACEMENT .............................................................................................................................................................. 17

TYRE PRESSURE ...................................................................................................................................................................................17

BOLT TORQUE .....................................................................................................................................................................................19

SPECIFICATIONS ......................................................................................................................................................................... 19

DECALS....................................................................................................................................................................................... 20

HANSA GLOBAL INDUSTRIAL LIMITED WARRANTY..................................................................................................................... 24

COMMISSIONING CHECKLIST AND REGISTRATION ..................................................................................................................... 26

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

1

What can my Hansa chipper process?

Intended uses of the chipper

The Hansa C40 chipper is built to process organic material including wooden branches not exceeding 178mm in diameter. It is

designed to be used on by commercial arborists, tree contractors and hire / rental companies. Do NOT use the chipper for any

other purpose.

Organic wastes include:

Prunings, stalks, roots, vegetable matter, hay, grass, bark

Branches

Palm fronds

Dead and hard timbers (Note: these will dull the knives faster)

Paper or cardboard

Do NOT process:

Flax, root balls

Soil, bones, sand, grit, stones, metal

If you have any questions, contact your authorised dealer.

Do NOT exceed 178mm branch diameter

Receiving your Hansa Brush Chipper

Congratulations on the purchase of a Hansa Model C40 Brush Chipper.

Chipper components

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

2

Safety

Preventing accidents is the responsibility of every equipment operator. The operator is responsible for any accidents or hazards

occurring to people or their property. Ensure every operator is familiar with the safe operation procedures and controls of the

machine, how to identify hazards, and the steps required to avoid injury while handling and operating the chipper. Relevant

information is contained in this manual.

Do NOT modify the design of the chipper.

Operator competency

Ensure that every person operating the chipper understands and follows the safe operating and maintenance procedures

as detailed in this manual.

Do NOT allow persons below the age of 18 to operate the chipper. Additionally, local regulations may restrict the age of

the operator.

Do NOT allow persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge to

operate the machine.

Identifying hazards and risks

Identify hazards and risks, and take preventative steps to avoid accidents and minimise risk. Possible hazards include, but are not

limited to, moving parts, thrown objects, weight of chipper and components, and the operating environment.

Below is a list of hazards and actions required to prevent injury.

Hazard

Risk

Corrective action

Dust

Injury or irritation of the

eyes

Respiratory irritation

Wear safety glasses

Process freshly cut materials and / or wear a dust mask

Exhaust Fumes

Respiratory irritation

Place the chipper in a manner that the operator or onlookers

are not exposed to direct exhaust fumes

Fire

Heat burns

Clear any build-up of chipping debris around the engine and

exhaust regularly

Hot Exhaust

Heat burns

Keep bare hands and other body parts a safe distance away

from hot exhaust

Belt Drive

Skin pinching and/or

abrasions

Ensure that the belt guard is in place, and keep away from

the belt

Cutting rotor and knives

Pinching, crushing, cutting,

severing

Keep hands and other body parts out of the inlet chute

Use a stick to push materials into the inlet chute

feed roller

Do NOT push material into the feed roller with your

hands

Feed swing arm

Crushing, severing

Do not touch or approach the feed roller motor and swing

arm while the machine is operating

Feeding roller and

feeding material

Being pulled into chipper

resulting in possible

crushing, cutting, severing

Do not stand directly in front of the inlet table while feeding

material into the chipper; stand to either side.

Do not climb onto the inlet table or enter the infeed chute

unless the machine is off, and the cutting rotor is stationary

Sound

Damage to hearing

Always wear hearing protection when operating the

machinery

Discharge material

Eye injury, minor cuts

Always wear safety glasses when operating the machinery

Do NOT stand in front of the outlet chute

Do NOT face the machinery in a place where the

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

3

outlet chute is directed on a hard surface

Feeding material

Cuts and scrapes

Wear tight fitting safety gloves

Wear tight fitting long sleeves and pants to cover bare skin

when operating the machinery

Weight of the chipper

Straining, crushing

Place the machinery on firm level ground

Do NOT attempt to move the machinery up/down

slopes unless is attached to a towing vehicle

Pinch points

Pinching, crushing

When opening/closing the inlet table, bonnet, or other

guard, it is recommended to use the handles provided

Petrol, oil, grease

Poisoning, skin irritation,

harmful vapours

Take care when handling petrol, oil and grease

Wash skin if contaminated with petrol, oil or grease

Do NOT refuel the chipper in enclosed areas

Towing safety

Rotate the discharge chute to face the opposite direction of the towing vehicle before towing and lock into position

Lock the feed table in the up position

Connect the tow coupling to the towing vehicle (check the ball dimensions are the same as the coupling)

Connect safety chain with shackle

If the machine is fitted with brakes, check handbrake is off and road brakes are on by removing the reversing lever

Plug in lights and check they are operational

Check wheel nuts and axle U-bolts periodically to make sure they are secure

Ensure the jockey wheel is in the up position and locked away during transport

Ensure the machine is towed in accordance with local trailer transport regulations

Operation

The chipper is self-feeding and has a large inlet opening. It can process:

•Prunings, stalks, vines, leaves, roots and vegetable matter, paper and cardboard

•Freshly cut material is better to process than dry material

•Maximum capacity is for the C40 is 178 mm

It is recommended to keep a wooden stick handy, approx. 60 mm diameter x 1000 mm long for:

•Pushing in short, brushy and very leafy materials

•Keeping the inlet table clear

Outlet chute adjustment

The C40 is fitted with a freely rotating outlet chute, allowing the operator to precisely

control the direction of material discharge from the machine. The chute can easily be

adjusted by undoing the clamping bolt, adjusting the outlet chute direction as needed, then

doing the clamping bolt back up. The outlet chute height can also be adjusted by cranking

the swivel handle on the back of the outlet chute.

Additionally, the top of the outlet chute is fitted with two deflector plates that can be

adjusted to control the angle and distance of discharged material. A wingnut is located on

the side of the upper deflector to lock it in place.

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

4

Feed roller control

The C40 is equipped with a feed roller which facilitates the process of feeding material

into the machine. The feed roller is controlled via the yellow control bar which surrounds

the inlet table. The control bar has three settings:

1) Reverse

2) Neutral

3) Feed

When the bar is fully pushed in, the feed roller will be set to reverse. When the bar is fully

pulled out, the feed roller will feed material. The neutral position lies between the reverse

and feed positions.

Automatic Feed Controller (AFC)

The feed roller is fitted with an electronic automatic feed control system which is designed to limit the feed rate of material into

the machine in order to prevent the engine from stalling.

This system eliminates the need to control the speed at which the branches are fed into the chipper manually. A sensor detects the

RPM of the rotor; once this speed drops to a pre-set level the feed roller stops and the branch stops feeding into the machine. The

engine then picks up in RPM and once it reaches a pre-set speed the feed-roller will start feeding again. The feed roller will also

reverse back slightly after stopping (reducing the friction between the wood and knives), resulting in a quicker engine recovery.

The feed roller will only work once the engine is turned on and the engine has reached full throttle after engaging the rotor. If the

green LED light on the AFC controller is flashing this indicates the feed roller isn’t turning. When this changes to a solid green light

(when the engine reaches maximum RPM) the feed roller will be operational.

The AFC has 19 different pre-set positions at which the feed will stop.

Adjusting the AutoTrip setting:

1. Turn the ignition key into the ‘ON’ position. Alternatively, this can be adjusted when the machine is in operation.

2. The version number will initially be displayed on the LCD display, wait until this clears.

3. Push the ‘Menu’ button once.

4. Adjust the AutoTrip setting down using the ‘Menu’ button or up using the ‘Set’ button. There are 19 different positions at

which the feed will stop. At setting 1 the engine is dropping further in RPM, whereas at setting 19 the engine is only

dropping marginally in RPM before the feed roller stops. Adjust to a setting which is most suitable to you. Once adjusted

the screen will return to the hour meter / tachometer display after five seconds, saving the desired setting.

If there are any problems with the electronic automatic feed system, the chipper can be used with the auto-feed disabled. To

disable auto-feed, adjust the AutoTrip setting down to 0 or up to 20.

WARNING! Be careful using the machine with auto-feed disabled as the machine can be stalled easily.

Engine LED panel

The engine LED panel has a self-contained engine safety shutdown system as well as a number of warning indicators.

Feed –Neutral –Reverse

1 –System OK indicator

2 –Low oil pressure

3 –Low alternator output

4 –Air filter restriction

5 –High coolant temperature

6 –Low fuel indicator

4

5

2

1

3

6

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

5

Hour meter / tachometer

The LCD display will toggle between the current engine RPM and machine hours every 5 seconds. Alternatively, the operator can

toggle between the two by pushing the ‘Set’ button.

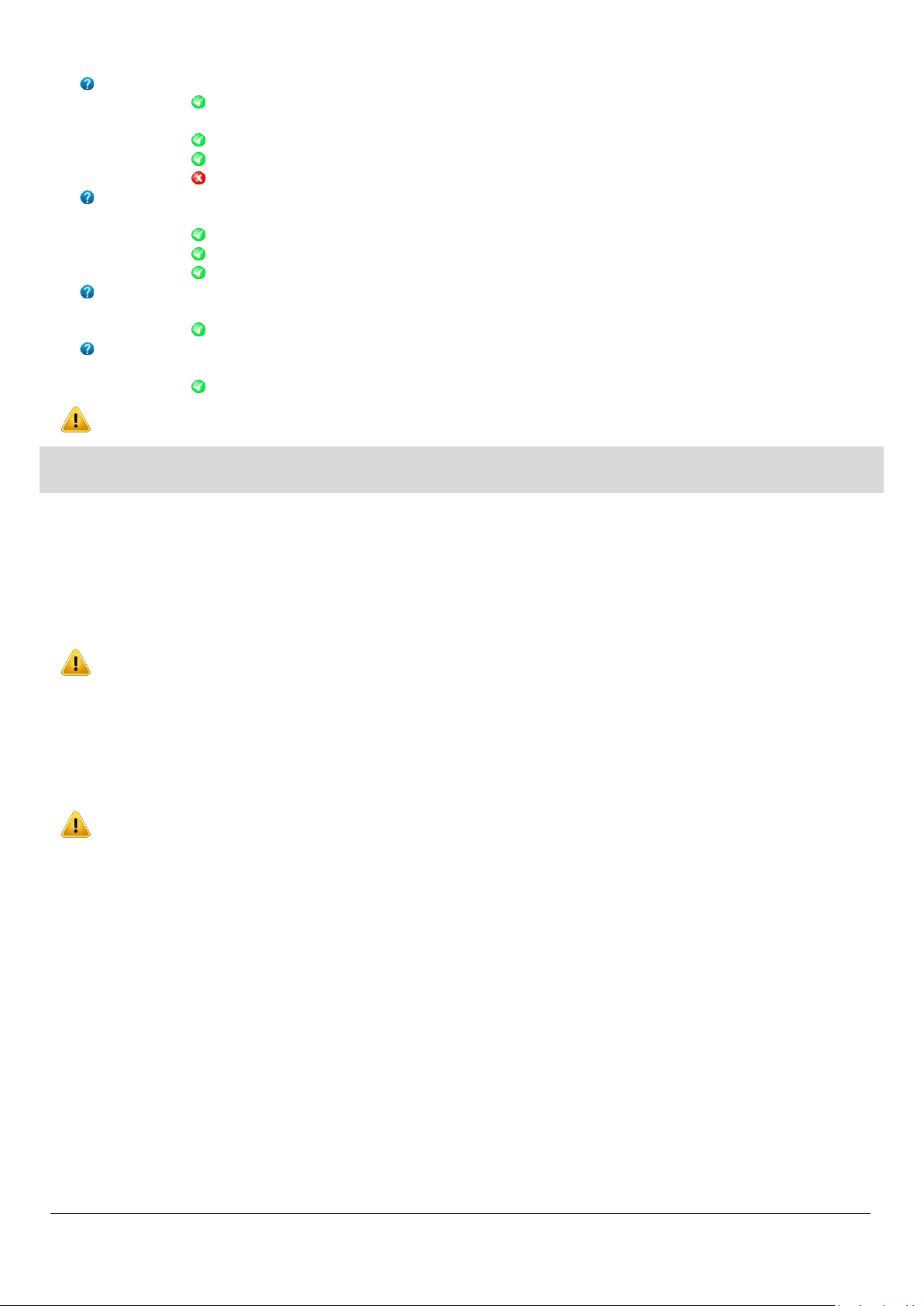

Checklist before operation

Engine:

✓Check oil level in engine

✓Check condition of air cleaner

✓Refer to engine manual for more details

Check Hydraulics:

✓Check level of hydraulic fluid

✓Check all hydraulic components for leaks

General:

✓Check drive belt and pump belt for proper tension

✓Check machine for proper lubrication

✓Check nuts and bolts to ensure they are tight

✓Check tires for proper air pressure as stated on the tire

✓Check diesel level

✓That the fuel cap is secured and there is no fuel leaking from the tank

✓Check direction of the discharge chute

✓Check guards are all in place and in good condition

✓Check all labels are legible. Replace if necessary (contact Hansa for replacements)

✓Refer to maintenance section for more details

Safe setup procedures

Ensure all pre-operation checks have been done

Setup the work site so there is no danger to traffic or public and provide adequate warnings

Ensure the chipper is positioned on firm level ground

Ensure the feed control bar is in the neutral position when starting the chipper

Ensure the inlet table is clear of material when starting the chipper

Ensure the throttle control lever is the initially in the idle position when starting the chipper

Ensure the outlet chute is discharged onto soft ground (e.g. grass)

Do NOT allow the outlet chute to discharge chip onto hard surfaces (such as a paved or gravel surface)

Ejected material can rebound and cause injury

Keep children and spectators clear of the work area at all times

Do NOT operate the chipper where there is a hazard to onlookers

Do NOT allow any person under the age of 18 to operate the chipper

Refuelling:

Take extra care in handling fuels

They are flammable and vapors are explosive

Use only an approved fuel container

Always replace and securely tighten fuel cap after refuelling

Allow engine to cool down before refuelling

Do NOT smoke when using or refuelling the chipper

Never remove fuel cap or add fuel with the engine running

Never refuel the chipper indoors

Never store the chipper or fuel container inside where there is an open flame, such as a water heater

If fuel is spilled, do not attempt to start the engine. Wipe up the spilled fuel, and move the chipper away from

the area of spillage before starting

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

6

Safe operating procedures

Wear safety equipment: Safety glasses and hearing protection

must be worn at all times

Wear work gloves: The wearing of work gloves is optional but

highly recommended - ensure that the gloves fit tightly

Do NOT wear loose fitting gloves or gloves with long cuffs

Loose gloves may get snagged by branches, which could result in the operator being pulled into the chipper

Tie long hair up

Long hair could be snagged by a branch and may be pulled into chipper

Wear clothes that sit tightly

Avoid scarves and any items that can get caught in the chipper or snagged on branches

Place the chipper on even ground and direct outlet chute onto soft ground

Ensure the chipper is positioned so that there is a minimum inlet table height of 600 mm off the ground

Ensure exhaust is pointing away from the working area and downwind from the operator and onlookers

Keep proper balance and footing at all times and stand at the same level as the chipper

Do NOT climb onto the inlet table to push material into the feed roller

Keep your face and body away from the inlet chute. Stand to the side of the inlet table while feeding material into the

chipper

Standing to the side gives better access to the control bar and helps in keeping clear from flying debris

Feed only freshly cut material into the chipper

Do NOT feed in materials covered in gravel, stones and dirt as this can rebound, injure the operator and damage

the machinery

Prune to a size that suits the chipper’s capabilities

Pre-cut side branches

The branch will ‘self-feed’ more efficiently

Keep the engine clean of debris and other accumulations

This prevents damage to the engine or possible fire

Feed limbs and branches through butt end first, leaving the bushy head on

This helps guide the limb down the inlet chute

It reduces spinning and the occurrence of ejection of small pieces back up the inlet chute

Feed soft materials intermittently with branches

The wood chips tend to clean out any soft residue left in the chipper

The chipper can clog up with soft, wet or fibrous materials

Keep well clear of the outlet chute discharge area, even when the chipper is not currently processing material

High velocity, sharp discharge can cause serious injury

Keep the outlet free of blockage

If blockage occurs, turn the engine off and wait for rotor to stop spinning. Open the outlet chute and remove

material until the outlet chute is clear

Keep the feed roller free of blockage

If blockage occurs, turn the engine off and wait for

rotor to stop spinning. Remove the feed roller

guard by unhooking the four rubber latches.

Unhook the springs from the base of the chassis.

Lift the swing arm up and insert the rotor pin

(located underneath the control panel) into the

tab on the housing to lock the swing arm in place

(as per the diagram below). You may now safely

clear the blockage. Remove the rotor pin, lower

the feed roller, reposition the springs, then

replace the guard

Turn off the engine whenever you leave the work area

DO:

Rotor pin

Feed roller motor

Swing arm

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

7

Run the chipper in an enclosed area

Exhaust fumes contain carbon monoxide which is poisonous, colourless, odourless, and tasteless

Operate the chipper wearing loose clothing and untied long hair

Stand at a higher level than the base of the chipper when feeding material into it

Feed flax and cabbage tree leaves into the machine

These stringy materials can wrap around the rotor shaft and work their way into the bearing.

If any stringy material becomes wrapped around the rotor shaft, remove it before it works itself into the bearing

Process old materials such as dried wooden branches

They get very hard and springy when dried out

They are more awkward to handle

The knives dull much quicker

Feed short, stubby pieces of wood into the chipper

They bounce and spin in the inlet chute

Feed short stubby pieces together with longer pieces

Feed branches that are too large (max 160 mm / 178 mm branch diameter)

The chipper engine will stall, which could result in damage to the engine or drive belts

Put soil, sand, grit, stones or pieces of metal into the chipper

This will damage the sharp edge of the cutting knives and can rebound and injure the operator

Put root balls and dead wood into the chipper

This dulls the knives quickly

Overload the chipper

If the cutting rotor is slowing down, feed the material in slower

Transport the chipper while the engine is running

Tamper with the engine governor settings on the chipper

The governor controls the maximum safe operating speed and protects the engine and all moving parts from

damage caused by overspeed

Operate the chipper with blunt knives

This causes excessive vibration which may result in damage to the chipper

Remove any guards on the chipper unless the engine is turned off and the cutting rotor has come to a complete standstill

Enter the inlet chute

Get on, or lean over the feed table

Put hands or any other part of the body or clothing:

Inside the inlet chute

Inside or near the opening of the discharge chute

Near any moving part

Use the feed control bar as a handle to manoeuvre the machine

Starting procedure

Before proceeding, ensure the ‘safe setup procedure’ has been followed on page 5 of this manual.

DO NOT:

Ensure the rotor is disengaged by winding the

engagement handle in the clock-wise direction until

the handle comes to a stop (located next to the control

panel).

Additionally, ensure the throttle control is set to idle.

1

Throttle

control

idle

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

8

Shutdown procedure

On the control panel, insert and turn the key clockwise

into the start position while simultaneously holding the

oil pressure switch bypass button. Allow the engine to

warm up for 1-2 minutes.

Increase the throttle to 1/3 (up to the first notch on the

throttle control gate). Gradually and slowly engage the

rotor by winding the engagement handle in the counter

clock-wise direction until it comes to a stop. This should

be done slowly to allow enough time for the cutting

rotor to pick up speed without stalling the engine.

Increase throttle to full for chipping (move the throttle

lever to the left-most position).

Note: Engine must run at full throttle for the automatic

feed and feed roller to operate. Refer to the

‘Automatic Feed Controller’ section on page 4 to set

the automatic feed control to the desired setting.

To shut the machine down, move the throttle control

lever to the idle position (far-right position).

2

3

4

1

Throttle

control

idle

Throttle

control

full

Throttle

control

1/3

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

9

Troubleshooting

The chipper won’t start

•The engine oil level might be too low

The chipper is fitted with oil alert and will not start if the oil level is too low

Check the oil level and top up if required

•The chipper is placed on a slope

The chipper is fitted with oil alert and will not start if the oil is not level

Move the chipper to level ground

Belt drive engagement will not work

•The housing might be blocked

Turn engine off, disconnect the spark plug wire, ensure rotor has completely stopped, remove debris,

restart engine, then attempt to re-engage the belt drive

Drive belts squealing/smoking

•Drive belts are loose/damaged

Turn the engine off, disconnect the spark plug wire, ensure rotor has completely stopped. Follow the

belt tensioning procedure on page 13

Discharge slows down

•The chipper is clogged up

Turn the engine off, disconnect the spark plug wire, ensure rotor has completely stopped, remove debris,

then close and lock the outlet chute

Outlet chute is blocked

Outlet is pasted with wet/leafy material

Feed hard, dry material in with softer material

Turn the engine off, disconnect the spark plug wire and ensure rotor has completely stopped. Open up

the outlet chute and clear blockage

The material is ejected in long strips

•The knives and/or anvil might be blunt

Turn the engine off, disconnect the spark plug wire and ensure rotor has completely stopped. Inspect

and sharpen or replace knives and/or anvil as required. Ensure correct clearances between knives and

anvil

Once the engine has been given enough time to slow

down to idle speed (about 10-15 seconds), disengage

the rotor by winding the engagement handle in the

clock-wise direction until the handle comes to a stop.

WARNING! Only engage and disengage the rotor at

idle speed otherwise excessive vibration and belt

friction may cause damage.

Allow the engine to cool down by running at idle for at

least 1 –2 minutes before shutting down. Turn the

ignition key anti-clockwise into the off position to shut

the chipper down.

WARNING! The heavy rotor will continue to turn for

some time after the engine has been shut down. Do not

open the rotor housing cover until the engine and

cutting disk have completely stopped and the rotor is

disengaged.

2

3

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

10

The chipper starts making unusual noise, the cutting rotor strikes a foreign object or the chipper starts to vibrate

Turn the engine off, disconnect the spark plug wire, ensure rotor has completely stopped, then inspect

for damage

Replace or repair any damaged parts

Check for and tighten any loose parts

Do NOT attempt to repair the chipper unless you are competent to do so

The chipper stalls when material is being fed

Auto Feed Control is not working

Check that AFC is on

Check the Autotrip setting is not at setting 0 or 20 (manual mode)

If AFC is not working, contact Hansa

The feed roller is not turning

Engine is not running at full throttle

Increase the engine throttle to max RPM

The feed roller is running too fast/slow

Hydraulic pump belt loose/broken

Tension/replace belt

Maintenance & service

Knife re-sharpening and knife replacement

How do I know that the knives need re-sharpening?

Chipper is vibrating excessively when processing material

Chipper is making more noise than usual when processing material

Rotor RPM is dropping more quickly than usual

Material comes out in long strips

Blunt knives will cause excessive vibration

Blunt knives result in damage to the chipper

How to re-sharpen the knives:

If you don’t have a surface grinder or are unsure how to re-sharpen the knives, contact a professional saw doctor or Hansa to

arrange re-sharpening.

Tools and materials required for re-sharpening (approx. 40 mins):

•24 mm ring spanner

•19 mm ring spanner

•16 mm ring spanner

•14 mm Allen key

•Torque wrench with a 24 mm socket and 16mm crows-foot wrench

•A stick magnet (optional)

•Surface grinder

•Coolant

WARNING! Do NOT open the housing unless the engine and cutting rotor have completely stopped.

WARNING! Do NOT operate your chipper with blunt knives.

WARNING! Be careful when working around the sharp knives.

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

11

Remove the knives for sharpening:

Open the rotor housing cover by removing the

two housing cover locking bolts with a 19 mm

spanner, then lift the rotor housing cover to

access the cutting rotor. Rotate the cutting rotor

to gain access to the knives, then insert the rotor

pin (normally located under the control panel)

into the housing and through the cut-out in the

rotor to lock it in place.

Using a 24 mm spanner and a 14 mm Allen key,

remove the knives from the rotor. There are three

bolts that you must remove on each knife to do

so.

Be careful not to drop the bolts or knives

into the chipper.

A stick magnet can be used to retrieve

them if this does occur.

Measure the width of the knife and check that it

will be at least 96 mm after sharpening.

If the knives will be shorter than 105 mm, then

the knives should be replaced. Please contact

your nearest Hansa dealer.

Sharpen the knives:

Sharpen the knives on a surface grinder. A cutting

angle of 36 ° is critical for the performance of the

chipper. Make sure there is plenty of coolant used

when grinding to avoid softening of the steel knives.

Note: You do not need to sharpen your knives unless

both sides of the reversible knives have been used.

1

2

3

MIN 96 mm

4

36 °

Rotor

locking pin

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

12

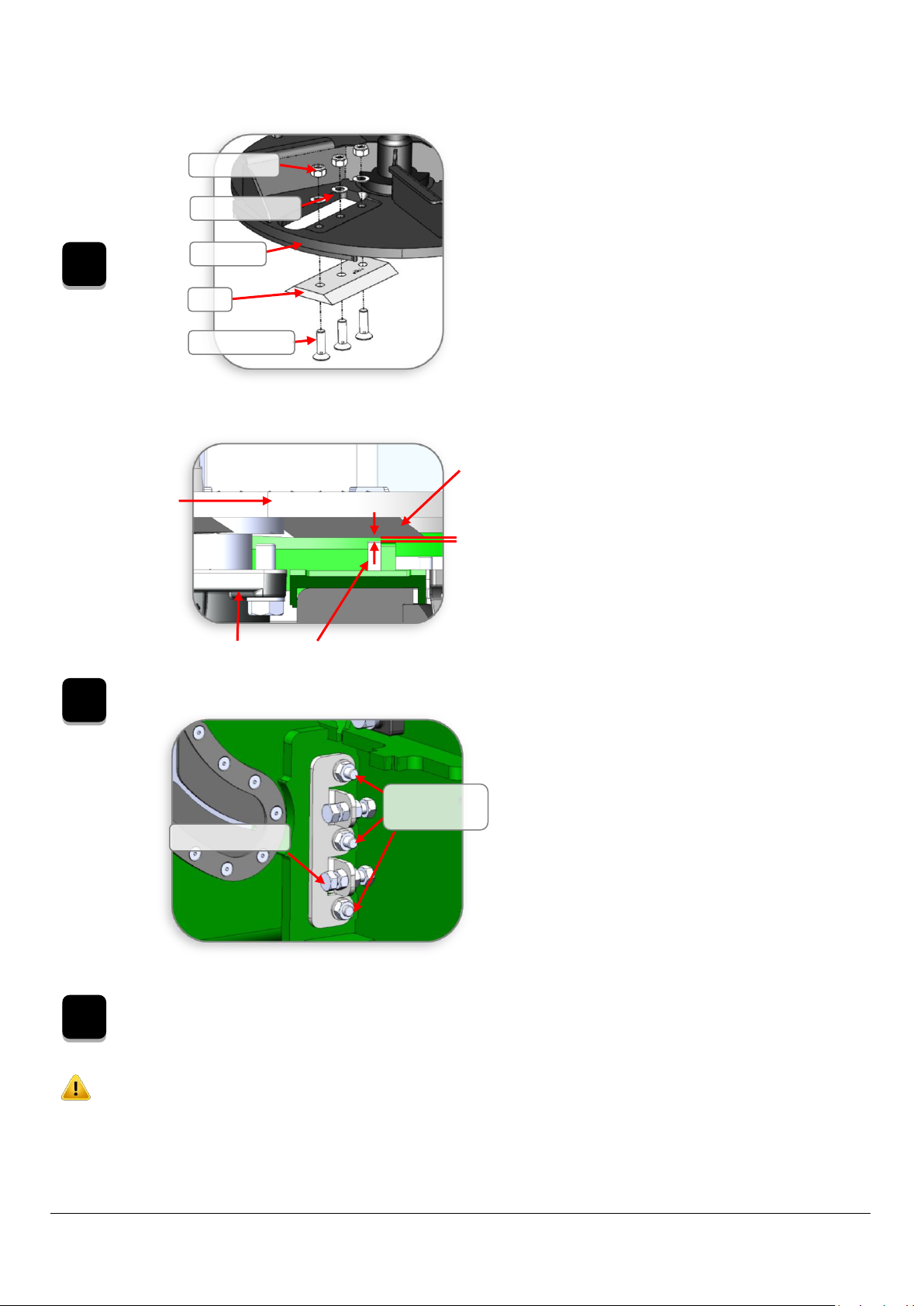

Reinstall the knives:

Clean all mounting surfaces and remount the knives

in the reverse procedure. Torque the knife clamping

nuts up to 190 Nm.

After sharpening, the width of the knives will have

been reduced, therefore the gap between the knives

and anvil may require adjustment. There should be

3 mm of clearance between the knife and the anvil.

If there is not enough clearance, the knife edge may

touch the anvil through deflection when cutting

heavy branches and damage the sharp edge. Too

much clearance will allow small twigs and fibrous

materials to be dragged through without being cut.

To adjust the gap between the knives and the anvil,

first loosen the locking nuts from the adjustment

bolts on the anvil mounting plate using a 16 mm

spanner. Now tighten or loosen the two adjustment

bolts. Tightening these bolts will cause the anvil

mounting plate to slide further along the slotted

holes. Ensure you tighten the two bolts evenly to

avoid setting the anvil on an angle.

Once the correct anvil position has been set, ensure

the locking nuts on the adjustment bolts are

tightened. Additionally, ensure the clamping nuts

are torqued to 44 Nm.

Remove the rotor pin and turn the rotor slowly by

hand to check that it turns freely.

Close and secure the outlet chute.

WARNING! Every time the knife clamping bolts are torqued up to 190 Nm and loosened off again, the life of the bolts is

reduced. The knife clamping bolts must be replaced at most after every six sharpens. Contact Hansa for replacement

bolts (m16x50 countersunk bolts of grade 12.9 or higher). Use only genuine Hansa bolts.

5

6

7

Locking nuts

Rotor disk

Clamping bolts

Knife

Countersink

clamping bolts

Adjustment bolts

Anvil

Rotor

disc

Knife

3 mm

clearance

Bearing

Top view: Knife and anvil set-up

Spring washers

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

13

Anvil adjustment

Whenever the chipper knives are inspected/sharpened, the condition of the anvil should also be checked. If the edge of the anvil

is significantly rounded and/or uneven, then it should be reversed or replaced. Typically, the anvil will maintain its sharp edge for

about 500 hours of operation.

Anvil replacement

Remove the feed roller guard by unhooking the

four rubber latches. Unhook the springs from the

base of the chassis. Lift the swing arm up and

insert the rotor pin (located underneath the

control panel) into the tab on the housing to lock

the swing arm in place.

To remove the anvil, you must remove the three

countersink clamping bolts using a 16 mm socket

and extension. If the bolt head turns, hold it with

a 6 mm Allen key.

Note: Do NOT use the Allen key to turn the bolt;

turn only the nut.

Note: Ensure the gap between the knives and the

edge of the anvil is 3 mm. If not, then the anvil can

be adjusted via the two adjustment bolts between

the clamping bolts.

If the other side of the anvil hasn’t been used yet: rotate the anvil 180 degrees and place it back on the feed roller

housing wall. If both sides of the anvil are blunt: remove the anvil and replace it with a new one. Contact Hansa

if a replacement anvil is required.

Tighten the clamping bolts back up using a 16 mm socket, ensuring there is a spring washer between the clamping

plate and each nut. Torque the nuts to 44 Nm.

1

2

3

4

Countersink

clamping bolts

Rotor pin

Feed roller motor

Swing arm

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

14

Belt tension

Correct belt tension is crucial for minimising belt wear and maximising machine efficiency. To check the belt tension, fully engage

the belt then open the bonnet. There should be approximately 5 mm deflection in the belt when pressing firmly on the belt (as per

the image below). Alternatively, the tension can also be checked by looking at the tensioning device from underneath the machine;

the notch on the idler arm should line up with ‘15°’ on the tensioner (as per the image below). If required, adjust belt tension.

Note: After using the machine for the first time, or after replacing the belts, it is recommended to check the tension again after the

first 5 hours of operation, as the belt will stretch as it wears into the system.

Belt tension adjustment

The belt tension can be adjusted by moving the M16 nyloc adjustment nut (below the machined engagement block) up or down

the engagement thread. You will need to use a 24 mm spanner to do so. The belt tension will increase as the nut is moved down

the thread.

Belt replacement

If the belts in your chipper look similar to any of the following images or are clearly broken, then they need to be replaced.

To remove the belts, open the bonnet and fully disengage the belts. The C40 requires three SPB1260 belts.

Adjustment

nut

Cracked underside of belt

Sidewall belt wear

Soft, swollen belt

Worn cover on back of belt

Split belt cover

Check for

deflection

here

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

15

Hydraulic pump belt adjustment

The hydraulic pump is driven by a synchronous belt. The belt does not require any tension, however the belt should not have any

slack either. The belt can be adjusted by loosening the four mounting bolts (using a 13 mm spanner) and moving the pump/pulley

up or down the slotted holes (as per the image below). The lower two bolts are best accessed from beneath the machine. If the

belt is damaged in any way, contact Hansa for a replacement.

Greasing bearings & pivot points

Points that need to be greased are as follows (as per the diagram on the following page):

1. Two bearings on the rotor shaft, one under the engine cover and the other above the inlet opening

1

2

3

4

5

6

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

16

2. Two bearings on the feed wheel

3. Two bearings on either side of the feed wheel pivot

4. Four grease nipples for pivoting the outlet chute

5. One grease nipple on the engine engagement screw (must be accessed from below the machine)

These points must be greased every 50 operating hours. Ensure a suitable grease is used (bearing grease or all-purpose grease).

Hydraulic system

Replace oil filter after first 50 hours, then every 250 hours.

The hydraulic oil should be changed every 800 hours. It is a closed system therefore it should not become contaminated, however

if contamination is detected oil should be changed. Use only a good quality brand, 32 grade hydraulic oil.

Fill the hydraulic oil tank so that the oil level is at the line indicated by the cold oil level label to the left of the oil level indicator.

The level should be checked with the engine off while the oil is cold

For any repair in the hydraulic system, contact Hansa Products or seek advice from a competent service agent.

Engine servicing

For servicing of the engine, please refer to the engine manual. Change oil, oil filter, fuel filter and air filter as recommended in the

manual. Ensure the correct engine oil is used.

Other servicing

✓Check all bolts and other fasteners for the correct torque setting

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

17

✓Check wheel nuts and U-bolts are fastened correctly

✓Check and repack wheel bearings with grease every 12 months

✓Check air pressure in tires. Inflate to pressure as indicated on the tire

✓Check safety chains and hitch

Rotor bearing replacement

Replacing rotor bearing on engine side of rotor:

1. Remove engine pulley by unbolting both grub screws in bush. Then screw one grub screw into the third hole and tighten

until the pulley separates from the bush. Slide bush off the shaft, followed by the pulley.

2. Remove two grub screws in the bearing.

3. Remove M16 nuts and bolts bolting the bearing to the housing.

4. Remove and replace bearing.

5. When replacing the pulley ensure the rotor pulley is lined up to the engine pulley with a straight edge. Ensure the grub

screws are tightened evenly so the pulley is tightened evenly.

6. The gap between the end of the sensor and the sensing plate should be approximately 3 mm. Adjust the sensor

accordingly. If it is set further away, then the sensor may not work properly and therefore the AFC will not work.

Replacing rotor bearing on inlet chute side of rotor:

It is recommended to have this bearing replaced by a specialist Hansa dealer.

Tyre Pressure

The recommended tyre pressure is 65 Psi.

Hansa C40 O&M Manual –OM-013 Revision E 23/10/19

© Hansa Chippers 2019

18

Maintenance & service intervals

Maintenance interval - service hours

10 or

50 or

100

250

500 or

800

Yearly

As req.

Service

Daily

Weekly

Biannually

Engine oil change - initial change

Initial

Hydraulic oil filter - initial replacement

Initial

Belt tension –initial check

Initial

Engine oil level –check

•

Coolant level - check

•

Radiator screen –check/clean

•

Air cleaner element –clean

•

•

Bearings –grease

•

Engine engagement rod –grease

•

Outlet swivel –grease

•

Knives–check, sharpen or replace

•

•

Belt guarding –remove and clean chip build-up

•

•

Drive belts tension - check/adjust

•

Hydraulic pump belt tension - check/adjust

•

Fan belt –check

•

Engine oil & filter –change

•

Nuts & bolts –check torque

•

Tires & rims –check

•

Hydraulic system –check

•

Spring mounting –check U bolts

•

Brake fluid - check

•

Hydraulic oil filter - replace

•

Battery electrolyte level & terminals - check

•

Engine fuel filter –replace

•

Outlet chute –remove & clean swivel

•

Feed roller tension springs - replace

•

•

Anvil - check

•

•

Air cleaner element –replace

•

Hydraulic oil & filter –replace

•

Feed roller teeth –sharpen

•

•

Engine system

•

Battery –replace

•

Drive belts –replace

•

Hydraulic pump belt –replace

•

Knives –replace

•

Anvil –replace

•

Hazard labels –replace

•

Table of contents

Other Hansa Chipper manuals