66

-6-

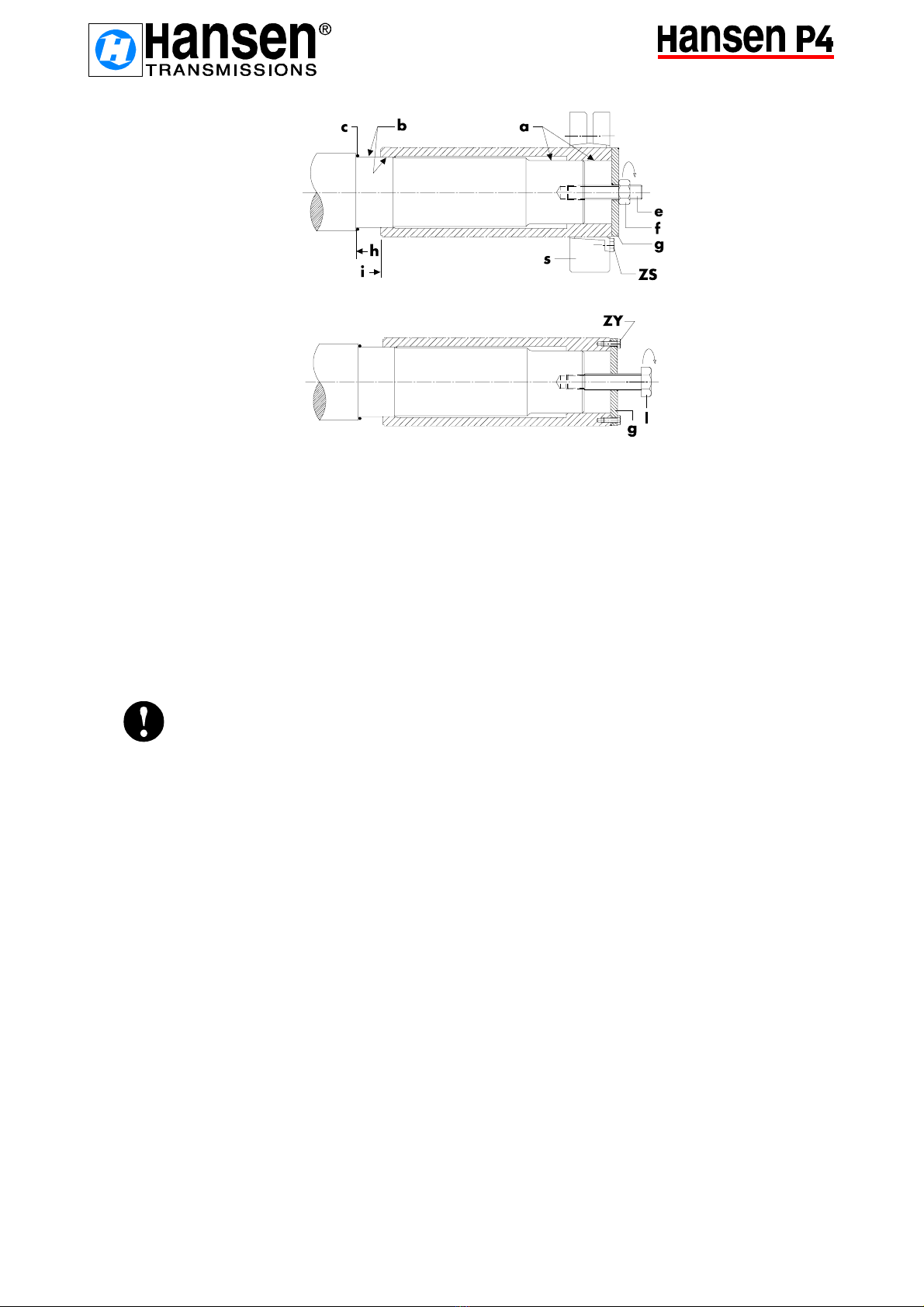

5.2. EXTERNAL LOADS

If external loads act on the gear unit, thrust blocks must be installed against the unit's feet, to

prevent gear unit from shifting. Components transmitting radial load to the shaft should be

mounted as close as possible to the housing.

Avoid exaggerated tension in transmission belts mounted on input or output shafts. On gear

units with built-on motor and V-belt drive, tension has been factory set. Tension should be

rechecked after 24 hours service. Chain transmissions must be mounted without preliminary

tension.

In case a pinion is mounted on the shaft extension of the gear unit, care should be taken to

have normal required backlash between pinion and gear and good contact pattern must be

assured.

5.3. ERECTION

5.3.1. Levelling

Always mount gear unit in position for which it was ordered.

Before altering this position or inverting the unit, please consult HANSEN.

It may be necessary to readapt the lubrication system.

5.3.2. Alignment

Align gear unit as accurately as possible with driving and driven machinery. Install gear unit

level to better than 5 mm per 1 m (5/32 inch per 3 feet or 5mrad or 17 arc minutes) or within the

limits indicated on the outline drawing for positions other than horizontal.

Maximum allowable misalignment depends on the couplings fitted on the shaft extension,

please refer to data provided with coupling.

Use three fixation points of gear unit for alignment. Adjust other fixation points by shimming to

0,1 to 0,2 mm (0.004 to 0.008 inch), depending on the size of the gear unit.

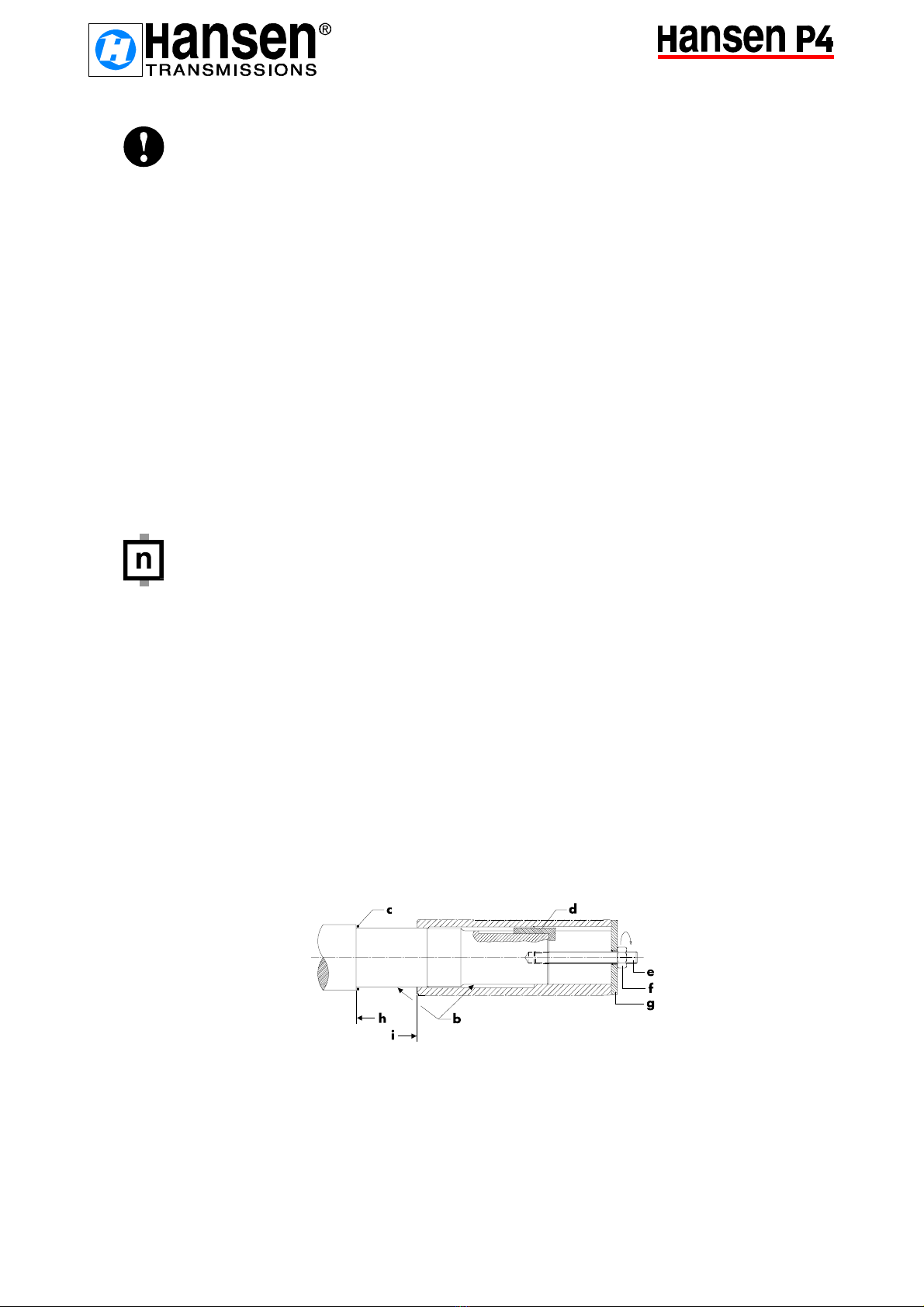

5.4. SECURING OF SOLID SHAFT GEAR UNIT

Gear unit must be mounted onto a rigid and stable bedplate or foundation in order to avoid

vibrations.

Use fixation holes indicated on dimensional drawing.

After correct alignment and shimming of all points, fix gear unit solidly onto its foundation with

appropriate size bolts, grade 8.8 according to DIN 267 or SAE grade 5 for bolts 1 1/2" and

smaller, ASTM.A-354 grade BC for bolts larger than 1 1/2". Dimensions and tightening torques:

see table.

Note: for some horizontal executions with parallel shaft and fans, the protection hood of the fan

must be removed (and remounted afterwards) to enable tightening of the bolts.

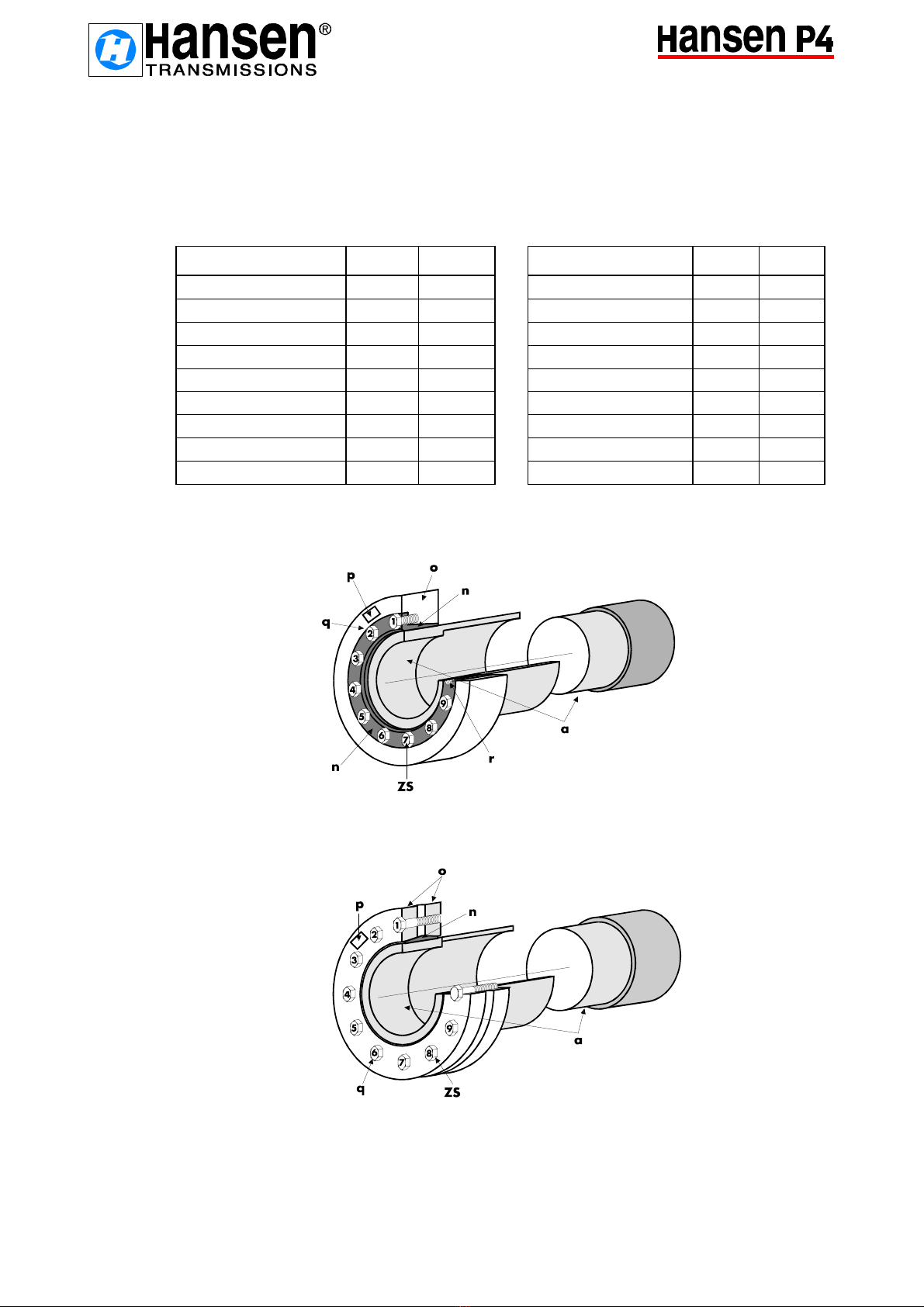

Horizontal mount

-Single stage gear units (type QHP.1)

Gear unit size C D E F G

ISO M20 M24 M24 M30 M30

Bolt size UNC 3/4" 7/8" 1" 1 1/8" 1 1/4"

Nm 285 450 660 830 1150

Tightening

torque lbf.in 2500 4000 5800 7300 10000