Hanskamp MultiFill 003-561-005 Owner's manual

EN

Arcle number: 010-106-000

Date: February 2022

Version 2.6 - Adjusted instrucon manual

According to Annex VIIA of the Machinery Direcve 2006/42/EC for completed machinery

Doenchem,

The Netherlands

www.hanskamp.nl/en

Liquid dosing system

Vloeistof doseersysteem

Flüssigkeitsdosiersystem

Pompe remplissage automatique

liquide

Installaon and operaon instrucons

MultiFill

003-561-005 up to 003-565-005

2 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Preface

Contents

This manual contains the informaon necessary for the correct installaon and

operaon of the MulFill dosing system.

Study and understand this informaon thoroughly before conguraon of the MulFill.

Failure to do so could result in damage to equipment. Please consult your milking

equipment dealer if you do not understand the informaon in this manual, or if you

need addional informaon.

All informaon in this manual has been compiled with care. Hanskamp shall not be

liable for errors or faults in this manual. The recommendaons are meant to serve as

guidelines. All instrucons, pictures and specicaons in this manual are based on the

latest informaon that was available at the me of publicaon. Your MulFill may

comprise improvements, features or opons that are not covered in this manual.

Applicability

The table below shows the type numbers of the MulFill for which this manual is

applicable.

Model designaon

Contact number local service provider

We suggest you note down the name, address, telephone number and e-mail address

of your local service provider in the table below. This makes sure you can easily nd

the informaon.

Name

Address

Telephone number

E-mail address

Model Model number

MulFill 003-561-005 up to 003-565-005

3 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

1. Introducon

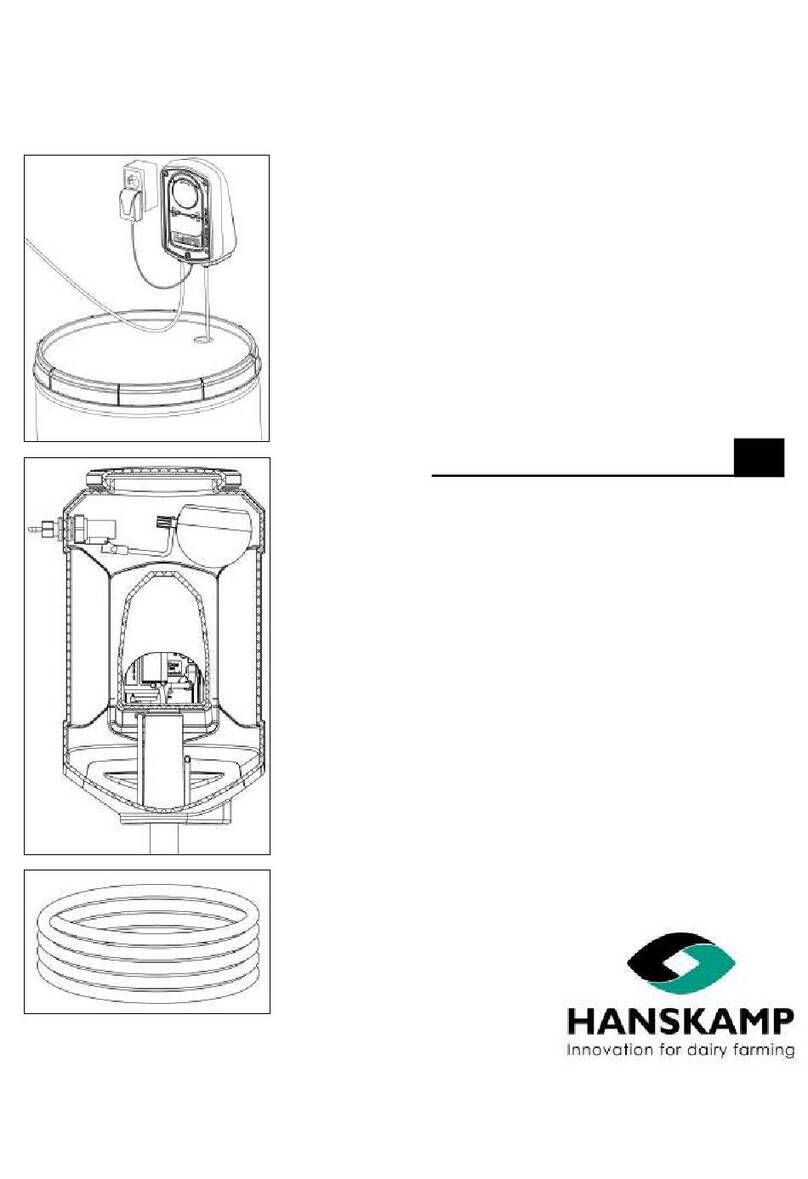

The MulFill automac lling system for MulDos storage drums consists of a self-

priming electric pump (230 V), a exible transparent hose, and a oat. This threepart set

enables the transport of liquids from a larger storage drum to any place in the barn,

where the MulDos storage drums are situated. Installaon is simple and quick. The

MulFill pump simply needs to be connected to the MulDos storage drums and a wall

outlet.

The informaon in this manual is aimed at farmers and technicians.

• Dairy farmers use the informaon to test and adjust the MulFill or to list

overviews.

• Technicians use the informaon to install and set up the MulFill.

4 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

2. Safety

2.1 Introducon

The safety alert symbol idenes important safety messages on your MulFill and in

the manual. When you see this symbol, be alert to the possibility of personal injury or

death. Follow the instrucon of the safety message.

Safety Alert Symbol

2.2 Signal Words

Note the use of the signal words DANGER, WARNING and CAUTION with the safety

messages. The signal word for each message uses the following guidelines:

Cauon! Indicates a potenally hazardous situaon that, if not avoided, could

result in injury or damage of equipment or surroundings.

Danger! Indicates an imminently hazardous situaon that, if not avoided, will

result in death or serious injury.

2.3 Safety Instrucons

You are responsible for the safe operaon and maintenance of your MulFill. You must

make sure that you and anyone else who is going to operate, maintain or work in the

vicinity of the MulFill, knows all the related safety informaon in this manual.

You are the key to safety. Good safety pracces protect you and the people around

you. Make these pracces a working part of your safety program. Make sure everyone

who operates, maintains or works near the MulFill obeys the safety precauons. Do

not risk injury or death by ignoring good safety pracces.

• MulFill owners must train operators before they operate the MulFill. This

training must be repeated at least annually.

• The operator must read, understand and obey all safety and operang

instrucons in the manual.

• A person who has not read and understood all safety and operang instrucons

is not permied to operate the MulFill.

• Do not modify the equipment in any way. Unauthorized modicaon may impair

the funcon and/or safety and could aect the life of the equipment, and

persons.

• Only use approved spare parts, and make sure they are installed by authorized

technicians only.

5 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

2.3.1 General safety

• Read and understand the manual and all safety signs before you connect power

supplies to operate or adjust the MulFill.

• Only trained persons are permied to operate the MulFill.

• Install all protecve covers and guards before you operate the MulFill.

• Wear proper protecve clothing and equipment.

• Disconnect and isolate the electrical power supply before you clean or do

maintenance on the MulFill.

• Make sure you know how to contact your local medical emergency center.

• Contact your nearest milking equipment dealer if you have any quesons.

• Review safety related items with all operators frequently (annually).

2.3.2 Electrical safety

• Only authorized electricians are permied to install the electrical power supply

for the MulFill.

• Make sure the electrical grounding of the electrical system and all parts of the

MulFill meet the local rules and regulaons.

• Replace any damaged electrical lines, conduits, switches and components

immediately.

• Isolate the electrical power supply before you open the lid of the MulFill to work

on the electrical system.

2.3.3 Installaon safety

• Read and understand the instrucons in this manual.

• Make sure the MulFill is installed correctly.

2.3.4 Operang safety

• Read and understand the applicable manual and all safety signs before you

connect power supplies to operate or adjust the MulFill.

• Only trained persons are permied to operate the MulFill.

• Switch o the electrical power supply by pulling the plug out of the power point

and secure the plug before you clean or do maintenance on the MulFill.

• Install the covers and guards before you operate the MulFill.

• Keep away hands, feet, hair and clothing from all electrical parts.

• Keep away unauthorized persons, especially small children, from the MulFill at

all mes.

• Before the electrical supply is aached to the MulFill, make sure all parts are

installed rmly and that all the parts are in good condion.

• Contact your nearest milking equipment dealer if you have any quesons.

6 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

2.3.5 Maintenance safety

• Read and understand the applicable manual and all safety signs before you

connect power supplies to operate or adjust the MulFill.

• Only trained persons are permied to maintain the MulFill.

• Switch o the electrical power supply by pulling the plug out of the power point

and secure the plug before you clean or do maintenance on the MulFill.

• Wear protecve clothing and safety goggles when you do work on the electrical

system.

• Make sure all the covers and guards are installed when maintenance work is

complete.

2.3.6 Safety warnings

• General safety warnings are shown in this safety warnings secon. Specic safety

messages can be found in applicable parts of this manual when potenal hazards

may occur if the instrucons or procedures are not followed.

7 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

3. Installaon instrucon

General comment:

The Hanskamp MulFill dosing system is a rell system for automacally lling the

MulDos container. This installaon instrucon will guide you through the

installaon of the MulFill system (g. 1). Read this instrucon carefully and follow

the safety instrucons. Examples of installaon can be found at www.hanskamp.nl.

Order numbers and names of accessories can be found in the aachment.

Transport and storage:

The MulFill dosing system set consists of a MulFill wall mount with one oat

valve set per MulDos container. The MulFill is packed in a cardboard box. These

boxes can be stacked on a pallet. The boxes may be shipped separately. For box

content, see annex 3, page 17.

Cauon! Always use an appropriate vehicle (forkli truck, pallet fork,

pump truck, etc.) to move the pallet.

Cauon! Parts may fall o the pallet when it is being unpacked.

Safety:

The user and installer are solely responsible for the safe operaon and maintenance

of the MulFill dosing system. When changing the HanskampQualityTube of the

pump, always disconnect the electric system, in order to prevent entrapment of the

ngers.

Important: do not remove the sckers!

Maintenance of the sckers:

• Keep the safety sckers clean and legible.

• Clean the safety sckers with soap and water.

• Do not use any solvents or abrasives that could damage the safety sckers.

• Replace missing or illegible safety sckers.

• Safety sckers are obtainable from Hanskamp. Always specify the item numbers in correspondence.

1

Type descripon;

To be found on the control box

Product

name

Serial number

Arcle number

CE-marking

Art. no. scker

8 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Installing the oat in the MulDos storage tank:

1. Install the oat on the oat valve (g. 2).

2. Drill a 22 mm hole, 440 mm from the boom of the container (g. 3 and 4).

3. Twist the rst of the two plasc nuts o the oat (g. 5).

4. Insert the oat valve set through the hole, x the oat with plasc nuts (g. 7).

5. Screw the adaptor nipple (art. no. 001-170-001) ghtly onto the oat valve by

hand (g. 5).

Installing/connecng mulple drums:

1. Connect the drums with the aid of the T-coupling (art. no. 001-178-000) (g. 8).

2. Secure the tube with cable es, preferably place the tube in a protecve sleeve.

Cauon! Make sure that the tube is not pinched when xing it.

Cauon! Drill a small hole into the top of the storage drum for venlaon

purposes.

5

6

2

3

4

7

8

Cauon! Fill the container completely

by hand the rst me. Let the MulFill

rell only the last millilitres.

6

Orice supplied as standard (small).

Use with low viscosity uids only.

Install large orice (supply small orice

separately).

9 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Mounng the MulFill:

1. Check parts for completeness with the help of the item list.

2. Loosen the outer three hexagon socket screws (art. no. 003-510-000) that

aach the MulFill pump to its housing and remove the pump.

Cauon! The MulFill should be placed near a power outlet.

The MulFill can be aached in two dierent ways.

3a. To the wall:

Drill holes in the back of the MulFill as shown in gure 9. The required

distances of the holes are shown in gure 10. Install the wall mounng, about

20 cm above the storage container. The maximum sucon length of the

MulFill is 2 meters. (Mounng material is not included.)

3b. To a surface:

Drill holes in the boom of the MulFill. The place of the holes can be chosen

freely (see g. 11 for minimum distance between the hoses and the plate).

Install the wall mounng. The maximum sucon length of the MulFill is 2

meters. (Mounng material is not included.)

4. Unscrew the cover of the pump housing (g. 12).

5. Pinch a hole into the centre grommet, using a small, at screwdriver.

6. Carefully open the cover of the motor housing.

7. Push the cable of the power supply through the centre grommet.

8. Strip the insulaon at the ends of the wires.

9

10

11

Distance between tube and plate:

± 8 mm

12

10 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

9. Connect the wires of the power supply to the PCB. Connect the posive cable

(black with white stripe) to the posive terminal (Br), and the negave cable

(black) to the negave terminal (Wh) (g. 13).

10. Push to close the engine cover.

11. Screw the pump housing onto the wall mount by hand evenly, using the

accompanying screws (art. no. 003-510-000) (g. 14).

14

003-510-000 (3x)

Pressure sensor

Inlet pump circuit

Speaker for alarm-

signal

Power LED (green)

On = print acve

Pressure sensor

Reference pressure

Pressure signal available (blue)

On = pressure higher than 2 bar

Motor LED (red)

On = signal on motor output Magnet LED (orange)

On = magnet sensor detects magnet (not used)

Alarm led (red)

On = alarm acve + soundsignal

zwart/black/schwarz/noir

zwart met wie streep/

black with white stripe/

schwarz mit weißen Streifen/

noir avec un trait blanc

Alarm LED (red)

On = alarm acve + sound signal

- every second = motor has been running

for 6 hours

- every 10 seconds = overvoltage

Reset: power o -> power on

13

11 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

12. Loosen and remove the rotor of the pump by turning it

counterclockwise by hand.

Cauon! Loosening the rotor manually poses a small risk of injury.

13. Use the 50 m PVC hose as pressure hose and cut it to size. Use

the 2 m hose as sucon hose.

Please note! Hanskamp can only guarantee proper operaon if the length of

the sucon hose is 2 meters or less.

14. Take the sucon hose and push it, from below, onto the right-hand feedthrough

coupling (art. no. 003-572-000).

15. Push the HanskampQualityTube onto the other side of the feedthrough coupling

and secure it with a cable e. Tighten the cable e as rmly as possible.

16. Push the pressure hose, from below, onto the hose connector on the le-hand

side (art. no. 001-179-000) (g. 17).

Cauon! The HanskampQualityTube is not suitable for acids. A hose kit

especially suitable for acids is available from Hanskamp.

Cauon! When ghtening the cable e, there is a risk of injury from pinching.

Cauon! Always cut the hose straight. A hose cut at an angle can impair proper

funconing.

Cauon! Make sure that the end of the hose is placed at the boom of the

storage tank, otherwise the pump will not be able to pump all the uid.

1x pumping hose Ø11,5 HanskampQualityTube art. no. 003-529-005

1x sucon hose = 2 m PVC hose Ø10x7 art. no. 001-006-002

1x pressure hose = 50 m PVC hose Ø14x10 art. no. 001-007-001

15

Pressure hose

Ø14x10 mm

HanskampQualityTube

16

17

Sucon hose max. 2 m

Ø10x7 mm

12 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

17. Tighten the cable e rmly so that the hose cannot come loose.

18. Take the HanskampQualityTube and bend it as much as possible to t it into the

form of the pump housing.

19. Push the loose end of the HanskampQualityTube onto the same hose nozzle to

which the pressure hose is aached.

Cauon! When ghtening the cable e, there is a risk of injury from pinching.

Cauon! Always cut the hose straight. A hose cut at an angle can impair proper

funconing.

20. With the side of the conical recess, turn the rotor onto the sha of the pump

motor. With the last rotaon, press the HanskampQualityTube into the recess

of the pump housing as well as possible. The tube is now clamped between the

rollers and the pump housing. Tighten the rotor on the motor sha by hand (g.

19 and 20).

21. Now take the transparent pump cover (art. no. 003-502-000) and the 4

corresponding knurled screws (art. no. 003-509-001). Posion the cover properly

in front of the cover recess in the pump housing and ghten the screws evenly

unl the cover is rmly in place (g. 22). Please note: Tight is ght!

22. Connect the pressure hose to the reducer of the oat set and insert the sucon

hose into the storage tank.

23. Manually ll the MulDos container, unl the level reaches the oat valve.

24. Plug the power adapter into a wall outlet, to start the pump automacally.

Please note! During the rst revoluons, no pumping process can be seen, as

the rotor is ghtening itself on the motor sha.

Please note! To prevent loss of liquid in case of leakage, the MulFill stops

automacally aer 6 hours of connuous rotaon and emits a sound signal.

To restart the MulFill, briey disconnect the power supply and then

reconnect it, using the power adapter.

18

19

20

21

22

13 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Maintenance:

Check the MulFill system every day for failures and wear. Carry out a visual inspecon

of the sucon and pressure hose and the electrical wiring. Replace the Hanskamp-

QualityTube if it shows signs of wear (leakage), according to the steps described (see

instrucons from step 6). A suitable repair kit can be obtained from Hanskamp. Also

check the rollers and bearings for wear. For these too, Hanskamp can supply repair kits.

Cauon! Always disconnect the pump motor from the power supply before

carrying out maintenance and/or disassembly.

Disassembly:

In case of disassembly, all parts must be separated according to material type and must

be processed within the proper type of waste management system.

Overview of changes included in this installaon and operaon instrucons:

Warranty limitaons:

The warranty excludes costs and expenses due to:

- Use of the units for purposes other than intended, non-compliance with the

specicaons in the installaon and operaon instrucons;

- The consequences of any intervenon by engineers other than engineers

recognised and approved by Hanskamp for carrying out service, maintenance and

other technical work;

- Incidents such as freezing, ice, re, ooding, inundaon or any other form of

extreme water damage and lightning;

- Defects in the electrical system or grounding system;

- Damage to the electrical system due to vermin and the like.

The warranty is not applicable to consequenal damage that is not related to the

machine itself. All systems have been tested. However, in the event of disturbance,

Hanskamp cannot be held responsible for consequenal damage.

Nr. Release date Chapter(s) Notes

108/2014 First edion

1.1 03/2015 All New address

1.2 04/2015 All Update of illustraons

1.3 10/2015 All General review

1.4 06/2016 Arcle numbers changed

1.5 10/2017 All Added arcles 001-006-002, 003-529-005 and 003-524-001 in parts list

1.6 01/2018 All Mulple couplings replaced by 1 coupling

1.7 04/2018 All Auto-stop MulFill

1.8 07/2018 Components Wall plug power supply changed from 12V DC to 24V DC

1.9 01/2019 Technical specicaons Pressure switch changed

2.0 03/2019 Installaon oat valve Added warning noce to ll up the container completely at rst use

2.1 08/2019 All Knurled screw added & upgrade to new MF-motor

2.2 02/2020 Page 12 Changed warning aer step 24.

2.3 05/2020 Page 10 Added PCB overview

2.4 09/2021 Page 10 + 15 Switch-o pressure increased from 1.3 to 1.5 bar

2.5 10/2021 Page 8 + 11 + 15 + 16 + 17 Transport hose changed to 14x10 mm

2.6 02/2022 Page 10 + 15 Adjusted cut-out pressure (1.5 to 2 bar) and start-up pressure (0.3 to 0.8 bar)

14 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Declaraon for completed machinery IIA

(According to Annex VIIA of the Machinery Direcve 2006/42/EC, for completed

machinery)

We,

Hanskamp AgroTech BV

Broekstraat 17

7009 ZB Doenchem

The Netherlands

Authorised compiler(s) of the technical le:

H.J. Hanskamp

Declare enrely under our own responsibility that the product:

003-561-00X up to 003-565-00X MulFill (230 V)

Universal rell system for constant supply of concentrate liquids.

to which the declaraon relates, fully complies with the provisions of the following

direcve(s):

Machinery Direcve 2006/42/EC

and completely or parally meets the following essenal requirements and that the

relevant technical documents were drawn up in accordance with annex VIIA. The

product also complies with the spulaons in the following annex(es):

NEN-EN-IEC 60204-1

NEN-EN-ISO 12100:2010

NEN-5509

NEN-EN 349

NEN-EN-ISO 13857

Power Supply

EMC direcve 2004.108/EC

EN 55022:2010

EN 61000-3-2:2006+A1:2009+A2:2009:

EN61000-3-3:2008:

If the MulFill is not connected and the spulated securies are not complied with,

this declaraon of agreement becomes void and no rights can be derived from it.

The Netherlands, Doenchem 01-08-2019 H.J. Hanskamp

15 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Technical specicaons 10106 MulFill

Capacity 200 ml/ min

Voltage 230 Volts

Sucon height 2 meters

Pressure height 4 meters

Max. length pressure hose 75 meters

Control range Regulates between 2 and 0.8 bar

Cercate NEN 3140

Power cord 3 meter cord with plug

Annex 1: Arcle numbers and technical specicaons MulFill

Arcle numbers Descripon

003-561-005 MulFill black, complete, 230 V

003-562-005 MulFill green, complete, 230 V

003-563-005 MulFill blue, complete, 230 V

003-564-005 MulFill red, complete, 230 V

003-565-005 MulFill orange, complete, 230 V

16 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Annex 2: Exploded view MulFill and rotor (003-524-001)

003-514-

003-516-000

003-513-

003-503-000

003-504-001

003-507-000

003-508-000

003-514-000

003-513-000

Remove

17 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Annex 3: Loose components

Loose spare parts for the purpose of maintenance or other work can be reordered

through your dealer. Please use the corresponding item numbers as indicated below.

Components MulFill

Art. no. Descripon Num-

ber

001-006-002 PVC hose, 2 m, Ø10x7 1

001-006-006 PVC hose, 6 cm, Ø10x7 1

001-179-000 Hose connector, 8 mm - 10 mm 1

001-947-000 Membrame grommet, thermoplasc

elastomer 1

003-510-000 Hexagon socket screw with ange

M5x10 3

003-515-000 Countersunk screw with hexagon socket

M5x30 3

003-524-001 Rotor complete, incl. castors, xing

material and rotor part 1

003-525-000 MulDos pump housing, complete with

cover

003-529-005 HanskampQualityTube Q-prene, 0.48 m 1

003-569-000 Sucon tube Ø8x1, AISI304, L = 300 mm 1

003-572-000 Feedthrough coupling plasc 9-9 1

003-589-000 Feedthrough coupling for MulFill with

connecon for pressure switch 1

Colour opons wall mount

Art. no Descripon

003-520-000 Wall mount MulDos, black, incl. 3 inserts

003-540-000 Wall mount MulDos, green, incl. 3 inserts

003-541-000 Wall mount MulDos, blue, incl. 3 inserts

003-542-000 Wall mount MulDos, red, incl. 3 inserts

003-543-000 Wall mount MulDos, orange, incl. 3 inserts

Components Rotor (003-524-001) MulFill

Art. no. Descripon Number

003-503-000 Rotor part, red 2

003-504-001 Plasc roller, black, Ø31.6 mm 2

003-507-000 Bearing 6000RS 2

003-508-000 Circlip 2

003-513-000 Conical adapter, stainless steel 1

003-514-000 Adapter, stainless steel 1

003-516-000 Countersunk screw with hexagon

socket M5x10 2

Addional parts MulFill

Art.nr. Descripon Number

001-007-001 PVC hose Ø14x10 50 m

002-260-000 Float valve set MulFill 1

MulDos pump housing complete with cover 003-525-000

Art. no. Descripon Number

003-501-000 MulDos pump housing 1

003-502-000 MulDos pump housing cover,

transparent 1

003-507-000 Bearing 6000RS 10x26x8, stainless

steel 1

003-509-001 Knurled screw M5x29 a2, stainless

steel 4

003-519-000 Mulsert 003-M5 - inserts for plasc

MulDos 4

010-066-000 Scker with serial no. MulDos, to be

applied on pump housing MulDos 1

Components Motor MulFill

Art. no. Descripon Num

-ber

001-425-000 Rubber grommet Ø14-Ø5, 8.4 mm 1

001-434-000 Motor, black, 28 RPM 1

001-435-000 Hotmelt Permacol 30.288 0,2

003-546-000 O-ring 10x2 NBR70 1

003-591-000 MulFill control PCB SS 2K2, 0.25 W 1

003-599-000 Plasc Ø4 coupling, perpendicular screw

-in 1/8” 1

010-091-000 Scker on connecon block IM Motor 1

010-306-000 Scker on MulFill Motor 18 RPM 1

011-041-000 Plug-in power supply unit 230V AC-24V

DC, 1500 mA 1

011-234-000 Housing for sensor PCB, grey 1

082-342-002 Air tube PU/2 cm 4x2, transparent 1

082-342-029 Air tube PU/29 cm 4x2, transparent 1

18 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Annex 4: Hazard warnings and user instrucons HanskampQualityTube

003-529-005 HanskampQualityTube

For (milking equipment) dealers, resellers and users of the MulDos.

Aenon! Not intended for medical use.

Read the notes and instrucons carefully before using or reselling the MulDos.

The following warnings and instrucons must be followed to avoid cracks or leaks in the

hose that may result during use and which could cause damage to property and/or injury

to persons.

Warning:

1. The HanskampQualityTube is made of ‘Thermoplasc Material’, and as such,

the performance is aected by temperature and pressure.

2. Some liquids can be absorbed or extracted by the HanskampQualityTube. It is the

responsibility of the end user to observe and document the specicaons, safety

regulaons and documentaon of the HanskampQualityTube.

3. It is the responsibility of the end user to determine if the composion of the tube

is suitable for the intended use.

4. The HanskampQualityTube is not intended or suitable for medical purposes.

The use of this tube in a medical seng is the sole responsibility of the (milking

equipment) dealer and/or the end user.

5. To avoid catastrophic disconnecon during use, always use detachable clamps

when aaching the hose to a coupling or ng.

6. In the event that the hose ruptures, it is advisable for the end user to have a

replacement system available.

7. No tube lasts forever. This also applies to the tube of the MulFill. With prolonged

use or improper installaon, the tube will tear.

The following factors have been found to aect the service life of the

HanskampQualityTube in the MulDos liquid pump:

- Type of uid being pumped/transported.

- % occlusion of tubing walls.

- Pumping speed (i.e. roller impacts/minute) and total number of impacts.

- Level of system back pressure.

- Temperature of uid being transported as well as temperature of the operang

environment.

- Friconal drag due to improper maintenance or wearing of rollers and guides.

- Twisng, kinking, or excess lengths of the HanskampQualityTube installed in the

MulFill.

- Wall thickness and thickness variaon.

19 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Measures to prevent possible damage to property or consequenal damage from the

use of the HanskampQualityTube in the MulDos:

- Carefully set up and monitor each of the aforemenoned variables during use of

the HanskampQualityTube in the MulDos.

- Read and heed the instrucons of Hanskamp (manufacturer) or the (milking

equipment) dealer of the apparatus, the MulDos regarding the Hanskamp-

QualityTube installaon, pump rollers, guide rollers, sucon hose, power supply,

maintenance and calibraon.

- Inspect the HanskampQualityTube for any damage prior to installaon.

- Make sure that the HanskampQualityTube is the correct length and ensure that

the HanskampQualityTube is neither twisted nor bent when installed in the

MulDos.

- Connuously check the hose circuit for signs of hose rupture or leakage of the

HanskampQualityTube and take acon upon their occurrence.

Material safety data sheets are available free of charge by Hanskamp.

Copyright and disclaimer

The informaon given in this publicaon is provided for informaon purposes only and does not constute an oer for sale. The products supplied may

dier from those illustrated. No part of this publicaon may be reproduced or made public without prior permission in wring from Hanskamp AgroTech

B.V. Although this publicaon was put together with the utmost care, Hanskamp AgroTech B.V. is not liable for any damage that might arise due to

errors or gaps in this publicaon. The instrucons for installaon and use in Dutch are the original instrucons for installaon and use. The translaons

into other languages have used the Dutch instrucons for installaon and use as the source document. Hanskamp AgroTech B.V. does not accept any

liability for dierences between the translaons. If there are doubts about the content and accuracy of the translated instrucons for installaon and

use, the Dutch instrucons for installaon and use constute the authoritave document.

20 - 20

Hanskamp AgroTech B.V. (The Netherlands) www.hanskamp.nl/en

MulFill

EN Dosing system - Dosiersystem - Système de dosage - Doseersysteem

Hanskamp AgroTech B.V.

Broekstraat 17

7009 ZB Doenchem

The Netherlands

Tel: +31 (0)314 - 393 797

Fax: +31 (0)314 - 393 826

www.hanskamp.nl/en

Visit us on:

Other manuals for MultiFill 003-561-005

1

This manual suits for next models

1

Table of contents

Other Hanskamp Industrial Equipment manuals