Hanson PHASE ONE User manual

PHASE ONE™

DISINTEGRATION TESTER

USER GUIDE

Hanson Research Corporation

40-108-001-Rev. A—14 November 2016

Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 SAF-1

About Hanson Research

Hanson Research is a global technology

company specializing in analytical test

instruments for the pharmaceutical industry.

Founded by the innovator of modern

dissolution test technology, Hanson Research

helps ensure the world’s pharmaceuticals are

pure, safe, and effective by manufacturing

equipment that sets the global standard for

quality, innovation, and long-term value.

Hanson instruments are used by scientists in

over 75 countries worldwide and are

supported by the industry’s top customer

service team. For more information, visit

hansonresearch.com.

Headquarters

Hanson Research Corporation

9810 Variel Avenue

Chatsworth, CA 91311, USA

Main: 818.882.7266

Toll Free: 800.821.8165

Fax: 818.882.9470

hansonresearch.com

Copyright © 2016 Hanson Research Corporation. All

rights reserved. Phase One

™

is a trademark of

Hanson Research Corporation.

Sales and Support

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 SUPPORT

Congratulations on your purchase of the Hanson Phase One™ Disintegration Tester.

While we are certain you will enjoy this new product, we also understand from time to

time you may have a question or technical issue requiring our assistance. Please feel

free to contact us at any time by any of the methods below. We’re happy to help!

Website: www.hansonresearch.com

Tech Support Request Form: www.hansonresearch.com/tsr

E-Mail: [email protected]

Phone: (+1) 818.882.7266

Toll Free: 800.821.8165

Fax: (+1) 818.882.9470

Corporate Headquarters

Hanson Research Corporation

9810 Variel Avenue

Chatsworth, CA 91311, USA

Revision History

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 RH-1

Document Revision History

Revision Date Revised Description of Change

A 14 November 2016 Original issue

To confirm that you have received the latest version of this user

guide, contact Hanson Research Technical Support.

Table of Contents

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 TOC-1

Table of Contents

A. Introduction ……………………………………. A-1

B. Regulatory and Safety ……………………….. B-1

C. Installation ……………………………………… C-1

D. Operation ………………………………………. D-1

E. Disintegration Testing …………………….…. E-1

F. Maintenance ………………………………….. F-1

G. Troubleshooting ………………………..…….. G-1

H. Specifications ………………………..…….….. H-1

I. General Warranty ………………………….….. I-1

A. Introduction

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 A-1

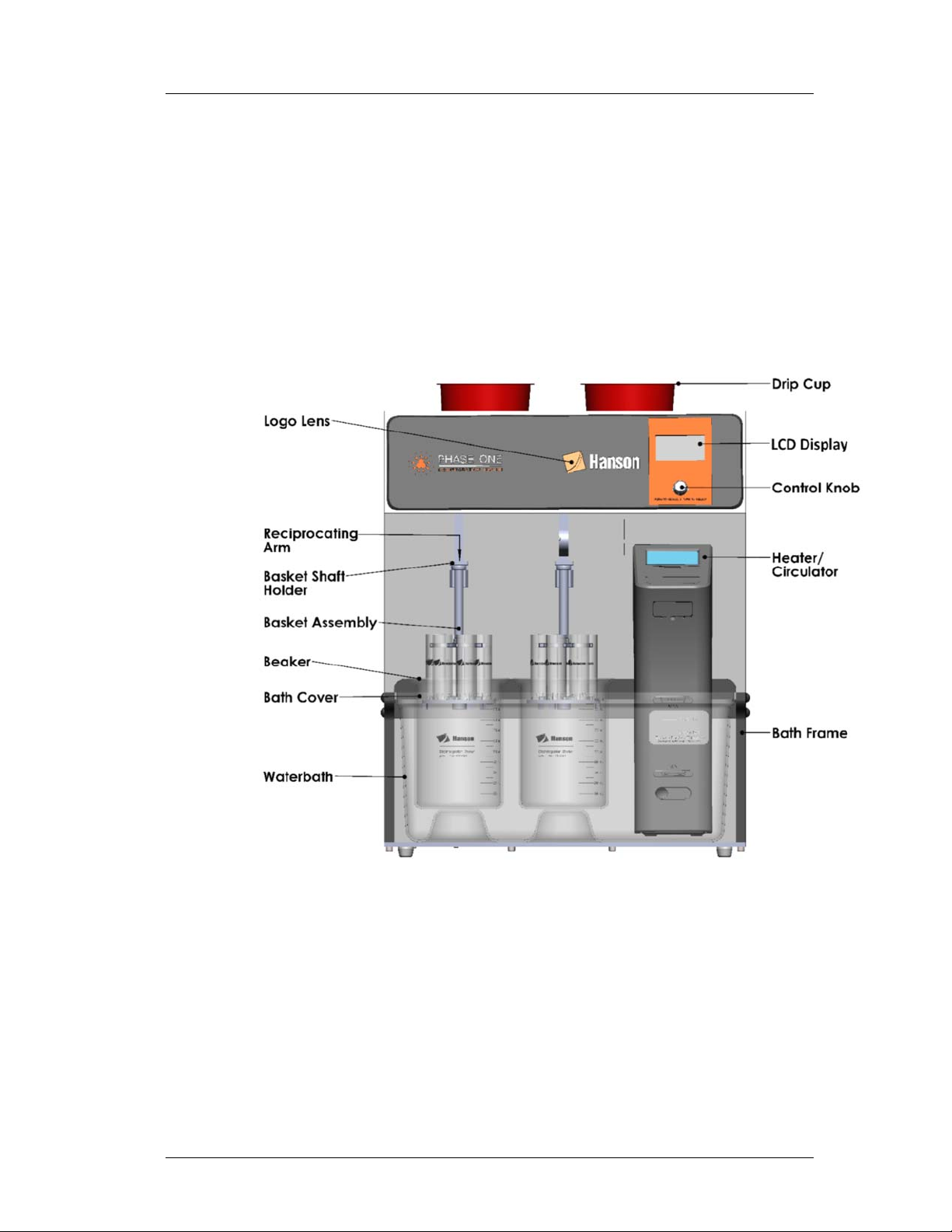

Phase One Disintegration Tester Overview

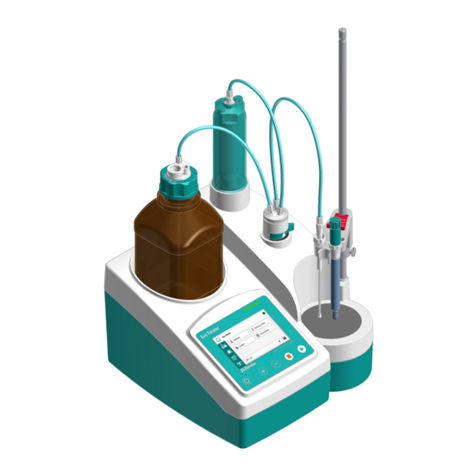

The Phase One Disintegration Tester is a two-basket system

designed to facilitate testing of tablet disintegration in

conformance with USP Chapters <701> and <2040> and other

harmonized international standards. The unit consists of a

waterbath, two beakers, two basket assemblies, one

heater/circulator, a set of two reciprocating arms driven by a

single electric motor, and other components as shown in the

illustration below.

The tester supports methods requiring two baskets running

simultaneously; the baskets are not independently controlled.

The standard tester configuration comes with two beakers and

two baskets pre-configured for 6-tube (USP Apparatus A) with

plastic disks. 3-tube baskets for Apparatus B are available

separately. The quick-connect basket assemblies snap onto the

basket shaft clips on the ends of the reciprocating arms that

provide the dipping action. The waterbath is easily removed

without tools for periodic cleaning.

A. Introduction

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 A-2

Tester Power Requirements

The internal power supply of the tester automatically switches

to accommodate either 120VAC/60Hz or 240VAC/50Hz. All

testers come with a detachable 120VAC cable with a 3-prong

plug to connect to the power source and a standard female

adapter to connect to the input module on the back of the tester.

Operating the tester on 240VAC requires an appropriate cable

(or adapter) suitable for connecting safely to the power source

and to the back of the tester.

Heater/Circulator

Heating and circulation of bath water is provided by a stand-

alone PolyScience Heater Circulator (H/C) unit featuring a built-

in over-temperature shut-off circuit. The H/C is self-contained

with an easy-to-read LCD display and a touchpad for setting the

temperature.

Heater Power Requirements

Heater/circulator power is dedicated to either 120VAC/60Hz (10

amps) or 240VAC/50Hz (6 amps), depending on which version

was purchased. The H/C has its own power cord configured for

the power supply specified at the time of the order. If the power

source outlet is configured differently than the plug on the H/C

cable as supplied, an appropriate adapter will be required. Note:

the outlet plug for the 240VAC version is IEC Type E.

WARNING! The maximum possible temperature able to be set

for the heater is 98 °C (factory-set limit). However, to avoid

distortion of the waterbath, bath lid, and baskets, and to protect

the tester warranty, the heater should never be allowed to run

higher than 55 °C.

Do not set heater

above 55 °C

A. Introduction

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 A-3

User Interface

The user interface of the Phase One Disintegration Tester

consists of an LCD display and a rotary control knob that allows

the user to select and activate each of the tester’s settings. All

operations are controlled with this knob.

Drip Cups

The low-profile plastic drip cups included with the unit are

designed to be placed under wet baskets for drip containment,

for example when baskets are being removed from the basket

shaft holders. They will also fit on top of the beakers and can be

used to plug the holes in the waterbath lid to reduce

evaporation.

Tester Operation Overview

Once the tester has been unpacked, installed and qualified,

routine operation consists of four steps: tester initialization; test

setup; running the disintegration test; and cleanup. The tester

has the ability to run a timed test or a continuous free run test.

A quick-start overview of the operational procedure is as

follows:

1. Power up tester and heater and initialize the tester.

2. Fill waterbath with DI water to the level indicated on the

label on the front of the bath.

3. Set heater/circulator to desired target temperature. (Do

not exceed 55 °C.)

4. Fill beakers with media to appropriate level.

5. Place tablets in baskets (along with plastic disks if

necessary).

A. Introduction

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 A-4

6. Install baskets on arms by snapping into basket shaft

holder.

7. Highlight the desired test mode—timed or free run.

8. If a timed test, set the time limit.

9. Start the test and monitor at appropriate points.

10. End the test and perform cleanup.

The above steps are described in greater detail in the Operation

section of this user guide.

Recommendations for Using This Manual

Hanson Research recommends the following steps for making

best use of this user guide:

1. Review the Introduction section for an overview of the

instrument.

2. Carefully review and follow all safety instructions.

3. Unpack, inspect, and install the tester according to

instructions in the Installation section.

4. Conduct an initial test of the system using the

procedures outlined in the Operation section.

5. Review the cleaning, maintenance, and troubleshooting

sections to become familiar with keeping the tester in

good working condition.

6. Immediately contact Hanson Technical Support with any

questions on how to properly operate and maintain the

Phase One Disintegration Tester.

B. Regulatory and Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 B-1

Regulatory Compliance

Hanson Research hereby certifies that this product, including

hardware and firmware, was designed, evaluated, validated,

inspected, and tested to approved specified quality

requirements of Hanson Research Corp. in conformance with

current USP, EP, JP, and other international standards (India &

Korea).

Canadian Emissions Notice

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set forth in the

Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits

radioélectriques dépassant les limites applicables aux appareils

numériques de la classe A prescrites dans les réglements sur

le brouillage radioélectrique édictés par le Ministére des

Communications du Canada.

General Safety Considerations

This equipment contains moving parts, which have the

potential to pinch or jam.

The installation category (overvoltage category) for this

instrument is Level II. The Level II category pertains to

equipment that receives its electrical power from a local

source such as an electrical wall outlet.

This instrument must be connected to a grounded

electrical outlet.

Never work on the electrical components in the system

while there is power to the unit. DISCONNECT POWER

BEFORE SERVICING THE INSTRUMENT.

Review all safety and environmental precautions pertaining

to any chemicals that are to be used in conjunction with

this equipment.

B. Regulatory and Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 B-2

CSA Safety Considerations

• For indoor use only

• Maximum altitude 2,000 meters

• Environmental operating temperature 5 °C to 40 °C

• Operating relative humidity 80% for temperatures up to 31

°C, decreasing linearly to 50% relative humidity at 40 °C

• Mains supply ratings 100-240 V~, 50-60 Hz, 15 A

• Mains supply voltage fluctuations not to exceed ±10% of the

nominal voltage

• Installation Category II (overvoltage categories)

• Pollution Degree 2

• Please note potential pinch hazards described below.

• Additional hazards may exist if the equipment is not

operated according to the instructions in the user guide.

B. Regulatory and Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 B-3

The following safety symbols are used throughout this manual.

Symbol Definition

General warning of potential damage or

danger from a variety of sources

Electrical grounding connection.

Pinch hazard; keep hands and fingers clear.

B. Regulatory and Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 B-4

Warning Label Placements

A warning label is placed on the rear cover below the top middle

screw. This symbol indicates instrument maintenance must be

performed only by authorized service personnel. Injury can

occur if untrained personnel are servicing the tester with the

rear cover removed.

An electrical grounding symbol is placed on the inside floor of

the tester casing.

A warning label placed on the front of the heater/circulator alerts

the operator to the fact that the PolyScience manual must be

studied before operating the heater.

B. Regulatory and Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 B-5

Pinch Hazards

There is a potential pinch point between the top of the basket

arms and the top edge of the slots through which the basket

arms extend when the arms travel to their uppermost position.

Although there is a clearance of about 15 mm (0.6 inches)

between the top of the arm and edge of the slot, and although

the arms cannot move further because the drive mechanism

prevents it, the operator should nevertheless keep clear of the

arms while they are moving.

A similar potential pinch point exists between the bottom edge

of the arms and the bottom edge of the slots when the arms are

fully lowered. The risk of injury is low since the arms are driven

downward only by gravity. Nevertheless, the operator should

remain clear of the arms while they are moving.

B. Regulatory and Safety

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 B-6

To authorized service personnel

When the back cover is removed, and power is supplied to the

drive motor, multiple components will rotate and slide when the

tester is commanded to run. These components are a potential

pinch hazard. Keeps hands free of this area when power is on.

C. Installation

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 C-1

Tester Installation

Review all safety instructions before proceeding with installation

of the Phase One Disintegration Tester.

The installation process consists of three steps:

1. Selecting an appropriate location, which includes

confirming environmental and space requirements.

2. Reviewing and conforming to electrical requirements.

3. Unpacking and installing the tester into the confirmed

location.

Proceed by following the instructions below.

Environmental Requirements

The installation location should be clean and free of factors that

may affect the integrity of disintegration testing results, such as

excessive vibration and significant variations in temperature.

Space Requirements

Please refer to Specifications section for space requirements

based on the physical dimensions of the tester.

The bench should be level and flat. It must be capable of

supporting the full weight (including water) of the tester.

Electrical Requirements

Each tester requires two grounded outlets within 1 meter (3 feet)

of the system—one for the disintegration tester, and one for the

heater/circulator. See power requirements in previous section.

Power cords must meet the following specifications: IEC 320-

C13 connector; SJT 18AWG, 3C, 60 °C, 300 V.

Unpacking and Inspection

Note: Moving, lifting, and carrying the Hanson Phase One

Disintegration Tester requires two people working together to

prevent damage to the instrument. Lift the instrument by the

bottom plate while supporting the back of the tester to prevent

it from tipping. The tester weighs 65 lbs. (29.5 kg).

Review all safety

instructions before

proceeding!

C. Installation

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 C-2

Unpack the Tester

While unpacking the tester, first make note of any damage to

the shipping container. If the container is damaged, contact the

shipper immediately.

1. Remove straps from shipping container.

2. Slide box up and away from enclosed components.

3. Remove any accessory boxes.

4. Carefully remove tester from shipping container.

5. Remove blue tape securing arms and remove plastic

wrap covering the bath lid.

6. Remove the bath lid.

7. Clean waterbath of packing material or other debris.

8. Place tester in final location on bench.

Assemble the Tester

1. Place heater into bath compartment (do not secure).

2. Install bath lid on top of bath while centering the heater

in the slot in the bath lid.

3. Clamp heater into place using knob on back of heater.

4. Use the cable clamps provided with the tester to route

the heater power cable, if desired.

5. Note: beakers and baskets cannot be installed until the

tester is initialized (Section D – Operation).

Electrical Connections

1. Ensure power switch on left back side of tester is in the

Off (O) position.

2. Ensure power switch back of heater unit is in the Off

(O) position.

3. Insert power cable into back of tester; plug outlet end

into power source.

4. Plug heater power cord into power source outlet.

D. Operation

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 D-1

Operation

Please review and follow all safety and installation instructions

before operating the Phase One Disintegration Tester. Before

turning on power to the unit, fill the bath with deionized water,

or better, to the line indicated on the front of the bath (without

beakers in place).

Power on the Tester

The power switch for the tester is located on the back side of

the unit. The switch is oriented for horizontal activation (toggle

to the left—-ON; toggle to the right—OFF (as viewed from the

front of the unit).

From the front of the tester reach around to the lower left back

corner to toggle the switch to the ON position. Except for

servicing, troubleshooting, operator preference, or protocol,

there is no need to turn the unit off after this.

The basket arms will not move when the tester is first powered

on. The LCD interface will display the Hanson name and logo

for a few seconds, along with the firmware version number as

shown below.

Fill bath before

turning on heater.

D. Operation

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 D-2

Initializing the Tester

With the unit powered on, the orange logo lens will begin

flashing, indicating an operator action is required. The

INITIALIZE screen will appear, instructing the operator to push

the control knob, with a caution that the arms will begin moving.

When the control knob is pressed, the arms will begin seeking

the HOME position, also called the LIFT position, in which the

baskets are raised completely out of the beakers.

When the initialization process is complete, the orange logo

lens will stop flashing and the main menu screen shown below

will appear on the display.

D. Operation

Phase One Disintegration Tester User Guide—40-108-001 Rev. A—14 November 2016 D-3

Screen Navigation Using the Control Knob

Rotating the control knob at this screen will highlight the three

most frequently used options of the instrument—TIMED TEST,

TOOLS MENU, and FREE RUN.

As each option is highlighted on the screen, a description of that

function is shown at the bottom of the display. Pushing the

control knob activates the highlighted option.

As each new screen is displayed, turning the control knob left

and right will highlight the options available on that screen. For

example, the green, yellow, and blue circles shown below

illustrate how an operator can reach various functions on other

screens by pushing the control knob at each circled option.

This manual suits for next models

2

Table of contents

Other Hanson Laboratory Equipment manuals