Hanson Media-Mate Plus User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

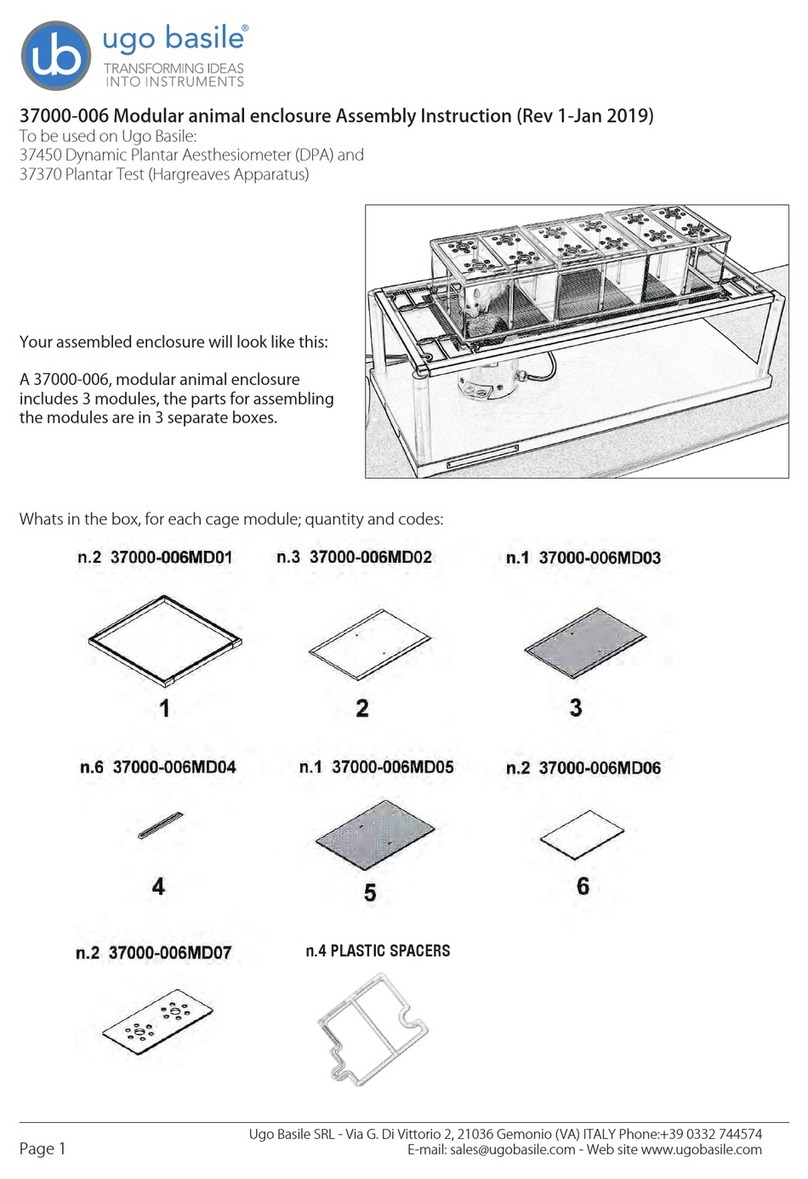

Media-Mate Plus

Operation Manual

25-710-800 Rev. O

DATE: 23Apr2015

Media-Mate Plus: p/n 25-710-101

Hanson Research Corporation

9810 Variel Avenue •Chatsworth, CA 91311 USA

(800) 821-8165 •(818) 882-7266 •FAX (818) 882-9470

www.hansonresearch.com

2014 Hanson Research Corporation

This product is covered under one or more of the following US Patents: 3,572,648 4,108,602 4,274,286 5,198,109 5,296,139 5,639,953 5,639,974 5,682,001

6,006,777 6,076,410 6,422,098 Des.377,152 Des.424,458 & Other Patents Pending.

(blank page)

Media-Mate Plus Operation Manual 25-710-800-O

Table of Contents

What’s New________________________________________________________________________ iii

Section One – Safety Considerations ____________________________________________ 1

General____________________________________________________________________ 1

Safety Markings_____________________________________________________________ 1

Section Two – Introduction _____________________________________________________ 3

Design Features ____________________________________________________________ 3

Section Three – Specifications __________________________________________________ 4

Section Four – How It Works____________________________________________________ 5

Section Five – Installation ______________________________________________________ 9

Location___________________________________________________________________ 9

Unpacking _________________________________________________________________ 9

Parts Identification _________________________________________________________ 10

System Check-out__________________________________________________________ 10

Installation ________________________________________________________________ 14

Start Up __________________________________________________________________ 15

Section Six – Validation and Calibration _________________________________________ 16

Pre-Heat Temperature Calibration_____________________________________________ 16

Adjustment of Sensor Display Temperature ____________________________________ 16

Volume Delivery Calibration _________________________________________________ 17

Fine Adjustment of the Delivery Volume _______________________________________ 17

Deaeration Validation _______________________________________________________ 20

Temperature Controller (PID) Set-Up __________________________________________ 20

Temperature Calibration Record______________________________________________ 21

Volume Calibration Record __________________________________________________ 22

Deaeration Validation Record ________________________________________________ 23

Section Seven – Operating Instructions _________________________________________ 24

Volume Selection __________________________________________________________ 24

Temperature Setting________________________________________________________ 24

Fill Time Setting ___________________________________________________________ 25

Configuring the Dispense Head ______________________________________________ 26

Media-Mate Plus Interface with Distek 2100 and 2100B ___________________________ 27

Test Cycle ________________________________________________________________ 29

Table of Contents i

Media-Mate Plus Operation Manual 25-710-800-O

Section Eight – Troubleshooting _______________________________________________ 30

Volume Delivery Problems___________________________________________________ 30

Temperature Control Problems_______________________________________________ 30

Deaeration Problems _______________________________________________________ 31

Service Procedures ________________________________________________________ 31

Liquid in Vessels___________________________________________________________ 32

Section Nine – Maintenance ___________________________________________________ 33

General Cleaning___________________________________________________________ 33

Cleaning the Media Tank and Fluid Lines ______________________________________ 33

Lubrication________________________________________________________________ 34

Replacing the Filter Element _________________________________________________ 34

Fuse Replacement _________________________________________________________ 35

Section Ten – Moving and Storage______________________________________________ 37

Storage___________________________________________________________________ 37

Moving ___________________________________________________________________ 37

Section Eleven – Parts, Supplies, and Accessories ________________________________ 38

Spare Parts and Kits________________________________________________________ 38

Tools and Accessories______________________________________________________ 38

Section Twelve – Sales and Support ____________________________________________ 39

Section Thirteen – General Warranty ____________________________________________ 40

Table of Contents ii

Media-Mate Plus Operation Manual 25-710-800-O

What’s New

Revision O

Section Three - Specifications

Changed Tank Capacities to “about 18 liters”.

Section Seven – Operating Instructions

Changed Temperature Setting to “at least the 18-liters mark.”

Section Eight – Troubleshooting

Changed Temperature Control Problems to “Fill Tank to at least the 18-liter mark.”

Revision M

Section Six – Validation and Calibration:

Updated Adjustment of Sensor Display Temperature steps.

Updated new Watlow controller.

Section Seven – Operating Instructions:

Added newer dissolution tester models.

Revision L

Section Three – Specifications:

Changed “Media Tank Volume (unusable)” to 2 L to reflect low volume tank upgrade.

Revision K

Section Five – Installation:

Added photo of filter housing.

Section Seven – Operation:

Adjusted fill time recommendations for new 0.007” gap fill tubes.

Section Nine – Maintenance:

Added procedure for replacing filter on systems equipped with a filter housing.

Section Eleven – Parts, Supplies, and Accessories:

Added new fill tube to parts list.

Revision J

Section Six – Validation and Calibration:

Calibration Gauge Set (p/n 91-902-045) added.

Section Eleven – Parts, Supplies, and Accessories

Numerous spare parts, kits, tools, and accessories added.

Section Twelve – Sales and Support

Hanson Research Corporation contact information and procedure updated.

What’s New iii

Media-Mate Plus Operation Manual 25-710-800-O

Section One – Safety Considerations

General

1. The Instrument should be on its own circuit to prevent problems and circuit overload.

2. Never work on the electrical components in the system while there is power to the

Instrument. Disconnect power: Do not run Instrument with the protective cover

removed from the electrical control cabinet.

3. Do not fill the tank through the filter port on the tank; the Instrument may not handle the

back-pressure.

4. Review all safety and environmental precautions pertaining to any chemicals that are to

be used in conjunction with this Instrument.

Safety Markings

For your own safety, you must observe the following safety warning signs. The safety warning

signs indicate a possible source of danger and provide preventative information.

Sign Location Safety Warning

Control Panel

Caution! Keep media and other liquids away from the

control panel and away from all electrical components.

Control Panel

Caution! Do not press start switch until indicator lights

are off.

Control Panel

Caution! Do not restart Instrument with liquid in flasks

without consulting troubleshooting section.

Interface Panel

Heater

Caution: No operator-accessible parts inside. Refer

servicing to qualified personnel only. Risk of electrical

shock. Do not open.

Achtung: Es gibt keine vorn Benutzer zo wanenden

Teile. Oberlassen Sie Reparaturen dem qualifizierten

Service-fachmann. Hochspannung. Nicht öffnen.

Attention: Aucune pièce remplaçable par l’utilisateur.

Toute réparation doit être effectuée par un technicien

qualifié. Risque d’ electrocution. Ne pas ouvrir.

Interface Panel

Caution! Turn Instrument off and remove power cord

before replacing fuses. Fuses must be replaced with

the same current rating and type described next to the

fuse holder.

Heater

Caution! Heater is hot; do not touch.

Section 1 Safety Considerations 1

Media-Mate Plus Operation Manual 25-710-800-O

Sign Location Safety Warning

Interface Panel

Note! Line and Neutral fused separately.

Inside Control

Note! Protective conductor terminal.

Pump Panel

Caution! Withdraw power cord to mark prior to plugging

into grounded electrical outlet. Withdrawing the full

length of the cord may jam the retracting mechanism.

Section 1 Safety Considerations 2

Media-Mate Plus Operation Manual 25-710-800-O

Section Two – Introduction

The Hanson Research Media-Mate Plus is a portable, automatic dissolution prep system. The

Instrument will preheat, filter, measure, deaerate and deliver dissolution media to numerous

Dissolution Test Stations.

Design Features

1. Portable Cart: The cart is compact and easy to maneuver.

2. Control: The electronics are enclosed within the cart for protection and may be easily

removed for service. The control panel is a user-friendly design with digital readout of

actual media temperature and temperature set point.

3. Pressure/Vacuum Air Pump: The air pump is enclosed within the cart frame for quiet

operation. It is easily removed for service.

4. Dispense Head: The dispense head connects to the dispense tubing with quick

disconnects and is user-configurable for filling six or seven dissolution vessels in parallel.

The dispense head is designed to interface with the Hanson Research SR-6, SR-8, and

SR8-Plus Dissolution Test Stations as well as most test stations made by other

manufacturers.

5. Heater Assembly: The heater is an integral design comprised of the heater element,

temperature sensor, overload sensor, and level sensor. The heater is easily removed for

cleaning or for placement in spare media tanks.

6. Volume Setting: The dispense volume is user-selectable from 250 to 1000 mL in 50 mL

increments. The measure system has been factory-calibrated and is easily recalibrated

by the user.

7. Media Tank:The tank is chemically inert and is equipped with a 5-micron filter and

standard hose bib for quick and easy connection. The tank is easily removed for cleaning

or for replacement with spare tanks. A chemically inert cover prevents evaporation and

provides a docking location for the dispense head.

8. Retractable Cord Reel: The Instrument is equipped with a 14-gauge, 3-conductor, 20 ft

cord-reel.

Section 2 Introduction 3

Media-Mate Plus Operation Manual 25-710-800-O

Section Three – Specifications

Weight

Without media:

67 kg (148 lbs)

With 40 liters of media:

107 kg (236 lbs)

Size

Length:

80.9 cm (31.9 in.)

Width:

53.4 cm (21.0 in.)

Height:

114.0 cm (44.8 in.)

Electrical

Voltage:

115 VAC or 230 VAC ± 10%

Frequency:

50/60 Hz

Current:

13 Amp (115 VAC) or 8 Amp (230 VAC)

Phase:

single

115 VAC Units

230 VAC Units

4 Fuses (TT Type):

One 1/2 Amp, 250 VAC,

One 3/4 Amp, 250 VAC,

One 8 Amp, 250 VAC,

One 15 Amp.

One 1/2 Amp, 250 VAC,

One 3/8 Amp, 250 VAC,

One 5 Amp, 250 VAC,

One 8 Amp, 250 VAC.

Environment

Maximum ambient temperature:

5°C below temperature set point

Maximum humidity:

<85 %

Performance

Cycle time:

less than 5 minutes

Pre-heat temperature range:

30°C to 45°C

Pre-heat temperature control accuracy:

± 0.5°C

Pre-heat temperature readout accuracy:

± 0.2°C

Pre-heat time (21 to 37 deg C):

60 minutes

Delivery volume range:

250 mL to 1000 mL

Delivery volume accuracy:

± 1.0 %

Deaeration:

95% saturation maximum

Filtration:

5 micron nominal

NOTE: Accuracy may be improved by fine adjustment (see

Section 6 – Fine Adjustment of the Delivery Volume).

Tank Capacities

Media Tank Volume (usable):

40 liters (10.5 gal)

Media Tank Volume (unusable):

2 liters (0.53 gal)

Media Volume to Top of Filter:

8 liters (2.1 gal)

Media Volume when low water level sensor turns heater off:

about 18 liters

Materials Wet

Tank

High Density Polyethylene

Heater

Teflon Coated

Filter

Polyethylene

Flask

S.A.N (Styrene/Acrylic/Nitrile)

Fittings and Fill Hose

PVC

Tubing

Stainless Steel and Tygon

Section 3 Specifications 4

Media-Mate Plus Operation Manual 25-710-800-O

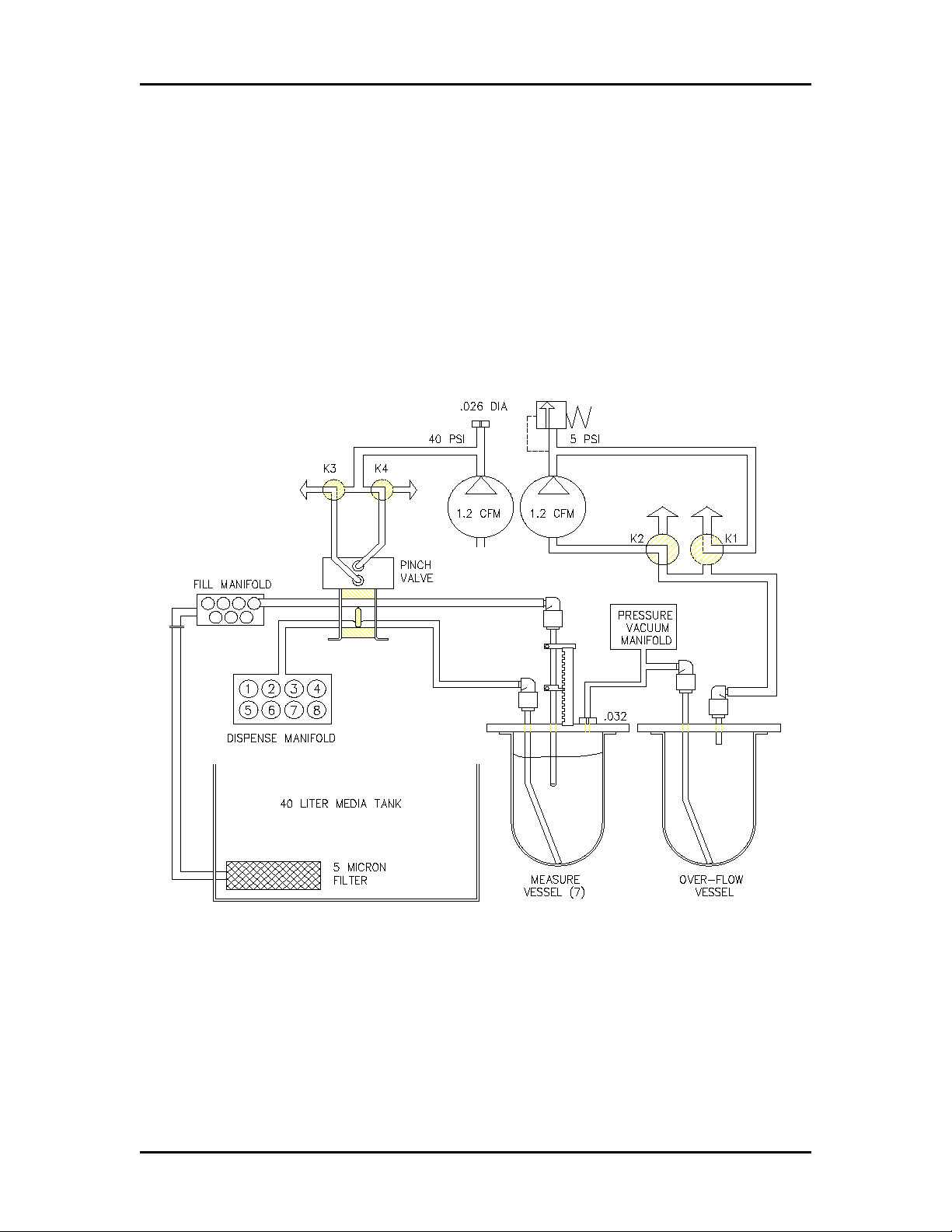

Section Four – How It Works

The Hanson Research Media-Mate Plus uses a self-tuning PID controller and a Teflon heater

to heat the media. Media is moved by low pressure or vacuum and directed by a two-position,

multi-channel pinch valve. The media is deaerated by a thin film vacuum process. The media

volume is accurately measured by a user-set incremental measuring system. A programmable

timer controls the following sequence of events:

1. Fill (Fill Light “ON”)

Vacuum draws heated media from the media tank into the measure vessels. The fill time

thumbwheel has been set such that actual fill time is sufficient to fill measure vessels slightly

above the required volume. The media is deaerated during the fill cycle by thin film vacuum

technology.

Figure 4-1

Section 4 How It Works 5

Media-Mate Plus Operation Manual 25-710-800-O

2. Level (Level Light “ON”)

Pressure in the measure vessels returns excess media back to the media tank. The volume

of media remaining in the vessels is the amount set by the adjustment of the incremental

standards.

Figure 4-2

Section 4 How It Works 6

Media-Mate Plus Operation Manual 25-710-800-O

3. Dispense (Dispense Light “ON”)

The pinch valve is shifted, opening the dispense lines and closing the fill lines. Pressure in the

measure vessels delivers media out the dispense manifold.

Figure 4-3

Section 4 How It Works 7

Media-Mate Plus Operation Manual 25-710-800-O

4. Standby (no lights on)

The Instrument is waiting for the operator command to start a cycle. Air flows through the

measure vessels and out the fill lines into the media tank. This provides media circulation for

optimum temperature control.

Figure 4-4

Section 4 How It Works 8

Media-Mate Plus Operation Manual 25-710-800-O

Section Five – Installation

Location

Environment

The media tank temperature must exceed ambient room temperature by at least 5°C for

maximum performance of the temperature control system. Therefore, for best results, the

ambient temperature should not be allowed to exceed 32°C (90°F) for 37°C tests, or 27°C

(81°F) for 32°C tests.

Easy access to a water source and waste disposal for filling and emptying of the waterbath is

convenient, although not necessary.

Space

The Media-Mate Plus System is designed to be mobile up to 6.25m (20 ft). The laboratory floor

should be level and flat to prevent the Instrument from moving when left unattended.

Electrical

The Media-Mate Plus System requires a single, grounded electrical outlet, within 5.63 m (18 ft)

of the location of the Instrument.

The Instrument is available in two configurations, 115VAC and 230VAC. The voltages are set

at the factory and cannot be changed (see model number label on control interface panel next

to fuses to determine voltage). The electrical requirements are summarized in Section 3 of this

operation manual.

Unpacking

The Media-Mate Plus is shipped fully assembled in one box. The shipping box is specifically

designed to provide maximum shipping protection and to facilitate unpacking. The shipping

box consists of a lower cardboard tray secured to a pallet with a large box placed over the

Instrument. The upper box is strapped to the lower tray and pallet.

NOTE: Shortages or damages must be reported immediately to the freight carrier and to Hanson

Research. Notify Hanson Research by telephone (818) 882-7266 or FAX (818) 882-

9470.

To Unpack:

1. Move package close to final destination with pallet-moving equipment.

2. Cut and remove straps.

3. Remove upper box taking care not to damage box.

4. Remove Instrument from box.

5. Reassemble empty box and store for possible future use.

Section 5 Installation 9

Media-Mate Plus Operation Manual 25-710-800-O

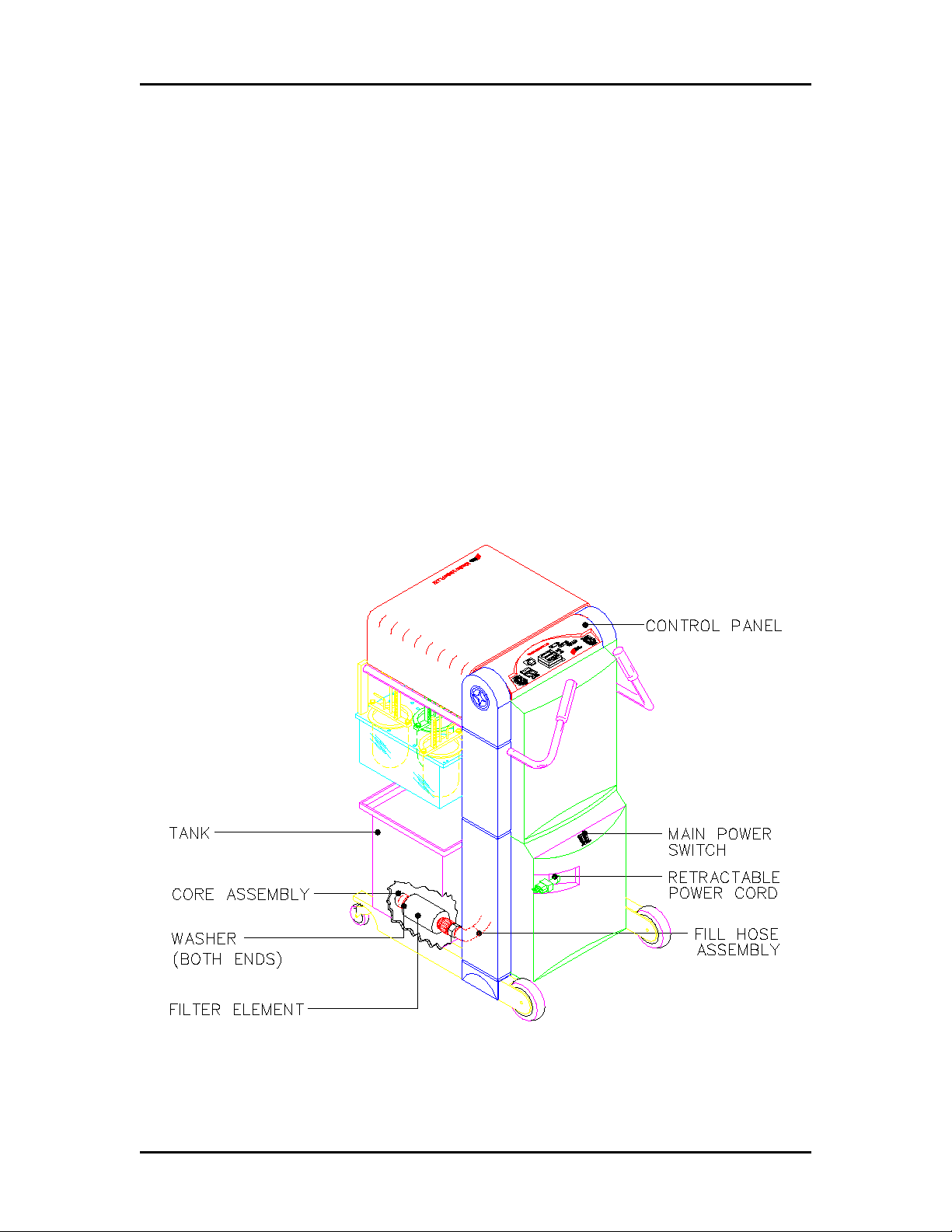

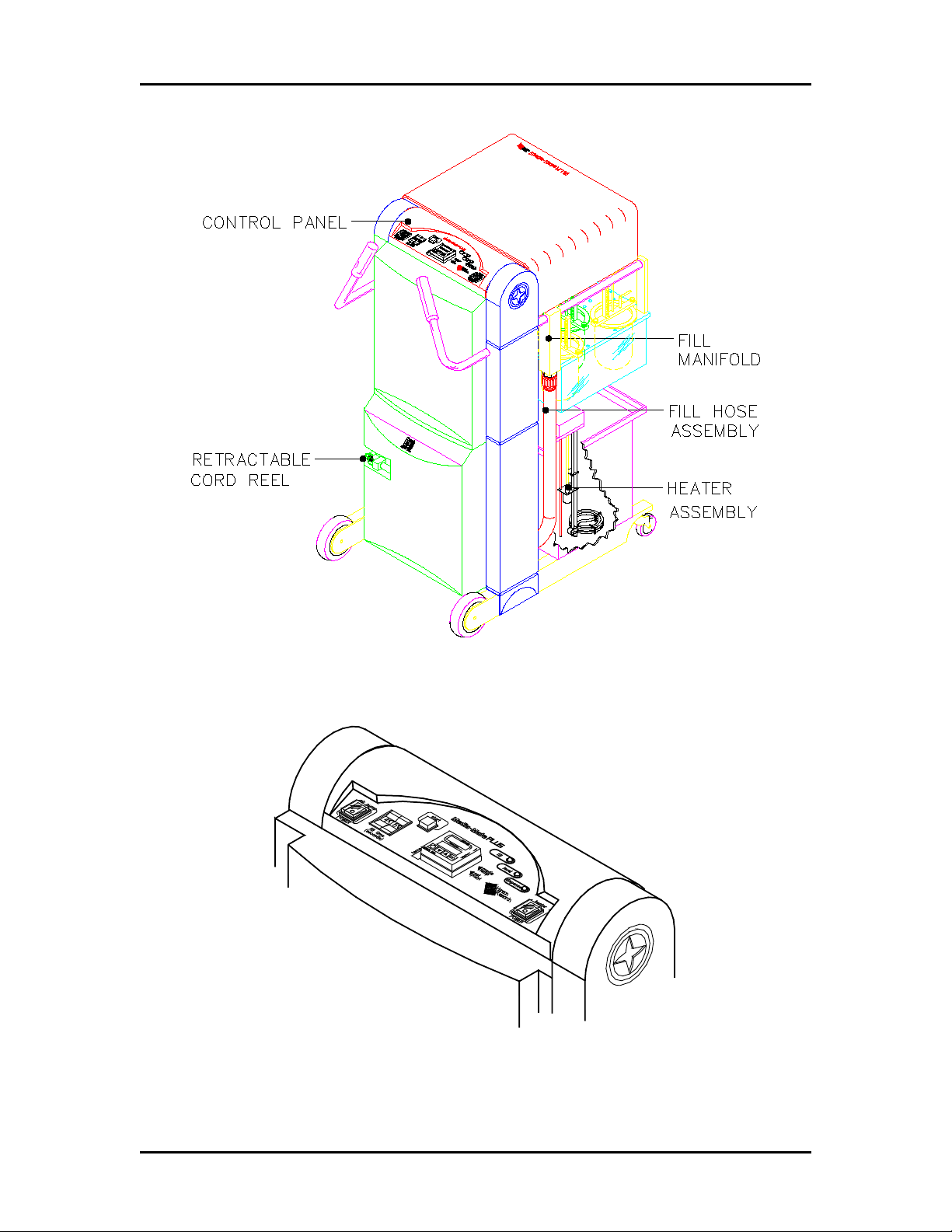

Parts Identification

Throughout this operation manual, reference is made to various components by name. Figures

5-1 through 5-6 are provided to assist in the visual identification of these components.

System Check-out

1. After removing the Instrument from the box, remove all other shipping materials.

2. Visually inspect the Instrument for damage or missing parts

3. Remove the Heater Assembly from its shipping position within Tank.

4. Remove Dispense Head (see Figure 5-5) from shipping position within Tank, remove from

bubble pack, and place as shown.

5. Ensure filter housing has slots facing down.

6. Visually inspect all electrical and pneumatic connections at Interface Panel.

7. Review Operating Instructions. (see Section 7)

Figure 5-1

Section 5 Installation 10

Media-Mate Plus Operation Manual 25-710-800-O

Figure 5-2

Figure 5-3: Control Panel

Section 5 Installation 11

Media-Mate Plus Operation Manual 25-710-800-O

Figure 5-4: Interface Panel

Figure 5-5

Section 5 Installation 12

Media-Mate Plus Operation Manual 25-710-800-O

Figure 5-6

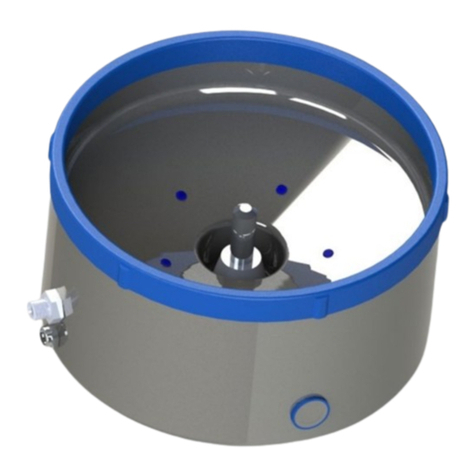

Filter Housing Assembly

Note: The filter housing assembly will function best if the slots are facing the bottom of the tank.

Removed from tank to provide clear view. Clear Filter housing shown only to provide clarification

on function.

Section 5 Installation 13

Media-Mate Plus Operation Manual 25-710-800-O

Installation

CAUTION

The Instrument should not be plugged in until installed as per the instructions below.

1. Clean the inside of the Tank as necessary to remove any packing debris and fill with

approximately 40L of DI water (see Section 9 – Cleaning the Tank and Fluid Lines).

2. Install the Heater Assembly into the Tank as shown (see Figure 5-2). Place Tank Cover

onto Tank (see Figure 5.5).

CAUTION

The filled Tank is heavy and solution may spill. This installation requires two people. The

person holding and pushing the Tank onto the Cart legs should be capable of supporting

the weight of the Tank.

3. One person aligns the Media-Mate Plus cart legs with steps on Tank from the back. Tip

the Tank just enough so that the Cart legs can be pushed under the Tank. Lift the opposite

side of the Tank and push as you slide the Cart legs under.

HINT: Keep the front wheels of the Cart straight.

4. Remove the Fill Hose Assembly from its holding position on the side of the Tank and

connect to the Fill Manifold (see Figure 5-2).

5. Connect the Heater connector into the Interface Panel (see Figure 5-4).

6. Connect the Dispense Tubing to the Dispense Head and position over the holes in the

Tank Cover (see Figure 5-5).

NOTE:Configure the Dissolution Test Station Vessel Pattern (see Section 7 – Configuring

the Dispense Head).

Section 5 Installation 14

Table of contents

Other Hanson Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Fisher Scientific

Fisher Scientific Fisherbrand Isotemp FBG Series Installation and operations

Memmert

Memmert HPPeco quick start guide

Xiitech

Xiitech 1060 Operation Intructions

Esco

Esco Labculture PLUS LP2-4S Series manual

Micronic

Micronic Tracxer TS201 Getting started

Ametek

Ametek TMC CleanBench Aktiv user guide

Cascade Sciences

Cascade Sciences CVO-2-HT Installation and operation manual

Agilent Technologies

Agilent Technologies Intuvo 900 Safety manual

Ocean Optics

Ocean Optics HL-2000-FHSA Installation and operation manual

Buchi

Buchi DuMaster D-480 Operation manual

Fluke

Fluke Micro-Bath 7102 user guide

Keysight

Keysight PV8900 Series Operating and service guide