MG0103E070216

HEAD OFFICE

1381-3, Juan-Dong, Nam-Gu Incheon, Korea

TEL:(82-32)876-4697 FAX:(82-32)876-4696

MAIN PRODUCTS

- DIGITAL : Temperature Controller, Counter, Timer,Speedmeter,

Tachometer, Panel Meter, Recorder

- SENSOR : Proximity Switch/Photo Electric Sensor,

Rotary Encoder, Optical Fiber Sensor,

Pressure Sensor

- ANALOG : Timer, Temperature Controller

Digital Gas Indicator

HDM3

We appreciate you for purchasing HanYoung NUX Co.,Ltd

product. Before using the product you have purchased,

check to make sure that it is exactly what you ordered.

Then, please use it following the instructions below.

INSTRUCTION MANUAL

Before you use, read safety precautions carefully, and use this product

properly. The precautions described in this manual contain important

contents related with safety; therefore, please follow the instructions

accordingly. The precautions are composed of DANGER, WARNING and

CAUTION.

There is a danger of occurring electric shock in the input/output terminals

so please never let your body or conductive substance is touched.

1.If there is a concern about a serious accident caused by a malfunction

or abnormality of this product, please install an external protection

circuit and devise a scheme for preventing an accident.

2.This product does not contain an electric switch or fuse, so the user

needs to install a separate electric switch or fuse externally.

(Fuse rating: 250V 0.5A)

3.There is voltage output of 24V built in this indicator.

4.Do not use load of more than 700mA.

5.To prevent defection or malfunction of this product, apply a proper

power voltage in accordance with the rating.

6.When altering the usage input range (SH, SL), ensure this is altered

prior to anything else. When the SH, SL are altered, it impacts the

other data and may generate unwanted results.

7.To prevent electric shock or malfunction of product, do not supply the

power until the wiring is completed.

8.Since this product is not designed with explosion-protective structure,

do not use it any place with flammable or explosive gas.

9.Do not decompose, modify, revise or repair this product. This may be a

cause of malfunction, electric shock or fire.

10.Reassemble this product while the power is OFF. Otherwise, it may be

a cause of malfunction or electric shock.

11.If you use the product with methods other than specified by the

manufacturer, there may be bodily injuries or property damages.

12.There is a possibility of occurring electric shock so please use this

product after installing it onto a panel while it is operating.

1.The contents of this manual may be changed without prior notification.

2.Make sure that there is no damage or abnormality of the product

during the delivery.

3.Use this product within the range of the operating ambient

temperature, 0 ~ 50 (When it is closely installed Max 40 ) and

ambient humidity, 20 ~ 90 % RH (No condensation).

4. Do not use this product at any place with occurring corrosive

(especially noxious gas or ammonia) or flammable gas.

5. Do not use this product at any place with direct vibration or impact.

6. Do not use this product at any place with liquid, oil, medical

substances, dust, salt or iron contents. (Use at Pollution level 1 or 2)

7. Do not polish this product with substances such as alcohol or benzene.

(Use neutral detergent.)

8. Do not use this product at any place with a large inductive difficulty or

occurring static electricity or magnetic noise.

9. Do not use this product at any place with possible thermal

accumulation due to direct sunlight or heat radiation.

10.Install this product at place under 2,000m in altitude.

11.When the product gets wet, the inspection is essential because there is

danger of an electric leakage or fire.

12.To avoid an effect of inductive noise to input signal cables, use the

product after separating the input signal cables from power, output and

load cables.

13.Separate an input signal cable from an output signal cable. If

separating is not possible, please use the input signal cable after

shielding it.

14.If there is excessive noise from the power supply, using insulating

transformer and noise filter is recommended. The noise filter must be

attached to a panel which is already connected to a ground and the

wire between the filter output side and power supply terminal must be

short as possible.

15.If twisting the power cables closely together then it is effective against

noise.

16.Turn the power OFF when replacing a sensor.

17.The front of this machine is waterproof, in accordance to IP65,

however, as for the meter and panel, the attached gasket must be

used in order to ensure waterproof property. Therefore, please be sure

to insert the gasket in between the panel and the meter unfolded.

18.Do not connect anything to the unused terminals.

19.After checking the polarity of terminal, connect wires at the correct

position.

20.When this product is connected onto a panel, use a circuit breaker or

switch approved with IEC947-1 or IEC947-3.

21.For the continuous and safe use of this product, the periodical

maintenance is recommended.

22.Some parts of this product have limited life span, and others are

changed by their usage.

23.The warranty period for this product including parts is one year if this

product is properly used.

Safety information

WARNING

DANGER

CAUTION

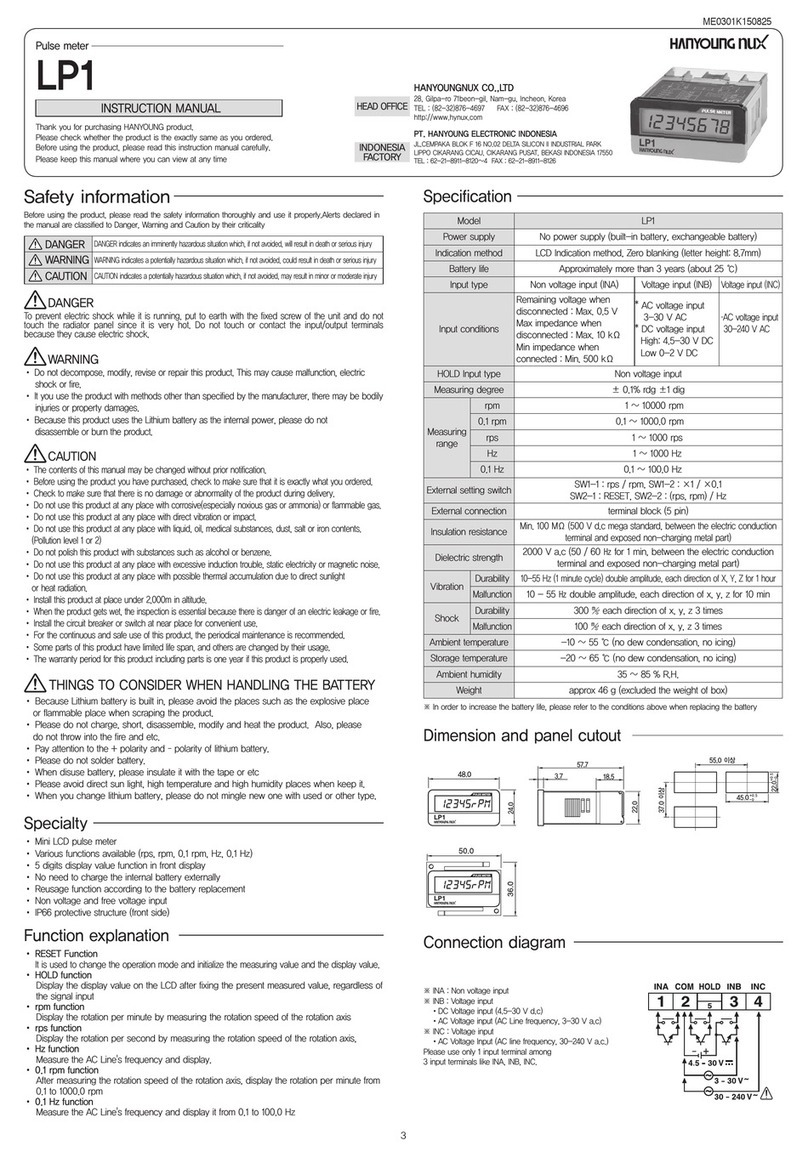

Ratings and Capacity

Dimension and Panel Cutout

Code

Rated Voltage

Input

Output

Insulation resistance

Dielectric strength

Operating condition

Storage condition

100-240 V a.c, 50/60 Hz( 10 %)

Input points : 3 channels

Accuracy : 0.1 % of FS

Sampling cycle : 125 ms 3 channels = 375 ms

Input correction : -100 ~ 100 % of FS

Input Filter : 0 ~ 100 s

Output points : 6 points

Contact capacity : 5 A 240 V a.c, 5 A 30 V d.c

Resolution : 125 ms

Hysteresis : 0 ~ 10 % of FS

500 V d.c 20

2300 V a.c 50/60 Hz for 1 minute

Temperature : -5 ~ 50

Humidity : 20 ~ 90 % RH(No dew condensation)

Temperature : -25 ~ 70

Humidity : 5 ~ 95 % RH(No dew condensation)