9

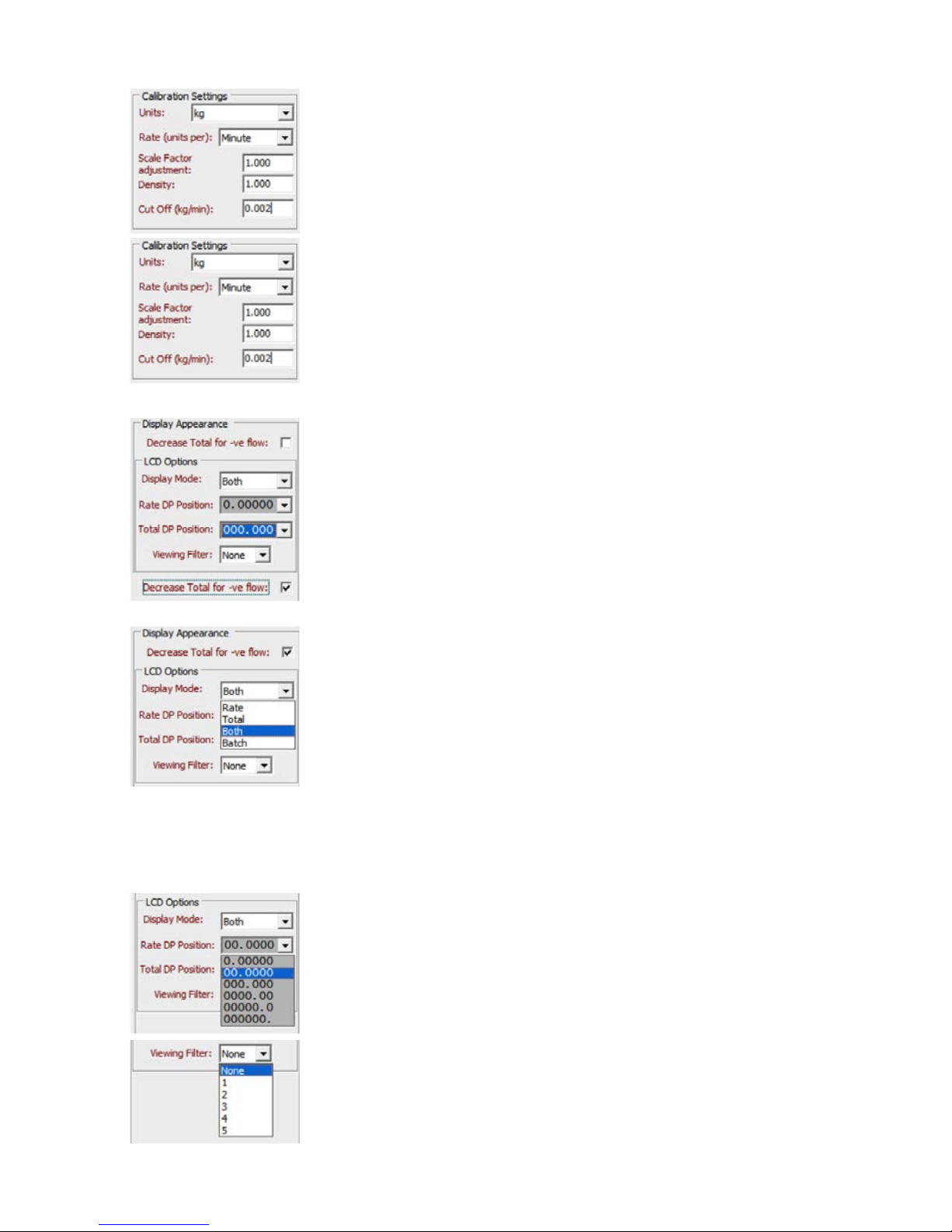

Scale Factor Adjustment: This is a fine tune adjustment on the

signal to compensate for errors introduced by erratic flow or other

system irregularities DENSITY: The flowmeter is fundamentally a

volumetric device but a density figure can be entered here if one

of the mass units are selected. Caution must be used however

as there is no temperature/density correction.

Cut Off: Flow values below this level will be set to zero.

DISPLAY APPEARANCE:

Decrease Total for -ve flow: The meter will not register negative

flow unless this box is checked.

For reverse flow the rate will show a “-“ sign before the rate

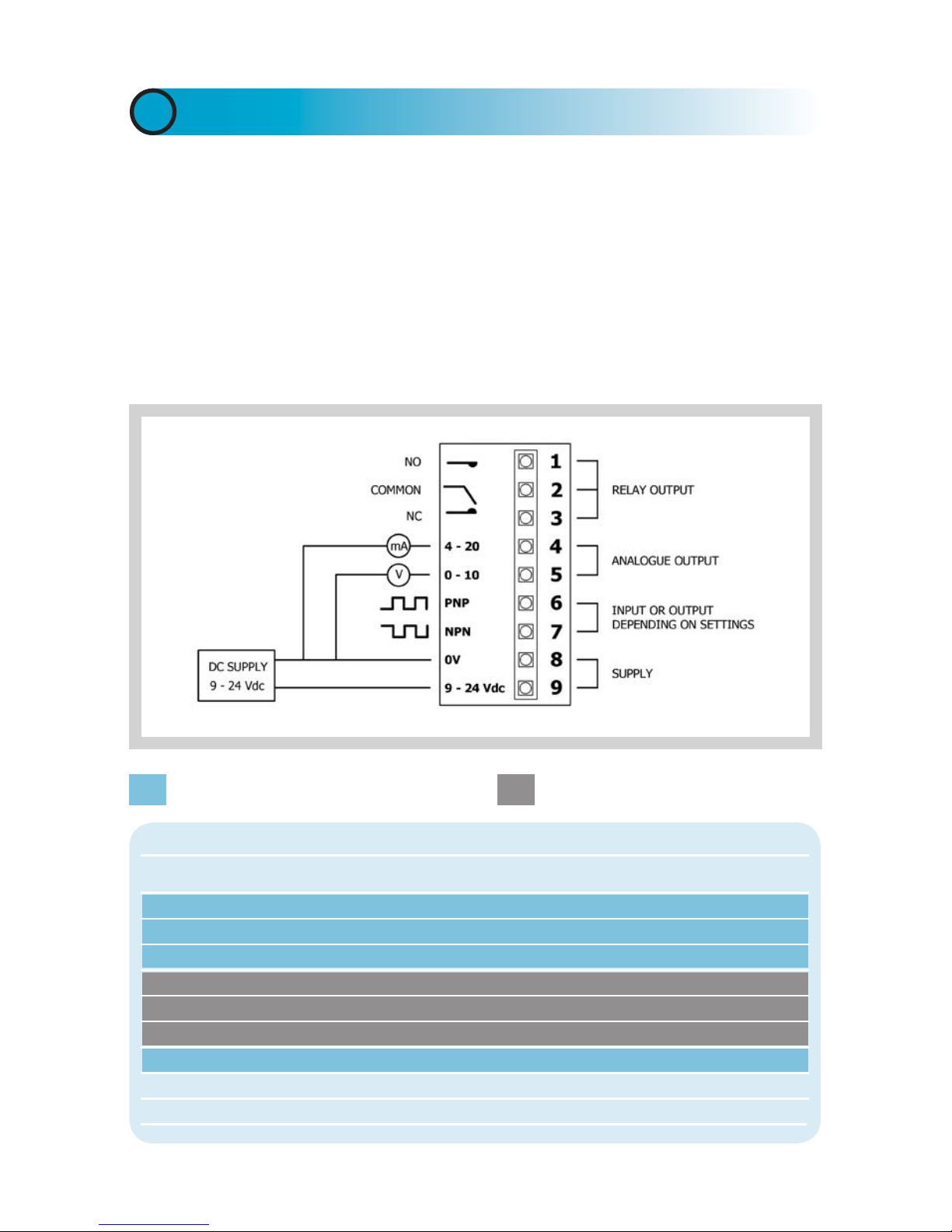

and the total will be reduced accordingly. One of the transistor

outputs (PNP or NPN on Pin 6,7 or Pin 8) could be configured to

give a logic level when reverse flow is detected. Once selected

the totaliser will adjust with the negative flow and the NPN and

PNP outputs will give a pulse output in proportion to the reverse

flow seen. The analog pins will not give outputs.

Display Mode: The down arrow selects from the various display

and Metraflow functions.

The options are:-

Rate – The display will show flow rate only.

Total – The display will show total flow only.

Both – The display can be cycled from rate to total using the

left hand button on the Atrato or the left button in the “Real time

window”. The TOTAL can be Reset at any time on the display

model by pressing the Right Hand Button when the Total is being

displayed. Alternatively, a remote input can be used if either pin

6 or pin 7 has been utilised.

Rate DP Position: Use the drop down menu to choose the

required decimal point position.

Total DP Position: Use the drop down menu to choose the

required decimal point position.

If the decimal point is set too low and the display value exceeds

the setting capacity the display will show ----oF----.

Viewing Filter: This prevents the display, flow switches and

analogue outputs from jittering with irregularities in the flow

from say a peristaltic pump. The increments are arbitrary with

the degree of damping approximately doubling with each level.

Increments go up to 5, which may take up to a minute to stabilise.