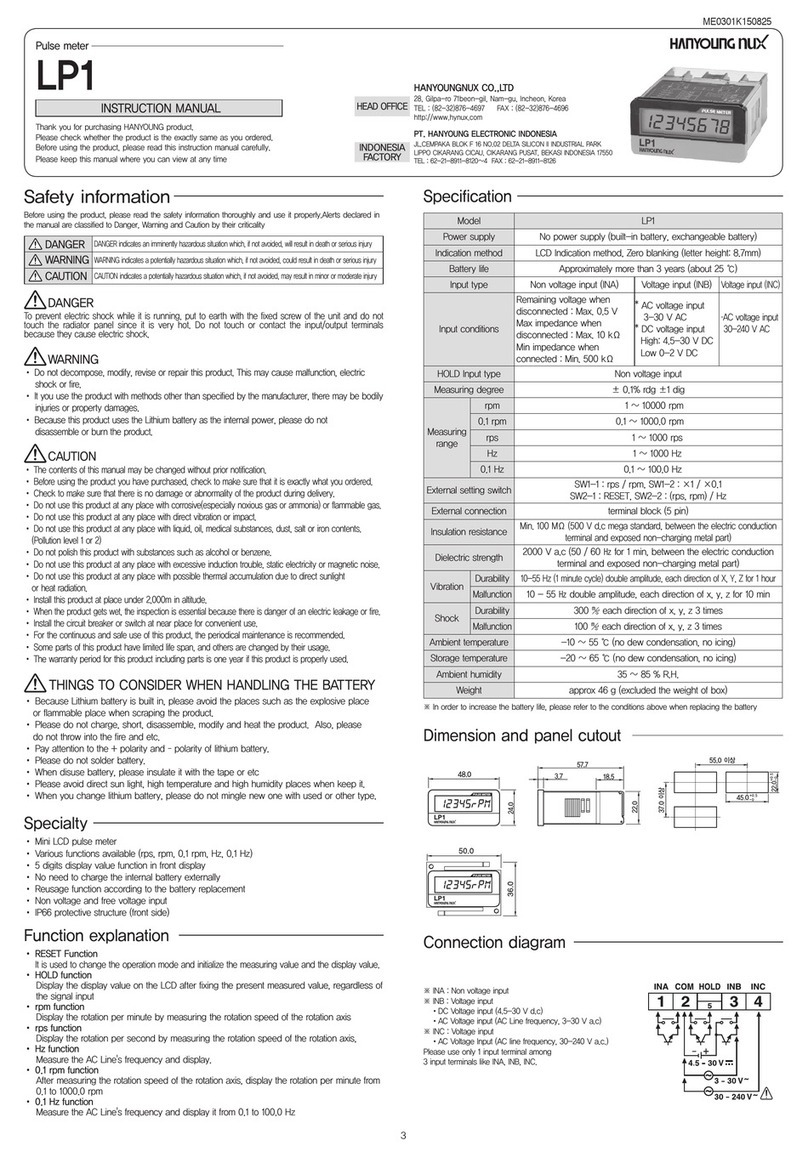

MI0115E080226

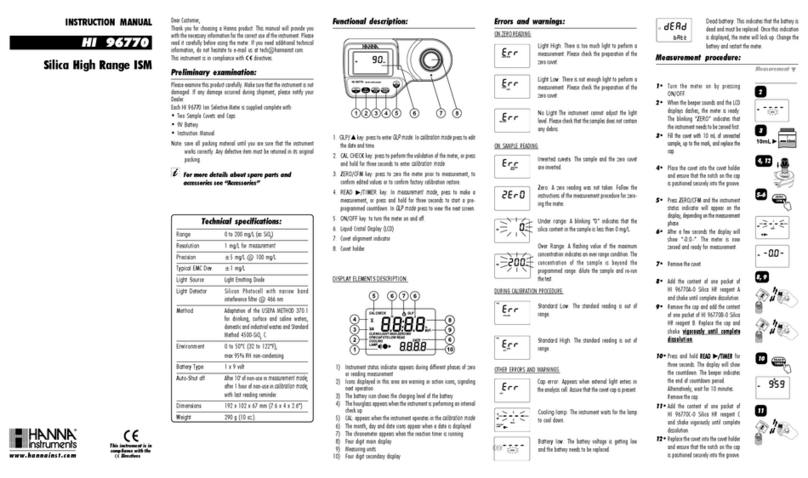

Ratings

Specification

HEAD OFFICE

1381-3, Juan-Dong, Nam-Gu Incheon, Korea

TEL:(82-32)876-4697 FAX:(82-32)876-4696

MAIN PRODUCTS

- DIGITAL : Temperature Controller, Counter, Timer,Speedmeter,

Tachometer, Panel Meter, Recorder

- SENSOR : Proximity Sensor/Photo Electric Sensor,

Rotary Encoder, Optical Fiber Sensor,

Pressure Sensor

- ANALOG : Timer, Temperature Controller

Rotary

Encoder

HE series

Thank you for purchasing HANYOUNG product.

Please check whether the product is the exactly same as

you ordered. Before using the product, please read this

instruction manual carefully.

INSTRUCTION MANUAL

1. If intense vibration or impact is applied on the transmitter for length measurement, the wrong

pulse is generated causing malfunction, therefore, absolute care is necessary when selecting

the installation and disposition location.

2. As much as the amount of pulse per cycle, the slit gap of rotation slit is narrower, therefore can

be easily affected by vibration, and the vibration applied during slow rotation or when

stationary, may get transmitted to the shaft or the main body, causing wrong pulse generation,

therefore, please take caution. The vibration applied to the transmitter for length measurement

can become a cause for wrong pulse generation, so please take caution in terms of

installation location or location for attachment.

An internal pressure of 500V DC exists between the Case and the electric circuit, however, there

are dangers of damage the electrical circuit if voltage is applied accidentally, so do not perform

mega tests.

On Mega Test

1. During installation, do not apply impact on or twist the shaft of the transmitter for length

measurement.

2. During installation, do not apply excessive force when combining the shaft of transmitter for

length measurement and the instrument.

3. During installation, take caution because the life span of the transmitter for length

measurement is dependent on the usage condition and the environment.

4. Do not decompose, modify, revise or repair this product. This may be a cause of malfunction,

electric shock or fire.

5. Reassemble this product while the power is OFF. Otherwise, it may be a cause of malfunction

or electric shock.

On Installation

About vibration

1. Separate an input signal cable from an output signal cable. If separating is not possible,

please use the input signal cable after shielding it.

2. If there is excessive noise from the power supply, using insulating transformer and noise filter

is recommended.

3. Do not connect anything to the unused terminals.

4. After checking the polarity of terminal, connect wires at the correct position.

5. As for wiring, ensure they are as short as possible.

6. Having the same pipe for wiring of the transmitter for length measurement with the power line

or an identical connection could cause malfunction, therefore please take caution.

7. Wrong connection of the wiring of transmitter for length measurement may damage the

internal circuit. Please take sufficient caution.

About Wiring

1. Before using the product you purchased, make sure that it is exactly what you ordered.

2. Make sure that there is no damage or abnormality of the product during the delivery.

3. The transmitter for measuring the length is composed of precision parts, so can easily be

damaged with external impact, therefore handle with care.

4. The shield wire of the transmitter for length measurement is not connected to the case.

5. When the product gets wet, the inspection is essential because there is danger of an electric

leakage or fire.

6. For the continuous and safe use of this product, the periodical maintenance is recommended.

7. If you use the product with methods other than specified by the manufacturer, there may

be bodily injuries or property damages.

Safety information

CAUTION

As for

Rotary Encoder

Case,

connect on the control board case

by 3~5.5MM electric wire. For the

0 V terminal, connect on the

control board case with identical

type of electrical wire and earth it.

Perform as indicated above,

and earth the

Rotary Encoder.

Distance from

control box

30 m Max.

30 m Min.

Wiring of Rotary Encoder

For noise prevention

The caution on the safety stated above, must be kept, otherwise malfunction

can be induced.

Mode

HE40B

40 mm

Shafttype

HE50B

50 mm

Shafttype

Shaftexternal

diameter

6: 6 mm

8: 8 mm

(Option)

8: 8 mm

Phase

type

2 : A,B

3 : A, B, Z

3C : A, B,

/Z

4 : A, /A,

B, /B

6 : A, /A,

B, /B

Z, /Z

(Standard :

A, B, Z)

Pulse number per

revolution

*1,10,50,60,100,

120,200,250,300,360

,400,500,512,600,80

0,1000,1024,2000,20

48,3000,3600,5000

*1,10,50,60,100,

120,200,250,300,360

,400,500,512,600,80

0,1000,1024,2000,20

48,3000,3600,5000

“ * ” mark : Only A, B phase can output (Line Drive output is A, /A, B, /B)

The item that is not in the above revolution is order made product

Output type

O : NPN

Open

collector

N : NPN

Voltage

T : Totem-

pole

L : Line driver

(Line Drive:

5V d.c)

Power

voltage

5: 5V d.c

12: 12V d.c

(5-12V d.c)

24: 24V d.c

(12-24V d.c)

Wire

Specification

Nomark:

Standardtype

C: Connector

HE40B 6600 3 T 24

HE B

-- - -N-

NPNVoltageoutput

A, B, Z phase A,B,Z,A,B,Zphase

Phase difference between A. B phase:

T/4 T/8(Cycle of A phase = T)

300 kHz

5 - 12 V d.c / 12 - 24 V d.c 5 % 5 V d.c 5 %

70 mA Max.(No-load) Line Drive output below 30 mA (No-load)

WIRE

40: 40gf (0.004 N mMax.)

50: 80gf (0.008N m Max.)

40: 40g Max., 50 :80 g Max.

40: Radial: Within2 kgf, Thrust: Within1 kgf

50: Radial: Within2.5 kgf, Thrust: Within1.2 kgf

5000rpm

1.2 x 10

8

/rpm : hour

Over100 (Base on500 Vd.c megabetween terminaland case)

800V a.c(Between terminaland caseat 60Hzfor 1minute)

10~55Hz(Cyclefor 1minute),Doubleamplitudewidth:1.5mm,EachX YZdirectionfor 2hours

40: 50G Max., 50:75G Max.

-10~ 60 (Withoutcondensation), StorageTemperatur :-25 ~85

35~ 85% R.H.

ProtectionIP 50(IEC Standard)

5P, 5.0 mm,Length :1.5 m,Shield cable

(LineDriver Type: 8P, 5.0 mm,Length : 1.5m, Shieldcable)

40: 170g, 50 :200 g

8.0mm Coupling,Bracket ( 40mmBracket Separatesales)

Loadvoltage : 30V Max.

LoadCurrent : 30mA Max.

ResidualVoltage :0.4 VMax.

1Max.

(Cable length 1.5 m / sink=30 mA)

1Max.

(Cablelength1.5m/

sink=10mA)

1Max.

(Cablelength1.5m/

sink=30mA)

ForLow

LoadCurrent:30mA

Max.

ResidualVoltage:0.4V

Max.

ForHigh

LoadCurrent:10mA

Max.

ResidualVoltage:Above

-2.5Vofratedvoltage

ForLowLoadCurrent:

20Max.

ResidualVoltage:0.4V

Max.

ForHigh

LoadCurrent:20mA

Max.

ResidualVoltage:2.5V

Max.

HE B

----O-

NPNOpencollectoroutput

HE B

-- - -T-

TotemPole Output

HE B

-- - -L-

LineDriverOutput

Mode #

Output type

Output type

Phase difference

on Output

Max Response

Frequency

Power voltage

Current

Consumption

Connectionmethod

Control output

Response Time

Starting Torque

Moment of inertia

Permissible Shaft

Loading

Max. Permissible

Revolution

Bearing Life

Insulation Resistance

Dielectric strength

Vibration Resistance

Shock Resistance

Operating Ambient

Temperature

Operating Ambient

Humidity

Protection

Wire Specification

Weight

Accessory

Electrical Specification

Mechanical Specification