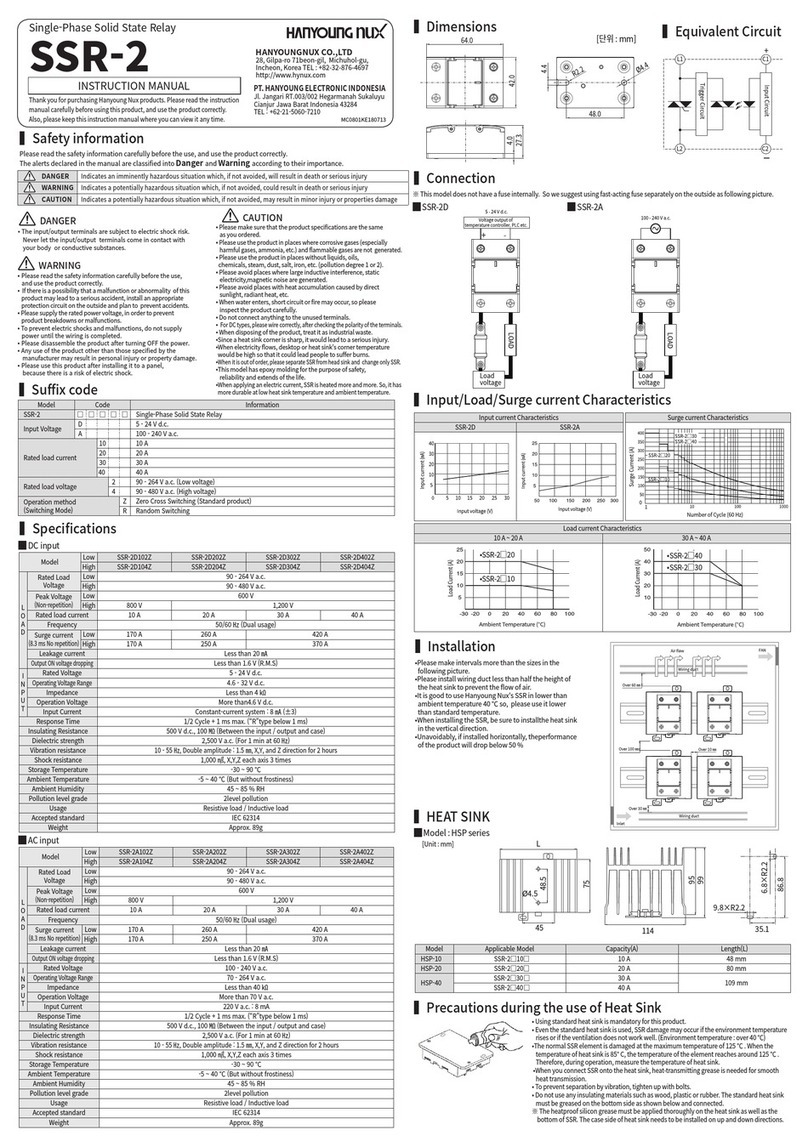

HANYOUNG NUX PFD RM User manual

12-24 V d.c 10 % (Ripple 10 % Max.)

50 mA Max.

Control : Open collector output, 100 mA

Stability :Open collector output, 100 mA

Remote / Reset input

0-1000

400 cps, Up/Down, 0~9999

12~9999 rpm

(Light On) / (Dark On) Output

NORMAL , ON DELAY, OFF DELAY, ONE Shot Time Output

1~9999 ms

Wavelength / 660 nm

Protection circuit from reversed power supply connection, Output short-circuit protection

1ms Max

10 % Max

LED 7, 4 digits FND

Auto-teaching, Manual

Adjustable bightness, 180 rotation display

Display time fixation, Zero reset, Initial reset, Lock function

Sunlignt : 10,000 lx Max., Incandescent lamp : 3,000 lx Max.

Operating : -10 ~+ 55 , Storage : -25 ~ +70 (Without freezing)

35 ~ 85 % R.H.

10-55 Hz(Cycle for 1 minute), Double amplitude : 1.5 mm, in each direction X YZ for 2 hours

500 (50 G), X YZ for 3 times

500 V a.c (50-60 for 1 minute)

Above 20 (500 V d.c)

DIN rail

cable 2 m, 5 P, 4

Bracket

MK0801E080108

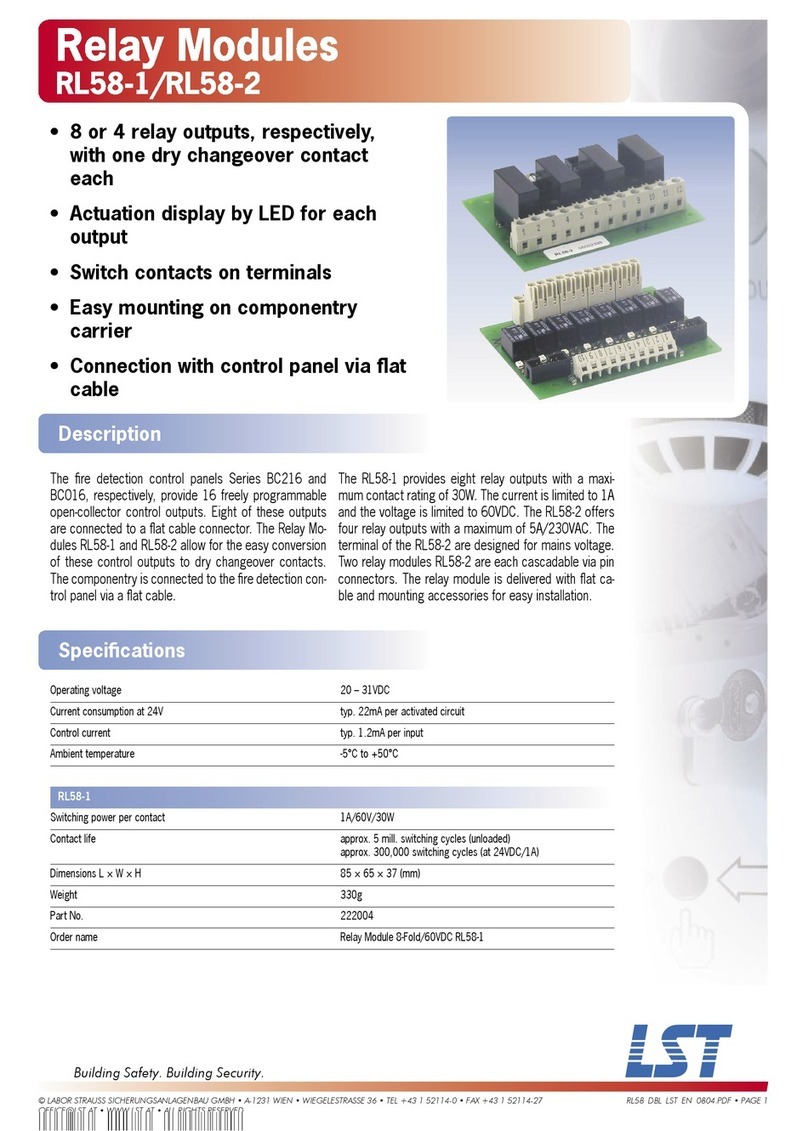

Fiber Sensor Controller

PFD RM

We appreciate you for purchasing HanYoung NUX Co.,

Ltd product.Before using the product you have purchased,

check to make sure that it is exactly what you ordered.

Then, please use it following the instructions below.

1. To prevent defection or malfunction of this product, supply proper power voltage in

accordance with the rating.

2. Since this product is not designed with explosion-protective structure, do not use it at any

place with flammable or explosive gas.

3. Remove this product while the power is off. Otherwise, it may cause malfunction or

electric shock.

4. Due to the danger of electric shock, use this product installed onto a panel while an

electric current is applied.

Before you use, read safety precautions carefully, and use this product properly. The

precautions described in this manual contains important contents related with safety;

therefore, please follow the instructions accordingly. The precautions are composed of

DANGER, WARNING and CAUTION.

10 bit A/D 4Digit

Red LED

Multi-functions(MARK/RPM/COUNTER)

NPN Open collector

PNP pen collector

PFD

Light source

Use

External output

Multifunction: With built-in RPM/Count function, control output is possible

without a separate meter.

Safety information

WARNING

1. The contents of this manual may be changed without prior notification.

2. If you use the product with methods other than specified by the manufacturer, there may

be bodily injuries or property damages.

3. Avoid continuously switching the power source On and Off.

4. Use a dry cloth to wipe off the substance when cleaning the lens or cases. Never use

thinner or organic solvents.

5. Do not use this product at any place with much dust, vibration or impact.

6. Before inserting power source, make sure that the circuit wiring is properly connected.

7. In the case of wiring loaded inductors such as DC Relay and others to output, use diode,

varistor and others to prevent surge.

8. To avoid malfunction caused by noise, do not put high voltage or power line with sensor

wire in a same conduit

9. Make its wiring be shorter as possible and wire extension shall be within 30 m.

CAUTION

10. Consider the fact that the sensing distance may be varied in accordance with the size,

color, surface condition, material, glossy, non-glossy or others of a sensing object.

11. Prevent strong disturbance light such as sunlight and others which directly enter into the

directional angle of the sensor by putting a glare shield.

12. In the case of using multiple sensors (more than 2 sensors), there is a possibility of

malfunction caused by mutual interference so, for Through-Beam type, sensors shall be

installed in a divergent way or there shall be proper distance between them.

13. When using the Switching Power Supply as the power source, earth the Frame Ground

(F.G) terminal and be sure to connect the noise-eliminating condenser between 0 V and

F.G.

If you do not follow the contents described in the safety information then it is possible to be

a cause of the product’s malfunction so please follow them.

Frame

Power

Supply

(SMPS)

C(0.01 -0.1 /500 V)

- Noise Eliminating

Condenser -

Photo

sensor

NPN

PNP

Main

Subsidiary

COUNTER

RPM

Multi functions

PFD-RMN

PFD-RMP

Type

Kinds

Model

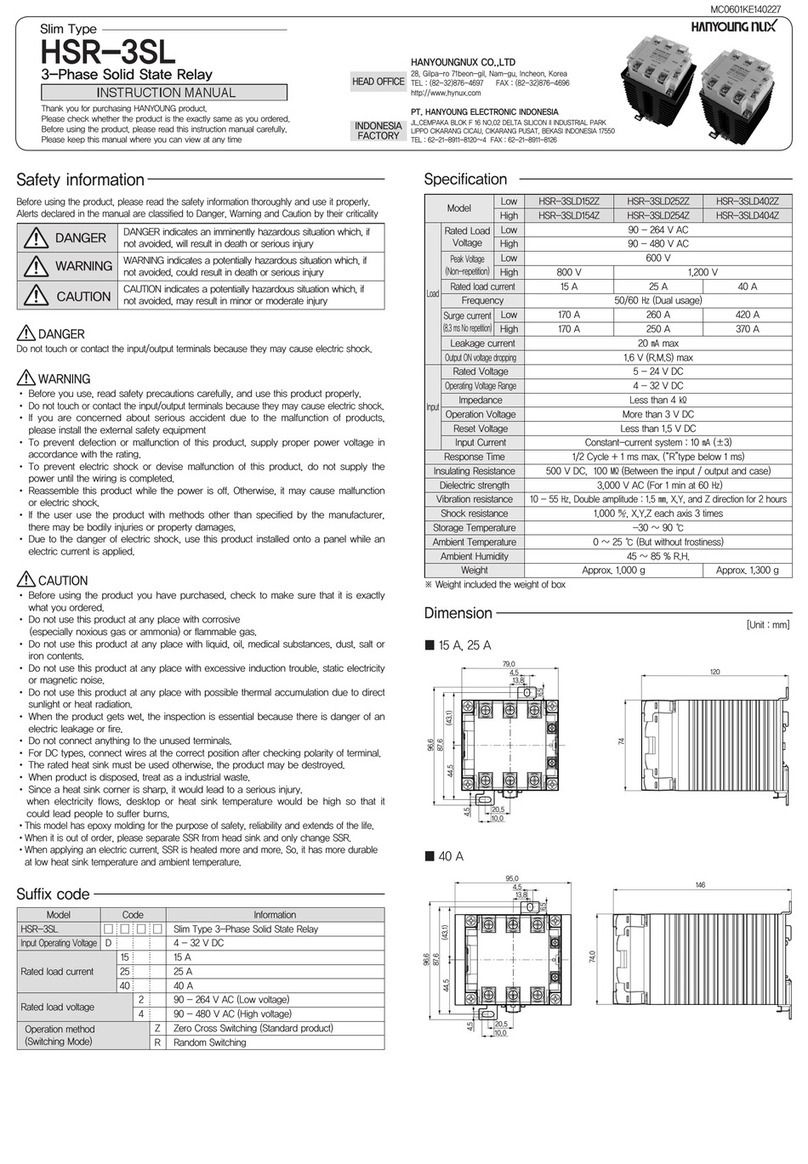

Rated Voltage

CurrentConsumption

Output

External Input

Mtensity of light

Multi

-functions

Output

On/Off Delay

Lightsource/Wavelenght

ProtectionCircuit

Responsetime

Varationrate

Displayform

Sensitivityfixation

Additionalfunctions

OperatingAmbient illumination

OperatingAmbiruttemp.

OperatingAmbient Humidity

VibrationResistance

ShockResistance

DielectricStrength

InsulationResistance

ConnectionMethod

Accessory

Ordering information

Rating

Dimension

Multi-functions

Multi-functions

Counter

RPM

UP / DOWN mode, Free scale 1~999

Range: 0 ~ 9999 Counting speed: 400 cps (50 % duty )

Output mode : N, F, C, R, K, P, Q, A 8 kinds

External reset : Min. signal width 5 ms

Range : 0 ~ 9999 rpm Speed guard output

Free scale : 1 ~ 1000 Measring Cycle setting

Cautions) Use by combining the Fiber Unit in the form of transmission type at the time of

RPM/Count Measurement.

Malfunction can occur from the increase in the light receiving change range by speed

when using for the reflection purpose.

Distance measurement at the optical measurement mode changes in accordance with the

Fiber Cable and within 20m is recommended.

INSTRUCTION MANUAL

HEAD OFFICE

1381-3, Juan-Dong, Nam-Gu Incheon, Korea

TEL: (82-32)876-4697 FAX:(82-32)876-4696

Circuit wiring & Fixture

NPN type PNP type

Segment (4 Digit FND) Display

Displays bars at the Number, Letter, and

Bar Display Mode such as the amount of

light entering, mode error message, set up

values, and set up items

PAGE1: Sensor Manual Sensitivity Set Up Page

PAGE2: Sensor Output Mode Set Up Page

PAGE3: Count/RPM Function Set Up Page

PAGE4: Additional Function Set Up Page

CNT: Holds one operation mode from Up Counter, Down Counter, and RPM

display functions.

(FUN Operates with Counter or RPM display

according to the function set at the [3-1] Mode.)

Caution: Refer to the Parameter Chart for the Detailed Set Up and function of FUN

Optical Fiber Unit Input Hole External Diameter: 2.2 mm Fiber unit

The set up range

of hysteresis is

1~10% of the criterion

value.

The set up range of

stability is 2~20% of

the criterion value and

is greater than the

hysteresis value.

Wiring

Input / Output circuit

Name of parts

Depending on receiving level,OUT,

STB operation

Delay setting and Output operation

(in Light ON)

LED Display (State)

Displays the state of Fiber Sensor

OUT: Lights on for interface output (OUT1)

STB: Displays safe regions at the RUN Mode (OUT2))

Sensor input display is on over the set up region at the RPM/Count Mode

D/L: Lights on for Light On and Lights off for Dark On

OND: Lights on when On Delay is set at the Output

OFD: Lights on when Off Delay is set at the Output

RUN: Lights on when operating at RUN

CNT: Lights on when operating at CNT (Up Counter / Down Counter / RPM)

(RUN and CNT simultaneously light on when operating at the RPM Mode)

Push Button ( UP, DN)

Function change and value set up at each executive mode (RUN, FUN, CNT)

Slide S/W (RUN, FUN, CNT)

Sets up executive modes and priority operation at all functions

RUN: General Fiber Sensor Operation Mode

Various light amount set up & display function

(Ordinary Light Amount Display / Bar Display / Maximum,

Minimum HOLD Display / Percent Display)

Displacement Set Up function (OFFSET)

Various Auto Teaching Function

FUN: Various Additional Function Set Up Mode

Changeable a display mode press at RUN mode

ƒU

ƒU

ƒU

ƒU

Light Volume

BAR Display

Light Volume

Light Volume is more than

More than Low limit value of Stability

More than Low limit value of Adjust

Less than High limit value of Adjust

Less than High limit value of Stability

More than High limit walue of(Stability+10)

Max. / Min. HOLD display

Display Max. and Minimum value during

flickering

Percentage display

Display as standard

If set 300 as setting value

- If light value is 300, display

- If light value is 990, display

(Changeable at FUN mode[4-4]

0 select

180 select

press UP button in short

press UP button in long

180 rutation display

press DN button in short

press DN button in long

How to operate a button

Various display function

Auto Teaching Mode Entry: Press at the RUN Mode. ( TEAC => txxx )

Auto Teaching Mode Removal: Restores to the RUN Mode execution from the Teaching

Mode when is pressed.

The set up outline described in the below is the set up method at the Teaching Mode.

<1 Point Teaching > when detecting from a specific

location of walk

Place it at the location for detecting the walk

Complete the set up by pressing twice

(once: txxx switch, twice: _OK_ )

(The set up value becomes the optimal

value of 300~700 range.)

Walk : Object, Object to be Detected

<2 Point Teaching> when detecting delicate walk

(limited region detection)

Out if it is over 1/2 of the walk light amount and

background light amount

Place it at the location for detecting the walk

Press once. (Automatic Gain Adjustment)

(txxx switch)

Remove the walk initially placed at the location.

(Only background remains)

Complete the set up by pressing once. ( _OK_ )

<Maximum Light Amount> when detecting walk using transmission type fiber

Place it at the location for detecting the walk

Complete the set up by pressing twice

(once: txxx switch, twice: _OK_ )

Move to Group 1 in FUN mode

Manual sensitivity set

ƒU

ƒU

ƒU

ƒU

ƒU

Parameter menu and display Explannation Range Setting KEY

Set up the safe region at

the time of deciding the

presence of walk.

1) Move to the next parameter group by pressing when the parameter is displayed.

2) Current mode and current set up condition is displayed when moving the parameter.

3) Set up can be changed by firmly pressing on to for long time.

4) Just move the Slide S/W to RUN or CNT to move to the executive mode after completing the set up,

1. When using at the Counter or RPM Measurement Mode, set up with the

maximum value of [1-3]

hysteresis and [1-4] safe region (stability). (When using transmission type fiber unit)

2. In the case of Auto Teaching at the RUN Mode, GAIN [1-1] and

ADJU [1-2] values will change automatically.

GAIN

ADJUST

HYSTERESIS

STABILITY

Move to parameter 2 Group

1(min)

~8(max)

5-995

1~10 %

2~10 %

HYSTERESIS

:

:

Setting value

change

:

Setting

completition/

revert

Set up One Short

Time of Out1 Port.

(Unit: msec)

Set up the Up Counter,

Down Counter,

and RPM Meter Modes.

Set up the free scale.

Set up the adjust value at

the Counter.Set up the

maximum value at RPM.

Set up the minimum

value at RPM.

(Exclusive RPM Use)

Set up the output

motion mode of Counter

and RPM Meter.

Refer to the chart for

details of the motion mode.

MODE

PRESCALE

SETTING HI

SETTING LOW

OUT1 MODE

ONE SHOT TIME

Move to Group 3 in FUN mode

ƒU

ƒU

ƒU

ƒU

ƒU

ƒU

ƒU

Parameter menu and Display Explannation Range Setting KEY

Move to parameter 4

Group

Rpm Meter

Up Counter

Down Counter

1-999(Input / PRE=Display value)

1001-1999(Input PRE=Display value)

1 -9999

: Setting

value change

: Setting

completitio/rever

t

: Setting value

change

: Setting

completitio

/revert

OUT2 (STB LED) is outputted whenever the sensitivity value is greater than the [1-4] value.

(Use for verifying the presence of calculation.)

1) Move to the next parameter group by pressing when the parameter is displayed.

2) Current mode and current set up condition is displayed when moving the parameter.

3) Set up can be changed by firmly pressing on to for long time.

4) Just move the Slide S/W to RUN or CNT to move to the executive mode after completing the set up

Counter operation

RPM operation

10,20,30,40,50,100,200,

300,400,500,1000,2000,

3000,4000,5000 msec

( DOWN value

UP value)

Move to Group 2 in FUN mode

ƒU

ƒU

ƒU

ƒU

ƒU

ƒU

ƒU

Parameter menu and Display Explannation Range Setting KEY

1) Move to the next parameter group by pressing when the parameter is displayed.

2) Current mode and current set up condition is displayed when moving the parameter.

3) Set up can be changed by firmly pressing on to for long time.

4) Just move the Slide S/W to RUN or CNT to move to the executive mode after completing

the set up,

Dark_Light

ON_Delay

OFF_Delay

ONE Shot

Time

E-IN

CHANEL

Move to parameter 3 Group

:Light ON

:Dark ON

9999 ms

None

1-TE

AUTO

ch1

ch2

: Setting value

change

Setting

completitio/revert

Setting value change

: Setting

completitio/revert

Setting value

change

: Setting

completitio/revert

Set up One Short

Time of Out1 Port.

(Unit: msec)

Set up the Up Counter,

Down Counter,

and RPM Meter Modes.

Set up the free scale.

Set up the adjust value

at the Counter.Set up

the maximum value

at RPM.

Set up the minimum

value at RPM.

(Exclusive RPM Use)

Set up the output

motion mode of Counter

and RPM Meter.

Refer to the chart for

details of the motion

mode.

Set Up Example

Free Scale Set Up [3-2]

Example 1) counting one by one for input of 5 at the Counter Mode (Division Set Up 5)

Example 2) Counting in three for input of 1 at the Counter Mode, 3+1000=set up 1003

Example 3) 1/60 (set up 60) since 60rpm is 1cps when displaying as CPS at the RPM Mode

Example 4) displaying with RPMx5 for input of 5 at the RPM Mode (Set Up 5)

(Displaying RPM with 0.2 input as a base)

Setting HI [3-3]/Setting LOW [3-4]

Example 1) Up Counter: when setting 100 as the setting value (Set Up [3-3]: 100)

Example 2) Down Counter: when counting down from 200 to 0 (Set Up [3-3]: 200)

Example 3) RPM Meter: when assigning output conditions by specifying rpm range of

500~600 (Set Up [3-3] HI: 600, Set Up [3-4] LOW: 500)

Set up 8 levels of

amplifying rate for the

amplifying circuit of the

light receiver.

Set up the sensitivity

(criterion value)

Set up GAP of the

criterion at the time of

deciding the presence of

walk.

AutoTeaching Mode

Parameter

Viewing Adjust Value at the Teaching Mode

When verifying the adjust value after 1 Point, 2 Point, Maximum Light Amount and Auto Teaching

Displays the adjust value when is pressed once (if the adjust value is 540, A500 )

The sensor returns to the Teaching Mode when is pressed once again. ( txxx )

<Auto Teaching> when detecting moving walk without stopping it

Move the walk from the conveyor or operate the body of revolution

(motor, etc.)

Difference of light amount will be automatically distinguished for set

up after about 10 seconds when is pressed.

(AT_9 -> AT_8 ... AT_0 -> _OK_ )

Manual sensitvity

setting

(Basic input setting)

1 Group

GAIN

ADJUST

HYSTERESIS

STABILITY

Set

value

7

500

10

20

SENSOROUTPUT

(RUN MODE)

2 Group

DARK/LIGHT

ON DELAY

OFF DELAY

ONE SHOT

TIME

INPUT SW

CHANEL

Refer to the Parameter Group Set Up for the Details on the Adjusted Values.

1) Move to the next parameter group by pressing when the parameter is displayed.

2) Current mode and current set up condition is displayed when moving the parameter.

3) Set up can be changed by firmly pressing on to for long time.

4) Just move the Slide S/W to RUN or CNT to move to the executive mode after completing the set up

Set

value

L

OFF

OFF

OFF

AUTO

CH1

COUNTER/RPM SET

(CNT MODE )

3 Group

MODE(UP,DN,RPM)

PRESCALE

SETTING HI

SETTINGLOW

OUT1 MODE

ONE SHOT TIME

4 Group

LOCK

BRIGHT

BRIGHT TIME

DISPLAY 180

DEFAULT

Set

value

UP

1

100

100

(CNT)C

(RPM)L

50

Set

value

DS

7

OFF

0

-

The output is generated as one short when

the adjust value is reached and the

calculation value is reset.

It doesn t calculate during the one short

period.

The output is generated as one short when

the adjust value is reached and the

calculated value resets and calculation

begins at the declining edge where the one

short ends.

The output is generated as one short when

the adjust value is reached and the

calculation stops.

The calculated value is reset at the rising

Edge of Reset

Calculation begins at the declining Edge of

Reset

One shot time setting in FUN mode

Calculation stops and output is on when the

adjust value is reached.

The output off calculated value is reset at the

rising Edge of Reset.

Calculation begins at the declining Edge of

Reset.

Calculation continues even after reaching the

adjust value and the output stays on.

The output off calculated value is reset at the

rising Edge of Reset.

Calculation begins at the declining Edge of

Reset.

The output is generated as one short when

the adjust value is reached and the

calculation value is released with the Reset.

The output is generated as one short when

the adjust value is reached and when the

calculation stop one short time is over, the

calculated value starts calculation with the

Reset.

The output is generated as one short when

the adjust value is reached.

The calculated value is reset at the rising

Edge of Reset

Calculation begins at the declining Edge of

Reset

O

U

T

P

U

T

M

o

d

e

Explanations

Keep up value One shot value

(Standard)

(High)

(Low)

Between high limit value[3-3] and low limit value[3-4]

OUT1 ON, OUT2 OFF

More than high limit value[3-3] OUT1 ON

More than low limit value[3-4] OUT2 ON

More than high limit value[3-3] OUT1 ON

More than low limit value[3-4] OUT2 ON

Output mode[3-5] Explannation

Output operation mode [3-5]

Function and output explan ation in RPM mode

Function Output explan ation in Counter

1) Move to the next parameter group by pressing when the parameter is displayed.

2) Current mode and current set up condition is displayed when moving the parameter.

3) Set up can be changed by firmly pressing on to for long time.

4) Just move the Slide S/W to RUN or CNT to move to the executive mode after completing the set up,

5) LOCK Release Method: Press in order

Move to Group 4 in FUN mode

ƒU

ƒU

ƒU

ƒU

ƒU

ƒU

Parameter menu and Display Explannation Range Setting KEY

FUN mode lock

(refer to 5)

Lock

Bright

Bright

Time

Display

180

Default

Move to parameter 1

Group

: Enable

: Disable

[1-7]stages

OFF, 5, 10, 15, 20,

30 sec

1, 2, 3, 4 min

: normal

:180 rotation

: :

setting value change

: setting

completition/revert

Brightness setting

and FND brightness

control

Bright Time setting

Brightkeeping time

Display rotation

(180rotation)

Default setting

(Initial value setting)

Counter Function and Set Up Method

It is combining the counter function to the

ordinary fiber sensor function. It can be set

up to output when it yields arbitrary

calculated value by calculating the walk. The maximum calculated range is 9999. It can set

up Up Counter and Down Counter

and supports the output of free scale and 8 types of motion mode that is capable of division/

set up. At this time, the remote

input function is changed to external reset use. Free scale is capable of displaying division

and .

OUT2 can be used as sensor output and is generated when the display value is changed.

Initialization of Calculation Value at the state of CNT Mode Execution

The calculation display is `0’ at the Up Count Mode and is Setting value [3-3]

at the Down Count Mode

when is pressed. Calculation stops while the key is pressed on.

Initialization of calculated value with the remote reset external input

Set up example at the Counter Mode (Refer to the parameter set up for the details of set up.)

Caution) Must carry out sensor sensitivity set up process as well.

Set Up Example Calculate up to 350 by counting one each for input of 3 at the Up

Counter Mode and then one short time

Stop the calculation at 50 msec output. Reset when the remote reset is displayed and set up

to begin the calculation.

Operation Mode

Free scale

Setting Hi

Setting Low

Output Mode

One Shot Time

[Up]

[0003]

[0350]

[n]

[500]

UP Counter setting

3 setting

350 value

Refer to counter mode table

500 msec setting

[3-1] [MODE]

[3-2] [PRE]

[3-3] [S-HI]

No use in Counter mode

[3-5] [OUTM]

[3-6] [ONES]

FUNCTION PAGE SET VALUE REMARK

RPM Meter Function & Set Up Method

It is the RPM Display Function. It is capable

of measuring from 1~9999rpm and supports

speed monitoring output and

maximum/minimum adjust output. The speed monitoring output is materialized to give out

alerting output when goes beyond

10% of the adjust value. With the function support of free scale (0001~0999), CPS value can

be displayed when set up at 60.

Also, it supports the division and πË¡÷ functions. However, the display value cannot exceed

400 CPS/ps value. The output is

generated in one short.

Set Up Example at the RPM Mode (Refer to the parameter set up for the details of set

up.)

Caution) Must carry out sensor sensitivity set up process as well.

Set Up Example RPM is displayed in the case of one rotation based on the input of one for

exclusive use

of RPM display and the output is generated by having 500rpm to 550rpm as standard. For

between

500~550, set up as OUT1 ON / OUT2 OFF.

Operation Mode

Free scale

Setting Hi

Setting Low

Output Mode

One Shot Time

[Rpm]

[0001]

[0550]

[0500]

[S]

[OFF]

RPM Mode setting

1setting

OUT1 set value

OUT2 set value

Output Mode

Real time output

[3-1] [MODE]

[3-2] [PRE]

[3-3] [S-HI]

[3-4] [S-LO]

[3-5] [OUTM]

[3-6] [ONES]

FUNCTION PAGE SET VALUE REMARK

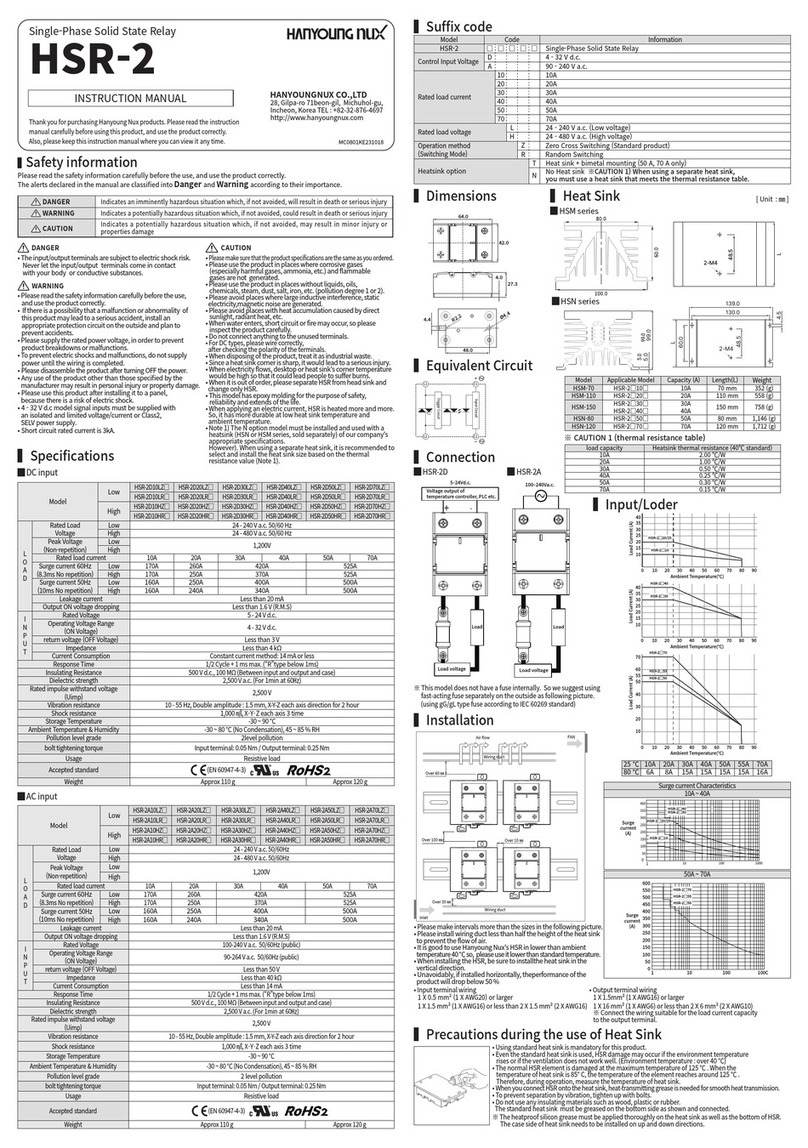

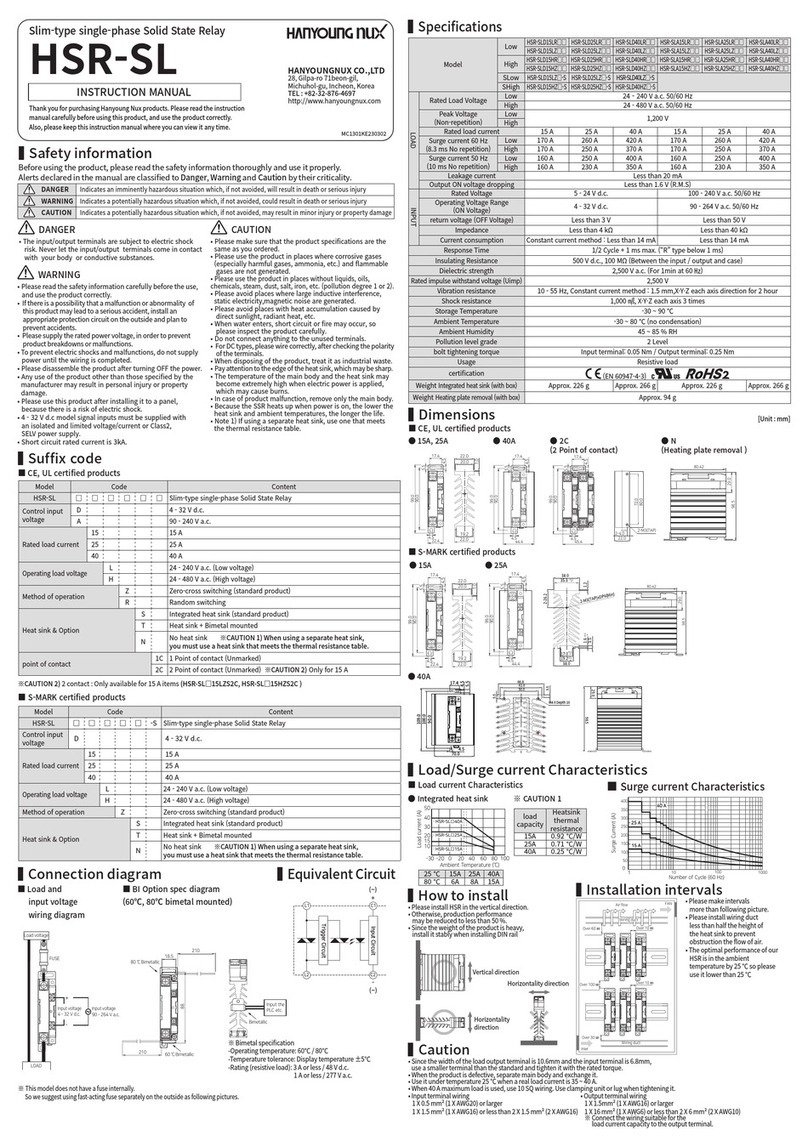

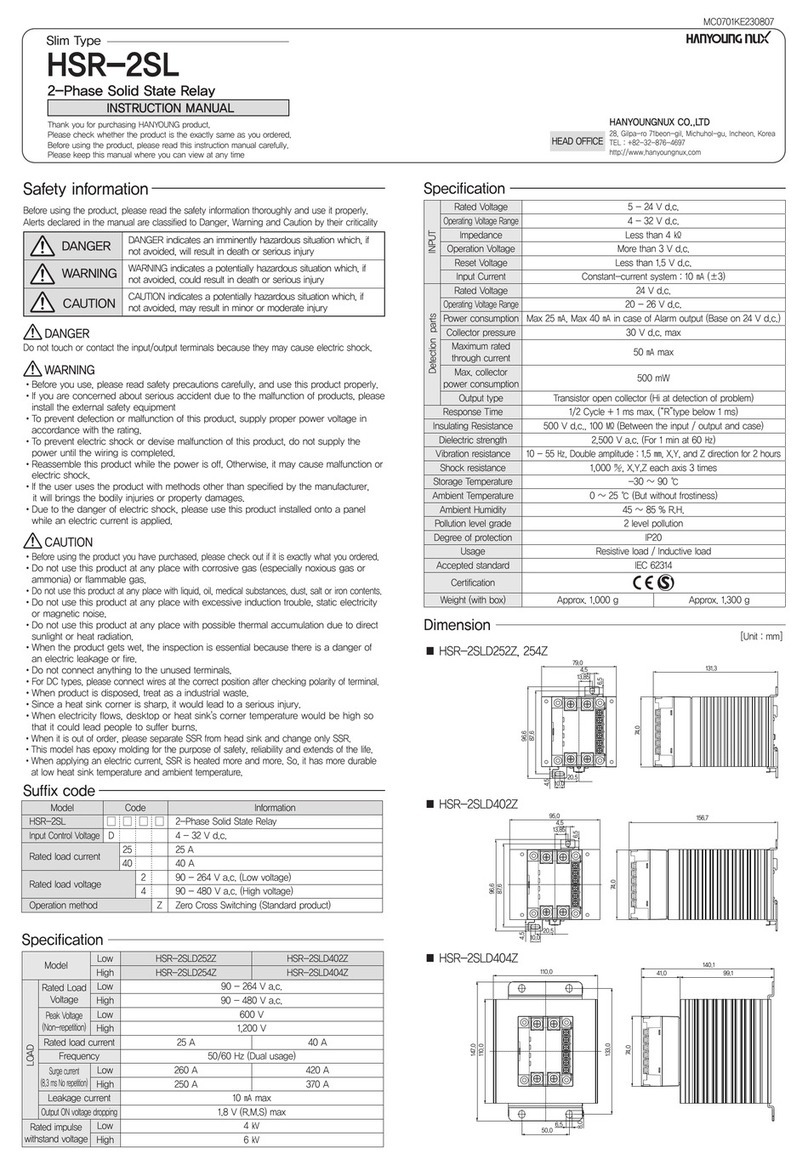

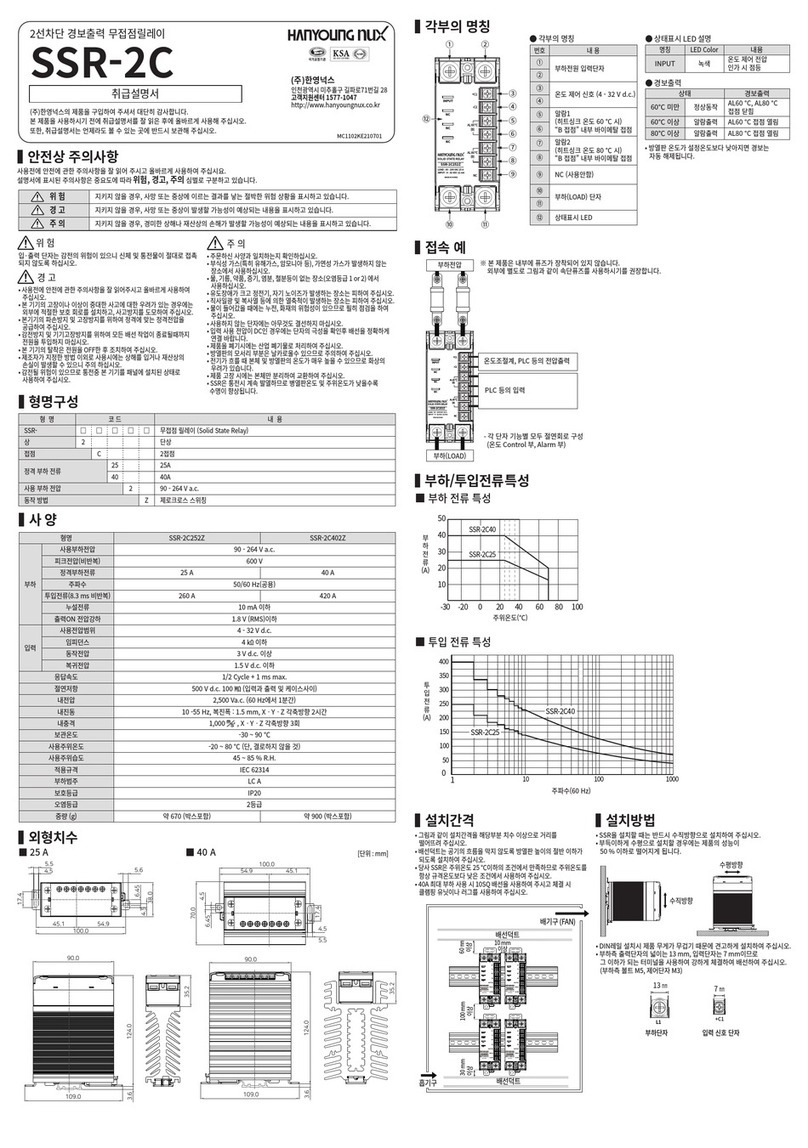

This manual suits for next models

2

Other HANYOUNG NUX Relay manuals

HANYOUNG NUX

HANYOUNG NUX SSR-2 Series User manual

HANYOUNG NUX

HANYOUNG NUX HSR-SL User manual

HANYOUNG NUX

HANYOUNG NUX HSR-2 Series User manual

HANYOUNG NUX

HANYOUNG NUX HSR-SL Series User manual

HANYOUNG NUX

HANYOUNG NUX HSR-2SL User manual

HANYOUNG NUX

HANYOUNG NUX SSR-2C Series User manual

HANYOUNG NUX

HANYOUNG NUX HSR-3SL series User manual

HANYOUNG NUX

HANYOUNG NUX HSR-3SL User manual

HANYOUNG NUX

HANYOUNG NUX SSR-2 User manual