8

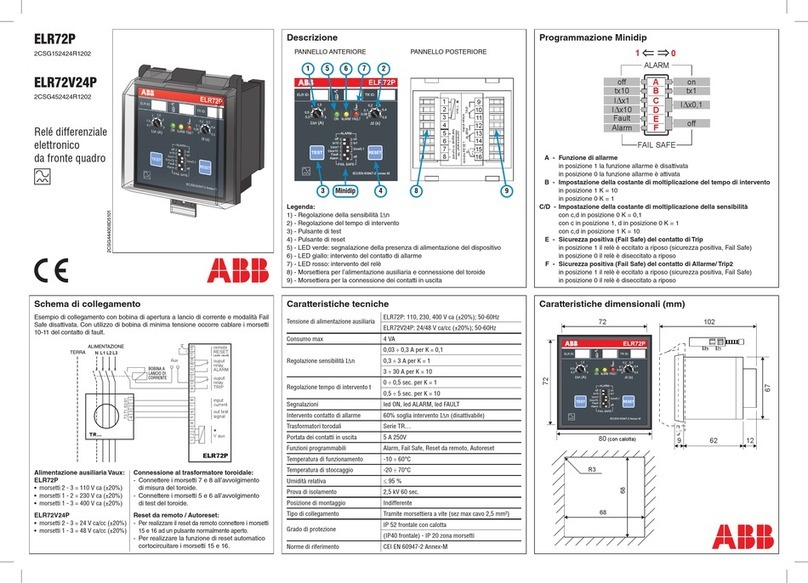

Fig. 4. System front panel of the voltage relay

SPAU 331 C.

1. The green LED Uaux on the system panel is

lit when the power supply of the relay is op-

erating.

2. The relay modules are provided with two

operating stages and each stage has its own

yellow/red LED operation indicator. The op-

eration indicator goes on with a yellow light

when the operation stage starts and with a

red light if the stage delivers a tripping signal

as well. The LED indicators can be given self-

reset or manual reset mode of operation. Nor-

mally, when the stage resets, the red opera-

tion indicator remains lit after being switched

on to indicate by whitch stage the tripping

was initiated.

3. The front panels of both relay modules are

provided with a numerical display for indi-

cation of measured and set values, two push-

buttons marked STEP and RESET, a pro-

gramming switchgroup SG1 for selection of

relay functions and four setting knobs for op-

eration values. The STEP push-button can

be used for scanning through the measured

and set values of the module and for presen-

tation of the values concerned on the display

of the module. The RESET push-button is

used for resetting locally the red operation

indicators for tripping. An unreset operation

indicator does not affect the operation of the

relay module and thus, the module is

constantely operative.

4. The front panels of the relay modules are pro-

vided with a red LED used as a self-supervi-

sion alarm indicator IRF which indicates that

the self-supervision system has detected a per-

manent fault in the protection relay. Further,

the relay modules are provided with separate

LED indicators on the front panel for indi-

cation of the measured residual and phase-

to-phase voltages.

5. The cover of the protection relay case is made

of transparent, UV-stabilized polycarbonate

polymer and provided with three push-but-

tons for scanning of the relay parameters by

means of the separate displays of the mod-

ules and the STEP push-buttons inside the

cover. To enable resetting of the modules by

means of the RESET push-buttons, the cover

of the relay case must be opened using the

locking screws for the case.

Detailed operation instructions are given in the

manuals describing the individual relay mod-

ules and in the document "General characteris-

tics of C-type relay modules".

Operation

indicators and

push-buttons

U

aux

Ser.No.

80...265 V

18...80 V

2

5

~

–

U1 U2 U3

–

fn=

50Hz

60Hz (

U

)

SPAU 331 C

0076B

n

U

/

=(

U

)

100V 110V

n

U

/

=100V 110V

0

RS 613

SGR

01

1

2

3

4

5

6

7

8

0000

SPCU 1C6

1

2

3

4

5

n

)(

U

o

>

/

>

tt

%

[]

>>

/

tt

%

[]

/

n

UU

o

%

[]

>>

n

)(

U

o

0000

SPCU 3C15

1

2

3

4

5

6

7

8

/

<

tt

%

[]

n

)(

U

<

/

n

UU

min

/

n

UU

<

/

n

UU

max

n

)(

U

<<

3

/

tt

%

[]

<<

/

n

UU

<<

3

0000