Page 10 For technical questions, please call 1-888-866-5797. 56385

SAFETY OPERATION MAINTENANCESETUP

Wiring

TO PREVENT SERIOUS INJURY FROM EXPLOSION

DUE TO SPARKING AT THE BATTERY CONNECTION:

Unplug the Remote Control Cable and disconnect the Battery Cables

before making other wiring connections.

TO PREVENT SERIOUS INJURY FROM LEAKING BATTERY ACID:

Do not use a dirty, corroded or leaking battery.

Only use a 12 V automotive (or equivalent) battery, in good condition.

1. Plan a route for the wiring from the point of the

vehicle where the Winch will be mounted, or

used, to the battery. This route must be secure,

out of the way of moving parts, road debris, or

any possibility of being damaged by operation or

maintenance of the vehicle. For example, you

may wish to route the wires under the vehicle,

attaching it to the frame using suitable fasteners.

WARNING! TO PREVENT SERIOUS INJURY: Do

not attach the wires to the exhaust system, drive

shaft, emergency brake cable, fuel line, or any other

components which may create damage to the wiring

through heat or motion, or create a fire hazard.

2. If you drill through the bumper or any part

of the body to route the wires, be sure

to install a rubber grommet in the hole to

prevent fraying of the wires at that point.

3. Route the Cables from the Winch to the battery,

following the precautions discussed above.

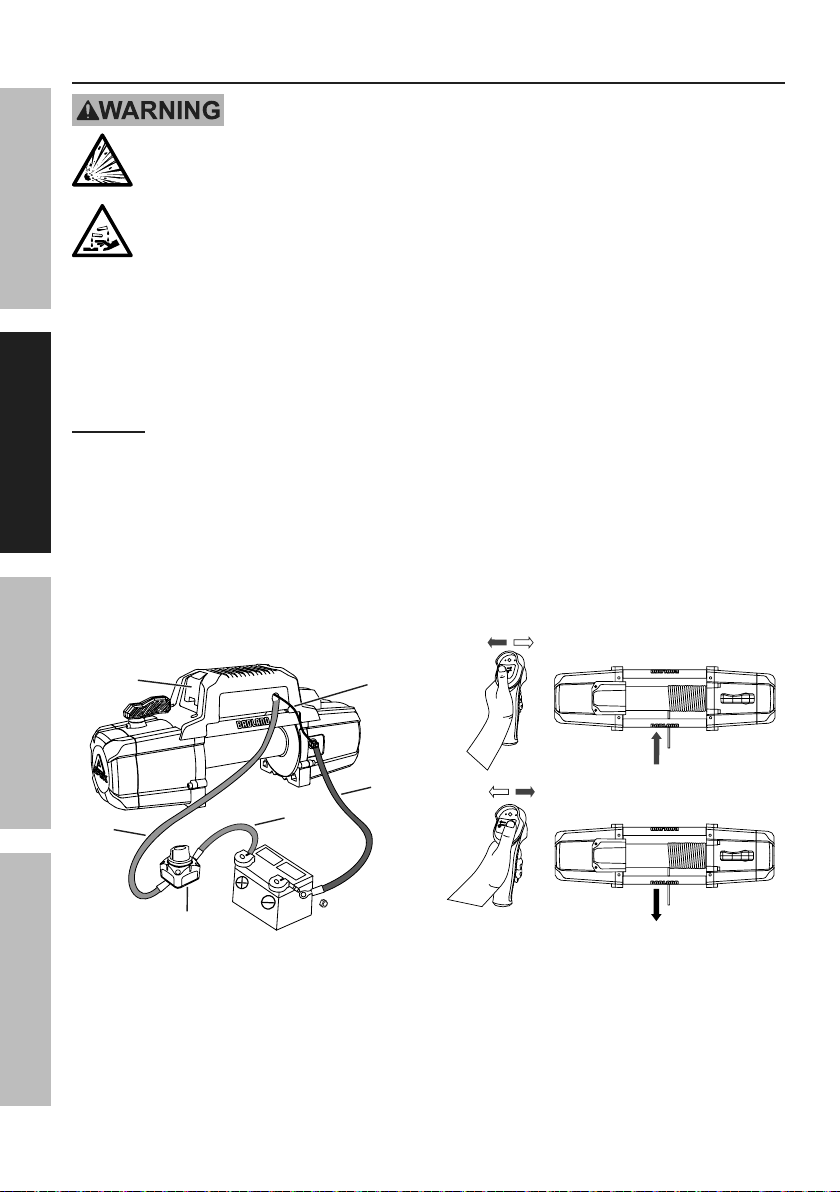

Refer to Figure C.

Disconnect

Switch

Black

Ground

Cable

Red

Battery

Cable

12"

Cable

Socket

Cover

Small

Black

Wire

Figure C: Wiring Connections

4. Attach the 12" 2AWG Disconnect Switch Cable

to the positive terminal on the battery.

5. Attach the 12" 2AWG Cable from the battery

to either terminal on the Disconnect Switch.

6. Attach the red Battery Cable from the Winch to

the remaining terminal on the Disconnect Switch.

7. Attach the black Ground Cable and the Small Black

Wire to the terminal at the rear of the Winch.

8. Attach the black Ground Cable from the Winch

directly to the negative terminal of the battery.

9. Lift the Socket Cover exposing the Remote Control

socket and Wireless Receiver Switch. Connect

the Remote Control Cable to the socket and the

Remote for wired remote control. For wireless

control do not use the Remote Control Cable and

turn on the Wireless Receiver Switch. Refer to

Remote Control Instructions on page 12.

10. Turn on the Disconnect Switch and operate the

remote controls briefly to test Winch function

and drum rotation direction. If operation is

reversed, the Battery Cables may be connected

backwards. Correct any such issue before use.

IN

OUT

Figure D: Remote Controls

11. Disconnect and turn off the Remote

Control when not in use.

12. Turn off the Disconnect Switch when the

Winch is not in use or when the vehicle

has returned to on-highway operation.