6SUPPLEMENT TO HARDI®COMMANDER OPERATOR’S MANUAL

Operation

Adjustment of ECP operating controls

1. Power switch

2. Manual pressure regulation

3. Main ON/OFF

4. End nozzle (Left/OFF/Right)*

5. Foam marker regulation*

6. Foam marker (Left/OFF/Right)*

7. Boom section valves

8. Valve function A-B*

*optional equipment

Before spraying, adjust the ECP operating unit

using clean water (without chemicals).

1. Choose the correct nozzle (see manual). Make sure

that all nozzles are the same type and capacity.

2. Put the tractor in neutral and set the parking brake.

Adjust the P.T.O. r.p.m. to the number of revolutions

that will typically be used while spraying. This must

be kept between 300-600 r.p.m. (540 r.p.m. pump)

or 650-1100 (1000 r.p.m. pump) to ensure correct

operation of the HARDI-MATIC system.

3. Turn power switch 1and main ON/OFF switch 3to

the “ON” position.

4. Make sure all boom switches 7are also in the “ON”

position. All nozzles should be spraying at this time.

5. Hold pressure regulating switch 2up (+) or down (-)

until the approximate spraying pressure is shown on

the system pressure gauge.

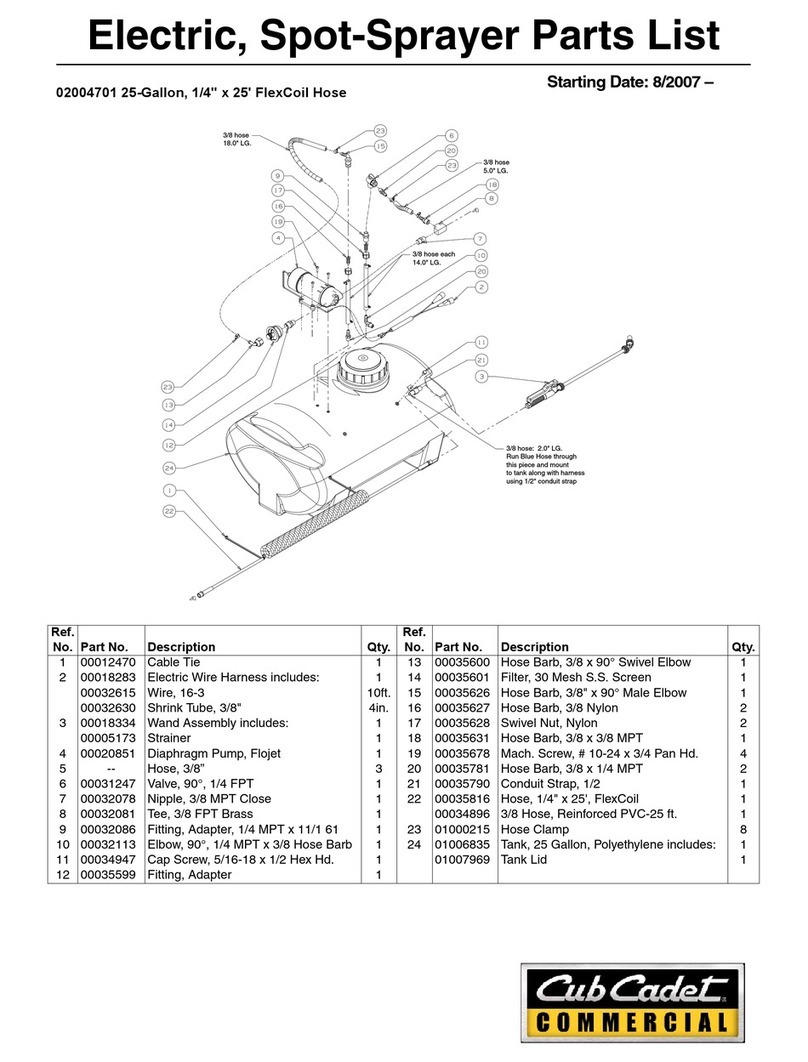

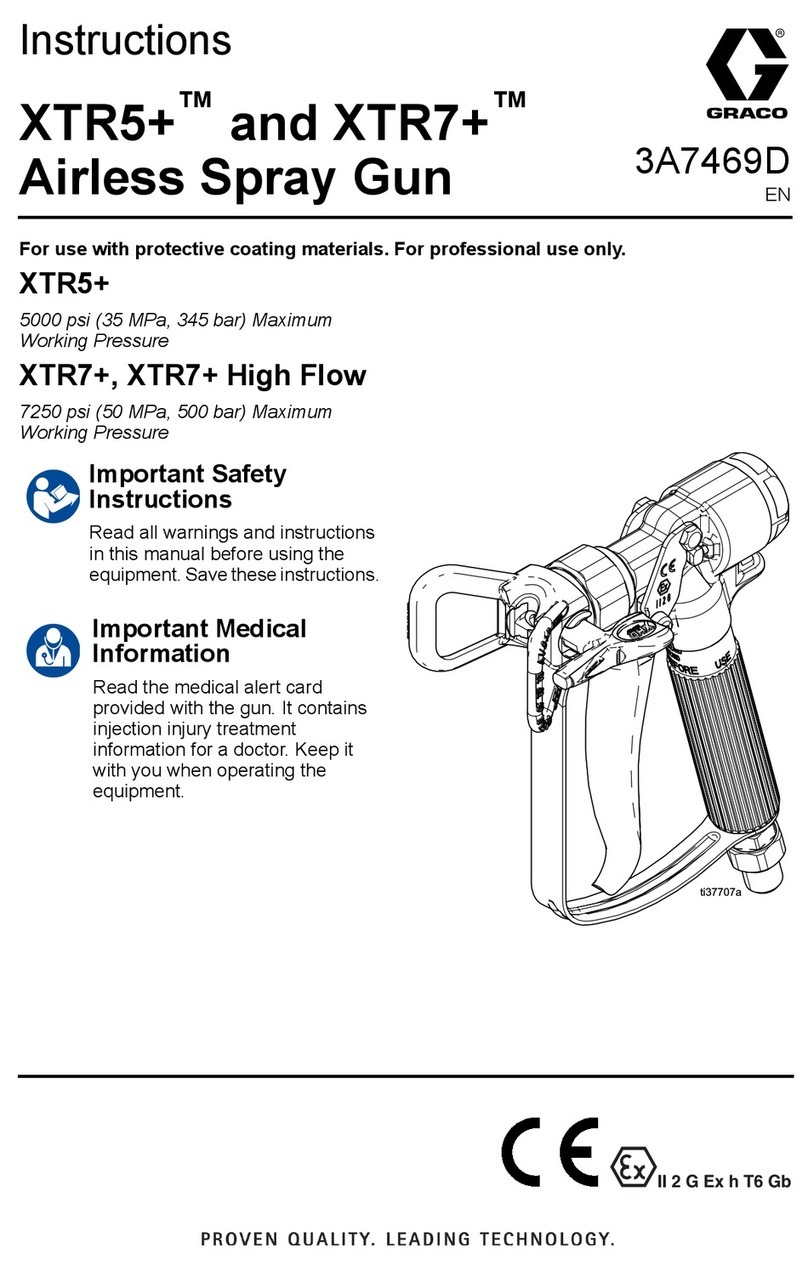

Pressure

Control

Valve

Distribution

Valves System Pressure

Gauge

Constant Pressure

Adjusting Screws

Adjustment of constant pressure

Note: Disconnect power to the Spraybox to allow

for manual operation of the boom distribution

valves. Adjustment will be made one section at a

time until all valves have been adjusted.

6. Perform steps 1-5 and use the pressure reading from

step 5 throughout the constant pressure adjustment

procedure.

7. Manually shut-off the first boom distribution valve by

turning the first green handle (the first boom section

should shut off).

8. Turn the adjusting screw under the valve just turned

off until the control pressure gauge again shows

the same pressure as when all boom sections were

open (Turn the screw clockwise for higher pressure,

counterclockwise for lower pressure).

9. Turn the boom distribution valve back on.

10. Repeat steps 6-9 for the remaining boom distribu-

tion valves.

Note: Hereafter adjustment of the constant boom pres-

sure will only be needed if you change to nozzles with

other capacities, but not required if only changing pres-

sure or application rate using the same nozzles.

Operating the control unit while spraying

In order to shut off the entire boom, flip ON/OFF switch

3to the "OFF" position. This returns all the pump

outputs to the main tank through the return system.

The diaphragm anti-drip valves ensure instantaneous

closing of all nozzles.

In order to shut off one or more sections of the boom,

switch the relevant distribution valve 7to the "OFF"

position. The constant pressure system ensures that

the pressure does not increase in the sections which

are still open.

In case of electrical failure, it is still possible to manually

override all functions of the operating unit. To operate

manually, disconnect the multiplug from the Spraybox

first and operate the handles by hand. It is possible to

change pressure and turn boom sections on or off.

Note: Since the on-off switch normally operates by

shutting off all the boom distribution valves, you will

need to manually shut off all the distribution valves to

shut off the complete control unit manually.

IMPORTANT! When the sprayer is stored, the

Spraybox and the multiplug must be pro-

tected against moisture and dirt. A plastic

bag may be used to protect the multi plug. Store the

Spraybox in a clean dry place.