Hardy Process Solutions 400 Series Specification sheet

This manual suits for next models

5

Table of contents

Other Hardy Process Solutions Scale manuals

Hardy Process Solutions

Hardy Process Solutions HIFS-3030-01-PS-T Specification sheet

Hardy Process Solutions

Hardy Process Solutions BSX Series User manual

Hardy Process Solutions

Hardy Process Solutions BW Series User manual

Hardy Process Solutions

Hardy Process Solutions HI 1769-WS Specification sheet

Hardy Process Solutions

Hardy Process Solutions Enviro Series User manual

Hardy Process Solutions

Hardy Process Solutions C Series Specification sheet

Popular Scale manuals by other brands

Medicus

Medicus 2956M5 Assembly and operation instructions

Acom

Acom JW-1 owner's manual

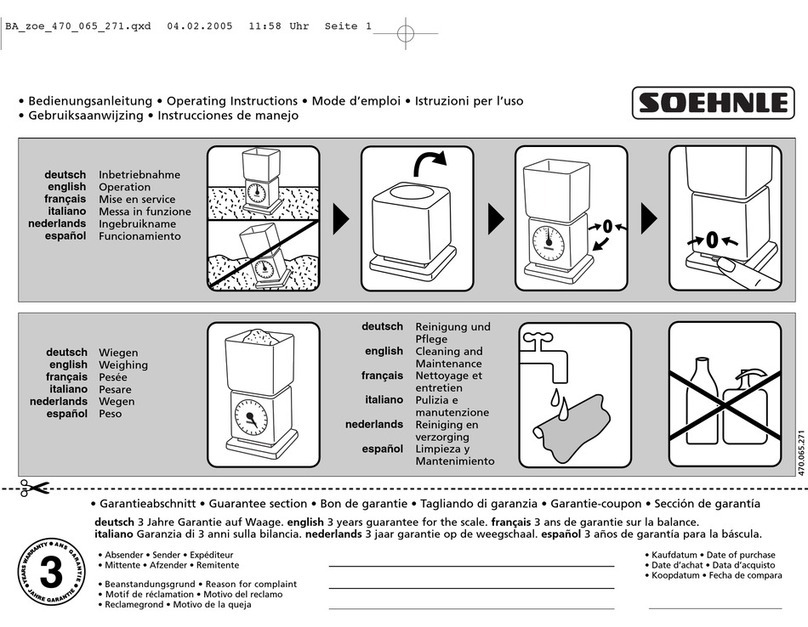

Soehnle

Soehnle Weighing Scale operating instructions

Escali

Escali Aqua Aqua Liquid Measuring Scale user manual

Advantus

Advantus Micro General 75705 Operation manual

Pennsylvania

Pennsylvania 5600 Set-up, operations and calibration manual